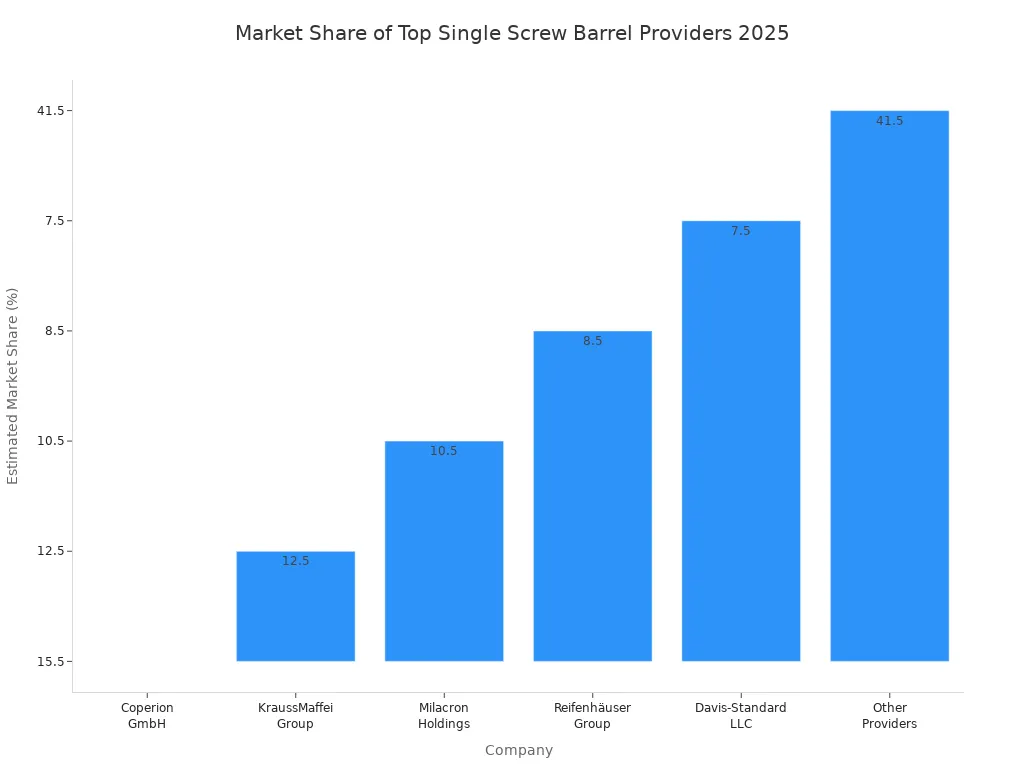

Kev lag luam thoob ntiaj teb rau ib leeg ntsia hlau txuas txuas ntxiv, nce mus txog ntau dua USD 840 lab hauv 2024 thiab npaj siab kom ncav cuag $ 1.38 nphom los ntawm 2034. Cov kev xaiv zoo tshaj plaws xws li Zhejiang Jinteng Single Screw Barrel, Xaloy X-800, thiab lwm tus xa cov kev ua tau zoo rauPVC yeeb nkab ib leeg ntsia hlau chim, PE yeeb nkab extruder ib leeg ntsia hlau chim, thiabib leeg ntsia hlau chim rau tshuab moldingdaim ntawv thov.

| Metric/Region | Tus nqi (2024) | Huab cua (2025-2034) |

|---|---|---|

| Ib Screw Feed Barrel Market | Tshaj USD 840 lab | USD 1.38 billion |

| Asia Pacific Market Share | 35.24% | Kev loj hlob ntawm 6.3% |

Dab tsi los saib rau hauv Ib Lub Ntsia Hlau Ib Leeg

Qhov tseem ceeb ntawm kev ua tau zoo

Qhov sib txawv ntawm kev sib txhuam coefficients ntawm lub polymer thiab chim los yog ntsia hlau nto cuam tshuam rau kev xa khoom muaj peev xwm. Yog tias qhov kev sib txhuam ntawm polymer thiab chim siab ntau dua li ntawm cov polymer thiab cov ntsia hlau, cov khoom txav mus rau pem hauv ntej zoo, ua rau cov zis ntau dua thiab cov txheej txheem zoo dua. Grooved chim nce kev sib txhuam quab yuam, txhim khu kev xa khoom muaj peev xwm thiab tso zis ruaj khov, uas yog cov txheej txheem tseem ceeb hauv kev extrusion.

