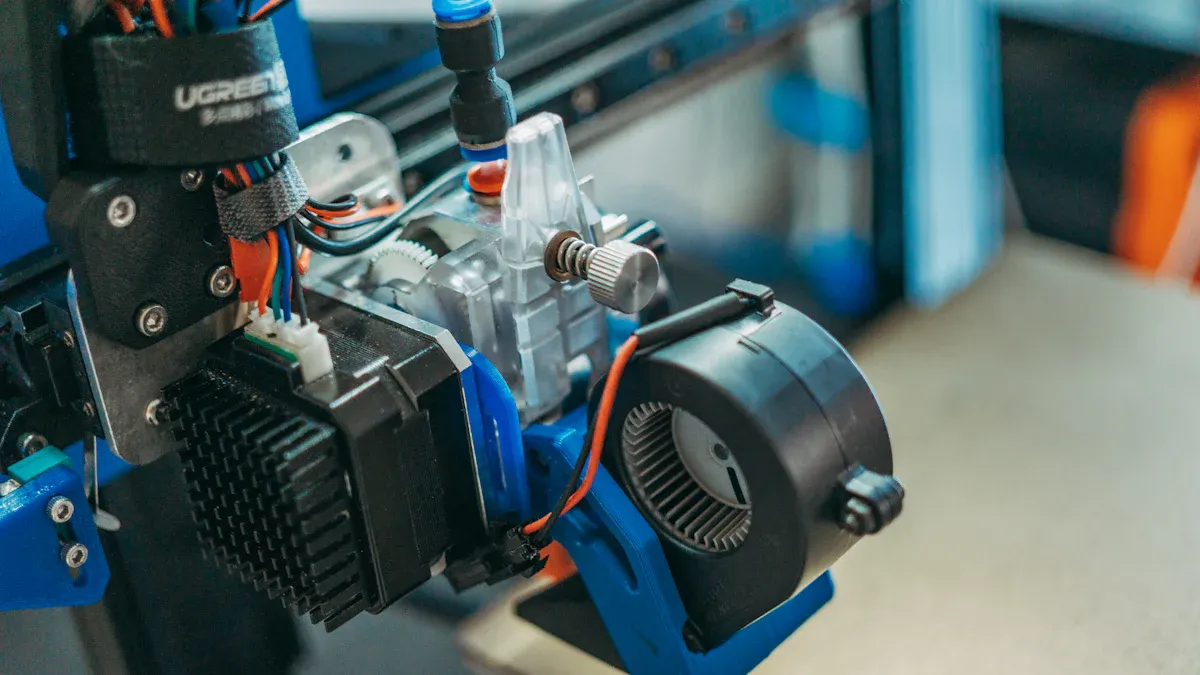

Twin ntsia hlau extruders ua lub luag haujlwm tseem ceeb hauv kev tsim khoom, tshwj xeeb tshaj yog nyob rau hauv cov khoom yas thiab roj hmab. Kev saib xyuas tsis tu ncua ntawm ntxaib ntsia hlau extruder yog qhov tseem ceeb kom cov tshuab no ua haujlwm zoo. Tshawb xyuas cov khoom xws li covyas extruder ntsia hlaurau hnav, aligning lubntxaib ntsia hlau extruder qhov chaw chim, thiab kev saib xyuas kev tswj xyuas kom ntseeg tau tias cov zis zoo ib yam. Cov kev coj ua no txuas ntxiv lub neej ntawm cov khoom siv, suav nrogyas extrusion tshuab ntsia hlau, thiab txo qis qis qis, txuag lub sijhawm thiab nyiaj txiag rau cov neeg ua haujlwm.

Cov Kev Pabcuam Tseem Ceeb rau Twin Screw Extruders

Tsis tu ncua tu thiab khoom purging

Ua kom lub ntxaib ntsia hlau extruder huv si yog qhov tseem ceeb rau kev tswj nws qhov kev ua tau zoo. Cov khoom seem tuaj yeem ua rau muaj paug, cuam tshuam rau cov khoom zoo. Kev tshem tawm tsis tu ncua nrog cov khoom siv huv huv lossis cov khoom siv tshwj xeeb tshem tawm pab tshem tawm cov kab mob xws li gels thiab cov khoom ntxiv. Nov yog qee qhov kev coj ua zoo huv:

- Ntxuav lub kaw lus nrog cov resin huv los yog ntxuav cov khoom kom tshem tawm cov khoom seem.

