Yas txhaj tshuaj molding ntsia hlau chim plays lub luag hauj lwm loj nyob rau hauv shaping yaj zoo thiab ntau lawm ceev. Engineers tsom rau ntawmTxhaj Molding chimtsim los txhawb kev ua haujlwm. Lawv siv cov khoom sib txawv rauTib Ntsia Hlau Yas Extruder TshuabthiabTib Ntsia Hlau Extrusion Tshuab. Txhua qhov kev xaiv pab cov tshuab ua cov yas zoo dua.

Yas Txhaj Molding Screw Barrel Structure thiab Performance

Hom chim: Bimetallic vs. Integral

Xaiv lub thoob hom yuav ua rau muaj qhov sib txawv loj npaum li cas aYas Txhaj molding ntsia hlau chimua. Bimetallic chim siv lub hauv paus muaj zog steel nrog cov tawv alloy hauv ob sab hauv. Qhov kev tsim no txuag cov ntaub ntawv tseem ceeb thiab cia cov neeg tsim khoom hloov tsuas yog cov ntaub qhwv, uas ua rau kev saib xyuas yooj yim dua thiab siv nyiaj ntau dua. Qhov haum ntawm lub hauv ob sab phlu thiab lub thoob yuav tsum yog qhov tseeb kom cov cua sov ntws zoo thiab tiv thaiv kev txav mus los. Bimetallic tej kas tham ua haujlwm zoo rau kev ua cov khoom abrasive lossis cov khoom siv ntxiv dag zog vim tias lawv tiv taus hnav thiab kav ntev dua.

Integral chim yog ua los ntawm ib qho. Qhov no ua rau lawv siab precision thiab txawm tias cua sov faib raws lub thoob. Lawv ua kom yooj yim rau nruab thiab tswj cov cua sov thiab cua txias. Txawm li cas los xij, lawv xav tau kev tswj xyuas nruj kom ua tau zoo. Thaum muab piv rau ob, ib lub thoob muaj kev saib xyuas yooj yim thiab cov cua sov sib xws, thaum cov khoom siv bimetallic muab kev hnav zoo dua thiab kev hloov pauv yooj yim dua.

| Performance Aspect | Integral chim | Bimetallic chim |

|---|---|---|

| Kev tsim kho | Ib-thooj, siab raug precision | Base chim nrog hloov tau alloy steel bushing |

| Thaum tshav kub kub Distribution | Uniform tshav kub faib raws lub thoob axis | Thaum tshav kub kub conduction tswj yog hais tias bushing haum yog meej |

| Hnav Resistance | Txheem hnav tsis kam | Enhanced hnav tsis kam vim alloy steel hauv ob sab phlu |

| Kev tu | Yooj yim installation thiab txij nkawm ntawm cua sov / cua txias tshuab | Replaceable bushing tso cai rau hloov qhov yooj yim dua |

| Khoom siv | Xav tau ntau dua precision thiab cov khoom zoo | Txuag cov ntaub ntawv tseem ceeb los ntawm kev siv cov hlau alloy tsuas yog hauv ob sab phlu |

Bimetallic barrels feem ntau siv sijhawm ntev dua li cov thawv ntim khoom, tshwj xeeb tshaj yog thaum ua cov ntaub ntawv tawv. Lawv cov qauv tsim txo qis qis thiab hloov cov nqi, uas pab ua kom cov khoom lag luam zoo.

Ntsia Hlau Geometry: L / D Ratio, Compression Ratio, thiab Dav Hlau Tsim

Lub geometry ntawm lubntsia hlau nyob rau hauv ib tug Yas Txhaj molding ntsia hlau chimpuab li cas plastics yaj thiab sib tov. Qhov sib piv L / D, uas sib piv cov ntsia hlau ntev rau nws txoj kab uas hla, cuam tshuam rau yaj uniformity thiab sib tov. Lub ntsia hlau ntev (siab dua L / D piv) muab cov yas ntau lub sij hawm rau yaj thiab sib tov, uas txhim kho cov khoom zoo. Txawm li cas los xij, yog tias cov ntsia hlau ntev dhau lawm, nws tuaj yeem ua rau thermal degradation, tshwj xeeb tshaj yog nrog cov yas uas muaj cua sov. Cov ntaub ntawv zoo li PVC thiab POM xav tau cov ntsia hlau luv luv kom tsis txhob muaj kev puas tsuaj, thaum cov iav ntim los yog cov yas muaj viscosity tau txais txiaj ntsig los ntawm cov ntsia hlau ntev dua thiab cov chaw sib xyaw ua ke.