Engineers kuj xav txog ntau yam kev qhia thaum ntsuas aIb Screw chim:

- Kev faib tawm lub sijhawm nyob, uas ntsuas ntws thiab sib tov efficiency.

- Rheological cwj pwm, nrog rau viscosity thiab shear rate.

- Siab thiab kub profiles raws li cov ntsia hlau.

- Conveying muaj peev xwm thiab tso zis stability.

- Mechanical yam xws li ntsia hlau hloov chaw thiab kev pheej hmoo ntawm cov ntsia hlau xauv-up.

- Melting cwj pwm thiab sib tov muaj peev xwm.

- Txheej txheem stability nyob rau hauv txawv tej yam kev mob.

Khoom Compatibility

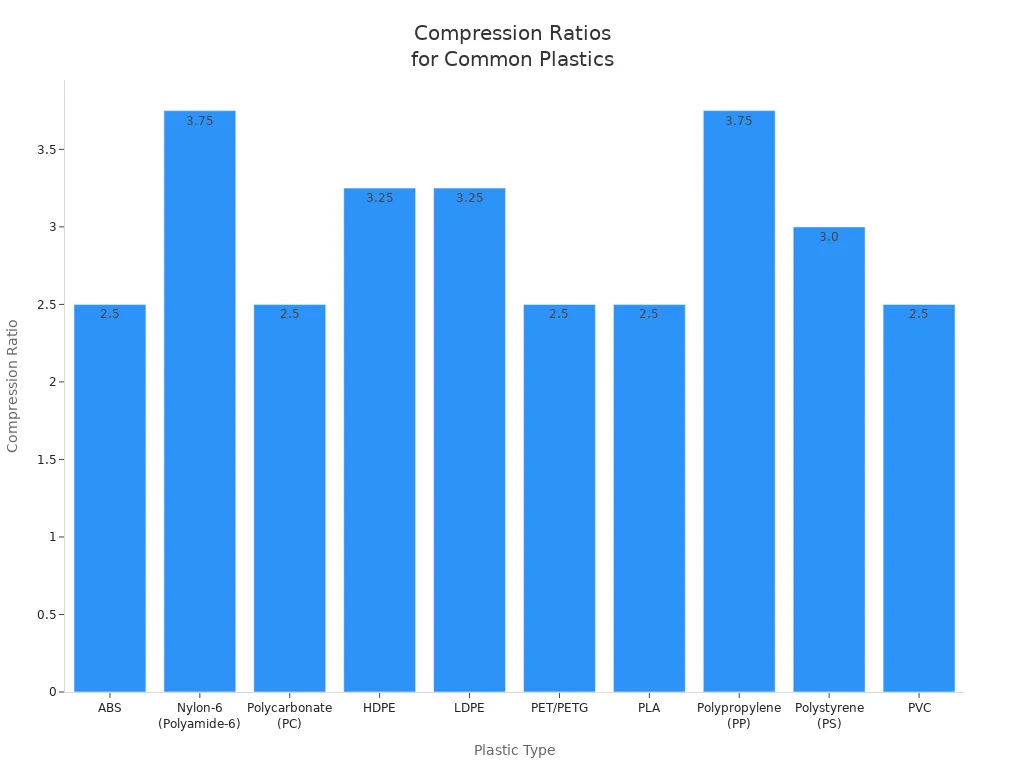

Xaiv lub thoob zoo txhais tau tias nkag siab tias nws cuam tshuam li cas nrog cov yas sib txawv. Cov lus hauv qab no qhia txog cov khoom siv tseem ceeb thiab lawv qhov tseem ceeb:

| Khoom Khoom | Qhov tseem ceeb rau kev sib raug zoo nrog cov yas hauv ib qho Screw Barrels |

|---|---|

| Thermal Sensitivity | Yuav tsum tau ceev faj tswj kub thiab maj mam compression kom tsis txhob degradation thaum extrusion. |

| Hygroscopicity | Cov ntaub ntawv uas nqus dej yuav tsum tau qhuav ua ntej extrusion los tiv thaiv qhov tsis xws luag xws li voids lossis degradation. |

| Kev ceev ceev | Cov ntaub ntawv tsis tshua muaj siab tuaj yeem ua rau muaj teeb meem kev noj zaub mov thiab yuav xav tau ntau dua compression piv lossis cov qauv pub tshwj xeeb. |

| Compressibility | Cov ntaub ntawv compressible heev cuam tshuam rau kev pub mis thiab yuav tsum tau hloov kho hauv kev tsim cov ntsia hlau kom ntseeg tau tias muaj qhov sib xws. |

| Qhuav Fluidity | Influences qhov ntev thiab steepness ntawm compression seem; high melt fluidity polymers tuaj yeem zam luv luv, steeper compression cheeb tsam. |

| Ntsia Hlau Nto Lubricity | Lubricity siab (piv txwv li, chrome plating) tiv thaiv cov ntaub ntawv lo thiab txhawb nqa cov khoom zoo ntawm cov yas molten. |

| Hardness | Tsim nyog rau kev hnav tsis kam, tshwj xeeb tshaj yog thaum ua cov khoom sib xyaw uas muaj fiber ntau lossis iav hais. |

| Clearance | Tight clearance nruab nrab ntawm cov ntsia hlau thiab chim tiv thaiv backflow thiab tswj cov zis efficiency. |

Durability thiab Lifespan

Durability tseem yog qhov tseem ceeb tshaj plaws rau cov tuam ntxhab. Cov thoob zoo siv cov ntaub ntawv zoo li nitrided steel los yog bimetallic alloys los tiv thaiv puas thiab corrosion. Cov yam ntxwv no txuas ntxiv kev pab cuam lub neej, tshwj xeeb tshaj yog thaum ua cov khoom ntim lossis cov khoom siv rov ua dua tshiab. Optimized ntsia hlau thiab chim tsim kuj txhim kho yaj homogeneity thiab txo downtime, uas pab tswj cov zis ruaj khov thiab txo qis zog siv.

Kev tu thiab yooj yim ntawm kev siv

Kev saib xyuas niaj hnub ua kom muaj kev ua haujlwm zoo ib yam thiab ua kom cov cuab yeej siv tau ntev.

- Kev tu tsis tu ncua tiv thaiv cov khoom tsim thiab ua kom muaj txiaj ntsig zoo.

- Kev tshuaj xyuas rau kev hnav thiab tsim kua muag yog qhov tseem ceeb vim tias kev puas tsuaj thiab corrosion ua rau qhov sib txawv ntawm cov ntsia hlau thiab lub thoob, txo cov zis thiab cov khoom zoo.

- Kev saib xyuas ntawm thrust bearings thiab cov ntsaws ruaj ruaj tiv thaiv kev sib tsoo, kev co, thiab xau.

- Kev sib raug zoo thiab tensioning ntawm lub zog tsav kom muaj zog hloov pauv tau zoo.

- Calibration ntawm sensors thiab tswj tuav tswj cov txheej txheem meej.

Cov dej num no pab txo qis qis, txhim kho cov khoom lag luam zoo, thiab ua kom zoo dua kev siv zog.