- Siv cov tshuaj ntxuav tes kom tshem tawm cov kab mob tawv ncauj.

- Xav txog cov txheej txheem zoo li disco purging rau kev tu kom huv.

Kev nkag siab txog kev ntxuav cov ntaub ntawv ua haujlwm li cas tuaj yeem ua kom cov txheej txheem ntxuav tau zoo dua. Lub extruder huv si tsis tsuas yog ua kom cov zis zoo ib yam nkaus xwb tab sis kuj tseem ua rau lub tshuab lub neej ntev.

Tsim nyog Lubrication ntawm txav qhov chaw

Lubrication plays lub luag haujlwm tseem ceeb hauv kev ua kom qhov txav ntawm cov ntsia hlau ntxaib extruder nyob rau saum toj. Tsis muajlubrication kom raug, kev sib txhuam nce, ua rau hnav thiab tsim kua muag. Cov roj nplua nyeem zoo txo qis kev sib txhuam, ncua lub neej ntawm cov khoom, thiab txhim kho kev ua haujlwm tag nrho.

| Qhov zoo | Kev piav qhia |

|---|---|

| Slipper | Ua rau muaj kev sib txhuam tsawg |

| Lub neej ntev | Extens lub neej ntawm iav, bearings, thiab seals |

| Kub | Lowers iav khiav hauj lwm kub thiab suab nrov |

| viscosity | Khaws viscosity txawm tias tshuab shearing |

| Kub kub | khaws cov viscosity siab ntawm qhov kub siab |

Kev kuaj xyuas thiab ua kom cov roj nplua nyeem tsis tu ncua ua kom lub tshuab extruder ua haujlwm zoo, txawm tias nyob rau hauv kev xav tau.

Kev soj ntsuam niaj hnub rau hnav thiab tsim kua muag

Kev tshuaj xyuas niaj hnub yog qhov tseem ceeb rau kev txheeb xyuas cov teeb meem muaj peev xwm ua ntej lawv nce ntxiv. Txheeb xyuas qhov hnav thiab tsim kua muag ntawm cov khoom xws li cov ntsia hlau thiab cov thoob tuaj yeem tiv thaivkim kho thiab downtime. Kev tshuaj xyuas kuj pab tswj cov khoom zoo ib yam.

| Cov txiaj ntsig | Kev piav qhia |

|---|---|

| Hnav thiab kua muag saib xyuas | Kev txheeb xyuas raws sijhawm ntawm kev hnav khaub ncaws tiv thaiv kev tsim khoom. |

| Tus nqi txo | Txo cov khoom siv tu thiab cov nqi thaum hloov xim. |

| Kev Ua Haujlwm Ua Haujlwm | Simplifies kev txij nkawm, shortens downtime, thiab txo kev siv zog. |

Los ntawm kev teem sijhawm kev tshuaj xyuas tsis tu ncua, cov neeg ua haujlwm tuaj yeem daws teeb meem me me thaum ntxov, kom ntseeg tau tias cov ntsia hlau ntxaib extruder tseem txhim khu kev qha thiab ua haujlwm tau zoo.

Saib xyuas thiab Hloov Cov Foob thiab Bearings

Cov ntsaws ruaj ruaj thiab bearings yog cov khoom tseem ceeb uas yuav tsum tau ua tib zoo saib xyuas. Cov ntsaws ruaj ruaj tuaj yeem ua rau xau, thaum cov kabmob puas tuaj yeem ua rau muaj kev sib txhuam thiab txo kev ua haujlwm. Saib xyuas cov khoom no thiab hloov lawv thaum tsim nyog ua kom lub extruder ua haujlwm ntawm qhov ua tau zoo.

- Kev kuaj xyuas tsis tu ncua tiv thaiv kev hnav ntxov ntxov thiab kev sib txhuam.

- Hloov cov ntsaws ruaj ruaj thiab cov bearings puas ua haujlwm thiab cov khoom zoo.

- Kev kho kom raug ncua lub neej ntawm extruder.

Los ntawm qhov tseem ceeb ntawm cov khoom no, cov neeg ua haujlwm tuaj yeem zam qhov kev puas tsuaj uas tsis tau npaj tseg thiab ua kom muaj txiaj ntsig zoo ib yam.

