kuv pom li casIb Screw Barrelshloov cov yas rov ua dua tshiab. Thaum kuv siv ib lub taub hau ib lub taub hau rau cov khoom siv rov ua dua tshiab, kuv pom zoo dua yaj zoo, sib tov tsis tu ncua, thiab hnav tsawg dua. KuvYas Extruder Rau Yas Recyclingkhiav smoother. Nrog rau qhov kub thiab txias ceev, kuvExtruder Rau Yas Recyclingua tiav cov zis ntau dua thiab pellet zoo.

- Melting flux

- Ntsia hlau ceev

- Barrel kub

- Shear stress Management

Ntsiab Mechanisms Tsav Efficiency

Txhim kho Melt Homogenization

Thaum kuv ua haujlwm kuv cov khoom siv rov ua dua tshiab, kuv tsom mus rau kev ua tiav cov yaj zoo ib yam. Melt homogenization txhais tau tias sib tov cov yas kom huv si thaum nws yaj, yog li txhua tus pellet muaj qhov zoo tib yam. Kuv kawm tau li ntawdtswj melt kub thiab ntwsyog qhov tseem ceeb. Cov kev tshawb fawb ntawm cov yas zoo li nylon thiab polypropylene qhia tau hais tias thaum kuv khaws cov yaj zoo li qub, kuv tau txais cov khoom siv rov qab zoo dua. Yog tias cov yaj tsis zoo ib yam, cov yas rov ua dua tuaj yeem ua tsis muaj zog lossis nkig.

Kuv pom qhov txawv ntawm cov pellet zoo thaum kuv siv ib lub taub hau ntsia hlau tsim los rau kev sib xyaw zoo dua. Piv txwv li, kev tshawb fawb ntawm melt-state shear homogenization qhia tau hais tias high-shear mixing nyob rau hauv ib lub taub hau ntsia hlau txhim kho lub cev thiab thermal uniformity ntawm recycled plastics. Cov txheej txheem no txo cov kab mob thiab hloov cov qauv polymer hauv ib txoj hauv kev uas pab nrog cov kauj ruam rov ua dua ntxiv. Kuv pom tias kuv cov pellets siv dua tshiab muaj qhov tsis xws luag thiab kev ua haujlwm zoo dua thaum cov yaj yog homogeneous.

