Ib qho kev kuaj ib leeg ntsia hlau extruder siv cov ntsia hlau tig kom yaj, sib tov, thiab zoo li cov polymers hauv ib lub thoob rhuab. Cov kws tshawb fawb tso siab rauvented ib leeg ntsia hlau extruder, ib leeg ntsia hlau tshuab, thiabwaterless granulator tshuabkom ua tiav kev sib xyaw kom zoo thiab muaj kev nyab xeeb, ua haujlwm zoo. Kev tshawb fawb qhia tiasntsia hlau ceev thiab kubncaj qha cuam tshuam cov khoom zoo thiab kev nyab xeeb.

Cov Cheebtsam tseem ceeb ntawm ib leeg ntsia hlau Extruder

Lub Ntsia Hlau

Cov ntsia hlauyog lub plawv ntawm ib leeg ntsia hlau extruder. Nws tig mus rau hauv lub thoob thiab txav lub polymer rau pem hauv ntej. Cov ntsia hlau melts, sib tov, thiab thawb cov khoom mus rau qhov tuag. Screw tsim, nrog rau txoj kab uas hla, qhov ntev-rau-inch ratio, thiab compression ratio, cuam tshuam zoo npaum li cas cov polymer melts thiab sib tov. Ib tug zoo-tsim ntsia hlau txhim kho melting tus nqi thiab efficiency. Grooves ntawm cov ntsia hlau los yog lub thoob tuaj yeem ua kom nrawm nrawm thiab pab tswj cov txheej txheem. Cov ntsia hlau ceev kuj hloov qhov sib xyaw thiab cov cua sov tsim tawm.

Tswv yim: Kho cov ntsia hlau ceev tuaj yeem pab tswj qhov kub thiab txias thiab cov khoom zoo.

Lub Barrel

Lub thoobnyob ib puag ncig cov ntsia hlau thiab tuav cov polymer thaum nws txav mus. Lub thoob muaj qhov sib txawv ntawm qhov kub thiab txias. Txhua cheeb tsam tuaj yeem teem rau qhov kub thiab txias los pab yaj cov polymer sib npaug. Piv txwv li, thawj cheeb tsam yuav txias dua los pab txav cov khoom polymer, thaum tom qab cov cheeb tsam kub dua los yaj cov khoom. Kev tswj qhov kub thiab txias hauv lub thoob yog qhov tseem ceeb rau kev khiav zoo thiab cov khoom zoo.Thermocouples ntsuas qhov kub hauv lub thoobkom cov txheej txheem ruaj khov.

- Barrel kub nqis nyob ntawm seb hom polymer thiab cov ntsia hlau tsim.

- Niaj hnub nimno extruders feem ntau muaj peb lossis ntau qhov chaw kub.

- Cov seem pub yuav tsum sov tab sis tsis kub dhau kom tsis txhob muaj cov khoom lo.

Cua sov System

Lub tshuab cua sov ua kom lub thoob ntawm qhov kub thiab txias. Cov cua sov yog muab tso rau hauv lub thoob thiab tswj los ntawm cov sensors. Lub kaw lus tuaj yeem kho txhua cheeb tsam kom haum rau cov kev xav tau ntawm cov polymer. Kev tswj cov cua sov zoo pab kom tsis txhob muaj teeb meem xws li cov khoom siv hluav taws kub los yog melting tsis sib xws. Lub tshuab cua sov ua haujlwm nrog kev tswj xyuas kom cov txheej txheem muaj kev nyab xeeb thiab ua haujlwm zoo.

Tuag

Cov tuag zoo li cov melted polymer raws li nws tawm ntawm ib qho ntsia hlau extruder. Tuag tsim cuam tshuam cov khoom kawg ntawm cov duab, nto, thiab loj. Ib tug zoo tuag muab ib tug du, txawm ntws thiab pab ua cov khoom uas muaj qhov ntev. Cov tuag yuav tsum tswj qhov kub thiab txias kom tsis txhob muaj qhov tsis xws luag. Kev hloov pauv hauv qhov kub thiab txias tuaj yeem hloov cov khoom zoo.

- Uniform tshaj tawm thiab tsawg kawg siab poob ntawm qhov tuag tawm yog qhov tseem ceeb rau kev ua tau zoo.

