Twin ntsia hlau extruder tshuab muaj kev sib xyaw ua ke thiab siab dhau, ua rau nws zoo tagnrho rau kev thov cov khoom siv yas. Ib leeg ntsia hlau extruders tseem nrov rau lawv cov nqi-zoo thiab efficiency. Kev loj hlob ntawm kev lag luam qhia txog kev xav tau muaj zog, nrog rau kev lag luam xws li ntim thiab tsheb cia siab rau cov tshuab no rau kev tsim khoom loj.Twin Parallel Screw Barrel SupplierthiabTwin Screws Rau Yas Extrudersxyuas kom meej qhov tshwm sim, thaumConical Twin Ntsia Hlau Twin Ntsia Hlaudesigns txhim khu kev yooj yim.

Cov Ntsiab Cai Ua Haujlwm thiab Cov Qauv Sib Txawv

Twin Ntsia Hlau Extruder Configuration

Twin ntsia hlau extruders sivob tug intermeshing screwsuas tig ua ke hauv ib lub thoob. Cov ntsia hlau no tuaj yeem ua ke los yog tig rov qab, nyob ntawm daim ntawv thov. Cov qauv tsim tso cai rau kev sib xyaw ua ke thiab kev sib xyaw ua ke, ua rau nws tuaj yeem ua tiav ntau yam khoom siv. Cov kws tsim khoom tuaj yeem kho cov ntsia hlau txoj kab uas hla, qhov profile, thiab chim geometry los ua kom zoo tshaj qhov tso zis thiab cov khoom zoo. Modular chim kev tsim kho thiab kev tswj xyuas qib siab pab tswj qhov kub thiab txias. Cov yam ntxwv no txhim kho cov khoom sib xws thiab cov khoom siv kho tshuab, tshwj xeeb tshaj yog nyob rau hauv kev thov kev siv xws liPVC yeeb nkab ntau lawm.

Nco tseg:Lub intermeshing tsim maximizes mixing efficiency thiab txhawb nws tus kheej tu, uas txo downtime.

Ib leeg ntsia hlau Extruder tsim

Ib leeg ntsia hlau extruders muaj ib tug yooj yim tsim nrog ib tug helical ntsia hlau nyob rau hauv lub chim. Qhov kev tsim no siv tsawg dua qhov txav, ua kom yooj yim rau kev khiav lag luam thiab tswj. Cov ntsia hlau thawb cov khoom mus rau pem hauv ntej feem ntau los ntawm kev sib tsoo, uas ua haujlwm zoo rau cov khoom ntws tsis tu ncua. Internal ntsia hlau cua txias thiab ib lub duab plaub zoo li pab tswj qhov kub thiab txias thiab ua kom ruaj khov. Qhov loj me thiab kev tsim kho ncaj nraim ua rau ib qho ntsia hlau extruders raug nqi thiab tsim nyog rau cov khoom loj.

| Tsim Specification / Nqi Factor | Ib leeg ntsia hlau Extruder yam ntxwv |

|---|---|

| Simplicity hauv Design | Tsawg qhov txav chaw, yooj yim rau kev khiav lag luam thiab tswj |

| Peev thiab Cov Nqi Ua Haujlwm | Txo cov peev nyiaj thiab cov nqi kho mob |

| Zog Efficiency | Siv lub zog tsawg dua rau cov haujlwm yooj yim |

| Kev tu | Ceev disassembly thiab tu |

| Tshaj tawm | Siab rau cov ntaub ntawv yooj yim |

Material Flow thiab Mixing Mechanism

Cov khoom ntws nyob rau hauv ib tug ntxaib ntsia hlau extruder yuav luag ntws, siab ntws, thiab ntws ntws. Lub intermeshing screws tsim shear thiab kneading teebmeem, uas txhim kho kev sib tov thiab additive dispersion. Co-rotating screws txhim khu kev sib xyaw ua haujlwm thiab pab tswj cov cua sov, txo qhov kev pheej hmoo ntawm cov khoom degradation. Nyob rau hauv sib piv, ib tug ntsia hlau extruders feem ntau yog nyob rau hauv lub luag hauj lwm, uas txwv tsis pub muaj peev xwm sib tov, tab sis ua kom ruaj khov tso zis rau cov ntaub ntawv yooj yim. Screw geometry, ceev, thiab cov khoom viscosity tag nrho cov cuam tshuam ntws thiab kev sib xyaw ua haujlwm.