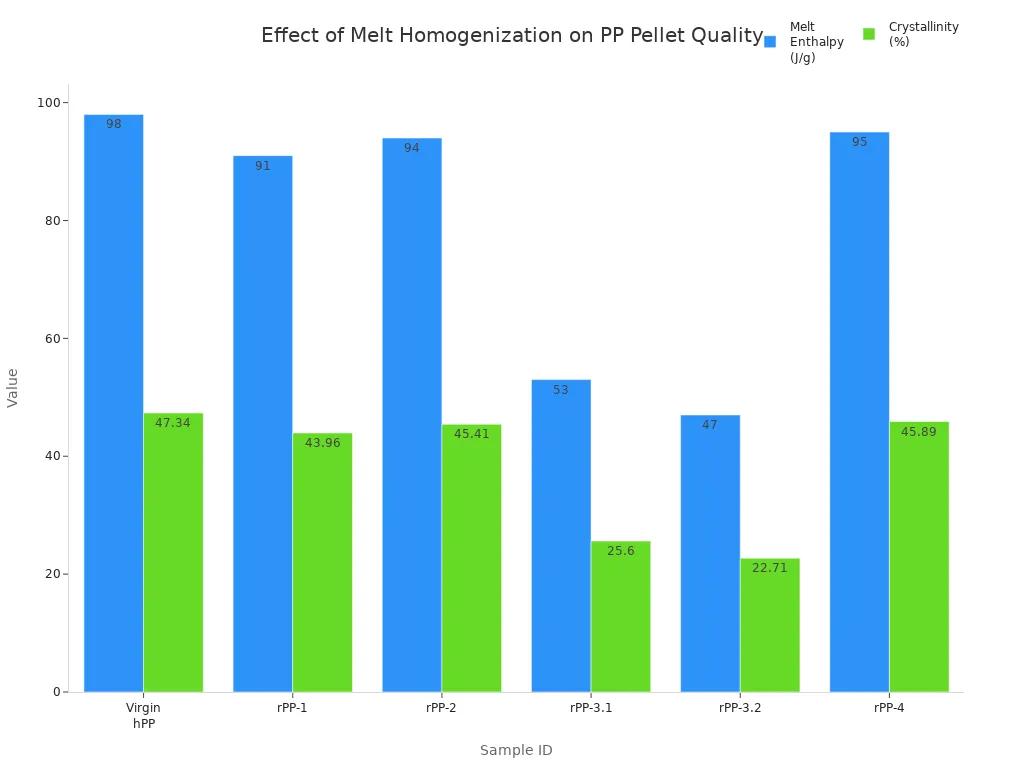

Cov lej rov qab li kuv pom hauv kuv lub khw. Thaum kuv piv cov qauv polypropylene siv dua, cov uas muaj crystallinity ntau dua thiab yaj enthalpy zoo li thiab ua tau zoo dua li cov yas yas. Ntawm no yog ib lub rooj uas qhia tau hais tias yuav ua li cas txawv cov txheej txheem ua rau pellet zoo:

| Qauv ID | Qhuav Enthalpy (J / g) | Crystallinity (%) |

|---|---|---|

| Virgin homopolymer PP (hPP) | 98 | 47.34 ib |

| Recycled PP-1 (rPP-1) | 91 | 43.96 ib |

| Recycled PP-2 (rPP-2) | 94 | 45.41 Nws |

| Rov ua dua PP-3.1 (rPP-3.1) | 53 | 25.60 Nws |

| Rov ua dua PP-3.2 (rPP-3.2) | 47 | 22.71 Nws |

| Recycled PP-4 (rPP-4) | 95 | 45.89 ib |

Kuv ib txwm tsom rau cov txiaj ntsig zoo li rPP-1, rPP-2, thiab rPP-4, uas nyob ze rau nkauj xwb PP. Cov nqi qis dua, zoo li rPP-3.1 thiab rPP-3.2, qhia kuv tias cov yaj tsis sib xyaw zoo lossis muaj kev sib kis.

Thaum kuv tswj cov yaj ntws thiab sib tov, kuv kuj pom cov khoom siv kho tshuab zoo dua hauv cov khoom kawg. Kuv cov pellets rov qab siv dua thiab tuav yuav luag zoo li cov yas tshiab, uas txhais tau hais tias kuv tuaj yeem siv lawv hauv cov ntawv thov ntau dua.

Optimized Ntsia Hlau Geometry

Cov duab thiab tsim ntawm cov ntsia hlau hauv kuv extruder ua qhov sib txawv loj. Kuv tau sim sib txawv ntsia hlau geometries thiab pom tias lawv cuam tshuam li cas rau kev siv lub zog, yaj zoo, thiab cov zis. Thaum kuv siv lub hau ntswj nrog txoj cai geometry, kuv tau txais kev sib xyaw ua ke ntau dua thiab muaj peev xwm ntau dua. Kuv kuj siv lub zog tsawg dua, uas txuag nyiaj thiab txo kuv cov khoom siv.

- Screw geometry cuam tshuam ntau npaum li cas kuv xav tau lub zog thiab qhov kub ntawm cov yaj nyob li cas.

- Kev ua kom nrawm nrawm tuaj yeem txo qis kev siv zog, tab sis tus qauv ntsia hlau yuav tsum phim cov khoom siv.

- Barrier screws thiab cov ntsiab lus sib xyaw pab ua kom sov sov txawm thiab txhim kho kev sib xyaw.

- Qee cov ntsia hlau tsim cia kuv khiav lub extruder sai dua yam tsis tau poob zoo.

- Txoj cai ntsia hlau geometry sib npaug zog efficiency nrog cov zis siab thiab zoo yaj zoo.

Kuv tau pom tias cov ntsia hlau thaiv, uas cais cov khoom thiab cov yas yaj, tso cai rau kuv khiav ntawm qhov nrawm dua thiab tau txais txiaj ntsig ntau dua. Txawm li cas los xij, kuv yuav tsum tau saib qhov kev sib tw kom ua kom lub cev tsis sib xws. Kev sib xyaw cov ntsiab lus zoo li Maddock shear seem muab kuv homogenization zoo dua, uas txhais tau tias tsawg dua qhov tsis xws luag hauv kuv cov pellets.