Sab saum toj Ib Screw Barrels rau 2025

Zhejiang Jinteng Ib Screw Barrel Review

Zhejiang Jinteng Machinery Manufacturing Co., Ltd. yog ib lub chaw tsim khoom hauv kev lag luam yas extrusion. Lub tuam txhab sivadvanced bimetallic technologythiab kev tswj xyuas nruj heev los tsim ib qho Screw Barrels uas xa cov kev ua tau zoo thiab kev pab lub neej ntev. Precision manufacturing thiab customization xaiv tso cai rau cov neeg siv kom phim cov thoob rau lawv cov kev xav tau tshwj xeeb extrusion.

| Specification Aspect | Paub meej/Qhov tseem ceeb |

|---|---|

| Cov ntaub ntawv hauv paus | 38CrMoAlA, 42CrMo, SKD61 |

| Cov khoom siv bimetallic | Stellite 1, 6, 12, Nitralloy, Colmonoy 56, Colmonoy 83 |

| Hardness Tom qab Hardening & Tempering | HB280-320 |

| Nitriding Hardness | HV 850-1000 |

| Alloy Hardness | HRC50-65 |

| Chromium Plating Hardness (tom qab nitriding) | ≥ 900HV |

| Nto Roughness | Rau 0.4 |

| Ntsia Hlau Ncaj | 0.015 hli |

| Alloy Qhov tob | 0.8-2.0 hli |

| Chromium Plating qhov tob | 0.025-0.10 hli |

| Cov yam ntxwv tshwj xeeb | Advanced bimetallic tech, nruj QC, precision, customization, robust ntim, 20-30 hnub tus me nyuam |

CovIb Screw chimlos ntawm Zhejiang Jinteng sivpremium bimetallic cov ntaub ntawv, uas muab zoo heev hnav thiab corrosion kuj. Qhov kev tsim kho no ua rau lub neej ua haujlwm ntev dua thiab txo cov nqi kho. Cov neeg siv khoom feem ntau qhuas cov khoom rau nws qhov zoo, tus nqi tsim nyog, thiab kev pabcuam tshaj lij. Lub tuam txhab tsom mus rau kev tsim khoom thiab kev ruaj ntseg zoo ua kom txhua lub thoob ua tau raws li cov qauv kev lag luam siab. Cov yam ntxwv no ua rau Zhejiang Jinteng Ib Screw Barrel ib qho kev xaiv sab saum toj rau cov ntawv thov yas extrusion qhov twg durability thiab precision teeb meem.

Lus Cim: Zhejiang Jinteng muaj kev hloov kho raws li cov neeg siv khoom kos duab, kom ntseeg tau qhov zoo meej haum rau ntau lub tshuab extrusion.

Xaloy X-800 Ib Screw Barrel Review

Xaloy X-800 Ib Screw Barrel siv cov khoom siv siab heev thiab kev tsim vaj tsev kom xa cov kev ua tau zoo tshaj plaws hauv kev xav tau extrusion ib puag ncig. Tungsten carbide hais yog uniformly dispersed nyob rau hauv ib tug corrosion-resistant nickel alloy matrix, muab lub thoob tshwj xeeb kuj rau abrasive hnav thiab corrosion. Qhov kev tsim no tso cai rau lub thoob los ua cov ntaub ntawv nyuaj-rau-kua xws li HMW-HDPE thiab LLDPE tau yooj yim.

- Xaloy X-800 tuav cov khoom sib xyaw ua kom zoo, nrog rau cov uas muaj 25% lossis ntau dua iav fiber ntau lossis cov ntxhia ua kua.

- Precision engineering thiab computer-tswj rau cov txheej txheem ua kom muaj kev sib faib bimetallic carbide faib.

- Kev tsim kho seamless, txog li 6100 hli ntev, tshem tawm kev pheej hmoo ntawm degradation los yog paug.

- Proprietary thaub qab steel txo kev ntxhov siab thiab txhim kho kev ncaj thaum lub sij hawm cua sov.

