Xaiv qhov zoonitrided screws thiab chimNws yog ib qho tseem ceeb rau kev ua kom pom kev ua haujlwm zoo hauv cov tshuab. Cov yam ntxwv xws li hom khoom, tsim kev sib raug zoo, thiab cov kev xav tau ntawm daim ntawv thov cuam tshuam rau qhov kev xaiv no. Kev paub txog kev txiav txim siab tsis tsuas yog txhim kho lub neej ua haujlwm ntawm cov khoom xws li covExtrusion Tshuab Ib Screw chimthiab covPvc Yeeb Nkab Ib Screw Barreltab sis kuj txhim kho tag nrho efficiency thiab productivity.

Kev xaiv cov khoom siv rau Nitrided Screws thiab chim

Xaiv cov khoom tsim nyog raunitrided screws thiab chimyog qhov tseem ceeb rau kev ua tiav kev ua tau zoo hauv ntau yam kev siv. Cov khoom siv tseem ceeb cuam tshuam rau kev ua haujlwm ntev, kev ua haujlwm, thiab kev ua haujlwm tag nrho ntawm cov khoom no.

Hom Cov Khoom Siv

Ntau cov ntaub ntawv feem ntau yog siv rau hauv kev tsim cov nitrided screws thiab chim. Txhua yam khoom muaj cov yam ntxwv tshwj xeeb uas cuam tshuam rau nws qhov tsim nyog rau cov ntawv thov tshwj xeeb. Nov yog qee yam ntawm cov khoom siv tshaj plaws:

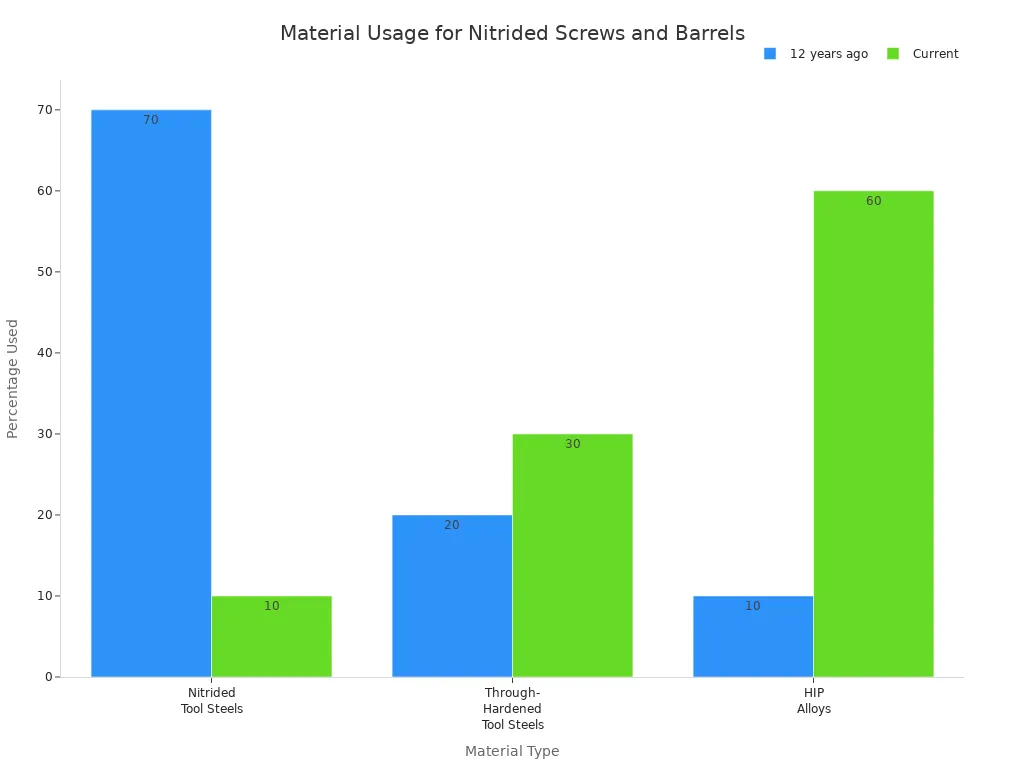

- Nitrided cuab yeej Steels: Keeb kwm, cov hlau no suav txog li 70% ntawm kev ua lag luam sib koom kaum ob xyoos dhau los. Txawm li cas los xij, lawv cov kev siv tau txo qis rau ib puag ncig 10% tam sim no.