Nov yog qhov sib piv ceev ntawm cov ntsia hlau hom thiab lawv cov teebmeem:

| Ntsia Hlau Geometry | Kev sib xyaw ua ke (homogeneity) | Tshaj tawm | Sau ntawv |

|---|---|---|---|

| Barrier Screws | Zoo ntawm high throughput, yuav tsum tau ceev faj tswj | Siab | Qhov zoo tshaj plaws rau cov khoom loj, saib rau kev sib xyaw tsis sib xws ntawm kev kub ceev heev |

| Peb-section Screws | Stable, tab sis qis dua | Nruab nrab | Zoo rau kev tsim khoom ruaj khov, tsis hloov pauv |

| Cov ntsiab lus sib xyaw | Zoo heev homogenization | Ntau yam | Maddock shear muab kev sib xyaw zoo tshaj plaws, tshwj xeeb tshaj yog rau cov yas tawv |

Kuv ib txwm xaiv cov ntsia hlau geometry uas phim cov yas kuv rov ua dua tshiab. Txoj kev no, kuv tau txais qhov sib npaug zoo tshaj plaws ntawm kev ceev, zoo, thiab kev siv lub zog.

Advanced Barrel Materials

Cov khoom ntawm cov ntsia hlau chim tseem ceeb npaum li nws tsim. Kuv vam khom cov thoob uas ua los ntawm cov hlau zoo zoo li 38CrMoAl, uas muaj zog thiab tawv. Thaum kuv siv cov thoob nrog nitrided nto, kuv pom ib tug loj dhia hauv hardness. Qhov no txhais tau tias kuv cov cuab yeej siv tau ntev dua, txawm tias thaum kuv ua cov khoom siv abrasive lossis cov khoom tsis huv.

- Alloy steels xws li 38CrMoAlA thiab AISI 4140 muab kuv lub zog uas kuv xav tau.

- Hmoov metallurgy steels muab kev hnav zoo dua thiab corrosion kuj.

- Nitriding kev kho mob txhawb nqa qhov tawv tawv, feem ntau ncav cuag HV900 lossis ntau dua.

- Bimetallic coatings, zoo li tungsten carbide, tiv thaiv abrasive fillers.

- Chromium plating ntxiv lwm txheej tiv thaiv xeb thiab hnav.

Kuv tau pom tias thaum kuv siv cov thoob nrog cov khoom siv siab heev thiab cov txheej txheem, kuv siv sijhawm tsawg thiab nyiaj txiag rau kev saib xyuas. Kuv extruder khiav ntev dua ntawm cov kev pabcuam ib ntus, thiab kuv tsis tas yuav txhawj txog ntau npaum li kev tawg. Qhov kev ntseeg siab no cia kuv tsom mus rau kev tsim cov pellets zoo dua qub.

Tswv yim:Ib txwm phim covcov khoom siv thoobrau hom plastics thiab additives koj ua. Cov ntaub ntawv nyuaj dua thiab cov coatings them tawm thaum koj lis cov khib nyiab los yog cov yas sib xyaw.

Los ntawm kev sib koom ua ke txhim kho yaj homogenization, optimized ntsia hlau geometry, thiab cov ntaub ntawv siab tshaj plaws, kuv ua tiav cov txiaj ntsig zoo dua thiab cov txiaj ntsig zoo dua hauv kuv cov khoom siv rov ua dua tshiab. Cov txheej txheem no ua haujlwm ua ke kom xa cov khoom zoo sib xws, cov khoom siv ntau dua, thiab cov nqi qis dua.

Kev daws cov teeb meem kev rov ua dua tshiab

Tackling Contamination thiab Variable Feedstock

Thaum kuv khiav kuv txoj haujlwm rov ua dua tshiab, kuv ntsib cov khoom noj uas tsis tuaj yeem xav tau txhua hnub. Qee cov khoom siv muaj cov yas huv, tsis sib xws. Lwm tus tuaj txog nrog av, hlau, lossis ya raws. Kuv paub tias qhov tsis sib xws ntawm cov khoom siv rov ua dua tshiab muaj qhov ntom ntom ntom dua li cov pellets nkauj xwb. Qhov no txo qhov kev xa tawm thiab ua rau kuv lub tshuab extruder ua haujlwm hnyav dua. Yog tias kuv tsis daws cov teeb meem no, kuv pom qhov kub thiab txias dua thiab degraded pellet zoo.