Degassing thiab Self-tu nta

Twin ntsia hlau extruders ua tau zoo ntawm degassing vim tias cov ntsia hlau intermeshing ua rau thaj tsam ntawm cov pa tso tawm. Qee lub tshuab txhawb kev degassing kev ua tau zoo txog li 500% piv rau ib tus qauv ntsia hlau. Kev tu tus kheej, xws li tus kheej-wiping ntsia hlau, pab tswj cov txheej txheem sib xws thiab txo qis sijhawm. Advanced filtration systems thiab precise controls extrusion parameters ntxiv txhawb cov txiaj ntsig no. Ib leeg ntsia hlau extruders muab kev tu kom yooj yim vim lawv txoj kev tsim kho yooj yim, tab sis lawv tsis phim qhov kev ua kom zoo ntawm cov ntsia hlau ntxaib.

Kev sib piv

Kev sib xyaw muaj peev xwm thiab homogeneity

Kev sib xyaw ua haujlwm zoo yog qhov tseem ceeb hauv kev ua haujlwm extrusion. Twin ntsia hlau extruders muab kev sib xyaw ua ke zoo tshaj vim lawv ob qhov sib txuas sib txuas. Cov ntsia hlau no faib tawm thiab faib cov khoom siv tau zoo, ua kom muaj qhov sib npaug ntau dua. Tus kheej-wiping mechanism ntawm cov screws tiv thaiv cov khoom tsim thiab xyuas kom meej sib tov. Hauv cov kev tshawb fawb tswj, ntxaib ntsia hlau extruders tsim cov hmoov qhuav nqus cov hmoov sib tov nrogsib xyaw uniformity thiab aerosol kev ua tau zoosib npaug los yog zoo dua li high-shear batch mixing. Cov kws tshawb fawb pom tias cov txheej txheem tsis xws li cov ntsia hlau ceev thiab tus nqi pub tsis cuam tshuam rau qhov sib xws ntawm cov khoom kawg. Qhov kev ua tau zoo no tso cai rau cov tuam txhab lag luam kom ua tiav cov khoom sib xyaw ua ke thiab cov khoom lag luam zoo ib yam, txawm tias muaj cov txheej txheem nyuaj.

Twin ntsia hlau extruders tso cai rau customization ntawm sib xyaw rog los ntawm kev kho cov ntsia hlau profiles thiab cov ntsiab lus. Qhov kev hloov pauv no ua rau kev ua kom zoo rau cov ntaub ntawv tshwj xeeb thiab kev siv, uas ua rau muaj kev cuam tshuam zoo dua thiab sib xyaw ua ke.

Peev xwm thiab Output Consistency

Kev sib xyaw ua ke thiab cov khoom tsim tawm yog qhov tseem ceeb rau kev tsim khoom lag luam. Twin ntsia hlau extruders ua tiavsiab dua tus nqithiab txheej txheem cov ntaub ntawv muaj txiaj ntsig ntau dua li cov qauv ntsia hlau ib leeg. Lawv tswj xyuas cov txheej txheem meej, uas ua rau cov khoom zoo sib xws thiab muaj qhov tsis xws luag. Cov lus hauv qab no qhia txog qhov sib txawv tseem ceeb:

| Hom Extruder | Cov yam ntxwv hla dhau | Output Consistency Yam ntxwv |

|---|---|---|

| Twin ntsia hlau extruder | Tshaj dhau ntau dua; kev ua tau zoo; zog npaum | Kev tswj cov txheej txheem meej; superior sib tov; zoo ib yam khoom zoo; tsawg qhov tsis xws luag thiab pov tseg tsawg dua |

| Ib leeg ntsia hlau extruder | Nruab nrab dhau los; yooj yim dua thiab raug nqi | Kev sib tw nrog lub siab sib xws; txwv kev sib xyaw muaj peev xwm; muaj peev xwm rau kev faib khoom tsis sib xws thiab cov khoom tsis raug |

Ib qho ntsia hlau extruders tuaj yeem muaj kev hloov pauv siab thiab cov khoom siv tsis txaus, uas tuaj yeem cuam tshuam cov khoom sib xws. Twin ntsia hlau extruders, ntawm qhov tod tes, muab kev lag luam ruaj khov thiab txhim khu kev qha, ua rau lawv zoo tagnrho rau cov khoom loj.