- Los ntawm-Hardened Tool Steels: Hom no tau pom qhov muaj npe nrov, nce ntawm 20% mus rau 30% nyob rau tib lub sijhawm.

- HIP Alloys: Cov alloys tau txais txiaj ntsig tseem ceeb, txav los ntawm 10% mus rau 60% hauv kev siv tam sim no.

Cov lus hauv qab no qhia txog cov kev hloov pauv ntawm kev siv cov khoom siv ntau xyoo:

| Hom khoom | Feem pua (12 xyoo dhau los) | Feem pua (Tam sim no) |

|---|---|---|

| Nitrided cuab yeej Steels | 70% | 10% |

| Los ntawm-Hardened Tool Steels | 20% | 30% |

| HIP Alloys | 10% | 60% |

Cov khoom ntawm Nitrided Materials

Nitrided cov ntaub ntawv nthuav tawm ntau yam khoom zoo uas txhim kho lawv cov kev ua tau zoo hauv kev lag luam. Cov txheej txheem nitriding qhia nitrogen rau saum npoo ntawm cov khoom, tsim ib txheej nitride nyuaj. Cov txheej txheem no txhim kho ntau yam khoom siv kho tshuab, ua cov khoom siv nitrided zoo heev.

- Hnav Resistance: Cov khoom siv nitrided pom tau zoo heev hnav tsis kam vim yog txheej txheej tawv tawv tsim thaum nitriding. Cov cuab yeej no yog ib qho tseem ceeb rau cov khoom uas raug rau cov kev mob abrasive, xws li hauv cov txheej txheem extrusion.

- Corrosion Resistance: Cov txheej nitride kuj muab kev txhim kho kev tiv thaiv corrosion, uas yog ib qho tseem ceeb thaum cuam tshuam nrog molten polymers thiab lwm yam corrosive hais.

- Hardness: Tom qab nitriding, cov ntaub ntawv tuaj yeem ua tiav qib siab tshaj 65 HRC. Qhov no hardness nce ntxiv ua rau tag nrho lub zog thiab kav ntev ntawm cov ntsia hlau thiab cov thoob.

- Comprehensive Properties: Nitrided steel thiab cov alloys tshwj xeeb xws li 38CrMoAl paub txog lawv cov khoom zoo tag nrho, ua rau lawv haum rau ntau yam kev siv.

Cov lus hauv qab no qhia txog cov khoom tseem ceeb ntawm cov khoom siv nitrided siv hauv cov ntsia hlau thiab cov thoob:

| Khoom | Kev piav qhia |

|---|---|

| Hnav Resistance | Cov khoom siv nitrided pom zoo hnav tsis kam vim cov txheej txheem nitriding. |

| Corrosion Resistance | Lawv muaj kev tiv thaiv corrosion zoo, txawm tias qee qib yuav muaj kev txwv. |

| Hardness | Tom qab nitriding hardness tuaj yeem tshaj 65 HRC, txhim kho tag nrho lub zog. |

| Comprehensive Properties | Nitrided steel thiab 38CrMoAl tau sau tseg rau lawv cov khoom zoo tag nrho. |

| Nitriding Txheej Qhov tob | Feem ntau, cov txheej nitriding ncav cuag 0.4-0.6 hli. |

Cov yam tseem ceeb uas yuav tsum tau xav txog hauv Kev Xaiv Nitrided Cheebtsam

Thaum twgxaiv nitrided screws thiab chim, ob yam tseem ceeb tuaj rau hauv kev ua si: tsim compatibility thiab daim ntawv thov yuav tsum tau. Kev nkag siab txog cov xwm txheej no ua kom ntseeg tau tias cov khoom xaiv tau ua tau zoo hauv lawv qhov chaw ib puag ncig.