Cov neeg siv khoom lag luam paub txog Xaloy X-800 raws li tus qauv thoob ntiaj teb rau kev txhuam thiab corrosion-resistant chim. Lub thoob lub neej ua haujlwm ntev thiab optimized ntsia hlau geometries pab txo cov teeb meem pib thiab txhim kho kev ua haujlwm. Xaloy cov kws tshaj lij, nrog rau ntau tshaj 75 xyoo ntawm kev siv tshuab casting thiab ntau tshaj 25 patents, txhawb kev ntseeg tau thiab tsim tau zoo ntawm no Ib Leeg Screw Barrel nyob rau hauv ntau yam kev siv extrusion.

Nordson BKG Ib Screw Barrel Review

Nordson BKG Ib Leeg Screw Barrels yog tsim los rau cov khoom ntim ntau lawm. Cov thoob no txhawb cov zis zoo ib yam thiab cov khoom siv siab, ua rau lawv zoo tagnrho rau cov tuam txhab lag luam uas xav tau kev ua tau zoo raws li qhov xav tau.

- Nordson BKG Master-Line underwater pelletizers tuaj yeem ua haujlwm txog 4,400 phaus ib teev.

- Tshiab cutter hubs thiab hniav designs nce throughput thiab txo hnav, txo downtime thiab tu.

- Abrasion-resistant ntsia hlau thiab lub thoob cov ntaub ntawv tswj kev ua tau zoo txawm tias muaj cov khoom sib xyaw ua ke.

- X8000 ntsia hlau encapsulation thiab X800 chim inlay cov ntaub ntawv muab tshwj xeeb abrasion thiab corrosion kuj.

- Lub Quantum system txo cov ntsia hlau rov qab lub sijhawm los ntawm 10 mus rau 15 feem pua, txhawb kev tsim khoom sai.

Nordson txoj kev tsom mus rau cov khoom siv qib siab thiab kev tsim vaj tsev ua kom ntseeg tau tias lawv Cov Ntsia Hlau Ib Leeg tswj kev ua tau zoo thiab cov khoom tsim tawm. Cov yam ntxwv no pab cov tuam txhab ua tiav kev tsim khoom ruaj khov, txo cov nqi tu, thiab ua kom muaj txiaj ntsig zoo tshaj plaws.

Reiloy Wear-Resistant Single Screw Barrel Review

Reiloy Wear-Resistant Single Screw Barrels siv cov khoom siv tawv tawv thiab cov thev naus laus zis siab tshaj plaws los xa cov khoom zoo tshaj plaws thiab kev tiv thaiv corrosion. Lub tuam txhab tsim nws tus kheej alloy hmoov, kom ntseeg tau zoo thiab kev ua tau zoo.

- Reiloy barrels feature bimetallic tsim nrog nickel-cobalt los yog npib tsib xee-raws li alloys uas muaj carbides loj thiab ceramic theem.

- Alloys xws li R121 (hlau-raws li nrog chrome carbides) thiab R239/R241 (nickel-raws li nrog tungsten carbides) muab tailored hnav tiv thaiv rau ntau daim ntaub ntawv.

- Inductive centrifugal casting thiab nruj kev ntsuam xyuas lav distortion-dawb, kav ntev.

- Cov thoob ua tau zoo nrog cov ntaub ntawv abrasive lossis corrosive, nrog rau cov yas uas muaj txog li 30% iav fiber ntau los yog cov ntsiab lus ntxhia siab.

- Cov ntsia hlau tau txais kev kho mob thib ob xws li tawv chrome plating, nitriding, thiab carbide encapsulation rau kev tiv thaiv ntxiv.

Reiloy kev cai tsim cov thoob thiab cov ntsia hlau los txhim kho kev ua tau zoo rau cov resins tshwj xeeb thiab kev siv. Txoj hauv kev no txhim kho cov yaj zoo, ua kom lub neej ua haujlwm ntev, thiab tuav cov khoom lag luam siab, txawm tias cov ntaub ntawv nyuaj.