- Tuag channel geometry thiab ntws sib npaug cuam tshuam qhov tseeb ntawm cov khoom zoo.

Tswj System

Lub kaw lus tswj tswj kev ua haujlwm ntawm ib qho ntsia hlau extruder. Nws saib xyuas qhov kub, siab, ntsia hlau ceev, thiab pub tus nqi. Cov neeg ua haujlwm siv cov kev tswj hwm los teeb tsa thiab kho cov txheej txheem tsis ua haujlwm. Kev saib xyuas lub sijhawm tiag tiag pab ua kom cov txheej txheem ruaj khov thiab nyab xeeb. Lub kaw lus tswj kuj tseem tuaj yeem khaws cov zaub mov txawv rau cov polymers sib txawv, ua rau nws yooj yim dua rov ua haujlwm zoo.

Hom Tib Ntsia Hlau Extruder rau Kev Siv Tshuaj

Cov chaw kuaj mob xav tau ntau hom extruders kom tau raws li cov kev xav tau tshwj xeeb. Txhua hom muaj cov yam ntxwv tshwj xeeb thiab qhov zoo rau kev ua cov polymer.

Vented Ib Ntsia Hlau Extruder

Ib tug vented ib leeg ntsia hlau extruder siv aob-theem ntsia hlau tsim. Qhov kev tsim no txo torque thiab horsepower xav tau thaum tswj cov zis thiab ntsia hlau ceev. Lub venting system tshem tawm noo noo thiab gases los ntawm polymer yaj. Cov kauj ruam no yog qhov tseem ceeb rau kev ua cov yas uas nqus dej. Tshem tawm cov volatiles no tiv thaiv tsis xws luag xws li splay thiab tsis muaj zog txhua yam khoom. Qhov chaw nres nkoj feem ntau ua haujlwm nyob rau hauv lub tshuab nqus tsev, uas pab degassing los ntawm kev txo qis. Ob-theem ntsia hlau kuj txhim kho kev sib xyaw los ntawm compressing thiab decompressing cov yas. Cov txheej txheem no tsim ib qho zoo sib xws. Cov neeg ua haujlwm yuav tsum sib npaug ntawm cov khoom tsim tawm ntawm ob theem kom tsis txhob muaj dej ntws los yog tso dej nyab. Cov yam ntxwv no ua rau lub vented ib leeg ntsia hlau extruder ua tau zoo thiab txhim khu kev qha hauv cov ntawv thov kev sim.

Lus Cim: Cov zis ruaj khov thiab siv hluav taws xob qis dua teeb tsa cov extruders sib nrug hauv kev tshawb fawb ib puag ncig.

Tib Ntsia Hlau Tshuab

Ib lub tshuab ntsia hlau npog ntau yam ntawm extruders rau melting, sib tov, thiab shaping polymers. Cov tshuab no muab kev tsim qauv yooj yim thiab ua haujlwm yooj yim. Cov kws tshawb fawb tuaj yeem tswj cov shear thiab kub zoo, uas pab nrog cov txheej txheem polymer yooj yim thiab cov dej num extrusion. Ib leeg ntsia hlau tshuab ua haujlwm zoo rau kev ua tubing, zaj duab xis, thiab lwm yam khoom siv yooj yim. Lawv tuaj nyob rau hauv txawv qhov ntau thiab tsawg thiab configuration kom phim ntau yam kev tshawb fawb xav tau.

| Hom Extruder | Cov yam ntxwv tseem ceeb thiab qhov zoo | Hom kev siv thiab tsim nyog |

|---|---|---|

| Ib leeg ntsia hlau Extruders | Yooj yim tsim, tswj zoo, ua haujlwm yooj yim | Tubing, zaj duab xis, yooj yim polymer formulations |

| Twin Ntsia Hlau Extruder | Superior mixing, ntau yam, intermeshing screws | Compounding, complex cov ntaub ntawv, tshuaj |

| Miniature / Micro Extruders | Me me, nqi-zoo, txhim khu kev qha | R & D, prototyping, txwv cov khoom kuaj |

Waterless Granulator Tshuab

Lub tshuab tsis muaj dej granulator hloov cov ntaub ntawv yas rau hauv granules yam tsis siv dej. Cov thev naus laus zis no txhim kho kev siv hluav taws xob thiab txo qhov cuam tshuam ib puag ncig. Cov txheej txheem ua kom cov granules qhuav thiab huv si, uas muaj txiaj ntsig zoo rau kev ua haujlwm ntxiv. Waterless granulator tshuab tuav ntau hom yas resins. Lawv pab cov kws tshawb fawb tsim cov granules zoo rau kev sim thiab txhim kho.

