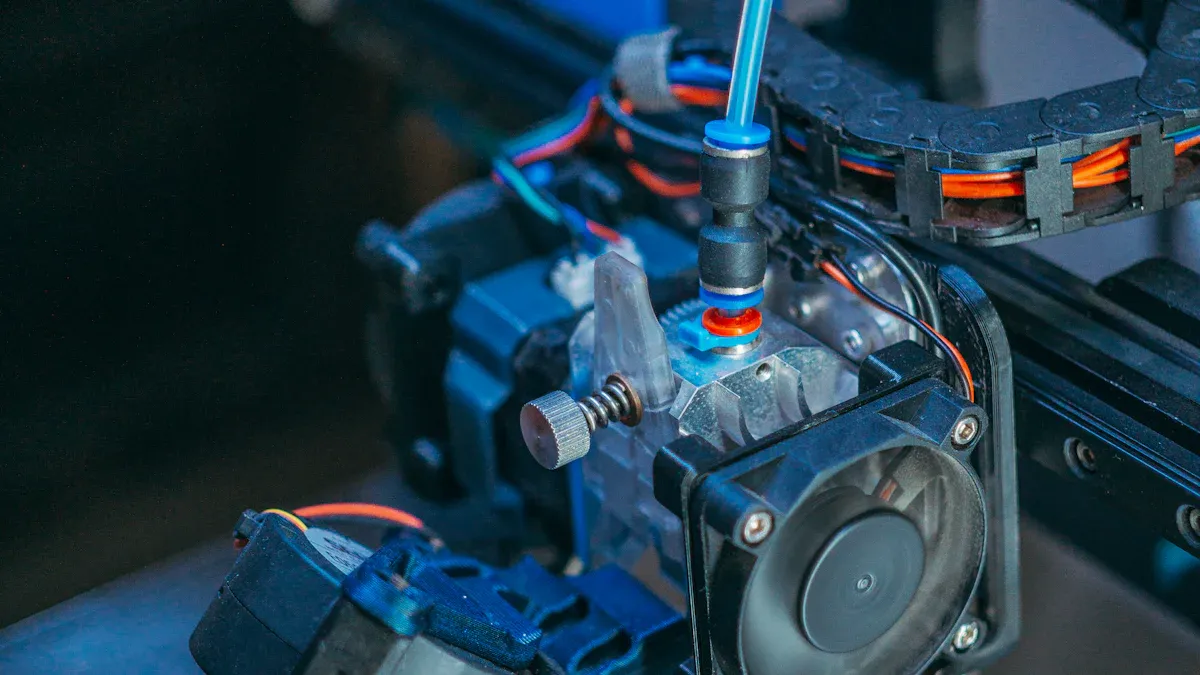

Xaiv txoj cai ntxaib ntsia hlau yas extruders kom efficiency thiab precision nyob rau hauv kev txhaj tshuaj molding txheej txheem. Cov tshuab no txhim kho cov khoom sib xyaw, txhim kho kev muaj peev xwm, thiab nthuav dav kev ua haujlwm, ua rau lawv tseem ceeb rau kev ntim khoom ntau.

- Lub ntiaj teb ntxaib ntsia hlau extruder lag luam, muaj nuj nqis ntawm USD 1,128.1 lab nyob rau hauv 2022, yog npaj kom ncav cuag USD 1,649.5 lab los ntawm 2031.

- Ib qho kev loj hlob ntawm 4.5% txhua xyoo qhia txog lawv qhov kev thov nce thoob plaws kev lag luam.

- Advanced designs, xws liTwin-screw extruder ntsia hlau chim, optimize kev ua tau zoo thiab kev ntseeg tau.

Compatibility, customization, thiab nqi-effectiveness tseem tseem ceeb yam tseem ceeb thaum xaiv ibOb chav ntsia hlau extruderrau cov ntawv thov tshwj xeeb, tshwj xeeb tshaj yog thaum xav txog aob chav ntsia hlau extruder tshuabtailored kom tau raws li cov kev xav tau ntau lawm.

