Conical twin screws yog qhov tseem ceeb hauv PVC yeeb nkab ntau lawm, qhov twg precision thiab efficiency yog qhov tseem ceeb. Kev thov thoob ntiaj teb rau cov khoom tshwj xeeb no, suav nrog conical twin ntsia hlau rau PVC yeeb nkab, underscores lawv qhov tseem ceeb.

- Lub Tuam Txhab Rotating Twin-Screw Extruder Kev Lag Luam tau npaj kom nthuav dav los ntawm USD 1.2 nphom hauv 2024 txog $ 2.5 nphom los ntawm 2033, nrog qhov zoo siab 8.9% CAGR.

- Kev loj hlob ntawm kev tsim cov khoom siv, tshwj xeeb tshaj yog nyob rau thaj tsam Asia-Pacific, ua rau qhov kev thov nce ntxiv no.

Niaj hnub nimno innovation, xws liPVC conical ntsia hlau, txhim kho cov ntaub ntawv homogeneity thiab txo qis qis qis, ua kom ruaj khov extrusion. Cov kev nce qib no ua rau muaj kev xav tau ntau ntxiv rau cov kev daws teeb meem siab hauvPVC yeeb nkab ntau lawm parallel ntxaib ntsia hlausystems, suav nrogtwin parallel ntsia hlau chim.

Txheej txheem cej luam ntawm Conical Twin Ntsia Hlau Rau PVC Yeeb Nkab

Tsim thiab Functionality

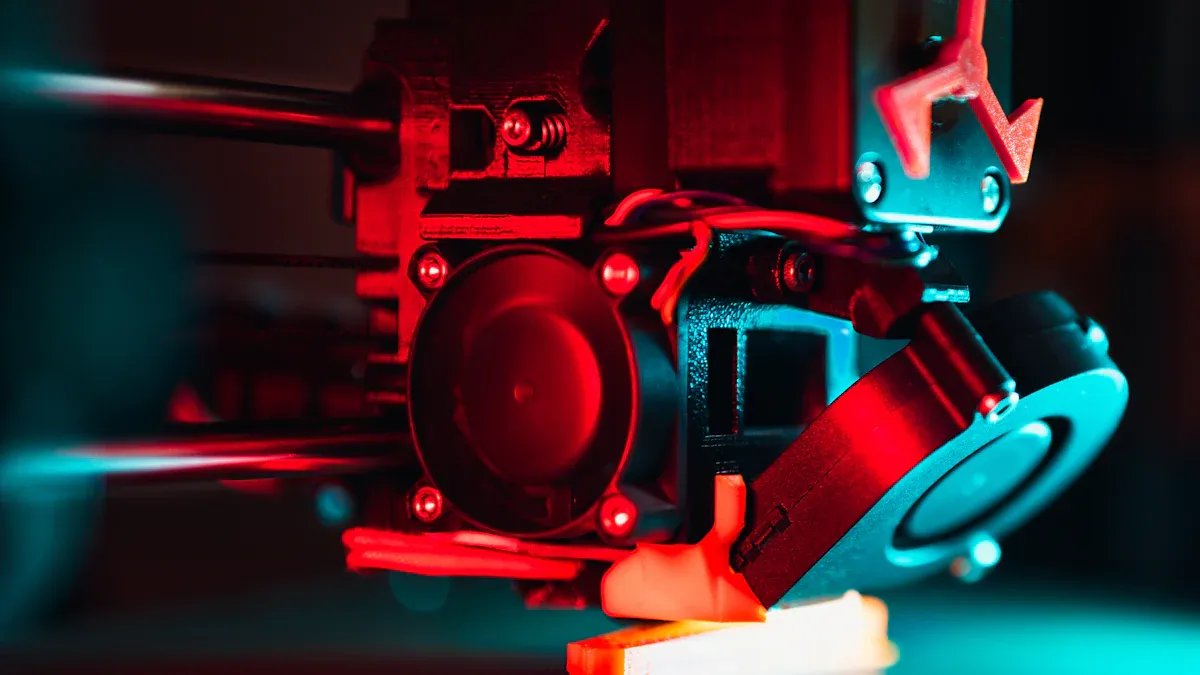

Conical ntxaib ntsia hlau extruders ua lub luag haujlwm tseem ceeb hauv PVC yeeb nkab ntau lawm los ntawm kev txhim kho cov khoom ua haujlwm zoo. Lawv tsim tsom mus rau kev ua tiav kev sib xyaw ua ke thiab homogenization, uas yog qhov tseem ceeb rau kev tsim cov kav dej zoo. Cov tshuab no compress thiab yaj cov ntaub ntawv raw, ua kom cov yas zoo ib yam. Cov screws feature optimized configurations, nrog rau kev tswj xyuas qhov kub thiab txias, kom muaj kev sib haum xeeb hauv cov khoom kawg.