Step-by-Step Polymer Extrusion txheej txheem

Pub cov khoom siv Polymer

Cov txheej txheem extrusion pib nrog kev pub cov khoom siv raw polymer rau hauv qhov pub hopper. Lub hopper xyuas kom meej txawm tias kev faib tawm thiab tiv thaiv kev thaiv, uas pab tswj kom muaj kev ruaj khov. Cov ntsia hlau hauv lub thoob pib tig, rub cov polymer pellets lossis hmoov rau pem hauv ntej. Kev tsim ntawm cov ntsia hlau, nrog rau nws txoj kab uas hla thiab qhov ntev-rau-inch, plays lub luag haujlwm tseem ceeb hauv kev ua haujlwm zoo ntawm cov khoom txav. Lub kaw lus tswj tau tso cai rau cov neeg ua haujlwm kho cov ntsia hlau ceev thiab pub tus nqi, uas pab kho cov txheej txheem rau cov polymers sib txawv.

- Pub hoppers yog tsim los tiv thaiv clogs thiab xyuas kom meej kev noj qab haus huv.

- Cov ntsia hlau conveys, compresses, thiab pib cua sov lub polymer.

- Kev tswj qhov kub thiab txias hauv lub thoob pab txhim kho cov txheej txheem melting.

Cov kev tshawb fawb thaum ntxov tau tsim tias kev tswj cov ntsia hlau ceev thiab qhov kub thiab txias ncaj qha cuam tshuam qhov zoo ntawm cov polymer txau thiab yaj. Niaj hnub nimno kuaj extruders siv cov kev tswj siab heev kom noj tau zoo thiab ruaj khov.

Melting thiab Plasticizing

Raws li cov polymer txav raws lub thoob, nws nkag mus rau qhov chaw sov. Qhov kub ntawm txhua cheeb tsam nce zuj zus, ua rau cov polymer soften thiab yaj. Cov ntsia hlau tig thiab lub thoob cov cua sov ua haujlwm ua ke los ua cov khoom siv yas, tig mus rau hauv cov khoom sib xws. Sensors muab tso rau hauv lub thoob ntsuas ob qhov kub thiab txias kom ntseeg tau tias cov polymer yaj hauv nws qhov kev ua haujlwm zoo tshaj plaws.

| Parameter | Kev piav qhia |

|---|---|

| Melt kub | Yuav tsum nyob twj ywm hauv cov khoom siv polymer kom tau txais txiaj ntsig zoo tshaj plaws. |

| Siab Tshaj Tawm ntawm Screw | Indicates melt quality thiab txheej txheem stability. |

| Kev Hloov Siab | Saib xyuas kom paub txog tej teeb meem nrog melting los yog ntws. |

| Qhov kub thiab txias | Taug qab los xyuas kom meej txawm tias cua sov thiab tsis txhob muaj qhov tsis xws luag. |

| Degree ntawm Melting | Tshawb pom qhov muag lossis los ntawm kev sim cov yeeb yaj kiab extruded kom pom tseeb thiab sib xws. |

| Screw Performance Index | Ua ke cov khoom no los ntsuas qhov zoo ntawm qhov tsis zoo (0) mus rau qhov zoo tshaj (1). |

Precise tswj ntawm qhov kub thiab txias yuav pab tiv thaiv kom tsis txhob degradation thiab ua kom cov yaj zoo ib yam. Kev saib xyuas lub sijhawm tiag tiag nrog cov cuab yeej siab tshaj plaws thiab cov txheej txheem spectroscopy muab cov ntaub ntawv txuas ntxiv, tso cai rau cov kws tshawb fawb los kho cov chaw raws li xav tau.