Qhov tseem ceeb ntawm Twin Screw Yas Extruders

Cov txiaj ntsig rau Txhaj Molding

Twin ntsia hlau yas extruders ua si ib qho tseem ceeblub luag hauj lwm hauv kev txhim kho cov efficiencythiab zoo ntawm kev txhaj tshuaj molding txheej txheem. Lawv cov qauv tsim ua kom muaj kev tswj xyuas meej txog kev sib xyaw ua ke, kev sib xyaw ua ke, thiab kev sib xyaw, uas yog qhov tseem ceeb rau kev tsim cov pwm zoo. Los ntawm kev tswj lub siab zoo, cov cav tov no tswj qhov kub thiab txias thiab viscosity, kom ntseeg tau tias cov khoom zoo ib yam.

Cov txiaj ntsig tseem ceeb suav nrog:

- Kev hloov pauv kev lag luam los ntawm batch mus rau kev ua haujlwm tas mus li, txhim kho kev ua tau zoo.

- Customizing cov khoom siv los ntawm kev sib xyaw ua ke zoo tshaj plaws, uas cuam tshuam ncaj qha rau cov khoom zoo.

- Yooj yim rau devolatilization nrog cov tswv yim tso qhov cua, tiv thaiv dej nyab thiab ua kom tshem tawm cov volatiles.

- Tso cai tswj kev ywj pheej ntawm cov nqi pub thiab cov ntsia hlau RPMs, optimizing compounding thiab devolatilization txheej txheem.

Lub co-rotating, intermeshing tsim ntawm ntxaib ntsia hlau yas extruders yog dav suav hais tias yog cov tshuaj compounding zoo tshaj plaws hauv kev lag luam yas. Qhov no ua rau lawv indispensable rau manufacturers nrhiav kom tau precision thiab kev cia siab rau hauv kev txhaj tshuaj molding.

Qhov zoo tshaj ib leeg ntsia hlau Extruders

Twin ntsia hlau yas extruders muaj ntau yam zoo dua lawv cov ntsia hlau ib leeg, tshwj xeeb tshaj yog nyob rau hauv cov nqe lus ntawm kev ua tau zoo, yooj, thiab efficiency. Cov lus hauv qab no qhia txog qhov sib txawv tseem ceeb:

| Feature | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Muaj peev xwm ua tau | Basic extrusion thiab yooj yim compounding. | Kov cov ntaub ntawv complex thiab intricate sib tov. |

| Kev ua haujlwm thiab kev ua haujlwm | Lower throughput, haum rau me me ntau lawm. | Ntau dua throughput, kom ntseeg tau cov khoom zoo. |

| Flexibility thiab Versatility | Txwv tsis pub yooj yim, ua haujlwm yooj yim dua. | Yooj yim heev nrog adjustable parameters. |

| Khoom siv yooj yim | Haum rau cov thermoplastics yooj yim thiab muab tub lim. | Zoo tagnrho rau complex formulations thiab high-viscosity cov ntaub ntawv. |

| Kev sib xyaw muaj peev xwm | Tsim nyog rau cov qauv yooj yim. | Superior mixing, zoo meej rau additive incorporation. |

| Degassing thiab Devolatilization | Muaj peev xwm txwv. | Muaj peev xwm ua tau zoo, ua tau raws li cov qauv nruj nruj. |

Cov txiaj ntsig no ua rau ntxaib ntsia hlau yas extruders xaiv rau cov tuam txhab lag luam txhawm rau txhim kho kev tsim khoom thiab cov khoom zoo. Lawv lub peev xwm los tswj cov khoom siv sib txawv thiab cov qauv tsim kom ntseeg tau tias lawv tseem yog lub hauv paus ntawm cov txheej txheem niaj hnub txhaj tshuaj molding.