Ib Screw Barrel Sib Piv Table

Feature Overview

Covua qauv rau 2025qhia tau hais tias muaj zog technical kev ua tau zoo thiab cov yam ntxwv tsom rau cov neeg siv. Cov lus hauv qab no qhia txog cov ntsiab lus tseem ceeb thiab cov ntsiab lus txhawb nqa rau txhua qhov kev xaiv ib leeg Screw Barrel:

| Hom qauv | Ntsia Hlau Diameter (mm) | L/D Ratio | Cov zis muaj peev xwm (kg / h) | Lub cev muaj zog (kW) | Nqe Range (USD) | Warranty | Kev them nyiaj yug tom qab muag |

|---|---|---|---|---|---|---|---|

| Zhejiang Jinteng kev lag luam | 30-200 Nws | 24:1–36:1 | 10 – 1,500+ | 15-180 Nws | 280-1,860 Ib | 12 mav. | 1-on-1 tech, ntiaj teb no, customization |

| Xaloy X-800 | 30-200 Nws | 24:1–36:1 | 10 – 1,500+ | 15-180 Nws | 1,000-1,800 Nws | 12 mav. | Kev pabcuam kws tshaj lij, kev xa khoom sai |

| Nordson BKG | 60-120 : kuv | 33:1–38:1 | 150-1,300 Nws | 55-315 : kuv | 1,200-1,860 Ib | 12 mav. | CE-certified, kev pabcuam ceev ceev |

| Reiloy Hnav-Resistant | 30-200 Nws | 24:1–36:1 | 10 – 1,500+ | 15-180 Nws | 1,000-1,800 Nws | 12 mav. | Kev cai tsim, ISO-certified |

Nco tseg: Tag nrho cov qauv muaj cov yam ntxwv siab heev xws li cov chaw noj zaub mov grooved, vented chims, thiab servo tsav kev koom ua ke rau kev ua haujlwm zoo thiab kev tswj xyuas.

Pros thiab Cons Summary

Txhua tus qauv Ib Leeg Screw Barrel coj lub zog tshwj xeeb rau cov yas extrusion. Cov lus hauv qab no qhia txog cov txiaj ntsig tseem ceeb thiab kev txwv:

| Feature/Aspect | Qhov zoo | Kev txwv |

|---|---|---|

| Nqi | Cov khoom siv qis dua thiab cov nqi tsim khoom | Tsis tshua muaj txiaj ntsig rau kev sib xyaw ua ke |

| Tsim Complexity | Yooj yim tsim, kho yooj yim | Tsis muaj ntau yam zoo li ntxaib-ntsia hlaurau cov hauj lwm siab heev |

| Kev ua tau zoo | Kev ntseeg tau rau tus qauv extrusion, lub zog txuag | throughput stability tuaj yeem poob ntawm kev kub ceev |

| Kev thov kom haum | Zoo tagnrho rau cov txheej txheem extrusion thiab viscous polymers | Tsis haum rau ntau kauj ruam lossis precision sib tov |

| Kev them nyiaj yug tom qab muag | Muaj zog technical support thiab customization xaiv | Lub sijhawm lav feem ntau txwv rau 12 lub hlis |

Tswv yim: Cov neeg siv yuav tsum sib phim lub thoob cov yam ntxwv rau lawv cov kev xav tau ntau lawm kom tau txais txiaj ntsig zoo tshaj plaws.

Xaiv txoj cai ib lub taub hau taub hau rau koj xav tau

Rau High-Volume Production

Cov neeg tsim khoom nrhiav kev tsim tawm siab yuav tsum tsom mus rau cov kev qhia tshwj xeeb uas ua kom muaj txiaj ntsig zoo thiab ua haujlwm ntev. Cov yam tseem ceeb muaj xws li lub taub hau taub hau, qhov ntev-rau-inch (L / D) piv, thiab lub cev muaj zog. Cov lus hauv qab no qhia txog cov kev ntsuas tseem ceeb rau kev ntim siab extrusion:

| Performance Metric | Nqe lus piav qhia / cuam tshuam |

|---|---|

| Ntsia Hlau Diameter | Loj diameters nce ntau lawm. |

| L/D Ratio | Cov ntsia hlau ntev dua txhim kho kev sib xyaw thiab cua sov, txhawb nqa ntau dua. |

| Compression Ratio | Xyuas kom tag nrho plasticization kom zoo ib yam. |

| Groove Qhov tob | Muaj feem xyuam rau kev xa khoom thiab kev sib xyaw; yuav tsum sib npaug zog thiab uniformity. |

| Qhov sib txawv ntawm Screw thiab chim | Tight gps tiv thaiv kom tsis txhob tawm thiab tswj kev ruaj ntseg siab. |

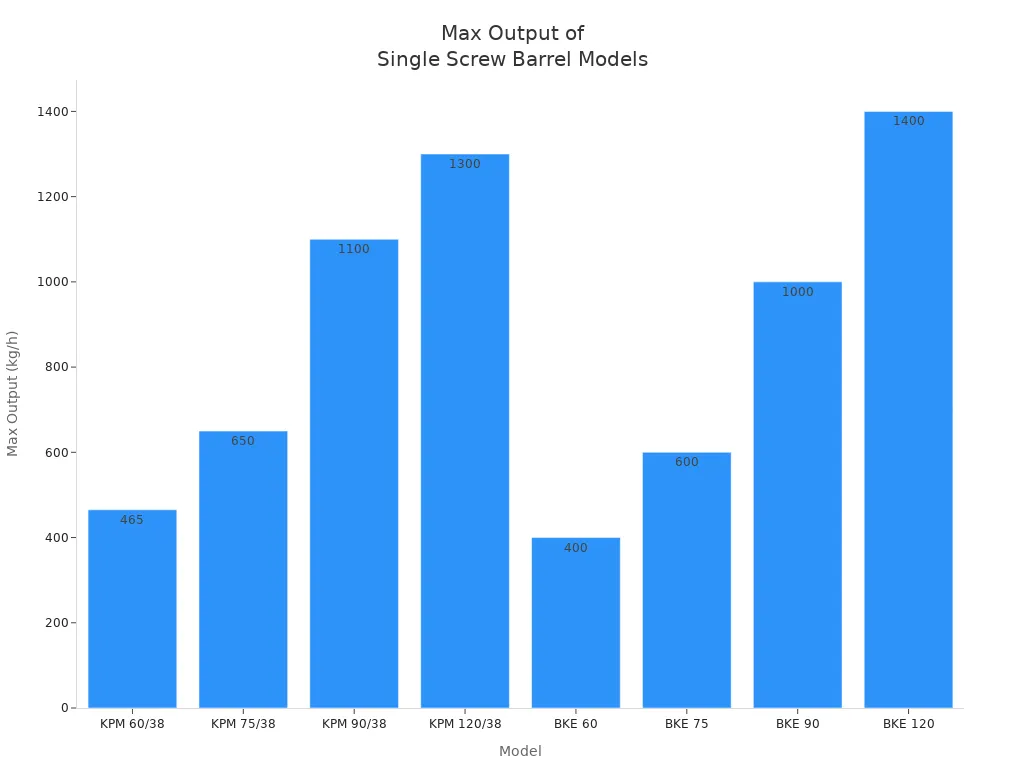

Cov qauv zoo li KPM 120/38 thiab BKE 120 xa tawm mus txog 1,400 kg / h, ua rau lawv zoo tagnrho rau kev ua haujlwm loj. Advanced cov ntaub ntawv thiabtswj qhov kub thiab txiasntxiv txhim khu kev ntseeg thiab lifespan.