Kev ua haujlwm, lub conical ntxaib ntsia hlau tsim qhia txog kev tswj cov ntsia hlau ceev thiab torque tis. Qhov no ua kom zoo dispersion ntawm additives, uas ua rau cov xim tsis sib xws thiab qhov ntev stability. Lub peev xwm los tswj cov ntawv tso zis siab thaum tswj cov khoom zoo ua rau cov extruders tseem ceeb hauv kev tsim khoom niaj hnub no.

Kev siv hauv PVC yeeb nkab Manufacturing

Conical ntxaib ntsia hlau tshuab haum rau ntau yam kev xav tau hauv PVC yeeb nkab ntau lawm. Lawv adaptability tso cai rau cov tuam ntxhab los kho cov kab diameters, optimizing cov zis thiab yaj zoo. Cov txheej txheem tswj niaj hnub ua ke rau hauv cov extruders tswj qhov kub, siab, thiab ceev, ua kom cov txiaj ntsig zoo ib yam.

| Application Aspect | Kev piav qhia |

|---|---|

| Kev kho ntawm Barrel Diameter | Optimizing ntsia hlau txoj kab uas hla txhim kho cov nqi tso zis thiab yaj zoo, haum rau PVC yeeb nkab xav tau. |

| Kev koom ua ke ntawm Modern Control Systems | Niaj hnub nimno tswj tswj qhov kub thiab txias, siab, thiab ceev, ua kom cov khoom zoo ib yam. |

| Saib xyuas thaum tsim khoom | Ua tib zoo saib xyuas cov txheej txheem txheej txheem pab tsim cov kav dej PVC zoo. |

Cov yam ntxwv no ua rau conical twin screws ib qho kev xaiv txhim khu kev qha rau cov tuam txhab lag luam txhawm rau ua kom tau raws li cov qauv nruj.

Qhov zoo ntawm Conical Design

Covconical tsim muaj ntau yam zoodhau ib txwm ntsia hlau systems. Nws ua kom zoo li plasticization thiab sib tov, uas yog qhov tseem ceeb rau cov khoom zoo sib xws. Cov qauv tsim txhawb kev tsim tawm siab, ua rau nws tsim nyog rau kev ua haujlwm loj.

| Cov txiaj ntsig / Advantage | Kev piav qhia |

|---|---|

| Uniform plasticization thiab sib tov | Xyuas kom zoo ib yam nyob rau hauv cov khoom kawg. |

| Cov zis siab | Muaj peev xwm ua tau ntau dua ntawm cov khoom siv extruded zoo. |

| ruaj khov zoo | Khaws cov khoom zoo nyob rau lub sijhawm, txo qhov kev hloov pauv. |

| Dav adaptability | Muaj peev xwm ua tau ntau yam thermoplastics, tshwj xeeb tshaj yog tawv PVC hmoov. |

| Lub neej ua haujlwm ntev | Tsim los rau durability, ua rau txo nqi hloov. |

| Direct molding ntawm PVC hmoov | Tso cai rau kev tsim cov khoom yas tam sim ntawd yam tsis muaj kev ua haujlwm ntxiv. |

| Plasticizing kev ua tau zoo | Zoo melts thiab sib tov cov ntaub ntawv rau kev pom extrusion. |

| Zoo extrusion quab yuam | Muaj peev xwm tuav cov kev kub ntxhov thaum lub sij hawm extrusion txheej txheem. |

Cov txiaj ntsig no qhia txog vim li cas conical ntxaib ntsia hlau rau PVC yeeb nkab tseem yog qhov kev xaiv zoo rau cov tuam txhab thoob ntiaj teb. Nws lub peev xwm los xa cov kev ua tau zoo ib yam, ua haujlwm ntev, thiab kev hloov kho kom ntseeg tau tias nws muaj feem cuam tshuam rau xyoo 2025 thiab dhau mus.