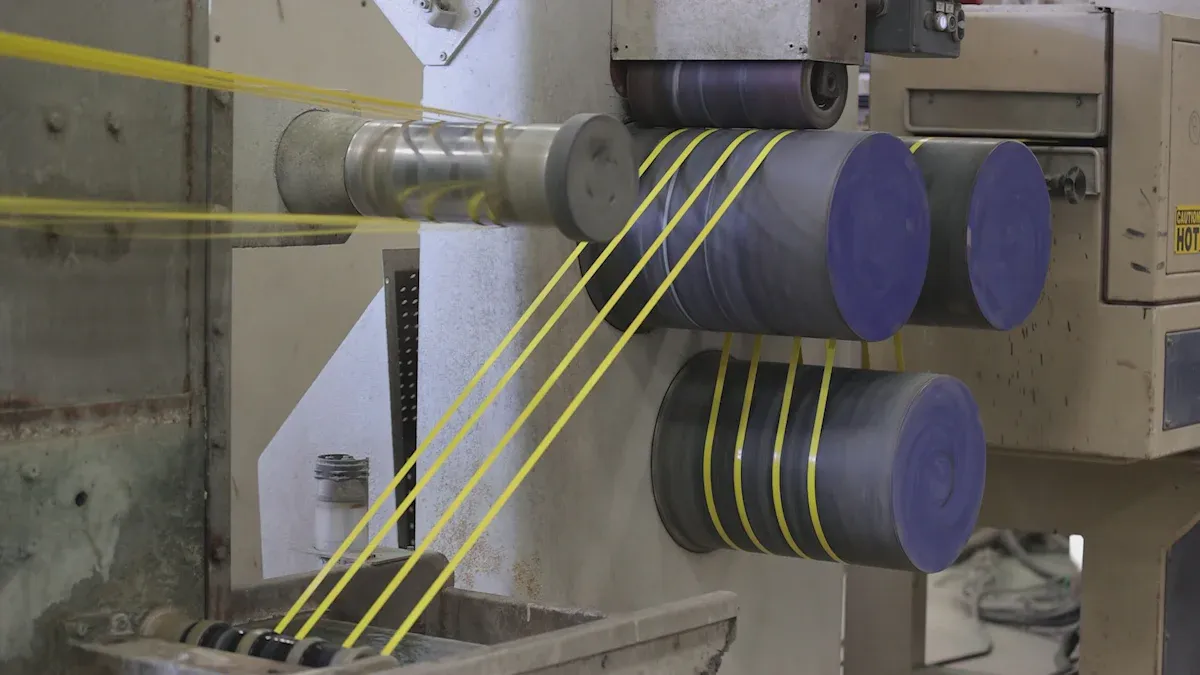

Mixing thiab Conveying

Thaum melted, lub polymer yuav tsum tau tov kom huv si kom ntseeg tau tias uniformity. Cov ntsia hlau tsim, suav nrog cov yam ntxwv zoo li cov ntu thaiv lossis thaj chaw sib xyaw, pab muab cov khoom sib xyaw thiab tshem tawm cov khoom seem seem. Raws li cov ntsia hlau tig, nws thawb lub molten polymer rau pem hauv ntej, xa nws mus rau qhov tuag.

Cov kws tshawb fawb siv cov kev teeb tsa siab heev nrogsampling ports thiab optical detectorskawm seb cov khoom sib tov zoo npaum li cas. Los ntawm kev txhaj tshuaj tracers thiab ntsuas seb lawv kis tau li cas, lawv tuaj yeem pom tias cov ntsia hlau ceev thiab geometry cuam tshuam li cas rau kev sib xyaw. Cov ntsia hlau siab nrawm tuaj yeem qee zaum tawm ntawm cov khoom tawg, tab sis cov ntsia hlau tshwj xeeb tsim kev sib xyaw ua ke thiab tiv thaiv qhov teeb meem no.Siab sensors nyob rau hauv lub chimntsuas seb cov polymer txav tau zoo npaum li cas, pab cov neeg ua haujlwm txhim kho cov txheej txheem.