Rau cov yas tshwj xeeb

Kev ua haujlwm engineering polymers lossis bioplastics yuav tsum tau ua tib zoo saib xyuas cov khoom thiab cov khoom tsim. Ib leeg ntsia hlau extruders tuav cov yas tshwj xeeb xws li polycarbonate, nylon, thiab PLA zoo thaum nruab nrog cov ntsia hlau customized tsim thiab kev tswj kub siab. Metallurgical xaiv, xws li corrosion-resistant alloys, tiv thaiv cov khoom puas thiab ua kom cov khoom zoo. Cov neeg ua haujlwm yuav tsum saib xyuas qhov kub thiab txiasntsia hlau ceevze ze kom tsis txhob degradation los yog tsis xws luag. Kev saib xyuas tsis tu ncua thiab kev ua haujlwm txawj pab daws cov teeb meem xws li kev sib tsoo tsis sib haum lossis kev hloov pauv siab.

Tswv yim: Sib koom tes nrog cov neeg muab khoom siv los kho cov ntsia hlau thiab chim rau cov ntaub ntawv rhiab lossis tshwj xeeb.

Rau cov neeg siv khoom siv nyiaj txiag

Nqi-zoo extrusion kev daws teeb meem feem ntau cia siab rau lub simplicity thiab versatility ntawm ib tug ntsia hlau extruders. Cov tshuab no muab kev nqis peev qis dua thiab txo tus nqi txij nkawm piv rau cov ntsia hlau ntxaib. Cov khoom siv los ntawm cov npe nrov npe tuaj yeem txo cov nqi qis dua yam tsis muaj kev ntseeg siab. Cov qauv tsim ncaj nraim txhawb nqa ntau yam kev siv, nrog rau cov kav dej, cov yeeb yaj kiab, thiab cov ntawv txheeb, ua rau nws yog qhov kev xaiv zoo rau cov lag luam nrog cov peev nyiaj tsawg.

- Ib leeg ntsia hlau extruders yog pheej yig thiab yooj yim los tswj.

- Cov tshuab siv tau muab kev txuag nyiaj ntxiv.

- Versatility txhawb ntau yam kev xav tau ntau lawm.

Kev soj ntsuam xyuas zoo ntawm kev ua tau zoo, kev ua tau zoo, thiab cov nqi mus sij hawm ntev ua kom muaj txiaj ntsig zoo tshaj plaws rau kev siv nyiaj txiag.

CovSab saum toj extruder chim rau 2025xa kev ntseeg tau, txuag hluav taws xob, thiab kev ua haujlwm ntev. Cov neeg siv khoom ntim siab tau txais txiaj ntsig los ntawm cov qauv tsim muaj zog thiab kev tswj hwm qib siab. Cov txheej txheem tshwj xeeb yuav tsum xaiv cov thoob nrog kev cai engineering thiabcov coatings ruaj. Cov neeg siv nyiaj tsom mus rau cov neeg yuav khoom tau txais los ntawm cov kev xaiv yooj yim, tsis tshua muaj kev saib xyuas. Cov neeg siv yuav tsum phim cov cuab yeej cuab tam rau lawv cov kev xav tau ntau lawm.

FAQ

Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm ib leeg ntsia hlau thoob hauv yas extrusion?

Ib leeg ntsia hlau chim muaj kev txhim khu kev qha, kev saib xyuas yooj yim, thiab kev siv nyiaj txiag. Lawv ua haujlwm zoo rau feem ntau cov qauv yas extrusion daim ntaub ntawv.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum tshuaj xyuas ib lub taub hau ntsia hlau rau hnav?

Cov neeg ua haujlwm yuav tsum tshuaj xyuas lub thoob txhua peb mus rau rau lub hlis. Kev kuaj xyuas tsis tu ncua pab tswj cov khoom tsim tau zoo thiab ua kom cov cuab yeej siv tau ntev.

Ib lub taub hau taub hau tuaj yeem siv ntau hom yas?

Yog lawm. Cov neeg tsim khoom tsim ib lub taub hau ntsia hlau los ua ntau yam ntawm cov yas, suav nrogPVC, PE, PP, thiab tshwj xeeb polymers.

Post lub sij hawm: Lub Xya hli ntuj-18-2025