Kev daws cov teeb meem tshwm sim hauv Twin Screw Extruders

Hais txog cov teeb meem overheating

Overheating tuaj yeem cuam tshuam qhov kev ua tau zoo ntawm cov ntsia hlau ntxaib extruder thiab txawm tias cov ntaub ntawv rhiab heev. Kev tswj lub chim kub thiab siab yog qhov tseem ceeb los tiv thaiv qhov teeb meem no. Cov neeg ua haujlwm yuav tsum saib xyuas qhov ntsuas kub tsis tu ncua thiab xyuas kom lub tshuab ua kom txias ua haujlwm zoo.

- Kev sib raug zoo ncaj qha muaj nyob nruab nrab ntawm qhov siab thiab qhov kub thiab txias. Rau txhua txhua 2-bar nce siab, qhov kub siab nce 1 ° C. Ua kom lub siab ruaj khov pab tswj cov cua sov.

- Txhim kho cov cuab yeej tsim hluav taws xob, xws li iav twj tso kua mis, tuaj yeem ua kom lub siab ruaj khov thiab tswj cov kub kub zoo.

- Lub sij hawm nyob luv luv nyob rau hauv ntxaib ntsia hlau extruders minimizes raug rau kub kub, uas yog tshwj xeeb tshaj yog zoo rau cov ntaub ntawv kub-rhiab heev.

Los ntawm kev hais txog overheating, cov neeg ua haujlwm tuaj yeem tswj xyuas cov khoom zoo sib xws thiab zam kev poob qis.

Tiv thaiv Screw hnav thiab puas

Ntsia hlau hnavyog ib qho teeb meem uas cuam tshuam rau kev ua tau zoo ntawm ntxaib ntsia hlau extruders. Kev tshuaj xyuas tsis tu ncua thiab siv cov ntaub ntawv hnav-tiv taus tuaj yeem pab tiv thaiv qhov teeb meem no. Nov yog qee cov lus qhia tswv yim:

- Tshawb xyuas cov ntsia hlau thiab cov thoob ntau zaus kom paub cov cim thaum ntxov ntawm kev hnav.

- Siv cov khoom zoo, hnav-tiv taus rau cov ntsia hlau thiab cov thoob kom ntev lawv lub neej.

- Xyuas kom zoo ib yam particle loj thaum lub sij hawm pub khoom noj kom txo tau abrasive hnav.

Tiv thaiv cov ntsia hlau tsis yog tsuas yog tswj cov khoom siv xwb tab sis kuj ua kom cov khoom zoo sib xws nyob rau lub sijhawm.

Troubleshooting Material Build-Up

Cov khoom tsim-up hauv lub extruder tuaj yeem ua rau cov zis tsis sib xws thiab txo kev ua haujlwm. Kev daws teeb meem zoo tuaj yeem txhim kho cov txiaj ntsig tau zoo.

Kev tswj qhov kub thiab txias profile yog qhov tseem ceeb. Kho qhov kub thiab txias setpoints softens cov resin, txhim kho dispersive sib tov thiab tiv thaiv cov khoom degradation. Tsis tas li ntawd, optimizing ntsia hlau tsim tso cai rau kev tswj kom zoo dua yaj viscosity, uas txhim khu kev sib xyaw efficiency.

Cov neeg ua haujlwm tseem yuav tsum tau ntxuav lub extruder tsis tu ncua kom tshem tawm cov khoom seem. Qhov kev xyaum no txo qis kev sib kis thiab ua kom muaj kev ua haujlwm zoo.

Kev daws qhov tso zis tsis raug zoo

Cov khoom tso tawm tsis zoo tuaj yeem ua rau cov khoom siv khib nyiab thiab nce nqi. Hais txog qhov teeb meem no yuav tsum muaj kev tsom mus rau kev tswj kom zoo thiab kev saib xyuas lub sijhawm.

- Ib lub chaw tsim khoom uas koom ua ke Tus Qauv Kev Tswj Xyuas Kev Ua Haujlwm (MPC) nrog lawv cov ntsia hlau ntxaib extruder pom 15% nce hauv kev nkag mus thiab 10% txo qis hauv cov khoom siv tshwj xeeb.

