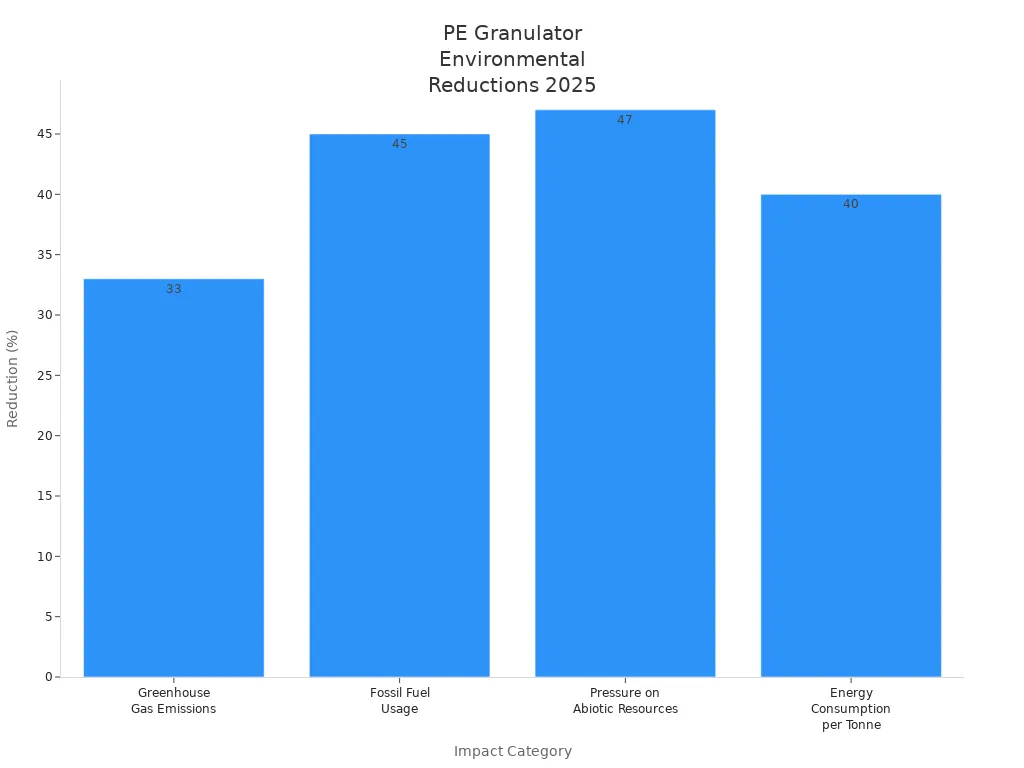

PE me me ib puag ncig granulators hauv 2025 siv lub tshuab ua haujlwm siab, kev ua kom zoo dua qub, thiab kev siv lub sijhawm tiag tiag los txiav kev siv hluav taws xob. Cov neeg ua haujlwm pom cov txiaj ntsig tam sim ntawd, xws li a40% poob rau hauv kev siv hluav taws xob ib tonnepiv rau tsoosib leeg ntsia hlau tshuab or vented ib leeg ntsia hlau extrudertshuab. Cov khib nyiab rov qab los kuj txhawb nqawaterless granulator tshuabkev ua haujlwm.

| Metric | Kev txo qis tau ua tiav hauv 2025 piv rau xyoo dhau los |

|---|---|

| Greenhouse Gas emissions txo | 33% txo |

| Fossil Roj Siv txo | 45% txo |

| Siab rau Abiotic Resources | 47% txo |

| Kev siv hluav taws xob ib Tonne | Tsawg li 10 kW-h / tonne, 40% tsawg dua li cov khoom siv niaj hnub |