Cov khoom tuav thiab Flexibility

Cov khoom tuav thiab yooj yim txiav txim siab npaum li cas tus extruder yoog rau cov khoom sib txawv thiab cov qauv. Twin ntsia hlau extruders ua tau zoo hauv kev ua cov hmoov, cov khoom noj nyuaj, thiab cov khoom sib xyaw ua ke. Lawv muab kev sib xyaw ua ke zoo tshaj plaws thiab sib faib sib xyaw, ua kom muaj ntau yam viscosity, thiab suav nrog ntau yam khoom ntxiv nrog yooj yim. Cov lus hauv qab no qhia txog cov kev sib txawv no:

| Feature | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Khoom siv | Qhov zoo tshaj plaws rau pellets thiab granules | Zoo dua rau cov hmoov thiab cov khoom noj nyuaj |

| Kev sib xyaw muaj peev xwm | Txwv rau kev faib khoom sib xyaw | Superior dispersive thiab distributive mixing |

| Thaum tshav kub kub rhiab heev | Lub sijhawm nyob ntev dua | Shorter, tswj lub sij hawm nyob ntau dua |

| Additive Incorporation | Basic additive suav nrog | Kuaj cov formulations complex nrog ntau additives |

| Viscosity Range | Ntau yam txwv | Wide viscosity muaj peev xwm |

Twin ntsia hlau extruders kuj muab cov txheej txheem kev tswj kom zoo dua qub, suav nrog kev tswj xyuas qhov kub thiab txias thiab lub sijhawm nyob luv dua. Cov nta no tau txais txiaj ntsig cov ntaub ntawv kub-rhiab heev thiab cov zaub mov tsis yooj yim. Ib leeg ntsia hlau extruders tseem pheej yig thiab txhim khu kev qha rau cov pellets zoo li tab sis tsis muaj qhov yooj thiabadvanced mixing peev xwmntawm twin screw systems.

Degassing Efficiency

Degassing tshem tawm cov gases thiab ya raws ntawm cov khoom thaum lub sij hawm extrusion. Twin ntsia hlau extruders muab kev ua haujlwm zoo degassing vim lawv cov ntsia hlau intermeshing tsim, uas ua rau thaj tsam ntawm cov pa tso tawm. Cov yam ntxwv no ua pov thawj tshwj xeeb tshaj yog muaj txiaj ntsig hauv cov ntawv thov uas xav tau cov khoom lag luam siab huv lossis thaum ua cov ntaub ntawv ua rau muaj roj. Txhim kho degassing ua rau muaj qhov tsis xws luag thiab txhim kho cov khoom zoo. Ib qho ntsia hlau extruders muab qhov yooj yim degassing tab sis tsis tuaj yeem phim qhov ua tau zoo ntawm cov ntsia hlau ntxaib extruders hauv cov ntawv thov.

Kev Tu Tus Kheej thiab Kev Tu

Cov yam ntxwv tu tus kheej txo qis qis thiab ua kom yooj yim txij nkawm. Twin ntsia hlau extruders siv tus kheej-wiping ntsia hlau ua los tiv thaiv cov khoom tsim thiab txhawb kev ua haujlwm tas mus li. Kev sim cov ntaub ntawv qhia tau hais tias kev kho cov extruder tsis xws li qhov dav thiab txheej qhov siab tuaj yeem txhim kho qhov roughness thiab wettability, txhim kho kev tu tus kheej. Cov ntaub ntawv zoo li cov thermoplastic elastomers ua kom pom tus lej tu tus kheej siab, uas txhais tau hais tias kev ntxuav phau ntawv tsawg dua thiab txo nqi txij nkawm. Ib leeg ntsia hlau extruders yog ib qho yooj yim rau disassemble thiab huv si vim lawv yooj yim tsim, tab sis lawv tsis muaj tib theem ntawm automated nws tus kheej tu raws li ntxaib ntsia hlau systems.