Cov ntsiab lus tseem ceeb los xav txog thaum xaiv Twin Screw Yas Extruders

Compatibility nrog Txhaj Moulding Machine

Xaiv lub ntxaib ntsia hlau yas extruder uas ua raws li cov lus qhia ntawm koj lub tshuab txhaj tshuaj molding yog qhov tseem ceeb. Compatibility xyuas kom seamless kev koom ua ke, txo downtime thiab txhim kho tag nrho efficiency. Cov neeg tsim khoom yuav tsum ntsuam xyuas lub extruder cov zis muaj peev xwm, ntsia hlau tsim, thiab cov khoom siv peev xwm ua kom tau raws li qhov xav tau ntawm lawv cov tshuab molding. Piv txwv li, ib qho extruder nrog lub zog ntau dua thiab cov ntsia hlau ceev tuaj yeem tuav cov ntaub ntawv nyuaj, ua kom cov txheej txheem noj thiab yaj.

Lub extruder zoo sib xws kuj txo qis kev siv zog thiab hnav ntawm cov khoom. Cov lus hauv qab no qhia txog cov yam tseem ceeb xws li cov ntsia hlau ceev thiab cov khoom siv cuam tshuam rau kev ua haujlwm:

| Qhov tseem ceeb | Kev cuam tshuam rau kev siv hluav taws xob | Kev cuam tshuam ntawm Kev Nyuaj Siab | Kev cuam tshuam rau Torque |

|---|---|---|---|

| Screw Rotational Speed (n) | Kev txo qis hauv kev siv hluav taws xob tshwj xeeb (45% txo) nrog kev nce ceev | Nce siab los ntawm 3.1 MPa (65%) nrog ceev dua | Nce torque nrog ceev dua |

| Cov ntsiab lus Bran (u) | Tsis muaj kev cuam tshuam loj rau kev siv hluav taws xob | Nce siab los ntawm 3.8 MPa (75%) nrog txo bran cov ntsiab lus | Txo torque los ntawm 34% nrog ntxiv bran cov ntsiab lus |

Nkag siab txog cov kev ntsuas no pab cov tuam txhab xaiv ib qho extruder uas ua tiav lawv cov kev txhaj tshuaj molding.

Customization Options rau cov ntawv thov tshwj xeeb

Twin ntsia hlau yas extruders muab cov kev xaiv tsis sib xws, ua rau lawv zoo tagnrho rau kev siv ntau yam. Cov tshuab no tso cai rau cov tuam txhab tsim kho cov ntsia hlau tsim rau kev ua haujlwm tshwj xeeb, xws li kev sib xyaw, kev sib tsoo, lossis kev sib xyaw. Txhua lub ntsiab ntawm cov ntsia hlau ua haujlwm rau lub hom phiaj sib txawv, thiab kev hloov kho me me tuaj yeem cuam tshuam cov txiaj ntsig ntawm cov khoom siv.

Cov yam ntxwv tseem ceeb customization muaj xws li:

- Slexible ntsia hlau configurations optimize mixing thiab cov ntaub ntawv txaus.

- Rearrangeable chim seem los txhim kho cov txheej txheem extrusion yam tsis muaj kev hloov kho dav dav.

Qib no ntawm kev hloov kho kom ntseeg tau tias cov tuam txhab tsim khoom tuaj yeem ua tau raws li cov cai tsim khoom tshwj xeeb thaum tswj hwm tus nqi. Piv txwv li, kev lag luam uas xav tau cov ntaub ntawv viscosity siab lossis cov qauv tsim muaj txiaj ntsig tau txais txiaj ntsig los ntawm cov yam ntxwv no.