PE Small Environmentally Granulators: Energy-Saving Technologies

High-Efficiency Motors thiab Transmission Devices

PE me me ib puag ncig granulators hauv 2025 cia siab rauhigh-efficiency motors thiab advanced kis khoom sivkom ua tiav kev txuag hluav taws xob tseem ceeb. Cov motors no hloov hluav taws xob hluav taws xob mus rau hauv lub tshuab hluav taws xob nrog tsawg tsawg, kom ntseeg tau tias feem ntau ntawm cov khoom siv hluav taws xob tau tsav cov txheej txheem granulation. Advanced kis tau tus mob ntxiv txhim khu kev qha no los ntawm optimizing yuav ua li cas lub zog txav ntawm lub cev muaj zog mus rau lub txiav thiab extrusion Cheebtsam. Thaum ua ke, cov thev naus laus zis no txo qis kev siv hluav taws xob tag nrho thaum lub sijhawm ua haujlwm. Qhov kev sib koom ua ke no tsim ib lub tswv yim zoo txuag hluav taws xob uas txhawb nqa kev siv hluav taws xob tsawg thiab kev ua haujlwm siab. Cov neeg tsim khoom tau txais txiaj ntsig los ntawm cov nqi hluav taws xob qis dua thiab txhim kho cov khoom siv. Kev siv lub tshuab ua haujlwm siab thiab cov khoom siv sib kis kuj tseem txuas ntxiv lub neej ntawm granulator, txo cov kev xav tau kev saib xyuas thiab kev poob qis.

Tswv yim:Kev hloov kho rau cov tshuab ua haujlwm siab thiab cov tshuab xa hluav taws xob tuaj yeem txiav lub zog siv txog li 30% piv rau cov qauv qub.

Intelligent Automation thiab txheej txheem optimization

Kev txawj ntse automation sawv ntawm lub hauv paus ntawm niaj hnub PE me me ib puag ncig granulators. Cov tshuab no siv cov kev tswj ntse los saib xyuas thiab kho cov ntsuas kev ua haujlwm tseem ceeb xws li kub, lub cev muaj zog, thiab kev co. Cov neeg ua haujlwm tuaj yeem tso siab rau cov yam ntxwv zoo li PLC kov cov ntxaij vab tshaus, uas tso cai rau kev hloov pauv hloov mus rau qhov kub thiab txias pellet loj. Sensors ntes cov teeb meem xws li tuag clogging los yog lub cev muaj zog overload, txo qhov kev pheej hmoo ntawm kev npaj txhij txog downtime.

- Ntse granulator tswj taug qab cov ntsuas kev ua tau zoo rau kev kwv yees txij nkawm.

- AI-raws li cov txheej txheem qhia txog kev npaj kho, xws li thaum hloov riam lossis roj bearings.

- Cloud-based platforms pab saib xyuas tej thaj chaw deb thiab xa cov lus ceeb toom saib xyuas.

- Lub hwj chim txee thaiv kev txhawb nqa yooj yim kev koom ua ke nrog lwm yam khoom siv.

- Automation txo cov kev cuam tshuam ntawm phau ntawv, txhim kho kev nyab xeeb thiab kev ntseeg tau.

- Txheej txheem optimization fine-tunes kev khiav hauj lwm tsis, streamlining granulation thiab txo lub zog pov tseg.

- Modular tsim tso cai rau kev hloov kho rau cov khoom sib txawv thiab cov kev xav tau ntau lawm.

Txheej txheem optimization cov txheej txheem ntxiv boost zog efficiency. Kev sib xyaw tshuab tsim ua ke ua ke shredding, txiav, extrusion, thiab pelletizing rau hauv ib qho kev lag luam tas mus li. Txoj hauv kev no txo qis kev ua haujlwm, sijhawm, thiab siv zog. Kev noj zaub mov zoo ib yam mechanisms ruaj khov cov khoom ntws, tiv thaiv kev poob qis thiab txhim kho cov khoom tsim tawm. Automation nta xws li nws pib pub noj tswj, dual channel lim, thiab nws pib-kho ntawm riam ceev kom du thiab npaum ntau lawm. Lub cev muaj zog-tsim lub cev muaj zog, kev hloov pauv ceev, thiab cov tshuab ua kom txias siab kuj tseem ua rau txo qis zog.