Tsim Compatibility

Tsim kev sib raug zoo yog qhov tseem ceeb rau kev sib koom ua tiav ntawm nitrided screws thiab chim rau hauv cov tshuab uas twb muaj lawm. Ob peb tus qauv tsim yuav tsum raug txiav txim siab kom ntseeg tau tias qhov kev sib raug zoo no:

| Tsim Feature | Kev piav qhia |

|---|---|

| Kev xaiv khoom | Nitrided steel yog nyiam rau nws cov tawv tawv thiab corrosion kuj. |

| Barrel Txheej | Bimetallic barrels nrog hnav-resistant txheej yog tsim nyog rau kev ua haujlwm siab. |

| Ntsia Hlau Geometry | Tshwj xeeb tsim ntsia hlau geometries txhim khu plastification thiab tso zis. |

| L/D Ratio | Qhov piv ntawm cov ntsia hlau ntev mus rau txoj kab uas hla cuam tshuam cov txheej txheem melting thiab kev sib xyaw. |

| Compression Ratio | Siab compression ratios txhim kho kev sib xyaw ua haujlwm thiab cov zis siab. |

| Davhlau Depth Measurement | Tswj cov khoom thauj khoom ntim thiab lub thoob dej ntws ua haujlwm. |

Nitrided steel muab cov kav ntev thiab tsis kam hnav, ua rau nws yog qhov kev xaiv nrov. Bimetallic chim txhim kho kev ua tau zoo nyob rau hauv ib puag ncig abrasive, thaum ntev screws txhim kho cov khoom ua haujlwm zoo. Kev sib xyaw ua kom muaj zog ntau ntxiv ua rau kev sib xyaw ua ke zoo dua thiab cov zis siab, uas yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo.

HMG Extrusion hais txog qhov tseem ceeb ntawm kev siv cov hlau hnyav hnyav nitriding rau cov ntsia hlau. Qhov kev mloog zoo rau kev nthuav dav no pab tswj cov kev ua siab ntev ntev, ua kom muaj kev sib raug zoo nrog cov tshuab uas twb muaj lawm.

Yuav tsum thov

Daim ntawv thov yuav tsum ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov tsim nyog ntawm nitrided screws thiab chim. Cov ntsiab lus tseem ceeb suav nrog:

- Kev txiav txim siab tsim: Cov qauv tsim yuav tsum suav nrog cov yam ntxwv ntawm cov khoom xws li viscosity, melting point, thiab flow rate.

- Uniform Melting thiab Blending: Kev tsim kom zoo xyuas kom cov ntaub ntawv yas zoo sib xws thiab sib xyaw ua ke, tiv thaiv overheating thiab hlawv.

- Nto Smoothness: Optimizing nto smoothness yog qhov tseem ceeb rau kev ntsuas cov khoom sib xyaw, shearing, thiab conveying. Qhov no cuam tshuam ncaj qha rau kev tsim khoom thiab cov khoom zoo.

Dimensional tolerances kuj cuam tshuam rau kev ua haujlwm. Hnav ntawm cov ntsia hlau thiab cov thoob tuaj yeem cuam tshuam rau plasticizing efficiency, rov qab siab, txhaj tshuaj ntim, lub sij hawm voj voog, thiab qhov sib xws. Cov khoom hnav tuaj yeem txo cov kev ua haujlwm tau zoo txog li 25%, nce kev siv zog, thiab ua rau muaj qhov tsis xws luag hauv cov pwm pwm. Kev tshem tawm ntau dhau ntawm cov ntsia hlau thiab lub thoob tuaj yeem ua rau cov dej xau, cov yaj tsis zoo, thiab kev txhaj tshuaj tsis sib haum.

Cov Tswv Yim Kho Kom Zoo Rau Lub Neej Ntev

Kev saib xyuas kom zoo ntawm nitrided screws thiab chim yog qhov tseem ceeb rau kev ua kom lawv lub neej ntev thiab ua kom pom kev ua haujlwm zoo. Kev ua raws li kev tiv thaiv kev tiv thaiv muaj zog (PM) tuaj yeem txo qhov hnav thiab ua kom lub neej ntev ntawm cov khoom no.

Kev tu thiab tu

Kev tu thiab lubrication tsis tu ncua yog qhov tseem ceeb rau kev tiv thaiv kev hnav ntxov ntxov. Nov yog qee qhov kev coj ua uas pom zoo:

- Siv Commercial Purging Compounds (CPCs): Cov tebchaw no txhim kho kev ua haujlwm huv thiab pab tshem tawm cov khoom seem ntawm cov ntsia hlau thiab lub thoob.