- Cov ntaub ntawv zoo thermal stability siv cov ntsia hlau ntev dua rau kev sib xyaw zoo dua.

- Thaum tshav kub kub-rhiab plastics yuav tsum tau luv luv screws los yog tshwj xeeb xov designs.

- Cov hom phiaj dav dav (L / D ~ 20: 1) haum rau cov khoom siv sib xws tab sis tuaj yeem pom cov xim txawv.

- Barrier screws (L / D ~ 24: 1) txhim kho kev sib xyaw rau cov khoom siv ntxiv.

- Cov ntsia hlau sib cais (L / D ~ 18: 1) pab cov khoom siv cua sov kom tsis txhob degradation.

- Kev sib xyaw cov ntsia hlau (L / D ~ 22: 1) muab cov txheej txheem yaj rau cov yas tshwj xeeb.

Qhov sib piv compression ntsuas ntau npaum li cas cov ntsia hlau compresses cov yas. High-viscosity plastics xav tau qhov sib piv siab dua kom yaj thiab sib tov zoo. Kho qhov sib piv compression pab sib npaug ntawm cov khoom thiab cov khoom zoo. Cov neeg tsim khoom feem ntau saib xyuas thiab txhim kho cov ntsia hlau tsim kom haum rau cov khoom xav tau.

Screw davhlau tsim kuj tseem ceeb. Rheologically optimized screws txhim kho yaj zoo los ntawm kev sib piv tus cwj pwm ntws ntawm cov polymer. Tswj Melt Delivery systems pab tswj cov kub thiab viscosity, txo qhov kev pheej hmoo ntawm degradation. Kev sib xyaw cov ntsia hlau thiab cov ntsia hlau dynamic barrier screws muab cov txheej txheem yaj thiab tiv thaiv qhov chaw tuag, uas ua rau cov yas tsis muaj cua sov los yog tsis muaj xim.