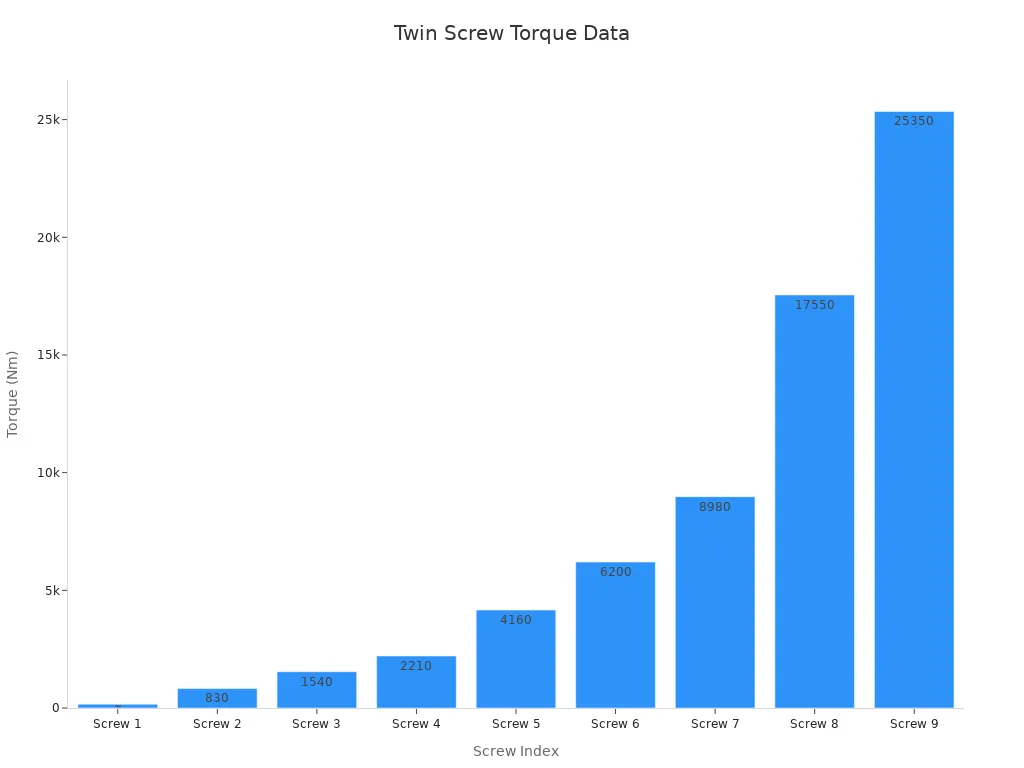

Kev ntsuas kev ua tau zoo: Torque, nrawm, thiab cov khoom siv dhau los

Kev ntsuas kev ua tau zoo ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov ua tau zoo ntawm cov ntsia hlau ntxaib yas extruders.Torque ceev, ntsia hlau ceev, thiab cov khoom siv dhau los yog qhov tseem ceeb tsis zoo uas cuam tshuam lub tshuab muaj peev xwm ua cov ntaub ntawv zoo. Piv txwv li, lub zog torque siab, tso cai rau lub extruder los ua cov ntawv thov, xws li kev sib xyaw ua ke nrog cov khoom siv hluav taws xob los yog ua cov khoom siv high-viscosity.

Cov lus hauv qab no muab cov duab thaij duab ntawm cov ntaub ntawv ua haujlwm rau ntxaib ntsia hlau extruders:

| Parameter | Tus nqi |

|---|---|

| Torque ceev | Lub zog siab txog 18 Nm / cm³ |

| Torque ntawm txhua tus ntsia hlau (Nm) | 160, 830, 1540, 2210, 4160, 6200, 8980, 17550, 25350 |

| Screw ceev (rpm) | 1200 rau feem ntau qauv, qee qhov ntawm 500 |

| Cov khoom dhau los | Muaj peev xwm ntawm 2,700 kg / h hauv PP + iav fiber ntau daim ntawv thov |

Cov kev ntsuas no qhia txog qhov ua tau zoo ntawm cov ntsia hlau ntxaib extruders piv rau cov qauv kev lag luam, ua rau lawv muaj kev ntseeg siab rau cov khoom ntim siab.

Tus nqi thiab nyiaj txiag xav txog

Tus nqi yog ib qho tseem ceeb thaum xaiv ib tug ntxaib ntsia hlau yas extruder. Cov neeg tsim khoom yuav tsum sib npaug cov nqi pib nqis peev nrog rau kev ua haujlwm ntev. Thaum cov extruders ua haujlwm siab yuav muaj tus nqi siab dua, lawv lub zog ua haujlwm tau zoo, ua haujlwm ntev, thiab txo cov kev tu ncua feem ntau ua rau qis dua tag nrho cov tswv cuab.

Factors cuam tshuam tus nqi muaj xws li:

- Screw thiab chim khoom zoo.

- Customization xav tau.