Pov tseg Thaum tshav kub kub rov qab thiab siv

Cov khib nyiab thaum tshav kub kub rov qab yog ib qho kev nce qib loj hauv PE me me ib puag ncig granulators. Thaum lub sij hawm granulation txheej txheem, cov cav tov ua kom sov ua ib tug byproduct. Tsis txhob cia cov cua sov no khiav tawm, cov tshuab niaj hnub no ntes thiab rov siv nws dua. Cov thev naus laus zis xws li cov twj siv hluav taws xob kub kub thiab cov khoom siv hluav taws xob latent siv cov ntaub ntawv hloov pauv theem (PCMs) rov qab cov cua kub uas tsis tshua muaj hluav taws xob thiab hloov kho nws rau kev siv hauv cov txheej txheem chav tsim lossis qhov chaw cua sov. Hauv kev ua qauv qhia, cov tshuab hluav taws xob hybrid tau zoo dua 80% ntawm cov cua sov pov tseg, txo kev cia siab ntawm hluav taws xob cua sov kom tsawg dua 20%. Qhov no tsis yog tsuas yog txhim kho kev siv hluav taws xob tag nrho tab sis kuj tseem muab kev lag luam zoo rov qab, feem ntau them rau nws tus kheej hauv qis dua peb xyoos. Kev sib xyaw ua ke ntawm cov khoom siv hluav taws xob thiab cov twj tso cua sov ua kom muaj kev ua haujlwm tas mus li thiab kev hloov pauv, ntxiv txiav cov nqi hluav taws xob thiab txo qis CO2 emissions.

| Technology | Muaj nuj nqi | Kev cuam tshuam rau kev siv zog |

|---|---|---|

| High Temperature Heat Pump | Upgrades pov tseg cua sov rau txheej txheem chav | Txo hluav taws xob cua sov |

| Latent Thaum tshav kub kub Storage (PCM) | Khaws thiab tso cua sov raws li xav tau | Enables load hloov |

| Hybrid System | Ua ke ob qho tib si rau kev ua haujlwm siab tshaj plaws | Rov qab 81.1% ntawm cov cua sov pov tseg |

PE me me ib puag ncig granulators teeb tsa tus qauv tshiab rau kev siv hluav taws xob hauv kev rov ua dua tshiab. Lawv cov thev naus laus zis txuag hluav taws xob zoo pab cov tuam txhab tsim khoom qis dua, txhim kho cov khoom tsim tau, thiab txhawb cov hom phiaj ib puag ncig.

Cov txiaj ntsig ntawm PE Me Ib puag ncig Granulators hauv 2025

Txo cov nqi khiav lag luam thiab kev siv zog

Cov neeg tsim khoom pom tseeb kev txuag nyiaj thaum lawv siv PE me me ib puag ncig granulators. Cov qauv cua txias tshem tawm qhov xav tau ntawm cov dej, uas txuag nyiaj rau kev kho dej thiab cov khoom siv tu. Cov granulators siv lub zog tsawg dua li dej-txias tshuab vim lawv cov qauv yooj yim thiab txhim kho kev ua haujlwm. Kev tu yuav yooj yim dua, thiab kev pheej hmoo ntawm kev tawg los ntawm cov teeb meem hauv cov dej poob. Cov neeg ua haujlwm tuaj yeem khiav cov tshuab no nyob rau hauv qhov chaw uas muaj dej me me lossis tsis muaj cua tsis zoo, ua kom cov khoom lag luam ruaj khov. Kev ua kom txias txias kuj tseem txhim kho cov khoom zoo thiab txo cov khoom pov tseg.

- Kev ua haujlwm cua txias tshem tawm cov nqi dej thiab kev saib xyuas ntsig txog.

- Kev siv hluav taws xob qis txhais tau hais tias cov nqi hluav taws xob tsawg dua.

- Cov qauv yooj yim txo cov kev xav tau kho thiab kev poob qis.

- Kev ua haujlwm ruaj khov nyob rau hauv ib puag ncig nyuaj kom ntseeg tau tias cov khoom tsim tawm.

- Cov khoom lag luam zoo dua ua rau cov khoom pov tseg tsawg dua thiab ua haujlwm zoo dua.