Cov khoom sib xyaw thiab kev kho deg

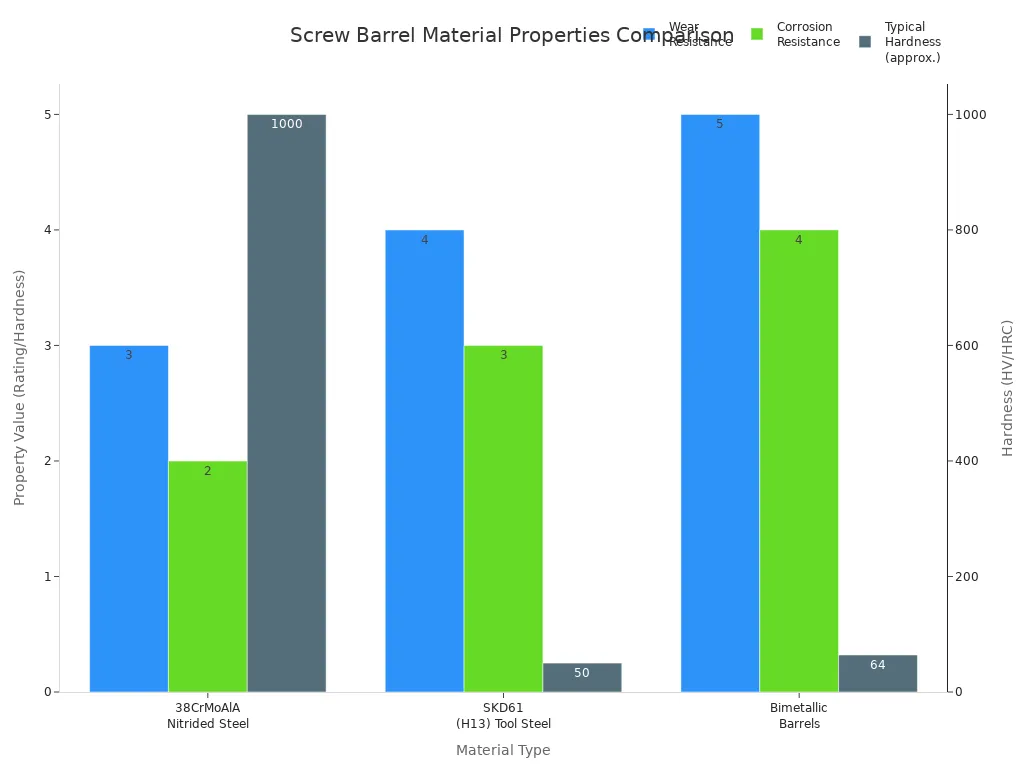

Cov ntaub ntawv siv los ua Plastic Txhaj Molding Ntsia Hlau chim cuam tshuam rau nws cov kav ntev thiab kev ua haujlwm. Nitrided steel muaj zoo hardness thiab hnav tsis kam rau cov qauv yas. Bimetallic barrels ua ke ib lub hauv paus hlau nrog ib lub alloy liner, muab zoo heev hnav thiab corrosion kuj rau tawv los yog ntim cov yas. Cov cuab yeej steel muab lub zog siab thiab hnav tsis kam rau qhov chaw huab cua.

| Hom khoom | Key Properties & Pros | Cons & txwv | Cov ntawv thov zoo tshaj plaws |

|---|---|---|---|

| Nitrided Hlau | High deg hardness; zoo hnav tsis kam rau unfilled resins; pheej yig | Tsis zoo corrosion kuj; tsis haum rau abrasive / tshuaj resins | Cov khoom lag luam zoo li polyethylene, polypropylene |

| Bimetallic Barrels | Hlau thaub qab nrog alloy liner; zoo heev hnav thiab corrosion kuj; lub neej ntev dua | kim dua; tej zaum yuav overkill rau kev siv | Cov iav-filled nylons, nplaim-retardant ABS, PVC, txhoj puab heev polymers |

| Nickel-raws li Alloys | Exceptional corrosion kuj; zoo rau nplaim-retardant thiab halogenated resins | Tsawg zog dua li hlau-raws li alloys; qis hnav tsis kam | Chemically txhoj puab heev polymers |

| Hlau-Based Alloys | Superior hardness thiab hnav tsis kam | Tsawg corrosion kuj dua li cov nickel-based alloys | Abrasive, siab puv resins |

| Cov cuab yeej hlau | Exceptional hardness thiab lub zog; siab hnav tsis kam | Tus nqi siab; susceptible corrosion tsis coatings | Kev hnav khaub ncaws hnyav heev, kev siv cov khoom siv siab |

| Tshwj xeeb Coated Barrels | Txheej zoo li tungsten carbide lossis chrome plating txhim kho hnav thiab tiv thaiv corrosion | Ntxiv cov nqi thiab complexity; txheej adhesion sib txawv | Kev cai los yog txhoj puab heev daim ntawv thov |

Cov kev kho deg zoo li nitriding thiab chrome plating txhawb nqa kev tiv thaiv thiab lifespan. Nitriding tuaj yeem ua ob lossis peb npaug ntawm kev pabcuam lub neej ntawm cov ntsia hlau thiab cov thoob. Chrome plating nce hardness thiab corrosion kuj, tab sis nitriding feem ntau ua tau zoo dua nyob rau hauv abrasive tej yam kev mob. Molybdenum txau nrog nitriding muab kev tiv thaiv ntau dua. Kev ua haujlwm kom raug thiab kev saib xyuas zoo pab txhawb cov txiaj ntsig zoo tshaj plaws.

Pub Chaw nres nkoj thiab Venting Design

Qhov chaw nres nkoj pub zaub mov tswj xyuas seb cov yas nkag mus rau hauv lub thoob li cas. Kev tswj qhov kub thiab txias ntawm qhov chaw noj mov kom cov khoom muaj viscosity nyob ruaj khov, uas pab tswj kom muaj kev sib haum xeeb thiab kev pub mis. Lub tshuab nqus tsev loaders thiab hopper receivers ua kom cov khoom txav tau yooj yim rau hauv lub tshuab, txo kev sib kis thiab nchuav. Qhov kev teeb tsa no ua kom cov khoom ua tau zoo siab thiab pub mis zoo ib yam.

- Lub tshuab nqus tsev loaders mount ncaj qha rau ntawm lub tshuab caj pas, txo kev sib kis.

- Hopper receivers siv lub ntiajteb txawj nqus los pub cov khoom, ua kom cov txheej txheem yooj yim.

Venting tsim kuj plays lub luag haujlwm tseem ceeb. Vent screws muaj thaj chaw tshwj xeeb uas tshem tawm cov dej noo thiab cov volatiles thaum ua. Qhov no yog qhov tseem ceeb rau cov ntaub ntawv hygroscopic thiab cov khoom siv rov ua dua tshiab. Venting ports cia gases thiab ya raws dim, tiv thaiv tsis xws luag thiab ua kom zoo extrusion siab.