- Advanced nta xws li automated controls and monitoring systems.

Kev nqis peev hauv cov khoom zoo siab extruder los ntawm cov chaw tsim khoom muaj koob npe ua kom muaj kev ua tau zoo dua thiab muaj cov khoom seem, txo qis sijhawm thiab cov nqi kho mob.

Kev ntseeg tau thiab kev tu vaj tse

Kev ntseeg tau yog qhov tseem ceeb rau kev tswj xyuas cov khoom zoo ib yam. Twin ntsia hlau yas extruders nrog cov khoom zoo, xws li cov ntsia hlau, cov thoob, thiab cov thawv iav, muab kev ua haujlwm zoo dua thiab kev ua haujlwm zoo. Kev saib xyuas tsis tu ncua yog qhov tseem ceeb sib npaug los tiv thaiv kev ua tsis tiav ntawm lub tshuab thiab txuas lub tshuab lub neej.

Cov kev tswj xyuas tseem ceeb muaj xws li:

- Kev soj ntsuam cov txheej txheem tsis tau txheeb xyuas cov teeb meem tshwm sim thaum ntxov.

- Ua raws li kev tiv thaiv kev tiv thaiv kom tsis txhob hnav thiab tsim kua muag.

- Kev cob qhia cov neeg ua haujlwm kom paub txog cov qauv hauv cov qauv nkhaus rau kev daws teeb meem zoo.

Extruder screws thiab chims muaj kev hnav thaum lub sijhawm, uas tuaj yeem cuam tshuam cov nqi tso tawm thiab tso tawm qhov kub thiab txias. Cov neeg tsim khoom yuav tsum xav txog qhov cuam tshuam txog kev lag luam ntawm kev hloov cov khoom hnav kom muaj txiaj ntsig zoo. Xaiv lub extruder txhim khu kev qha txo qis cov kev cov nyom no, kom ntseeg tau tias kev ua haujlwm ntev ntev.

Kev soj ntsuam manufacturers thiab lwm tus neeg

Cov txheej txheem rau kev xaiv tus neeg tsim khoom muaj npe nrov

Xaiv cov neeg tsim khoom tsim nyograu ntxaib ntsia hlau yas extruders yog ib qho tseem ceeb los xyuas kom meej lub sij hawm ntev ntawm kev txhaj tshuaj molding. Reputable manufacturers qhia kev cog lus rau innovation, zoo, thiab cov neeg siv khoom txaus siab. Kev ntsuas lawv cov tswv yim thiab kev lag luam muaj kev nkag siab zoo rau lawv txoj kev ntseeg siab.

| Hom tswv yim | Kev piav qhia |

|---|---|

| Nruam Innovation | Cov tuam txhab lag luam nqis peev hauv R & D txhawm rau txhim kho kev ua tau zoo thiab kev ua haujlwm ntawm extruders, ntsib ntau yam kev lag luam xav tau. |

| Strategic Partnerships | Kev sib koom tes nrog cov neeg ua haujlwm hauv kev lag luam thiab cov chaw tshawb fawb los txhawb kev txawj ntse thiab nthuav cov ntawv thov. |

| Kev sib koom ua ke thiab kev yuav khoom | Txhim kho cov peev txheej tsim khoom thiab kev nkag mus rau kev lag luam los ntawm kev sib koom ua ke thiab kev yuav khoom. |

Cov neeg tsim khoom lag luam uas tseem ceeb rau cov tswv yim no feem ntau xa cov kev daws teeb meem zoo raws li kev lag luam xav tau. Piv txwv li, Zhejiang Jinteng Machinery Manufacturing Co., Ltd. piv txwv li no los ntawm combining advanced tsim muaj peev xwm nrog precision machining khoom. Lawv tsom mus rau kev tsim kho tshiab thiab kev tswj xyuas kom zoo ua kom muaj kev ua tau zoo thiab cov neeg siv khoom txaus siab.