Nta thiab Specifications Tsav Efficiency

Plasticizing Performance thiab Material Homogeneity

Kev ua tau zoo ntawm plasticizing ntawm conical twin screws xyuas kom meej tias PVC cov ntaub ntawv yog melted thiab sib tov uniformly. Cov txheej txheem no yog qhov tseem ceeb rau kev tsim cov kav dej uas muaj qhov zoo sib xws thiab kev ua haujlwm zoo. Kev tsim cov ntsia hlau siab heev txhim kho cov khoom sib xws los ntawm kev nthuav dav cov ntsia hlau ntev, uas txo qis kev tsis lees paub thiab txhim kho kev tsim khoom tag nrho.

Tswv yim: Cov khoom siv sib xyaw ua ke txo qis qhov tsis xws luag hauv cov khoom kawg, ua kom cov kav dej ua tau raws li cov qauv kev lag luam nruj.

Kev sib koom ua ke ntawm kev tswj lub zog ncaj qha ntxiv ua kom zoo dua plasticization. Los ntawm kev tuav cov ntsia hlau tas li RPM, qhov no ua rau txo qis cov khoom tsim tawm thiab cov khoom siv khib nyiab. Tsis tas li ntawd, sab hauv ntsia hlau cua txias tshuab muab kev tswj xyuas qhov kub thiab txias, uas txhim kho qhov zoo ntawm cov yaj thiab ua kom cov txiaj ntsig zoo sib xws.

| Feature | Cov txiaj ntsig |

|---|---|

| Muaj peev xwm ntau lawm | Ua kom cov kav dej ntau ntau yuav tsum tau ua sai sai, ua tau raws li lub sijhawm kawg yam tsis muaj kev txi zoo. |

| Txhim khoNtsia Hlau Tsim | Cov txiaj ntsig tau ntev ntev ntawm cov ntsia hlau ntev, ua kom muaj qhov sib npaug ntau dua thiab txo qis kev tsis lees paub. |

| Direct Torque Control | Ua kom cov ntsia hlau tsis tu ncua RPM, txo cov khoom tsim tawm zoo hloov pauv thiab txo cov khoom siv. |

| Internal Screw Cooling | Muab kev tswj xyuas meej ntawm qhov kub thiab txias, txhim kho cov yeeb nkab zoo thiab ua kom cov zis zoo ib yam. |

Energy Efficiency thiab Fais Fab Optimization

Kev siv hluav taws xob hluav taws xob yog qhov tseem ceeb hauv niaj hnub PVC yeeb nkab extrusion. Conical twin screws ua tau zoo nyob rau hauv cheeb tsam no los ntawm kev siv lub zog txuag hluav taws xob. Cov tshuab no xa cov kev ua tau zoo tshwj xeeb thaum siv hluav taws xob tsawg, txo cov nqi ua haujlwm thiab kev cuam tshuam ib puag ncig.

Lub optimized ntsia hlau geometry minimizes lub zog poob thaum lub sij hawm extrusion txheej txheem. Qhov kev tsim no ua kom ntseeg tau tias lub zog siv hluav taws xob tau hloov pauv mus rau lub zog thermal, uas yog qhov tseem ceeb rau cov khoom siv PVC melting. Tsis tas li ntawd, lub peev xwm ua haujlwm ntawm qhov kub thiab txias txo qis kev siv hluav taws xob yam tsis muaj kev cuam tshuam qhov zoo ntawm cov khoom kawg.

Nco tseg: Lub zog txuag hluav taws xob tsis yog tsuas yog cov nqi qis xwb tab sis kuj ua raws li lub hom phiaj kev ruaj ntseg thoob ntiaj teb, ua rau lawv xaiv rau cov tuam txhab tsim khoom.

Adaptability rau PVC formulations thiab yeeb nkab loj

Conical twin screwsUa tau zoo kawg li versatility hauv kev tuav ntau yam PVC formulations thiab yeeb nkab ntau thiab tsawg. Lawv tus tsim kev hloov pauv hloov pauv ntawm kev ntom ntom ntom ntom, ua yeeb yam raws li cov khoom siv tsis zoo Qhov kev muaj peev xwm no ua kom cov txiaj ntsig zoo ib yam, txawm tias qhov ceev ntawm PVC resin hloov.