Kev saib xyuas tsis tu ncua thiab optimized extruder nqis pab tswj kev ua haujlwm siab thiab ua kom cov cuab yeej siv tau ntev.

Kev thov kom haum

Yas Twin Ntsia Hlau Extruder Daim Ntawv Thov

A yas ntxaib ntsia hlau extruderua haujlwm rau ntau yam kev lag luam uas xav tau kev sib xyaw ua ke, kev tswj kom meej, thiab hloov tau yooj yim. Cov neeg tsim khoom siv cov tshuab no rau kev sib xyaw ua ke, masterbatch ntau lawm, kev sib xyaw polymer, thiab ua cov khoom siv rov ua dua tshiab. Cov qauv tsim qauv tso cai rau cov engineers los kho cov ntsia hlau profile rau cov khoom siv tshwj xeeb, txhim kho kev ua haujlwm thiab cov khoom zoo. Tuam txhab uas muag nyob rau hauv lub tsheb thiab kev tsim kho sectors cia siab rau ntxaib ntsia hlau extruders rau high-kev ua tau zoo Cheebtsam. Cov ntawv ceeb toom qhia txog kev txhim kho hauv kev tsim khoom thiab cov qauv zoo, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov xws li kev hloov kho yas thiab cov khoom siv rov ua dua tshiab. Lub extruder chim kev lag luam txuas ntxiv mus hloov zuj zus, nrog nce kev saws me nyuam ntxaib thiab ntau cov ntsia hlau extruders nyob rau hauv high-volume thiab precision-thov sectors xws li kws tshuaj thiab zaub mov ua.

Qhov zoo tshaj plaws siv rau ib leeg ntsia hlau Extruders

Ib leeg ntsia hlau extrudersnyob twj ywm qhov kev xaiv zoo tshaj plaws rau kev ua haujlwm yooj yim, ntim ntau lawm. Cov tshuab no ua tau zoo ntawm kev tsim cov khoom lag luam nrog cov txheej txheem qhuav, xws li cov nplej zom, cov khoom noj tsiaj yooj yim, thiab cov khoom noj txom ncauj mov. Lawv cov qauv tsim ncaj qha ua kom muaj kev saib xyuas qis thiab cov nqi khiav lag luam. Cov lus hauv qab no qhia txog cov kev siv zoo tshaj plaws:

| Yam khoom | Nyiam Extrusion Hom | Kev xav |

|---|---|---|

| Pasta | Ib leeg ntsia hlau | Yooj yim qhuav formulation, tsawg sib tov |

| Basic Pet Food | Ib leeg los yog Twin Ntsia Hlau | Ob leeg ua haujlwm, ib leeg ntsia hlau yog tus nqi zoo |

| Puffed Rice Snacks | Ib leeg ntsia hlau | Raws li qhuav input, siab throughput |

Lub chaw tsim khoom noj khoom txom ncauj ua cov pob nplej puffed pom ib qho ntsia hlau extruders zoo tagnrho rau cov zaub mov yooj yim. Txawm li cas los xij, thaum hloov mus rau cov khoom lag luam multigrain, lawv xav tau cov ntsia hlau ntxaib extruder kom zoo dua sib xyaw thiab txo cov khib nyiab.

Kev lag luam piv txwv

- Cov tuam txhab khoom noj xws li Nestlé thiab Kellogg tau nqis peev hauv cov tshuab extrusion kom tau raws li qhov xav tau loj hlob rau cov khoom noj tiav.

- Kev tsim kho thiab kev tsim tsheb yog nyob ntawm cov khoom siv extruded, nrog rau cov tuam txhab xws li Bausano thiab KraussMaffei muab cov kev daws teeb meem.

- Additive manufacturing integrates nrog extrusion rau customized ntau lawm, raws li pom nrog CEAD thiab Arburg.

- Kev tswj hwm thiab ib puag ncig kev sib tw ua rau kev siv cov khoom siv hluav taws xob zoo, biodegradable-tshaj extrusion khoom.

Kev tsim kho thev naus laus zis, suav nrog automation thiab IoT txuas, txuas ntxiv txhim kho kev tsim khoom thiab cov khoom lag luam zoo thoob plaws kev lag luam.