Kuv vam khom kuv lub taub hau ib leeg los daws cov teeb meem no. Qhov zoo tshaj plaws pub cheeb tsam geometry, tshwj xeeb tshaj yog cov hnab ntim khoom loj, txhim kho kev pub noj thiab cov khoom khib nyiab. Qhov kev tsim no tiv thaiv cov khoom stagnation thiab ua kom cov dej ntws tsis tu ncua. Kuv pom tias kuv cov extruder tswj cov yaj zoo txawm tias thaum kuv ua cov khoom sib xyaw lossis cov khoom tsis huv.

Nov yog cov teeb meem tseem ceeb uas kuv ntsib hauv kev rov ua dua tshiab:

- Irregular regrind shapes thiab tsawg bulk ntom

- Txo kev hla dhau thiab ua haujlwm

- Cov kub yaj ntau dua thiab cov qhov rais ua haujlwm nqaim

- Kev sib kis thiab degradation ntawm cov khoom

- Kev hloov pauv hloov pauv nrog cov yas sib xyaw

Kuv lub taub hau ib leeg pab kuv kov yeej cov teeb meem no. Kuv pom kev noj zaub mov zoo dua, cov khoom siv zoo ib yam, thiab kev siv hluav taws xob qis dua. Cov tshuab no tso cai rau kuv ua ntau yam ntawm cov khoom siv rov ua dua tshiab yam tsis muaj kev txi zoo.

Kuv feem ntau piv ib qho ntsia hlau extruders rau ntxaib ntsia hlau extruders. Twin ntsia hlau tshuab muab kev sib tov zoo thiab degassing, tab sis lawv tawm tsam nrog kev kub siab thiab kev sib kis. Ib leeg ntsia hlau extruders, zoo li kuv, lis pom-intensive recycling thiab zam cov kab mob zoo dua. Nov yog qhov sib piv ceev:

| Feature | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Mixing Efficiency | Kev sib xyaw ua ke, txwv homogenization | Kev sib xyaw ua ke zoo heev, ua kom muaj kev sib faib / dispersive |

| Temperature Uniformity | Nruab nrab, nquag rau qhov kub / txias | Highly uniform melt kub faib |

| Tso zis ruaj khov | Zoo, tuaj yeem muaj pulsation | Raws li, ruaj khov tso zis |

| Material Versatility | Qhov zoo tshaj plaws rau homogeneous, cov ntaub ntawv nkauj xwb | Siv cov khoom siv ntxiv, sib tov, cov khoom noj tsis huv |

| Degassing muaj peev xwm | Txwv los yog tsis muaj | Siab, nrog lub tshuab nqus tsev ports thiab venting aav |

| Qhov zoo tshaj plaws siv Case | Me me, ntshiab nkauj xwb ABS | Kev lag luam nplai, tshwj xeeb, xim, rov ua dua ABS |

Kuv xaiv ib lub taub hau ntsia hlau rau lawv lub peev xwm ua haujlwm siab thiab kev ua siab ntev ntawm cov pa phem. Qhov kev txiav txim siab no pab kuv kom tsis txhob raug nqi kho mob thiab ua kom kuv txoj kab rov ua haujlwm zoo.

Txo kev hnav los ntawm cov khoom siv abrasive

Abrasive plastics thiab fillers, xws li iav fibers, talc, thiab calcium carbonate, nthuav tawm qhov kev sib tw loj hauv kuv cov nroj tsuag. Cov ntaub ntawv no hnav cov screws thiab chim sai sai. Kuv siv los hloov cov khoom feem ntau, uas ua rau muaj kev poob qis thiab cov nqi.

Tam sim no, kuv siv ib lub taub hau ntsia hlau nrog kev kho saum npoo thiab txheej txheej. Kuv lub thoob nta ib qhov chaw nitrided thiab bimetallic alloy txheej. Cov kev txhim kho no txhawb hardness thiab tiv thaiv puas. Kuv pom qhov sib txawv loj hauv kev ua haujlwm ntev. Kuv cov cuab yeej siv tau ntev dua, txawm tias thaum kuv ua cov khoom tawv tawv, abrasive plastics.