Shaping Los ntawm Tuag

Lub molten polymer ncav cuag qhov tuag, uas ua rau nws mus rau hauv daim ntawv xav tau. Tus tuag tus qauv txiav txim siab qhov khoom kawg qhov loj thiab qhov zoo ntawm qhov chaw. Engineers siv computer simulations thiab finite ntsiab tsom xam los tsim tuag uas tsim cov duab raug thiab txo qhov tsis xws luag. Lawv kuj ua kom zoo dua qhov ntws channel geometry kom sib npaug ntawm qhov nrawm thiab txo qhov sib txawv molecular orientation, uas tuaj yeem cuam tshuam cov khoom qhov ntev.

| Pov thawj Aspect | Kev piav qhia |

|---|---|

| Finite Element Analysis | Siv los kawm txog kev ntws thiab qhov tseeb ntawm qhov tuag. |

| Optimization Tsim | Txo qhov yuam kev thiab txhim kho geometric precision. |

| Kev sim validation | Pom zoo tswj nruj ntawm cov khoom loj. |

| Tus lej Simulation | Predicts tuag swell thiab interface txav kom tau zoo dua. |

| Molecular Orientation Control | Sib npaug ntws los tiv thaiv qhov tsis sib xws ncab thiab cov duab hloov pauv. |

Precise tswj ntawm cov khoom siv tuag thiab downstream kom cov khoom tawm ntawmIb leeg ntsia hlau Extrudernrog cov duab thiab qhov loj.

Cooling thiab Solidifying

Tom qab shaping, cov polymer kub tawm ntawm qhov tuag thiab nkag mus rau theem txias. Cooling solidifies lub polymer, xauv hauv nws cov duab kawg thiab cov khoom. Tus nqi cua txias nyob ntawm qhov kub extrusion, ambient tej yam kev mob, thiab qhov ceev ntawm cov khoom txav los ntawm qhov chaw txias.

| Parameter/Aspect | Kev soj ntsuam/Tshaj tawm |

|---|---|

| Extrusion kub | Polymer extruded ntawm 100 ° C |

| Ambient kub | Khaws ib ncig ntawm 20 ° C thaum sim |

| Txias tus nqi peak kub | Txog 72 ° C |

| Qhov cuam tshuam ntawm qhov nrawm | Qhov qis qis qis qis ua kom txias thiab txuas ntxiv lub sij hawm solidification |

| Txias tus cwj pwm | Qhov siab tshaj plaws poob raws li kev tshaj tawm txo; ncov hloov mus ntev dua |

| Cov nyhuv ntau txheej | Cov khaubncaws sab nraud povtseg tuaj yeem rov ua dua ua ntej, txhim kho adhesion |

Kev tswj xyuas qhov chaw txias hauv qhov ntsuas qhov nqaim, feem ntau nyob rau hauv ± 2 ° C, pab ua kom cov khoom zoo sib xws. Kev ua kom txias kom zoo tiv thaiv warping thiab ua kom cov polymer solidifies tusyees.

Daim ntawv thov ntawm Single Screw Extruder hauv Polymer Research

Material Formulation thiab Test

Cov kws tshawb fawb siv cov chaw sim extruders los tsim thiab sim cov khoom siv polymer tshiab. Cov kev tshawb fawb hauv paus thiab patents piav qhia li casntsia hlau tsimthiab kev tswj cua sov txhim kho melting thiab sib tov. Cov kev txhim kho no pab cov kws tshawb fawb tsim cov khoom tshiab nrog cov khoom tshwj xeeb. Piv txwv li, lub peev xwm qis extruder ua nrog cov ntaub ntawv hauv zos tau pom tias muaj kev ua tau zoo hauv kev tsim khoom hauv lab. Nws tau ua tiav txog li 13 kg ib teev twg thiab txo cov tsis xav tau cov khoom lag luam kawg. Cov txiaj ntsig no tau lees paub tias chav kuaj extruders txhawb nqa kev tsim kho tshiab thiab kev tswj xyuas zoo hauv cov khoom tsim.