Kev txiav txim siab ua haujlwm

Yooj yim ntawm kev siv thiab kev cob qhia

Cov neeg ua haujlwm pom cov tshuab extruder niaj hnub siv tau yooj yim vim muaj kev tswj xyuas siab heev. Cov tshuab no tso tawm cov ntaub ntawv ntawm lub sijhawm, lub tswb, thiab cov duab kos duab, uas pab cov neeg ua haujlwm saib xyuas thiab kho cov txheej txheem sai. Kev cob qhia yuav tsum yog nyob ntawm hom extruder. Ib leeg ntsia hlau extruders muaj tus qauv tsim, yog li cov neeg ua haujlwm tshiab tuaj yeem kawm paub txog kev ua haujlwm yooj yim thiab kev daws teeb meem hauv lub sijhawm luv luv.Twin ntsia hlau extrudermuaj ntau yam nta, xws li kev tswj daim ntawv qhia thiab kev daws teeb meem rau tej thaj chaw deb, uas yuav tsum tau muaj kev cob qhia ntxiv. Tswj cov txheej txheem nrog cov txheej xwm cav thiab sau cov ntaub ntawv pab cov tswv teb rau cov txheej txheem hloov thiab tswj cov khoom zoo.

Tswv yim: Kev nqis peev hauv kev cob qhia tus neeg ua haujlwm txhim kho cov txheej txheem kev ruaj ntseg thiab txo qhov kev pheej hmoo ntawm kev ua yuam kev.

Kev tu thiab Downtime

Kev saib xyuas tsis tu ncua ua kom cov extruders khiav tau zoo thiab txuas ntxiv lawv lub neej. Lub sijhawm tu ncua txawv ntawm ib qho ntsia hlau thiab ntxaib ntsia hlau extruders. Cov lus hauv qab no qhia txog cov ntsiab lus tseem ceeb:

| Hom Extruder | Kho qhov chaw tsom | Teem caij Highlights |

|---|---|---|

| Ib leeg ntsia hlau | Pub caj pas txias, ntsia hlau / chim hnav, thrust bearing check | Roj hloov txhua 4,000-5,000 teev |

| Twin Ntsia Hlau | Screw alignment, torque tis, chim segment checks | Lub tshuab cua txias tau ntxuav txhua txhua rau lub hlis |

Cov ntaub ntawv kho mob taug qab kev tshuaj xyuas, kho, thiab hloov qhov chaw. Cov ntaub ntawv no pab pawg pom cov teeb meem tshwm sim thiab npaj kev tiv thaiv kev saib xyuas. Kev tiv thaiv kev tiv thaiv tuaj yeemtxo downtime txog li 45%thiab ntxiv xyoo rau cov khoom siv lub neej.

- Cov ntaub ntawv tu vaj tse txhawb kev daws teeb meem thiab kev teem sijhawm zoo.

- Kev tsis saib xyuas cov ntaub ntawv ua rau lub sijhawm poob ntev dua thiab rov kho dua.

Tus nqi thiab rov qab los ntawm kev nqis peev

Tus nqi thiab rov qab los ntawm kev nqis peev (ROI) ua lub luag haujlwm tseem ceeb hauv kev xaiv extruder. Extrusion molding feem ntau xav tau aqis pib nqis peevdua li lwm txoj kev, xws li txhaj tshuaj molding. Automated systems txo cov nqi zog thiab cov khoom pov tseg, txhim kho kev tsim khoom. Kev ua haujlwm tsis tu ncua kuj tseem txo qis qis qis, uas txhawb ROI rau cov haujlwm siab. Cov tuam txhab feem ntau xaiv extrusion rau cov khoom yooj yim kom txuag tau tus nqi, thaum qhov nyuaj, qhov siab-precision tej zaum yuav ua rau cov nqi siab dua hauv lwm cov txheej txheem. Kev soj ntsuam xyuas zoo ntawm cov khoom siv, kev siv cov khoom siv, thiab kev xav tau kev ua haujlwm ua kom muaj txiaj ntsig zoo tshaj plaws rau lub sijhawm ntev.