Tswv yim: Qhov chaw pub noj kom zoo thiab lub qhov cua tsim pab tswj kev tsim khoom ruaj khov thiab txhim kho cov khoom zoo, tshwj xeeb tshaj yog thaum ua haujlwm nrog cov khoom siv rov ua dua lossis cov khoom siv rhiab.

Kev ua tau zoo ntawm Kev Txhaj Tshuaj Molding Ntsia Hlau Barrel Tsim

Melt Quality thiab Homogeneity

Ib tug zoo-tsim Yas Txhaj molding ntsia hlau chim pab tsim ib tug du thiab txawm yaj. Cov ntsia hlau geometry, nrog rau nwscompression pivthiab cov duab ntawm nws cov cheeb tsam, tswj yuav ua li cas yas pellets yaj thiab sib tov. Thaum cov compression piv piv nrog cov khoom, cov yaj ntws sib npaug. Qhov no txo cov teeb meem xws li splay marks lossis tsis tiav melting. Covnoj zonetxav thiab ua kom sov cov pellets, thaj tsam compression melts thiab nias cov khoom, thiab metering tsam ua kom cov yaj yog txawm. Nta xws li channel qhov tob thiab qhov sib xyaw ua ke pab cov ntsia hlau cua sov thiab muab cov yas sib xyaw. Barrier screws tuaj yeem cais cov khoom thiab cov yas yaj, ua kom yaj tau zoo dua thiab txuag lub zog.

Thaum cov yaj yog sib xws, cov khoom kawg zoo li zoo dua thiab ua haujlwm zoo dua. Kev sib xyaw tsis zoo tuaj yeem ua rau xim streaks, tsis muaj zog me ntsis, lossis hloov pauv ntawm qhov loj me. Zoo yaj homogeneity txhais tau hais tias tsawg dua thiab txhim khu kev qha qhov chaw. Cov neeg ua haujlwm tseem tuaj yeem siv cov sensors los saib cov yaj zoo thiab kho qhov chaw kom tau txais txiaj ntsig zoo dua.

- Kev sib tov tsis zoo ua rau cov xim streaks thiab tsis muaj zog.

- Zoo yaj zoo ua rau qhov zoo ib yam ntawm qhov loj thiab lub zog.

- Melt quality nyob ntawm qhov kub thiab txias, ntsia hlau ceev, thiab backpressure.

Lus Cim: Khaws qhov kub thiab txias kom ruaj khov thiab sib txuam ntsia hlau tsim rau hom yas pab kom tsis txhob muaj qhov tsis xws luag thiab ua kom cov khoom zoo siab.

Mixing Efficiency thiab Cycle Time

Kev sib xyaw ua haujlwm nyob ntawm tus ntsia hlau cov duab thiab cov yam ntxwv tshwj xeeb. Raws li cov ntsia hlau tig, nws thawb thiab folds cov yas, tsim kom muaj zogzog shear. Kev sib xyaw cov seem nyob ze ntawm lub taub, zoo li cov pins lossis cov davhlau ya nyob twg, pab muab cov yaj. Qhov kev txiav txim no nthuav tawm cov xim thiab cov khoom ntxiv sib npaug, yog li qhov kawg zoo nkaus li du thiab zoo ib yam. Barrier screws siv lub davhlau thib ob los cais cov yas yaj los ntawm cov khoom siv, ua kom nrawm nrawm thiab tiv thaiv cov chunks unmelted.

- Screw geometry tswj cov pellets txav li cas, yaj, thiab sib tov.

- Kev sib xyaw ua ke tsim ib lub voj voog ncig,sib tov ntau dua 95%ntawm cov khoom sai sai.

- Barrier screws thiab cov qauv tsim tshwj xeeb pab cais cov xim thiab cov khoom ntxiv.

Kev sib xyaw ua haujlwm tseem cuam tshuam rau lub sijhawm voj voog. Faster thiab ntau dua melting txhais tau tias lub tshuab tuaj yeem khiav ntau lub voj voog hauv lub sijhawm tsawg. Siv cov ntsia hlau barrier, txoj kab uas hla loj dua, los yog cov grooves sib sib zog nqus ua rau cov yas ua kom nrawm dua. Kev tsa cov ntsia hlau nrawm (thaum muaj kev nyab xeeb rau cov khoom siv) thiab txo qis rov qab tuaj yeem ua rau lub sijhawm luv luv. Cov cua kub siab tshaj plaws thiab cov cua txias ua kom lub thoob ntawm qhov kub thiab txias, pab qhov chaw txias dua thiab ua kom cov khoom txav mus.