- Lwm lub tuam txhab tau teeb tsa lub ntsuas hluav taws xob hauv kab los saib xyuas cov viscosity hloov pauv. Los ntawm kev kho cov ntsia hlau ceev thiab qhov kub thiab txias profiles raws li cov ntaub ntawv ntawm lub sijhawm tiag tiag, lawv txo cov nqi tsis kam lees los ntawm 25%.

Cov piv txwv no qhia txog yuav ua li cas daws cov teeb meem tsis sib xws tuaj yeem txhim kho cov khoom lag luam thiab txo cov khoom pov tseg.

Optimization Tips rau Twin Screw Extruders

Fine-Tuning Temperature Control

Kev tswj qhov kub thiab txias yog qhov hloov pauv kev ua si rau kev ua kom zoo dua qhov kev ua tau zoo ntawm cov ntsia hlau ntxaib extruder. Kho qhov kub thiab txias hauv cov cheeb tsam tshwj xeeb tuaj yeem txhim kho cov khoom melting thiab txo qhov hnav ntawm cov khoom. Piv txwv li:

- Kev teeb tsa thaj tsam 1 thiab 2 mus rau qhov kub siab dua txo qis hnav ntawm cov khoom siv yas yas. Qhov kev hloov kho no tso cai rau cov ntaub ntawv kom yaj tau zoo dua, txo qhov xav tau ntawm lub zog siv tshuab.

- Kev tshawb fawb los ntawm Maridass thiab Gupta, nrog rau Ulitzsch li al., qhia txog yuav ua li casoptimizing chim kubtxhim kho cov khoom siv thiab cov txheej txheem ua tiav.

Tsis tas li ntawd, kev tswj xyuas qhov tso tawm qis tuaj yeem ua kom cov cua sov ua kom sov. Txoj hauv kev no txo qis kev hnav ntawm cov ntsia hlau tawm thiab txhawb nqa thermal stability, ua kom muaj kev ua haujlwm zoo ib yam.

Txhim kho cov khoom noj thiab tuav

Cov khoom siv tau zoo pub noj thiab tuav ncaj qha cuam tshuam rau extruder cov khoom siv thiab kev siv hluav taws xob. Cov tuam txhab tau ua tiav cov txiaj ntsig zoo kawg nkaus los ntawm kev ua kom zoo dua cov txheej txheem no:

- Cov txheej txheem ntawm cov iav fiber ntau ntxiv cov polymers tau nce mus txog 18% los ntawm kev sib koom ua ke ntawm ib sab feeder thiab hloov kho cov ntsia hlau tsim.

- Kev xa tawm tau nce los ntawm 2000 kg / hr mus rau 2300 kg / hr, tsim ib qho ntxiv $ 180,000 hauv cov txiaj ntsig txhua xyoo.

- Kev txuag hluav taws xob ntawm 5% (lossis 138 MWh / xyoo) tau ua tiav vim muaj qib siab dua ntawm kev sau hauv extruder.

Cov kev txhim kho no tsis tsuas yog txhim kho kev ua haujlwm zoo tab sis kuj txo cov nqi, ua rau lawv yeej-yeej rau cov tuam txhab.

Kho Screw Configuration rau cov ntawv thov tshwj xeeb

Customizing cov ntsia hlau configuration tuaj yeem txhim kho kev ua tau zoo rau cov khoom sib txawv thiab kev siv. Cov kev hloov pauv tseem ceeb suav nrog:

- Hloov kho qhov tob channel kom ua kom zoo dua qhov compression piv rau cov thermoplastics.

- Ua kom cov ntsia hlau ntev-rau-inch (L / D) piv los txhim kho kev sib xyaw thiab melting efficiency.

- Kev sib xyaw cov ntsiab lus los yog Maddock mixers kom zoo dua sib xyaw thiab tswj qhov kub thiab txias.

- Kho lub kaum sab xis helix thiab suab kom ntseeg tau tias cov khoom siv tau zoo.

- Siv barrier screws cais cov ntaub ntawv melted thiab unmelted, txhim kho qhov sib xws.

Cov kev hloov kho no tso cai rau cov neeg ua haujlwm txiav cov extruder rau cov kev xav tau tshwj xeeb, ua kom cov txiaj ntsig zoo.