Phau ntawv txiav txim

Xaiv raws li kev xav tau kev ua haujlwm

Xaiv txoj cai extruder yog nyob ntawm kev saib xyuas kom zoo ntawm kev ua tau zoo. Muaj ntau manufacturers sivtxoj kev txiav txim siabuas muab cov techno-economic tsom xam, tus nqi kwv yees qauv, thiab AI-pab cov cuab yeej. Cov txheej txheem no pab cov neeg siv sib piv cov kev xaiv raws li tus nqi, tsim lub sijhawm, cov khoom siv, thiab cov kev xav tau tshwj xeeb hauv kev lag luam. Cov txheej txheem kev txiav txim siab ntau yam, xws li AHP, TOPSIS, thiab VIKOR, tso cai rau pab pawg los tshuaj xyuas ob qho tib si kom muaj nuj nqis thiab zoo. Kev sib tham AI chatbots tam sim no muab cov ntaub ntawv tsim nyog, kos duab los ntawm cov ntaub ntawv tshawb fawb loj los txhawb cov kev xaiv paub. Cov ntaub ntawv tshawb fawb qhia tau tias txoj hauv kev no txhim kho qhov kev txiav txim siab raug, nrog rau cov nqi kwv yees zoo sib xws nrog cov lus hais hauv ntiaj teb tiag tiag rau ntau yam khoom. Cov txheej txheem tso cai rau cov neeg siv los txiav txim siab ywj pheej los ntawm kev nthuav qhia cov ntaub ntawv nthuav dav, tsis yog tswj hwm ib qho kev daws teeb meem.

Tswv yim: Siv cov cuab yeej sib tham sib thiab cov ntaub ntawv tshawb fawb los sib piv kev ua tau zoo, tus nqi, thiab cov khoom sib raug zoo ua ntej xaiv qhov kawg.

Cov lus nug tseem ceeb los xav txog

Thaum xaiv ntawm aib leeg ntsia hlau los yog ntxaib ntsia hlau extruder, pab pawg yuav tsum tshuaj xyuas ntau yammechanical thiab kev ua haujlwm yam:

- Dab tsi yog qhov tsav thiab cov zog tiv thaiv koom nrog hauv txheej txheem extrusion?

- Qhov twg extrusion mechanism zoo tshaj plaws rau daim ntawv thov?

- Chamber tsim cuam tshuam li cas extrusion siab thiab ntws?

- Qhov hluav taws xob configuration yuav optimize cov khoom zoo?

- Puas muaj cov yam ntxwv zoo li kev sib xyaw ua ke lossis kev txhawb nqa?

- Cov khoom siv thiab cov kev ua haujlwm ua haujlwm sib cuam tshuam li cas?

| Kev txiav txim siab | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Txheej txheem Flexibility | Tsawg yoog raws, yooj yim rau kev khiav lag luam thiab tswj | Hloov tau yooj yim dua, txhawb kev sib txawv ntawm kev sib txawv |

| Tus nqi pib | Tsawg tus nqi yuav khoom | Kev nqis peev ntau dua |

| Tus nqi ua haujlwm | Txo kev siv hluav taws xob thiab cov nqi tu | Kev ua haujlwm siab dua thiab cov nqi kho mob |

| Kev Ua Tau Zoo | Kev tswj tau yooj yim dua, qis dua complexity, qis tso zis | Kev sib tw ntau dua, sib xyaw kom zoo dua, txhim kho cov khoom zoo |

| Khoom Compatibility | Haum rau ntau yam khoom siv | Zoo dua rau cov txheej txheem nyuaj thiab cov txheej txheem siab heev |

Cov kws tshaj lij hauv kev lag luam pom zoo kom txheeb xyuas cov hom phiaj tsim khoom, tag nrho cov nqi, thiab cov khoom xav tau. Kev sab laj nrog cov kws tshaj lij tuaj yeem pab xyuas kom cov extruder xaiv tau raws li qhov xav tau tam sim no thiab yav tom ntej.