- Optimized ntsia hlau chim tsim tiv thaiv clogs thiab qeeb.

- Lub tshuab cua sov thiab cua txias ua kom cov khoom ua kom khov sai.

- Cov khoom siv ruaj khov thiab cov coatings txo qis qis rau kev kho.

Hnav Resistance thiab Kho

Hnav yog ib qho kev txhawj xeeb loj rau txhua qhov Yas Txhaj Molding Ntsia Hlau chim. Abrasive fillers, corrosive plastics, thiab kev ua haujlwm ntev ntev tuaj yeem hnav cov ntsia hlau thiab lub thoob. Hom kev hnav zoo xws li hnav cov nplaum, hnav abrasive, thiab corrosion. Piv txwv li, abrasive hnav tshwm sim thaum cov khoom siv tawv tawv zoo li iav fiber ntau rub tawm ntawm cov hlau. Corrosive hnav yog los ntawm cov tshuaj hauv cov yas xws li PVC.

| Hnav Mechanism | Kev piav qhia | Tsim cov tswv yim txo qis |

|---|---|---|

| Adhesive Hnav | Hlau nto tiv tauj thiab hloov khoom siv. | Siv hardfacing alloys, tshawb xyuas cov qhab nia, xyuas kom cov khoom sib xws. |

| Abrasive Hnav | Shearing txiav txim los ntawm pellets los yog fillers. | Siv cov khoom siv tawv tawv, tsis txhob txhuam cov khoom siv, khaws cov khoom noj kom huv. |

| Corrosive Hnav | Tshuaj tua kab mob los ntawm tej yam yas. | Siv cov khoom siv corrosion-resistant, zam cov tshuaj hnyav. |

| Teeb meem kev sib tw | Misalignment ua rau rub thiab hnav tsis sib xws. | Xyuas kom muaj kev ncaj ncees thiab kev sib raug zoo. |

Kev xaiv cov khoom siv thiab kev kho saum npoo ua rau muaj qhov sib txawv loj. Cov kua nitriding ua rau lub ntsej muag hardness thiab hnav tsis kam. Bimetallic barrels nrog tshwj xeeb liners kav ntev, tshwj xeeb tshaj yog nrog cov yas tawv. Kev tshuaj xyuas tsis tu ncua thiab kev tiv thaiv kev saib xyuas, xws li ntxuav thiab tshuaj xyuas kev sib raug zoo, pab ntes teeb meem thaum ntxov. Advanced coatings thiab cov ntaub ntawv tshiab tuaj yeem txuas lub neej ntev txog li 40%, txo tus nqi kho thiab txo qis sijhawm.

- Kev tu ntau zaus nyob ntawm cov khoom siv thoob thiab cov txheej txheem.

- Kev tiv thaiv kev saib xyuas thiab kev tshuaj xyuas tsis tu ncua ua rau lub neej ntev ntev.

- Kev kho deg siab heev txo kev kho thiab hloov.

Adaptability rau cov khoom sib txawv thiab kev siv

Ib qho yooj yim ntsia hlau chim tsim cia manufacturers ua ntau hom yas. Screw geometry, xws li ntev, suab, thiab channel qhov tob, tuaj yeem hloov pauv kom haum rau cov khoom sib txawv. Lub hom phiaj dav dav, thaiv, thiab sib xyaw cov ntsia hlau ua haujlwm zoo tshaj plaws nrog qee yam yas. Cov tshuab cua txias, zoo li cov kav dej, khaws lub thoob ntawm qhov kub thiab txias rau txhua yam khoom.

- Ntsia hlau tsim thiab geometryphim cov yas sib txawv.

- Cov tshuab cua txias tiv thaiv overheating.

- High-strength alloys thiab coatings tuav cov mob hnyav.

Adaptable designs kuj ua rau nws yooj yim rau hloov ntawm txoj hauj lwm. Nta xws li ceev-disconnect adapters thiab ntsia hlau pushers pab tswv hloov screws ceev. Adaptive txheej txheem tswj siv sensors thiab tshuab kawm los kho tej chaw nyob rau lub sij hawm. Qhov no txo cov kev hloov pauv ntawm phau ntawv thiab ua kom muaj kev hloov pauv sai, yog li kev tsim khoom tuaj yeem hloov los ntawm ib qho khoom lossis cov khoom lag luam mus rau lwm qhov nrog tsawg downtime.