Environmental Impact thiab Carbon Footprint Reduction

PE me me ib puag ncig granulators pab cov tuam txhab txo lawv cov kev cuam tshuam ib puag ncig. Lawv txiav carbon emissions thiabkev siv zog, ua cov yas ua kom ntsuab.

| Environmental Benefit | Paub meej |

|---|---|

| CO2 Emission txo | 1.5 tonnes CO2 txo ib tonne ntawm regenerated pellets |

| Kev siv hluav taws xob txo qis | 30% tsawg zog siv los ntawm cov tshiab low-speed granulators |

| Txo suab nrov | 20dB qis suab nrov |

| Recycling Rate Txhim Kho | Kaw-loop recycling txo cov khoom siv raw |

| Case Piv txwv – Automotive | 300 tonnes ntawm cov yas tshiab tau txais kev cawmdim txhua xyoo los ntawm kev rov ua dua cov khoom pov tseg |

| Case Piv txwv – Agricultural | 85% hloov pauv tus nqi ua tiav los ntawm Indian cov neeg ua liaj ua teb siv cov pelletisers me me |

Cov tshuab no kuj txhawb kev lag luam ncig los ntawm kev hloov cov khib nyiab yas rau hauv cov granules rov siv tau. Cov txheej txheem no txo cov pov tseg pov tseg thiab txuag cov peev txheej ntuj.

Kev ua raws cai thiab kev hloov kho rau cov qauv kev lag luam

PE me me ib puag ncig granulators pab cov tuam txhab ua raws li cov cai nruj ib puag ncig hauv ntau thaj tsam. Cov tshuab txhawb nqa rov ua dua tshiab thiab txo cov kev siv pov tseg, uas ua raws li tsoomfwv cov kev pabcuam rau xoom pov tseg. Ntau tus qauv ua tau raws li cov qauv thoob ntiaj teb xws li ISCC PLUS, uas taug qab kev siv cov khoom noj kom ruaj khov thiab ua kom muaj kev ua raws li cov hom phiaj ntawm kev sib raug zoo thiab ib puag ncig. Lawv cov qauv siv tau yooj yim haum rau kev ua haujlwm loj thiab me me, pab cov lag luam hloov pauv cov kev cai hloov. Advanced automation thiabkev txuag hluav taws xobua kom yooj yim ua raws li cov cai tshiab ntawm emissions thiab suab nrov. Cov tuam txhab hauv North America thiab Europe siv cov granulators los txhawb cov hom phiaj kev lag luam thiab ua tau raws li cov qauv hauv zos thiab thoob ntiaj teb.

PE me me ib puag ncig granulators ua tiav lub zog siv hluav taws xob los ntawm kev siv cov qauv qis qis, cov yam ntxwv kho tau, thiab cov cuab yeej siv rov ua dua tshiab. Cov tshuab no pab kev lag luam txo nqi, txo cov khib nyiab, thiab txhawb kev lag luam ncig. Cov tuam txhab xaiv cov granulators no txhim kho kev ruaj khov, ua tau raws li cov cai, thiab tsim kom muaj lub neej tom ntej.

FAQ

Lub PE me me ib puag ncig granulator txuag hluav taws xob li cas?

Lub granulator siv high-efficiency motors thiab advanced automation. Cov yam ntxwv no txo qis kev siv hluav taws xob thiab txo cov khoom pov tseg thaum lub sij hawm tsim cov yas granule.

Tswv yim:Kev saib xyuas tsis tu ncua pab kom txuag hluav taws xob siab.

Lub granulator puas tuaj yeem siv ntau hom pov tseg yas?

Yog lawm. Lub tshuab txhawb ntau yam ntaub ntawv yas. Cov neeg ua haujlwm tuaj yeem kho qhov chaw rau txhua hom, ua kom cov granulation zoo ib yam thiab cov khoom tsim tawm.

Lub granulator xav tau dabtsi?

Cov neeg ua haujlwm yuav tsum kuaj xyuas lub cev muaj zog, ntxuav cov lim dej, thiab tshuaj xyuas cov hniav tsis tu ncua. Tej yam yooj yim tswj thiab modular qhov chaw ua rau niaj hnub tu ceev thiab yooj yim.

Post lub sij hawm: Lub Xya hli ntuj-17-2025