Cov neeg tsim khoom tau txais txiaj ntsig los ntawm cov yam ntxwv xws li kho cov ntsia hlau cores thiab gearbox tsim, uas tso cai rau cov haujlwm sib txawv ntawm lub cev muaj zog. Barrel tempering tshuab muab kev yooj yim los ntawm kev npog ntau yam ntawm cov zis, ua rau cov ntsia hlau tsim nyog rau ntau yam kev xav tau.

| Feature | Kev piav qhia |

|---|---|

| Ntsia Hlau Core | Fits tag nrho cov ntsia hlau tempering tshuab. |

| Gearbox Design | Tso cai rau ob peb lub cev muaj zog sib txawv (U lossis Z version). |

| Barrel Tempering Systems | Cov txheej txheem tuaj yeem xaiv ntawm cov tshuab sib txawv, suav nrog ntau qhov kev tsim tawm. |

| Txheej Txheem Siab Muaj Peev Xwm | Nws tuaj yeem ua haujlwm nrog qhov siab txog li 520 bar (7500 psi), haum rau me me lossis nyias-walled profiles. |

| Ceev ceev | Lub sij hawm nyob tsawg tsawg ua kom hloov xim sai dua, txuag cov khoom siv. |

Tsis tas li ntawd, conical twin screws siv lub zog tsawg dua piv rau ib qho ntsia hlau extruders rau tib tus nqi tso tawm. Qhov kev ua tau zoo no, ua ke nrog lawv cov kev hloov pauv, ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau cov tuam txhab lag luam txhawm rau tsim cov kav dej PVC zoo hauv ntau qhov sib txawv thiab cov qauv.

Kev nce qib hauv Conical Twin Screw Design rau 2025

Kev tsim kho tshiab hauv Cov Khoom Siv Ntsia Hlau thiab Geometry

Kev nce qib tsis ntev los no hauv cov khoom siv ntsia hlau thiab cov duab geometry tau hloov pauv qhov kev ua tau zoo thiab ua haujlwm ntev ntawm conical twin screws. Cov neeg tsim khoom tau siv cov thev naus laus zis tshiab los txhim kho kev ua tau zoo thiab hloov kho ntawm cov khoom no. Qhov tseem ceeb innovation muaj xws li:

- Kev siv cov khoom siv siab heev uas sib dua, ruaj khov dua, thiab tiv taus corrosion, ua kom muaj kev pab cuam lub neej ntev dua thiab txo nqi txij nkawm.

- Kev koom ua ke ntawm cov thev naus laus zis ntse rau kev saib xyuas lub sijhawm tiag tiag thiab kev hloov kho thaum lub sijhawm tsim khoom, txhim kho tag nrho cov txheej txheem tswj.

- Kev txais yuav 3D tshuab luam ntawv rau kev tsim qauv sai thiab tsim cov geometry nyuaj, uas muaj peev xwm txo tau cov nqi tsim khoom txog li 90%.

- Modular tsim uas tso cai rau kev hloov kho ntau dua, ua rau cov tuam txhab ua kom tau raws li ntau yam kev xav tau ntawm kev yooj yim.

Cov kev nce qib no tsis tsuas yog txhim kho kev ua haujlwm ntawmconical twin screwstab sis kuj ua raws li cov kev xav tau loj zuj zus ntxiv rau kev tsim khoom lag luam kom ruaj khov thiab muaj txiaj ntsig zoo. Los ntawm kev koom nrog cov kev tsim kho tshiab no, cov tuam txhab tsim khoom tuaj yeem ua tiav cov txiaj ntsig ntau dua thiab cov khoom lag luam zoo dua qub, ua rau cov conical ntxaib ntsia hlau rau PVC yeeb nkab yog qhov kev xaiv hauv kev lag luam.

Kev koom ua ke ntawm Kev Tswj Xyuas Ntsej Muag

Kev sib koom ua ke ntawm kev tswj xyuas ntse rau hauv conical ntxaib ntsia hlau tsim tau txhim kho kev soj ntsuam ntau lawm thiab kev ua haujlwm zoo. Cov txheej txheem tswj xyuas cov txheej txheem ntse tam sim no siv cov cuab yeej ntsuas qib siab thiab AI qauv los txhim kho cov txheej txheem extrusion. Cov tshuab no txheeb xyuas qhov sib txawv ntawm qhov sib txawv ntawm lub sijhawm, muab kev ntsuas qhov pom pom los ntawm cov neeg siv khoom siv hauv dashboards.

Piv txwv li, retrofitting uas twb muaj lawm ntsia hlau presses nrog ntse saib xyuas technology tau pom tau hais tias zoo kawg li kev txhim kho nyob rau hauv kev ua tau zoo. Los ntawm kev siv cov qauv kev txhim kho zoo li CRISP-DM, cov tuam txhab lag luam tuaj yeem txheeb xyuas thiab daws qhov tsis muaj txiaj ntsig hauv cov txheej txheem tsim khoom. Txoj hauv kev no ua kom cov khoom tsim tau zoo ib yam thaum txo cov khoom pov tseg.