Tswv yim: Adaptable ntsia hlau chim tsim pab factories tuav ntau hom yas thiab hloov txoj hauj lwm sai, ua kom ntau lawm saj zawg zog thiab npaum.

Troubleshooting Common Performance Issues

Txawm tias muaj kev tsim zoo tshaj plaws, teeb meem tuaj yeem tshwm sim. Cov teeb meem muaj xws lihnav ntau dhau, teeb meem kub, txhaws, suab nrov, thiab xim sib xyaw ua yuam kev. Txhua qhov teeb meem muaj nws tus kheej ua thiab daws.

| Teeb meem kev ua haujlwm | Nqe lus piav qhia thiab cov tsos mob | Ua rau thiab kev daws teeb meem |

|---|---|---|

| Hnav hnyav heev | Cov khoom xau, tsis zoo, kub kub, suab nrov | Siv bimetallic chim, hardfacing alloys, tu tsis tu ncua, kev sib raug zoo |

| Kev tswj qhov kub thiab txias | Discoloration, charring, npuas, warping | Faib cov thoob rau hauv ib cheeb tsam, siv cov sensors, maj mam preheating, rwb thaiv tsev tsho |

| Thaiv thiab tsim-Up | Kev kub siab, dej tsis zoo, dub specks | Ntxuav nrog purging compounds, kom ceev ceev ceev, foob chim thaum lub sij hawm downtime |

| Suab nrov lossis kev vibration | Suab nrov, kev vibration, kev sib txhuam | Tshawb xyuas kev sib raug zoo, bearings, siv kev vibration damping, cais cov khoom |

| Xim Mixing/Contamination | Xim streaks, ntxoov tsis sib xws, kev sib kis | Siv purging tebchaw, tu tsis tu ncua, optimize ntsia hlau tsim, foob tshuab thaum kaw |

Cov neeg ua haujlwm tuaj yeem daws tau ntau yam teeb meem los ntawm kev ua raws li ob peb kauj ruam tseem ceeb:

- Optimize ntsia hlau configuration thiab chim kub aav.

- Saib xyuas thiab kho qhov kub thiab txias ceev.

- Calibrate feeders thiab tiv thaiv cov khoom bridging.

- Tshawb xyuas cov ntsia hlau thiab cov thoob rau hnav, tshwj xeeb tshaj yog nyob rau hauv qhov chaw muaj kev ntxhov siab.

- Siv kev saib xyuas kev kwv yees los npaj kho thiab txo qis sijhawm.

- Khaws ib lub ntsia hlau seemthiab rov kho dua ob peb zaug xwb.

- Tsheb ciav hlau cov neeg khiav dej num kom pom cov cim ceeb toom ntxov.

Nco tseg:Kev tu tsis tu ncua, lubrication kom raug, thiab ua tib zoo saib xyuaspab kom cov yas txhaj tshuaj molding ntsia hlau chim khiav zoo thiab ua kom nws lub neej ntev.

Optimizing tus qauv ntawm Yas Txhaj Molding Ntsia Hlau chim boosts yaj zoo thiab khoom lub neej. Thaum manufacturers xaiv lubtxoj cai chim hom, ntsia hlau geometry, thiab cov ntaub ntawv, lawv pom smoother ntws, zoo sib tov, thiab tsawg dua. Kev saib xyuas tsis tu ncua, suav nrog kev ntxuav thiab tshuaj xyuas, ua kom cov tshuab ua haujlwm zoo thiab txo tus nqi.

FAQ

Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm bimetallic ntsia hlau chim?

Bimetallic barrels tiv taus hnav los ntawm cov yas tawv. Lawv kav ntev dua thiab txo downtime rau kev kho.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum tshuaj xyuas lub hau ntsia hlau?

Cov neeg ua haujlwm yuav tsum kuaj xyuas lub taub hau ntsia hlau txhua lub hli. Kev tshuaj xyuas tsis tu ncua pab ntes hnav thaum ntxov thiab ua kom cov tshuab ua haujlwm zoo.

Ib lub taub hau taub hau tuaj yeem ua haujlwm nrog ntau hom yas?

| Barrel Hom | Adaptability |

|---|---|

| Lub Hom Phiaj | Zoo |

| Barrier | Zoo heev |

| Sib tov | Zoo heev |

Ib lub thoob tsim tau zoo tuaj yeem ua tau ntau yam yas, tab sis qee cov khoom xav tau tshwj xeeb.

Post lub sij hawm: Aug-25-2025