- Ua raws li cov lus pom zoo ntawm Chaw Tsim Khoom: Ua raws li cov txheej txheem muab los ntawm cov ntsia hlau thiab lub thoob manufacturers rau kev saib xyuas tsis tu ncua.

Txhawm rau tswj cov khoom kom zoo, xav txog kev saib xyuas hauv qab no:

| Kev tu ntau zaus | Task Description |

|---|---|

| Txhua lub lim tiam | Hloov cov roj lubricating lim ntawm lub reducer thiab xyuas cov impurities. |

| Txhua hli | Xyuas cov coaxiality ntawm lub cev muaj zog coupling thiab calibrate nws. |

| Peb lub hlis twg | Ua kom tiav disassembly tshuaj xyuas ntawm cov ntsia hlau, chim, thiab pwm. |

Kev tshuaj xyuas thiab hloov

Kev tshuaj xyuas niaj hnub yog qhov tseem ceeb rau kev kuaj xyuas kev hnav lossis kev puas tsuaj hauv nitrided screws thiab chim. Cov kws kho mob yuav tsum suav nrog cov txheej txheem hauv qab no hauv lawv cov kev pab tu:

- Ua niaj hnub tshuaj xyuas ntawm plasticizing Cheebtsam.

- Ntsuas qhov hnav thaum lub sijhawm kuaj xyuas los tsim ib qho profile hnav.

- Txheeb xyuas lub neej ntev ntawm cov khoom siv rau kev npaj hloov thiab kho.

Kev tshuaj xyuas cov ntsia hlau thiab cov thoob tsis tu ncua tso cai rau kev tshawb pom ntxov ntawm cov teeb meem muaj peev xwm, ua kom muaj kev cuam tshuam sai. Cov lus hauv qab no qhia txog lub neej ntev ntawm ntau yam khoom siv:

| Hom Lub Npe | Lifespan (Xyoo) | Sau ntawv |

|---|---|---|

| Standard screws | 1-1.5 Nws | Rau cov khoom siv dav dav (piv txwv li, PP / PE) |

| Standard screws | 0.5-0.67 hli | Rau fillers (piv txwv li, fiberglass) |

| Barrel lifespan | 1.5-2 zaug | Feem ntau ntev tshaj qhov ntsia hlau lifespan; hloov yog tias muaj hnub nyoog tshaj 3 xyoos. |

| Hloov lub tswv yim | N/A | Hloov cov ntsia hlau thiab lub thoob raws li cov txheej txheem rau cov txiaj ntsig kev lag luam. |

Ua raws li cov nocov lus qhia saib xyuas, cov neeg ua haujlwm tuaj yeem ua kom lub neej ntev thiab kev ntseeg siab ntawm cov khoom zoo nitrided screws thiab chim.

Kev txiav txim siab nqi rau High Quality Nitrided Ntsia Hlau thiab chim

Thaum ua lag luam nyob rau hauv high-zoo nitrided screws thiab chim, nkag siab qhovtus nqi cuam tshuamyog qhov tseem ceeb. Cov tuam txhab yuav tsum sib npaug cov nuj nqis pib nrog cov txiaj ntsig mus sij hawm ntev los txiav txim siab paub.

Kev siv nyiaj rau kev ua tau zoo

Kev siv nyiaj rau cov khoom siv nitrided yuav tsum tau ua tib zoo xav txog ntau yam. Cov tuam txhab yuav tsum ntsuas cov hauv qab no:

- Hom yas ua tiav: Txiav txim seb daim ntawv thov puas muaj cov qauv lossis cov khoom siv ntxiv. Qhov kev xaiv no cuam tshuam rau kev xaiv cov khoom siv thiab cov nqi cuam tshuam.

- Additives siv: Ntsuas seb cov khoom siv ntxiv cuam tshuam li cas rau hnav thiab kev ua neej ntev. Cov xwm txheej no tuaj yeem cuam tshuam rau cov nuj nqis tag nrho.

- Ntau lawm nplai: Cov kev ua haujlwm siab yuav tsum tau ua qhov tseem ceeb ntawm cov alloys muaj zog. Kev nqis peev hauv cov khoom siv ruaj khov them nyiaj rau lub sijhawm ntev.

- Kev xav txog nyiaj txiag: Kev xaiv rau kev xaiv bimetallic lossis coated tuaj yeem ua rau kev txuag nyiaj mus ntev. Cov kev xaiv no feem ntau txo cov nqi kho thiab hloov cov nqi.