Cov qauv tsim tseem ceeb uas pab kuv txo qis hnav xws li:

- Optimized ntsia hlau geometry los tiv thaiv lub siab spikes thiab yaj turbulence

- Kev xaiv cov khoom hnav-resistant thiab cov txheej txheem tshwj xeeb

- Kev tsim qauv tsim tshwj xeeb rau cov khoom siv raw thiab cov fillers

- Precise machining rau du nto tiav

- Simulation software kom nkag siab txog qhov sib faib siab

Kuv kawm tau tias covkev hnav siab tshaj plaws tshwm sim nyob ze ntawm ntu kev hloov pauv, qhov twg solids wedge thiab siab nce. Los ntawm kev xaiv cov ntaub ntawv zoo thiab txheej txheej, Itxo hnav txog li 60%. Kev tshuaj xyuas tsis tu ncua thiab kev saib xyuas ntawm cov chaw hnav khaub ncaws siab, xws li cov chaw pub mis thiab tso tawm, khaws kuv cov extruder nyob rau hauv cov duab saum toj kawg nkaus.

Tswv yim:Kuv ib txwm phim kuv lub taub hau tsim rau cov yas thiab cov khoom ntim uas kuv ua. Txoj kev no txuas ntxiv cov cuab yeej siv lub neej thiab txhim kho kev tsim khoom.

Txhim kho cov txheej txheem ruaj khov thiab tso zis sib xws

Kev ua haujlwm ruaj khov yog qhov tseem ceeb rau kev tsim cov pellets zoo. Ua ntej kuv tau txais ib lub taub hau tshuab, kuv tau tawm tsam nrog kev ntws tawm, melting instabilities, thiab cov khoom tsis zoo conveying. Cov teeb meem no ua rau txo qis cov nqi tsim khoom, nce cov khoom seem, thiab cov nqi zog ntau dua.

Nrog kuv JT ib lub taub hau taub hau, kuv ua tiav cov dej ntws ruaj khov thiab cov zis zoo ib yam. Cov kev tswj hwm qib siab, suav nrog cov sensors thiab cov logic controllers, pab kuv tswj qhov kub thiab txias. Kuv saib xyuas cov txheej txheem cov xwm txheej zoo los tiv thaiv qhov kev hloov pauv uas tuaj yeem ua rau lub luag haujlwm tsis zoo.

kuv sivbimetallic alloys thiab advanced txheejlos txhim kho hnav thiab corrosion kuj. Cov yam ntxwv no yog qhov tseem ceeb rau kev ua cov khoom siv abrasive lossis rov siv cov yas. Cov txheej txheem ruaj khov tiv thaiv kev hloov pauv hauv cov khoom lag luam thiab txo cov khoom pov tseg.

Nov yog cov kauj ruam kuv ua kom muaj kev ruaj ntseg txheej txheem:

- Kev saib xyuas tsis tu ncua thiab hloov raws sij hawm ntawm hnav cov ntsia hlau thiab cov thoob

- Saib xyuas qhov kub thiab txias nrog kev tswj hwm qib siab

- Siv kev cai ntsia hlau profiles kom zoo dua yaj homogeneity thiab sib tov

- Tshawb xyuas cov chaw hnav khaub ncaws siab kom txo tau lub sijhawm poob qis

Cov kev tshawb fawb qhia tau hais tias kev ua kom zoo ntawm cov ntsia hlau ceev thiab qhov kub ntawm qhov chaw ua rau muaj kev nce ntxiv thiab txhim kho kev rov ua dua tshiab. Cov ntsia hlau qis qis nce torque thiab txo cov neeg kho tshuab lub zog, ua rau kev ua haujlwm zoo dua thiab ua kom zoo dua qub. Kuv tau sau cov ntaub ntawv tso zis ntau ntxiv ntawm 18% mus rau 36% tom qab optimizing kuv cov ntsia hlau chim tsim.

Nco tseg:Kev tshuaj xyuas zoo ib yam thiab kev saib xyuas kev kwv yees ua kom lub neej ntev ntawm cov cuab yeej siv thiab txhim kho tag nrho cov txheej txheem kev ruaj ntseg hauv kuv txoj haujlwm rov ua dua tshiab.

Los ntawm kev hais txog kev sib kis, hnav, thiab cov txheej txheem kev ruaj ntseg, kuv lub taub hau ib lub taub hau pab kuv xa cov pellets txhim khu kev qha, zoo dua qub. Kuv ua tau raws li qhov xav tau ntawm kev rov ua dua tshiab niaj hnub nrog kev ntseeg siab thiab ua haujlwm zoo.