Txhim kho cov txheej txheem Efficiency los ntawm Automation

Automation tau hloov pauv txoj kev ntxaib ntsia hlau extruders ua haujlwm. Cov txheej txheem Advanced nruab nrog sensors thiab kev saib xyuas lub sijhawm tiag tiag txo qhov kev xav tau ntawm phau ntawv cuam tshuam. Predictive txij nkawm nta txo qis downtime thiab txhim kho kev ntseeg tau.

Artificial Intelligence (AI) siv automation ib kauj ruam ntxiv los ntawm optimizing extrusion tsis thiab cov khoom ntws. Qhov no ua rau txo cov khoom pov tseg, kev tswj kom zoo dua qub, thiab kev txhim kho tag nrho. Cov neeg tsim khoom siv automation pom kev txhim kho tseem ceeb hauv kev tsim khoom thiab txuag nqi, ua rau nws muaj txiaj ntsig kev nqis peev.

Kev Tiv Thaiv Kev Ntsuas rau Twin Screw Extruders

Ua raws li Cov Txheej Txheem Kho Kom Zoo

Cov sij hawm saib xyuas niaj hnub yog cov caj qaum ntawm kev tiv thaiv kev saib xyuasntxaib ntsia hlau extruder. Kev saib xyuas tsis tu ncua ua kom cov tshuab ua haujlwm zoo thiab tsis txhob poob siab. Cov neeg ua haujlwm tuaj yeem npaj cov sijhawm tu ncua raws li cov ntaub ntawv keeb kwm, hloov lossis hloov kho cov khoom ua ntej lawv ua tsis tiav.

Tswv yim: Ib qho kev txhim kho kev tsim kho tsis yog tsuas yog tiv thaiv kev poob qis xwb tab sis tseem txuas ntxiv lub neej ntawm cov khoom siv.

Nov yog qhov kev tshawb fawb kev lag luam qhia txog cov txiaj ntsig ntawm kev saib xyuas niaj hnub:

| Cov txiaj ntsig | Kev piav qhia |

|---|---|

| Kev ua tau zoo tshaj plaws | Kev saib xyuas tsis tu ncua ua kom muaj kev ua tau zoo tshaj plaws los ntawm kev sib raug zoo thiab lubrication ntawm cov khoom. |

| Tiv thaiv kev poob qis | Teem sijhawm saib xyuas kom txo qis qhov kev xav tsis thoob, ua rau muaj kev cuam tshuam ntau lawm. |

| Kev txuag nqi | Kev kuaj xyuas niaj hnub tuaj yeem tiv thaiv cov teeb meem me me los ntawm kev ua teeb meem loj, txuag nqi kho. |

| Kev nyab xeeb | Kev saib xyuas raws sij hawm txo kev nyab xeeb rau cov neeg siv tshuab los ntawm kev hais txog cov khoom hnav lossis puas. |

| Lifespan Extension | Kev saib xyuas zoo ib yam tuaj yeem txuas ntxiv lub neej ua haujlwm ntawm extruder, tiv thaiv kev nqis peev. |

| Khoom Zoo | Cov tshuab ua haujlwm zoo tsim cov khoom lag luam zoo dua los ntawm kev tiv thaiv impurities hauv cov khoom ua tiav. |

| Zog Efficiency | Kev kuaj xyuas tsis tu ncua ua kom zoo rau cov khoom siv kom zoo dua qub, txo cov nqi ua haujlwm. |

Los ntawm kev ua raws li lub sijhawm saib xyuas, cov neeg ua haujlwm tuaj yeem zam kev kho tus nqi kim thiab ua kom cov khoom siv tau zoo.

Kev cob qhia cov neeg ua haujlwm ntawm kev coj ua zoo tshaj plaws

Cov neeg ua haujlwm ua lub luag haujlwm tseem ceeb hauv kev tswj cov ntsia hlau ntxaib extruders. Kev cob qhia lawv txog kev coj ua zoo tshaj plaws kom lawv nkag siab txog kev tswj cov cuab yeej kom raug. Cov kws qhia ntawv tuaj yeem txheeb xyuas cov cim qhia ntxov ntawm kev hnav thiab daws teeb meem me ua ntej lawv nce ntxiv.

Nco tseg: Cov kev cob qhia kev cob qhia yuav tsum suav nrog kev tshuaj xyuas niaj hnub, cov txheej txheem lubrication, thiab kev daws teeb meem ntau yam.

