Lub raj mis tshuab molding ntsia hlau chim

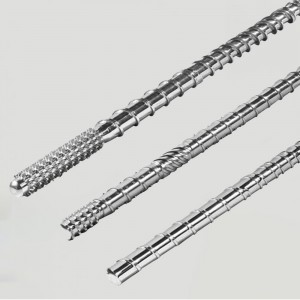

Cov ntsia hlau tsim kuj tseem tuaj yeem suav nrog ntau yam xws li kev sib xyaw ua ke, grooves, lossis cov txheej txheem thaiv kom txhim kho cov yaj thiab sib xyaw ua haujlwm. Cov yam ntxwv no pab ua kom tau raws li qhov sib txawv ntawm cov yas yaj thiab ua kom zoo ib yam ntawm cov pwm pwm.

Lub tshuab moulding chim yog ib lub tsev nyob cylindrical uas muab cov ntsia hlau kaw. Nws muab cov cua sov tsim nyog thiab lub siab xav tau los yaj cov khoom yas. Lub thoob feem ntau muab faib ua ntau thaj chaw cua sov nrog rau tus kheej tswj qhov kub thiab txias kom ua tiav cov melting thiab homogenization ntawm cov yas.

Ntsia Hlau Tsim: Cov ntsia hlau siv hauv tshuab tshuab moulding tshwj xeeb tsim los ua kom zoo dua cov txheej txheem melting thiab homogenization. Nws feem ntau ntev dua piv rau cov ntsia hlau siv hauv lwm cov txheej txheem yas. Qhov ntev ntev tso cai rau cov yas zoo dua thiab sib xyaw ntawm cov yas molten. Cov ntsia hlau kuj tseem muaj qhov sib txawv, xws li pub, compression, thiab metering zones, los tswj qhov ntws thiab siab ntawm cov yas yaj.

Barrel Design: Lub thoob muab cov cua sov tsim nyog thiab lub siab xav tau rau melting cov khoom yas. Nws feem ntau muaj ntau thaj chaw cua sov tswj los ntawm cov cua sov thiab cov ntsuas kub. Lub thoob feem ntau yog tsim los ntawm cov ntaub ntawv zoo, xws li nitride-kho steel lossis bimetallic alloys, kom tiv taus qhov kub thiab txias los ntawm cov khoom siv yas thiab cov ntsia hlau.

Kev Kho Ntog: Txhawm rau txhim kho qhov hnav tsis kam thiab ua haujlwm ntev ntawm cov ntsia hlau thiab lub thoob, lawv tuaj yeem raug kho saum npoo xws li nitriding, tawv chrome plating, lossis bi-metallic coatings. Cov kev kho mob no txhim kho lub zog thiab tsis kam hnav, ua kom lub neej ntev dua rau cov khoom siv.

Ob lub ntsia hlau thiab lub thoob feem ntau yog tsim los ntawm cov khoom siv siab hnav thiab corrosion kuj, xws li nitride-kho steel los yog bimetallic alloys. Cov ntaub ntawv no ua kom lub neej ntev thiab kev ua tau zoo, txawm tias thaum ua cov yas abrasive lossis corrosive plastics.

Kev tu thiab tu: kev tu thiab tu kom zoo ntawm cov ntsia hlau thiab lub thoob yog qhov tseem ceeb los xyuas kom meej qhov kev ua tau zoo thiab cov khoom zoo. Kev tu tsis tu ncua yuav pab tiv thaiv kom tsis txhob muaj cov khoom seem lossis cov kab mob uas tuaj yeem cuam tshuam cov txheej txheem melting thiab molding. Cov txheej txheem ntxuav sib txawv, xws li kev tu txhua yam, tshuaj tua kab mob, lossis purging nrog cov tshuaj ntxuav, tuaj yeem ua haujlwm.

Hauv kev xaus, lub tshuab moulding ntsia hlau thiab lub thoob yog cov khoom tseem ceeb hauv cov txheej txheem tshuab molding. Lawv ua hauj lwm ua ke kom yaj, sib tov, thiab homogenize cov khoom yas, tso cai rau cov khoom zoo ntawm hollow yas qhov chaw. Kev tu thiab tu kom zoo ntawm cov khoom no yog qhov tseem ceeb los xyuas kom muaj kev ua tau zoo thiab cov khoom zoo.