Ib qho Screw chim rau Recycling Granulation: Real-World Results

Kev nce ntxiv thiab kev ua tau zoo

Thaum kuv hloov mus rau ib lub taub hau ntsia hlau rau cov khoom siv rov ua dua tshiab, kuv pom qhov pom tseeb ntawm ob qho tib si dhau los thiab pellet zoo. Kuv cov pellets siv dua tam sim no qhia tau hais tias muaj zog zoo dua thiab ua kom pom tseeb dua. Kuv tuaj yeem tswj cov pellet loj dua qhov tseeb, uas pab kuv ua tau raws li cov neeg siv khoom nruj. Kev tswj qhov kub thiab txias ua kom cov dej ntws tsis tu ncua, yog li kuv tau txais qhov tsis xws luag tsawg dua thiab cov pellets zoo li qub.

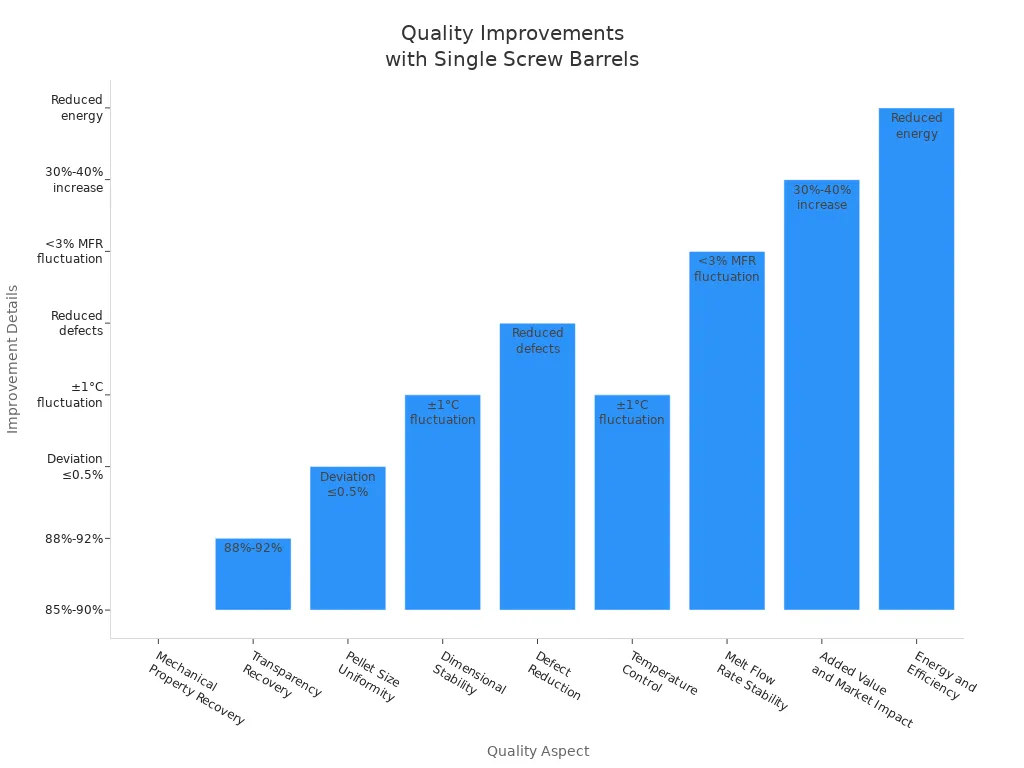

| Qhov Zoo | Txhim kho cov ntsiab lus |

|---|---|

| Mechanical Property Recovery | 85% -90% tus nqi rov qab, ntau dua nrog cov khoom siv zoo tib yam |

| Transparency rov qab | 88% -92% rov qab tus nqi |

| Pellet Loj Uniformity | Qhov sib txawv ntawm qhov loj me hauv 0.5% |

| Dimensional Stability | Qhov kub thiab txias (± 1 ° C fluctuation) ua kom ruaj khov |

| Kev txo qis | Tsawg impurities thiab tsis xws luag |

| Kev Tswj Kub Kub | 5-theem tswj, ± 1 ° C hloov pauv |

| Melt Flow Rate stability | MFR hloov pauv tsawg dua 3% |

| Ntxiv tus nqi thiab kev ua lag luam cuam tshuam | 30% -40% nce tus nqi ntxiv |

| Zog thiab Efficiency | Kev siv hluav taws xob qis dua, kev ua haujlwm siab dua |