Tus nqi pib siab ntawm bimetallic Cheebtsam, xws li nitrided screws thiab chim, tshwm sim los ntawm intricate manufacturing txheej txheem thiab cov khoom tshwj xeeb. Qhov kev nyuaj no ua rau cov nqi ntau lawm, uas cuam tshuam rau tus nqi kawg ntawm cov khoom no. Nyob rau hauv cov sectors xws li tsheb, qhov kev thov rau nitriding steel pub ntsia hlau chim stems los ntawm lawv superior hardness thiab hnav tsis kam. Cov khoom no qhia txog cov khoom siv siab thiab cov nqi tsim khoom.

Tus nqi mus sij hawm ntev vs. Tus nqi pib

Kev nqis peev hauv cov khoom zoo nitrided tuaj yeem ua rau muaj txiaj ntsig zoo rau lub sijhawm ntev. Cov khoom no feem ntau kav ntev li 2 mus rau 5 npaug ntau dua li cov uas tsis yog-nitrided. Qhov kev ua neej ntev no txo qhov zaus ntawm kev hloov pauv thiab kev saib xyuas, ua rau txo qis tag nrho cov nqi ntawm cov tswv cuab rau cov tshuab thiab cov tshuab siv cov khoom siv nitrided.

Cov lus hauv qab no qhia txog ntau yam cuam tshuam li cas rau tus nqi ntawm cov tswv:

| Qhov xwm txheej | Kev cuam tshuam rau tus nqi ntawm cov tswv cuab |

|---|---|

| Hnav Resistance | Kev hloov pauv tsawg dua, cov nqi qis dua |

| Kev tu ntau zaus | Tsawg downtime, txo nqi zog |

| Zog Efficiency | Cov nqi hluav taws xob qis dua |

| Kev Tshawb Fawb Txog Kev Tshawb Fawb | Kev tshawb pom ntxov, kev kho kom tsawg |

Los ntawm kev txiav txim siab txog tus nqi pib thiab tus nqi mus sij hawm ntev, tuam txhab lag luam tuaj yeem txiav txim siab cov tswv yim uas txhim kho kev ua haujlwm zoo thiab txo cov nuj nqis tag nrho. Kev nqis peev hauv cov khoom zoo nitrided screws thiab cov thoob tsis tsuas yog txhim kho kev ua tau zoo tab sis kuj tseem ua rau muaj txiaj ntsig zoo dua nyiaj txiag.

Xaiv txoj cai nitrided screws thiab tej kas tham yuav tsum tau ceev faj saib xyuaskhoom compatibilitythiab kev saib xyuas. Cov ntsiab lus tseem ceeb suav nrog xaiv cov khoom hnav-tiv taus zoo li nitrided steel thiab ua kev tshuaj xyuas tsis tu ncua. Los ntawm kev paub txog kev xaiv, cov neeg ua haujlwm tuaj yeem txhim kho kev ua haujlwm thiab txuas ntxiv lub neej ntawm lawv cov khoom siv tshuab.

Cov ntsiab lus tseem ceeb:

- Material compatibility cuam tshuam rau hnav thiab corrosion kuj.

- Kev saib xyuas tsis tu ncua txo qis qis qis thiab txhim kho kev ua haujlwm.

FAQ

Cov txheej txheem nitriding yog dab tsi?

Nitriding yog ib qho kev kho deg hardening uas diffuses nitrogen rau hauv cov khoom, tsim ib txheej nitride nyuaj.

Yuav ua li cas nitriding txhim kho cov ntsia hlau thiab chim siab?

Nitriding txhim khu kev hnav tsis kam, corrosion kuj, thiab txo kev sib txhuam, ua rau lub neej ntev kev pab cuam thiab txhim kho efficiency.

Yuav ua li cas cov kev tu ncua ntev lub neej ntawm nitrided Cheebtsam?

Kev tu tsis tu ncua, lubrication, thiab kev tshuaj xyuas pab kom pom kev hnav thaum ntxov, kom ntseeg tau tias kev ua haujlwm zoo thiab kev ua haujlwm ntev ntawm nitrided screws thiab chim.

Post lub sij hawm: Sep-16-2025