| Parameter | Tus nqi/Qhov tshwm sim |

|---|---|

| Tshaj tawm | 13.0 kg / h |

| Ntsia Hlau Ceev | 200 rpm |

| Barrel Diameter | 40 mm |

| Expansion Ratio | 1.82–2.98 Nws |

| Trypsin Inhibitor txo | 61.07% -87.93% |

Txheej txheem Optimization

Laboratory extruders pab cov kws tshawb fawb pom cov txheej txheem zoo tshaj plaws rau cov polymers sib txawv. Cov ntaub ntawv sim qhia tiaskev siv zog nyob ntawm qhov ceev ceev thiab cov khoom siv. Los ntawm kev kaw lub cev muaj zog thiab kho qhov chaw, cov kws tshawb fawb tuaj yeem txhim kho lub zog ua haujlwm thiab cov khoom zoo. Kev tshawb fawb kuj qhia tau tias hloov pauvntsia hlau ceevthiab ntxiv qee cov khoom xyaw tuaj yeem txhim kho li cas polymers sib xyaw thiab ntws. Cov kev tshawb pom no pab pawg teeb tsa kev nyab xeeb, ua haujlwm tau zoo, thiab rov ua dua cov txheej txheem rau kev tshawb fawb thiab tsim khoom.

Tswv yim: Kho cov ntsia hlau ceev thiab kub tuaj yeem sib npaug siv zog thiab txhim kho cov khoom zoo.

Small-Scale Product Prototyping

Lab extruders ua kom yooj yim los tsim cov khoom me me ntawm cov khoom tshiab. Cov pab pawg tuaj yeem tswj qhov kub, siab, thiab ntsia hlau ceev kom tau txais txiaj ntsig zoo. Txoj kev no txuag nyiaj thiab ua kom txoj kev loj hlob sai. Cov kws tshawb fawb tuaj yeem sim cov tswv yim tshiab sai sai thiab ua kom tiav cov kev vam meej. Compact extruders kuj tso cai rau kev hloov pauv ntawm cov khoom siv lossis tsim. Kev nce qib hauv automation thiab kev saib xyuas lub sijhawm tiag tiag ntxiv txhim kho cov txheej txheem tswj thiab txo cov khoom pov tseg.

- Precise tswj cov txheej txheem tsis

- Nqi-zoo thiab ceev prototyping

- Yooj yim yoog rau cov khoom sib txawv

- Txhim kho cov khoom zoo thiab uniformity

Cov lus qhia ua haujlwm thiab daws teeb meem rau ib leeg ntsia hlau Extruder

Teem lub Extruder

Kev teeb tsa kom raug ua kom ntseeg tau tias kev ua haujlwm ruaj khov thiab txuas ntxiv lub neej ntawm cov cuab yeej siv. Cov kws kho mob ua raws li cov nocov kauj ruam rau kev ua tau zoo:

- Nruab screwsnyob rau hauv lawv thawj txoj hauj lwm thiab sim tshiab screws ntawm tsawg ceev ua ntej ua hauj lwm tag nrho.

- Calibratetswj qhov kub thiab txiascov cuab yeej tsis tu ncua kom raug kho kom raug.

- Siv cov dej distilled hauv lub tank txias kom tsis txhob scaling thiab xyuas cov dej ntau zaus.

- Tshawb xyuas solenoid li qub thiab cov coils, hloov txhua qhov tsis raug.

- Kev ruaj ntseg txuas txuas txhua hnub thiab txheeb xyuas tias cov cua sov cheeb tsam relays thiab solenoid li qub ua haujlwm raug.

- Ntxuav lub tshuab nqus tsev twj tso kua mis thiab tso pa tawm; hloov cov hlua khi hlua khi raws li xav tau.

- Xyuas DC motor txhuam thiab tiv thaiv xeb.

- Preheat maj mam thaum pib thiab ua kom cov ntsia hlau nrawm nrawm.

- Lubricate txav qhov chaw thiab zawm cov fasteners tsis tu ncua.

- Rau kev khaws cia ntev, siv cov tshuaj tiv thaiv xeb thiab khaws cov ntsia hlau kom zoo.

Tswv yim: Ua raws li cov kauj ruam no pab tswj cov khoom zoo thiab cov cuab yeej siv tau ntev.