Kev kho qis qis thiab qis qis

Kuv tau kawm tias kev saib xyuas tsis tu ncua ua rau kuv lub taub hau ib lub taub hau kom rov ua dua granulation ua haujlwm zoo. Kuv ua raws li kev saib xyuas nruj thiab tshuaj xyuas lub thoob txhua lub lim tiam. Kuv ib txwm ua kom qhov kub thiab txias ceev kom tsis txhob muaj kev ntxhov siab ntawm lub tshuab. Kev huv, txheeb cov khoom noj khoom haus yas pab tiv thaiv kev puas tsuaj los ntawm cov kab mob. Kuv ntxuav thiab lubricate qhov chaw txav kom tsis txhob xeb thiab kev sib txhuam. Thaum kuv pom cov khoom hnav, kuv hloov lawv tam sim ntawd. Kuv xaiv cov thoob uas ua los ntawm cov hlau tawv tawv nrog cov txheej tshwj xeeb, zoo li nitriding, kom ntev lawv lub neej.

- Kev tshuaj xyuas lub thoob txhua lub lim tiamkhaws kuv cov cuab yeej ua haujlwm saum toj kawg nkaus.

- Kho qhov kub thiab txias kom tsis txhob hnav.

- Cov khoom noj huv huv txo cov kev puas tsuaj sab hauv.

- Kev tu thiab lubrication tsis tu ncua nres kev tawg.

- Kev hloov pauv qhov ua tau zoo kom tsis txhob muaj sijhawm poob qis.

- Cov alloys tawv thiab coatings ua rau lub thoob kav ntev.

Cov nroj tsuag ua raws li cov kauj ruam no qhia tsawg dua downtime thiab txo nqi kho. Kuv txoj kab rov ua dua tam sim no ua haujlwm tau zoo dua thiab ntseeg tau.

Case Study: JT Tib Ntsia Hlau Barrel hauv Multi-Plastic Recycling

Kuv tau teeb tsa JT tib lub taub hau rau kev rov ua dua tshiab hauv kuv cov nroj tsuag los tswj cov yas sib txawv xws li PE, PP, thiab PVC. Cov khoom hnav-resistant, xws li38CrMoAl thiab tungsten carbide, tau ncua lub thoob lub neej. Tam sim no kuv siv tsawg dua rau kev kho thiab hloov. Kuv cov kab ntau lawm tsis tshua nres, yog li kuv ua tau raws li kuv lub sijhawm xa khoom. Qhov kev ua tau zoo ib yam ntawm JT tib lub taub hau rau cov khoom siv rov ua dua tshiab tau txhim kho kuv cov zis thiab txo kuv cov nqi. Kuv pom kev cuam tshuam tsawg dua thiab zoo duapellet zoo, uas pab kuv nyob hauv kev sib tw hauv kev ua lag luam.

Kuv pom li cas ib lub taub hau ntsia hlau daws teeb meem rov ua dua tshiab. Kuv qhov kev paub dhau los qhia tau hais tias zoo dua yaj zoo, sib tov, thiab txheej txheem kev ruaj ntseg. Nrog rau ib lub taub hau rau kev rov ua dua granulation, kuv ua tiav kev ua haujlwm siab dua thiab kev ntseeg siab. Cov kev txhim kho no txhawb kev ua haujlwm huv, txo tus nqi, thiab pab kuv ua tau raws li kev lag luam loj hlob xav tau rau kev rov ua dua tshiab yas.

FAQ

Kuv tuaj yeem ua cov yas dab tsi nrog JT ib lub taub hau taub hau?

Kuv tuaj yeem ua ntau yam yas, suav nrog PE, PP, PS,PVC, PET, PC, thiab PA. Lub thoob hloov mus rau cov khoom sib txawv rau kev rov ua haujlwm zoo.

Kuv yuav txo qhov hnav ntawm kuv lub taub hau taub hau li cas?

Kuv siv cov thoob ua los ntawm tawv alloys nrog nitrided los yog bimetallic txheej. Kev tu tsis tu ncua thiab kev teeb tsa kom zoo pab kuv txuas lub thoob lub neej thiab ua kom muaj kev ua haujlwm siab.

Vim li cas melt homogenization tseem ceeb hauv kev rov ua dua tshiab?

Melt homogenization muab kuv cov pellets sib xws. Kuv pom tsawg dua qhov tsis xws luag thiab cov khoom muaj zog zoo dua. Kev sib xyaw ua ke pab kuv ua tau raws li cov qauv zoo thiab cov neeg siv khoom xav tau.

Post lub sij hawm: Aug-21-2025