Cov kev tswj xyuas ntse kuj tseem ua kom muaj kev hloov pauv rau qhov kub, siab, thiab cov ntsia hlau ceev, kom ntseeg tau tias qhov zoo tshaj plaws plasticization thiab cov khoom sib xws. Cov yam ntxwv no ua rau niaj hnub conical twin screws indispensable rau manufacturers aiming kom ua tau raws li cov qauv nruj hauv PVC yeeb nkab ntau lawm.

Kev Lag Luam Trends Shaping Yav Tom Ntej Designs

Lub neej yav tom ntej ntawm conical ntxaib ntsia hlau tsim yog tsim los ntawm ntau yam kev lag luam tseem ceeb. Cov qauv no qhia txog kev hloov zuj zus ntawm cov neeg tsim khoom thiab cov neeg siv khoom, nrog rau kev nce qib hauv kev siv tshuab thiab kev ruaj ntseg.

| trend | Kev cuam tshuam rau Conical Twin Screw Designs |

|---|---|

| Sustainability | Kev thov ntau ntxiv rau cov khoom siv biodegradable, ua rau tsim kev hloov pauv rau kev ua cov khoom siv hauv eco-phooj ywg. |

| Automation | Kev koom ua ke ntawm cov tshuab siab heev los txhim kho cov kab ntau lawm, txhim kho cov khoom siv thiab cov khoom zoo. |

| Kev kho kom haum | Modular tsim tso cai rau kev hloov kho sai hauv cov txheej txheem kev ua haujlwm, ua rau cov neeg siv khoom nyiam tshwj xeeb. |

| Digitalization | Txhim kho cov ntaub ntawv txheeb xyuas rau kev soj ntsuam kev ua tau zoo ntawm lub sijhawm, txhim kho kev txiav txim siab thiab kev tsim cov pob tshab. |

| Kev Loj Hlob | Kev kwv yees CAGR ntawm ntau dua 6% hauv tsib xyoos tom ntej, tau tsav los ntawm kev nqis peev hauv R & D rau kev ua tau zoo thiab kev ruaj khov. |

Cov qauv no qhia txog qhov tseem ceeb ntawm kev tsim kho tshiab thiab kev hloov pauv hauv kev tsim ntawm conical ntxaib screws. Los ntawm kev tuav cov kev hloov no, cov tuam txhab lag luam tuaj yeem nyob ua ntej ntawm kev sib tw thiab ua tau raws li qhov kev thov loj hlob rau cov kav dej PVC zoo.

Conical ntxaib screws tseem tseem ceeb hauv PVC yeeb nkab extrusion, kom ntseeg tau tias kev ua haujlwm zoo thiab zoo. Lawvadvanced nta, xws li lub zog optimization thiab cov khoom adaptability, tsav kev lag luam innovation. Kev nce qib tsis ntev los no hauv cov tshuab ntse thiab cov qauv tsim kom ruaj khov tso lawv ua cov cuab yeej tseem ceeb. Cov ntsia hlau no yuav txuas ntxiv txhim kho lub neej yav tom ntej ntawm kev ua haujlwm siab PVC.

FAQ

Dab tsi ua rau conical twin screws zoo tagnrho rau PVC yeeb nkab extrusion?

Conical ntxaib screws muab superior plasticization, cov khoom zoo sib xws, thiab cov zis siab. Lawv adaptability rau ntau yam PVC formulations xyuas kom meej npaum thiab zoo yeeb nkab ntau lawm.

Yuav ua li cas ntse tswj systems txhim kho cov txheej txheem extrusion?

Cov kev tswj ntse ntse optimize kub, siab, thiab ntsia hlau ceev. Lawv txhim kho cov khoom sib xws, txo cov khoom pov tseg, thiab ua kom cov khoom zoo sib xws los ntawm kev saib xyuas thiab hloov kho lub sijhawm.

Vim li cas lub zog efficiency tseem ceeb hauv conical ntxaib ntsia hlau tsim?

Kev tsim hluav taws xob tsim hluav taws xob txo qis kev ua haujlwm thiab kev cuam tshuam ib puag ncig. Optimized ntsia hlau geometry thiab cov tshuab tsav siab heev txo lub zog noj thaum tswj kev ua haujlwm siab extrusion.

Lub sij hawm xa tuaj: Plaub Hlis-24-2025