Lub luag haujlwm ntawm Cov Neeg Siv Khoom Tshawb Fawb thiab Cov Ntawv Pov Thawj

Kev tshuaj xyuas cov neeg siv khoom thiab cov lus pov thawj muab kev nkag siab zoo rau cov chaw tsim khoom lub koob npe nrov thiab kev ntseeg tau ntawm cov khoom. Cov nyiaj xub thawj no qhia txog cov kev paub hauv ntiaj teb tiag tiag, pab cov neeg yuav khoom muaj peev xwm txiav txim siab paub. Kev tshuaj xyuas zoo feem ntau hais txog cov ntsiab lus tseem ceeb xws li cov khoom ruaj khov, kev ua haujlwm yooj yim, thiab kev txhawb nqa tom qab muag.

Tswv yim: Nrhiav kev tshuaj xyuas uas qhia txog kev ua haujlwm ntev thiab kev saib xyuas kev paub. Cov kev nkag siab no feem ntau qhia qhov tseeb tus nqi ntawm extruder tshaj nws qhov pib yuav khoom.

Cov ntawv pov thawj los ntawm cov kws tshaj lij hauv kev lag luam tuaj yeem ua pov thawj tus neeg tsim khoom cov lus thov. Piv txwv li, kev tawm tswv yim los ntawm cov tuam txhab uas siv cov ntsia hlau ntxaib extruders rau cov ntaub ntawv siab viscosity los yog cov txheej txheem nyuaj tuaj yeem paub meej tias lub tshuab muaj peev xwm. Ib qho qauv zoo sib xws ntawm kev tshuaj xyuas zoo qhia tau hais tias tus neeg tsim khoom cog lus rau qhov zoo thiab cov neeg siv khoom txaus siab.

Qhov tseem ceeb ntawm Warranties thiab Technical Support

Warranties thiab technical support ua lub luag haujlwm tseem ceeb hauv kev ua kom tsis muaj kev cuam tshuam ntau lawm. Kev lees paub dav dav qhia txog cov chaw tsim khoom kev ntseeg siab hauv lawv cov khoom ua haujlwm ntev thiab kev ua haujlwm.Kev txhawb nqa kev ntseeg tauminimizes downtime thiab daws cov teeb meem kev khiav hauj lwm zoo.

Cov txiaj ntsig tseem ceeb ntawm kev txhawb nqa tom qab yuav khoom muaj xws li:

- Txhim khu kev txij nkawm ua kom muaj kev ua haujlwm zoo.

- Kev nkag tau yooj yim rau cov khoom seem txo qis kev tsim khoom qeeb.

- Kev txhawb nqa kev pab txhawb nqa kev ua haujlwm tsis muaj kev cuam tshuam.

Cov neeg tsim khoom muab kev lees paub dav dav thiab cov kev pabcuam txhawb nqa qhia tau hais tias kev cog lus rau cov neeg siv khoom zoo. Piv txwv li, cov tuam txhab nruab nrog cov cuab yeej saib xyuas thiab ntsuas qib siab tuaj yeem muab cov kev kuaj mob meej thiab kev daws teeb meem sai dua. Qhov kev txhawb nqa no tsis tsuas yog txhim kho lub tshuab ua haujlwm ntev, tab sis kuj tsim kev ntseeg siab nrog cov neeg siv khoom.

Nco tseg: Ib txwm txheeb xyuas qhov muaj cov khoom seem thiab cov kev ua haujlwm ntawm pab pawg txhawb nqa ua ntej ua tiav kev yuav khoom. Cov xwm txheej no cuam tshuam rau kev ua haujlwm ntev mus ntev.

Xaiv txoj cai ntxaib ntsia hlau yas extruder suav nrog kev ntsuas kev sib raug zoo, kev hloov kho, kev ua tau zoo, tus nqi, thiab kev ntseeg tau. Cov neeg tsim khoom yuav tsum ua qhov tseem ceeb rau cov khoom lag luam muaj npe nrov nrog kev lav zoo thiab kev txhawb nqa. Zam kev txiav txim siab maj mam ua kom muaj kev vam meej mus ntev.

Tswv yim: Tsim ib daim ntawv teev cov kev xav tau thiab sib piv cov kev xaiv kom ua tau raws li kev yuav khoom.

Post lub sij hawm: May-22-2025