Tej teeb meem thiab kev daws teeb meem

Cov neeg ua haujlwm yuav ntsib ntau yam teeb meem thaum ua haujlwm. Cov lus hauv qab no qhia txog cov teeb meem thiab kev daws teeb meem:

| Qeb qhov teeb meem | Tej Teeb Meem | Ua rau | Cov tsos mob | Kev daws teeb meem |

|---|---|---|---|---|

| Mechanical Failure | Ntsia hlau daig | Material buildup, lub lubrication tsis zoo | Lub cev muaj zog overload, suab nrov | Ntxuav, lubricate, tshuaj xyuas |

| Hluav taws xob poob | Lub cev muaj zog tsis ua haujlwm | Overheating, luv luv Circuit Court | Tsis pib, overheating | Tshawb xyuas qhov system, tsis txhob overload |

| Txheej txheem tsis ua hauj lwm | Plasticization tsis zoo | Tsawg ceev, tsis ncaj ncees lawm temp | Rough nto, npuas | Kho ceev, temp, khoom |

| Kev Tiv Thaiv Kev Tiv Thaiv | Kev tu | Tsis muaj kev tu, tshuaj xyuas | N/A | Teem sijhawm tu, tshuaj xyuas |

Kev tshuaj xyuas thiab kev saib xyuas tsis tu ncua tiv thaiv cov teeb meem feem ntau. Cov neeg khiav dej num yuav tsum ua raws li phau ntawv qhia thaum kho cov extrusion tuag kom tsis txhob muaj qhov yuam kev.

Kev xav txog kev nyab xeeb

Laboratory extruder ua haujlwm muaj ntau yam kev phom sij. Kev ntsuas kev nyab xeeb suav nrog:

- Hnav cov khoom tiv thaiv tus kheej xws li khau kev nyab xeeb thiab tsom iav.

- Tsis txhob hnav khaub ncaws xoob ze ze ntawm qhov chaw txav.

- Grounding tag nrho cov khoom siv hluav taws xob los ntawm cov neeg ua haujlwm tsim nyog.

- Khaws cov plag tsev kom qhuav thiab siv cov platforms los yog cov dej ntws los tiv thaiv kev swb.

- Txhim kho cov neeg tiv thaiv ntawm qhov txav mus los tiv thaiv tes.

- Siv cov kab pib rau threading es tsis txhob siv tes pub.

Nco tseg: Kev qhuab qhia kev nyab xeeb nruj txo qhov kev pheej hmoo ntawm kev kub nyhiab, hluav taws xob poob siab, thiab kev raug mob txhua yam.

Laboratory extruders txhawb kev nyab xeeb, ua haujlwm zoo polymer los ntawmprecision tswj qhov kub, siab, thiab ntsia hlau ceev. Cov kws tshawb fawb tau txais txiaj ntsig los ntawm kev tsim khoom me me, txo cov khib nyiab, thiab kev tsim qauv sai. Modular designs pab kom ceev hloov pauv thiab kho kom haum. Kev coj ua zoo ib yam thiab ua tib zoo mloog kom nthuav dav pab ua tiav cov txiaj ntsig txhim khu kev qha thiab txhawb nqa kev tsim kho tshiab hauv kev tshawb fawb polymer.

FAQ

Dab tsi polymers tuaj yeem kuaj ib tus ntsia hlau extruder txheej txheem?

A Laboratory ib leeg ntsia hlau extrudertuaj yeem ua cov thermoplastics feem ntau, suav nrog polyethylene, polypropylene, polystyrene, thiab PVC. Cov kws tshawb fawb feem ntau xaiv cov ntaub ntawv raws li qhov xav tau ntawm qhov project.

Yuav ua li cas venting txhim kho polymer zoo?

Qhov cua tshem tawm cov dej noothiab gases los ntawm polymer yaj. Cov kauj ruam no tiv thaiv qhov tsis xws luag, xws li npuas lossis qhov chaw tsis muaj zog, thiab txhim kho cov khoom kawg ntawm cov khoom siv kho tshuab.

Cov neeg ua haujlwm tswj qhov kub ntawm extrusion li cas?

Cov neeg khiav dej num tau teeb tsa thiab saib xyuas lub thoob qhov kub thiab txias siv qhov system tswj. Sensors muab cov lus teb rau lub sijhawm tiag tiag, tso cai rau kev hloov kho kom haum rau cov polymer melting thiab shaping.

Lub sij hawm xa tuaj: Plaub Hlis-01-2025