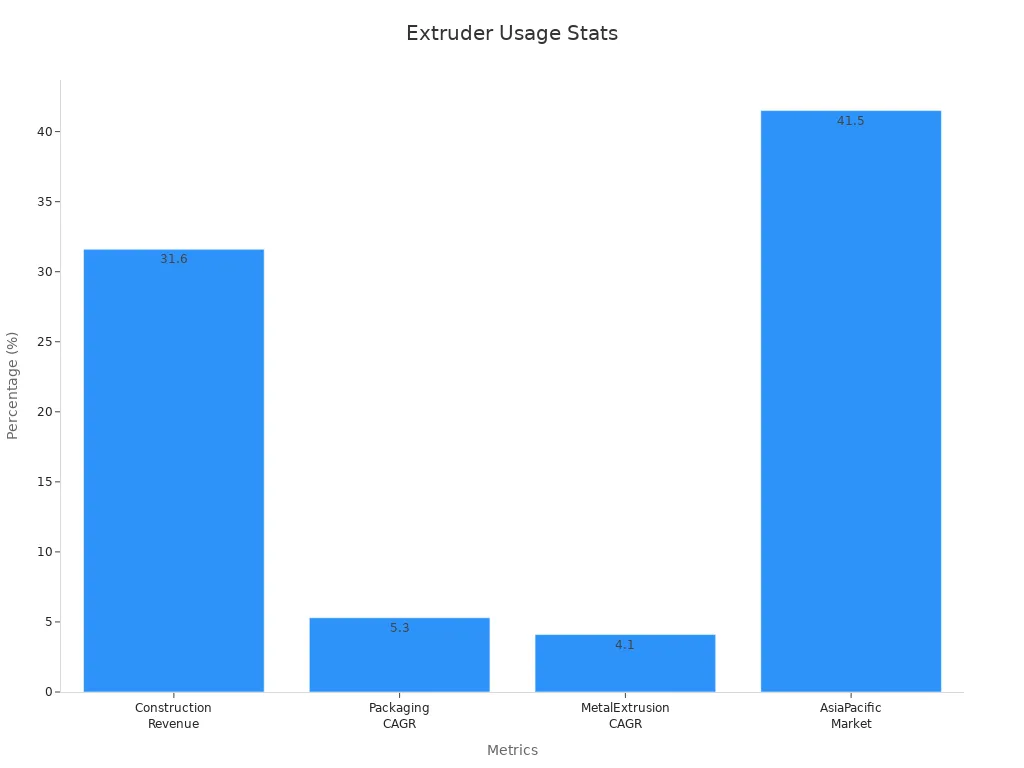

Twin ntsia hlau extruder technologytxhawb kev sib xyaw ua ke thiab hloov tau yooj yim rau kev ua cov yas nyuaj. Ib leeg ntsia hlau extruders tseem zoo tagnrho rau cov haujlwm yooj yim, ntim siab. Cov ntaub ntawv kev lag luam qhia tau hais tias qhov kwv yees 6% CAGR rau ntxaib ntsia hlau extruders, xav txog kev xav tau muaj zog thiab kev lag luam dav dav.

| Yam | Trend/Implication |

|---|---|

| Market CAGR | 6% (2024-2033) |

| Kev lag luam kev siv | Plastics, zaub mov, tshuaj, tshuaj |

| Yam khoom | Co-rotating ntxaib ntsia hlau extruders coj txoj kev loj hlob |

FAQ

Cov ntaub ntawv dab tsi tuaj yeem ua cov txheej txheem yas ntxaib ntsia hlau extruder?

A yas ntxaib ntsia hlau extruderua haujlwm polyethylene, polypropylene, PVC, ABS, thiab engineering yas. Nws txhawb kev sib xyaw ua ke, sib xyaw, thiab tsim cov masterbatch rau ntau yam kev lag luam.

Yuav ua li cas lub ntxaib ntsia hlau extruder txhim kho kev sib xyaw piv rau ib qho ntsia hlau extruder?

Twin ntsia hlau extruders siv intermeshing screws. Cov ntsia hlau no tsim muaj zog shear thiab kneading zog. Qhov kev txiav txim no ua kom zoo dua ntxiv cov khoom tawg thiab cov khoom sib xws.

Puas yog lub tshuab ntxaib ntsia hlau extruder haum rau cov khoom siv rov ua dua tshiab?

Yog lawm. Twin ntsia hlau extruder tshuab txheej txheemcov yas rov ua dua tshiabua tau zoo. Lawv muab kev tswj xyuas qhov kub thiab txias thiab kev sib xyaw ua ke, uas txhim kho qhov zoo ntawm cov khoom siv rov ua dua tshiab.

Post lub sij hawm: Jun-26-2025