Thaum cov neeg ua haujlwm paub txog qhov ins thiab outs ntawm lub tshuab, lawv muaj peev xwm ua tau raws sij hawm kho thiab hloov, txo downtime thiab txhim kho productivity.

Khaws Cov Khoom Muag Khoom Muag Npaj Npaj

Muaj cov khoom seem ntawm tes yog ib txoj kev cawm seej thaum muaj xwm txheej npaj txhij txog. Cov ntsaws ruaj ruaj, bearings, lossis cov ntsia hlau tuaj yeem nres kev tsim khoom yog tias tsis muaj kev hloov pauv tau yooj yim. Kev khaws cov khoom lag luam ntawm cov khoom tseem ceeb ua kom muaj kev txhim kho sai thiab txo qis sijhawm poob qis.

- Khaws cov khoom tseem ceeb xws li cov ntsia hlau, cov thoob, thiab cov ntsaws ruaj ruaj.

- Saib xyuas cov qib hnav kom xav tau kev hloov pauv.

- Koom tes nrog cov neeg muag khoom txhim khu kev qha kom ntseeg tau tias muaj khoom zoo thiab muaj.

Cov khoom lag luam zoo khaws cia cov haujlwm ua haujlwm tau zoo thiab tiv thaiv tus nqi qeeb.

Siv cov khoom siv zoo thiab cov khoom siv

Cov ntaub ntawv zoo yog lub hauv paus ntawm txhim khu kev qha ntxaib ntsia hlau extruders. Cov khoom siv ua los ntawm cov khoom siv ruaj khov zoo li nitriding steel txhim kho kev ua haujlwm thiab txo cov kev xav tau ntawm kev saib xyuas. Cov txheej txheem kev tsim khoom siab tshaj plaws, xws li quenching thiab nitriding, ntxiv txhim kho qhov ntev ntawm qhov chaw.

Kev nqis peev hauv cov ntaub ntawv hwm nyiaj them rau lub sijhawm ntev. Cov neeg tsim khoom muaj tsawg dua kev puas tsuaj, txo nqi kho, thiab ua haujlwm zoo ib yam.

Los ntawm kev saib xyuas qhov zoo, cov neeg ua haujlwm tiv thaiv lawv cov peev txheej thiab txaus siab rau ROI zoo dua los ntawm kev txo cov nqi khiav lag luam thiab lub sijhawm poob.

Kev saib xyuas tsis tu ncua ua kom ntxaib ntsia hlau extruders khiav zoo. Kev saib xyuas zoo txo qis lub sijhawm poob qis, txuas ntxiv lub neej ntawm cov cuab yeej siv, thiab ua kom cov khoom zoo ib yam. Cov neeg khiav dej num uas ua raws li cov lus qhia no tuaj yeem ua kom tau txais txiaj ntsig zoo tshaj plaws thiab zam kev kho kom raug nqi.

Tswv yim: Pib me me. Tsim ib lub sijhawm tu thiab cob qhia koj pab neeg. Cov kauj ruam no ua rau muaj qhov sib txawv loj hauv lub sijhawm ntev!

FAQ

Dab tsi yog txoj hauv kev zoo tshaj los ntxuav lub ntxaib ntsia hlau extruder?

Purging nrog cov khoom tsim nyog los yog tshem tawm cov khoom ua haujlwm zoo tshaj plaws. Nws tshem tawm cov residue thiab tiv thaiv kev sib kis, kom ntseeg tau tias kev ua tau zoo thiab cov khoom zoo.

Ntev npaum li cas yuav tsum tau ua raws li kev saib xyuas niaj hnub?

Cov neeg ua haujlwm yuav tsum ua raws li cov neeg tsim khoom pom zoo. Feem ntau, kev saib xyuas niaj hnub rau lub ntxaib ntsia hlau extruder yuav tsum tshwm sim txhua 500-1,000 teev ua haujlwm.

Dab tsi ua rau cov ntsia hlau hnav hauv cov ntsia hlau ntxaib extruder?

Cov ntsia hlau hnav feem ntau tshwm sim los ntawm cov khoom siv abrasive, kub ua haujlwm siab, lossis lubrication tsis raug. Kev tshuaj xyuas tsis tu ncua thiab siv cov ntaub ntawv hnav-tiv taus tuaj yeem pab txo qhov teeb meem no.

Post lub sij hawm: May-29-2025