Ib leeg ntsia hlau extrusion siv ib zaug tig ntsia hlau, thaum ntxaib ntsia hlau extrusion cia siab rau ob lub ntsiab lus sib txuas rau kev sib xyaw kom zoo. Qhov sib txawv no cuam tshuam cov khoom zoo thiab kev tswj cov txheej txheem. Rau kev yooj yim, ntim ntau lawm, aIb leeg ntsia hlau ntsia hlausuits feem ntau xav tau.Twin Ntsia Hlau Extruder BarrelsthiabTwin Screws Rau Yas Extruderszoo nyob rau hauv complex mix.

Ib leeg ntsia hlau Extrusion piav

Ib leeg ntsia hlau Extrusion ua haujlwm li cas

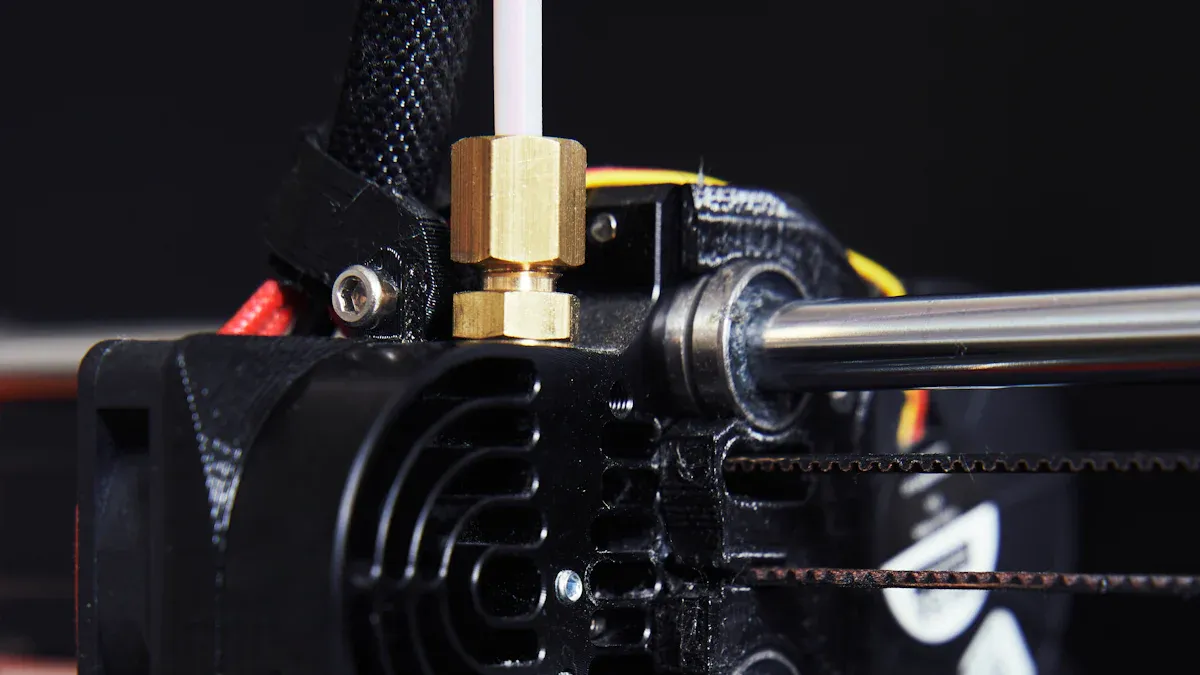

Ib leeg ntsia hlau extrusion siv ib zaug tig ntsia hlau nyob rau hauv ib tug rhuab chim chim. Cov ntsia hlau txav cov yas los yog cov khoom siv roj hmab rau pem hauv ntej, qhov kev sib txhuam thiab kub yaj nws. Cov khoom siv melted dhau los ntawm kev tuag los ua ib qho kev txuas mus tas li. Cov neeg khiav dej num tswj cov txheej txheem tseem ceeb xws li chim kub (feem ntau 160-180 ° C), ntsia hlau ceev, thiab tuag kub. Lub chav tsev nqa ceev thiab dej tank kub pab tswj cov khoom kawg ntawm txoj kab uas hla thiab txias. Cov ntsia hlau ua haujlwmPeb lub luag haujlwm tseem ceeb: conveying, melting, thiab mixing. Barrel tsimnta zoo li tawv tempering thiab chrome plating txo kev sib txhuam thiab ua kom zoo, ua kom cov haujlwm du.

Qhov zoo ntawm Single Screw Extrusion

Cov neeg tsim khoom xaivib leeg ntsia hlau extrusionrau nws simplicity thiab nqi-effectiveness. Tus tsim tso cai rau kev ua haujlwm yooj yim thiab txij nkawm. Kev nqis peev qis dua thiab cov nqi khiav lag luam ua rau nws txaus nyiam rau ntau lub lag luam.Zog efficiencystands, raws li lub system siv optimized cua sov thiab tsawg tsiv qhov chaw. Cov neeg ua haujlwm tuaj yeem ua tiav cov khoom zoo ib yam los ntawm kev kho qhov kub, siab, thiab ntsia hlau ceev. Lub kaw lus tswj hwm ntau yam khoom siv raw, ua rau nws muaj ntau yam rau kev xav tau ntau lawm.

Tswv yim: Kev saib xyuas tsis tu ncua thiab kev saib xyuas lub zog ntawm lub sijhawm tuaj yeem txhim kho kev ua tau zoo thiab cov khoom zoo.

Cov kev txwv ntawm Single Screw Extrusion

Ib leeg ntsia hlau extrusion ntsib qee qhov kev sib tw. Kev xa tawm tuaj yeem ua tsis ruaj khov ntawm cov ntsia hlau siab ceev, txwv cov nqi tsim khoom. Kev tuav cov khoom kub thiab cov khoom sib xws tuaj yeem nyuaj, tshwj xeeb tshaj yog nrog cov ntaub ntawv nyuaj. Cov txheej txheem yuav tawm tsam nrog kev sib xyaw ua ke lossis cov qauv tsim uas xav tau kev tswj xyuas meej. Pub tus cwj pwm thiab dhau los kuj yog nyob ntawm ntau yam ntawm cov ntsia hlau tsim thiab pub qhib geometry.

Cov ntawv thov ib leeg ntsia hlau Extrusion

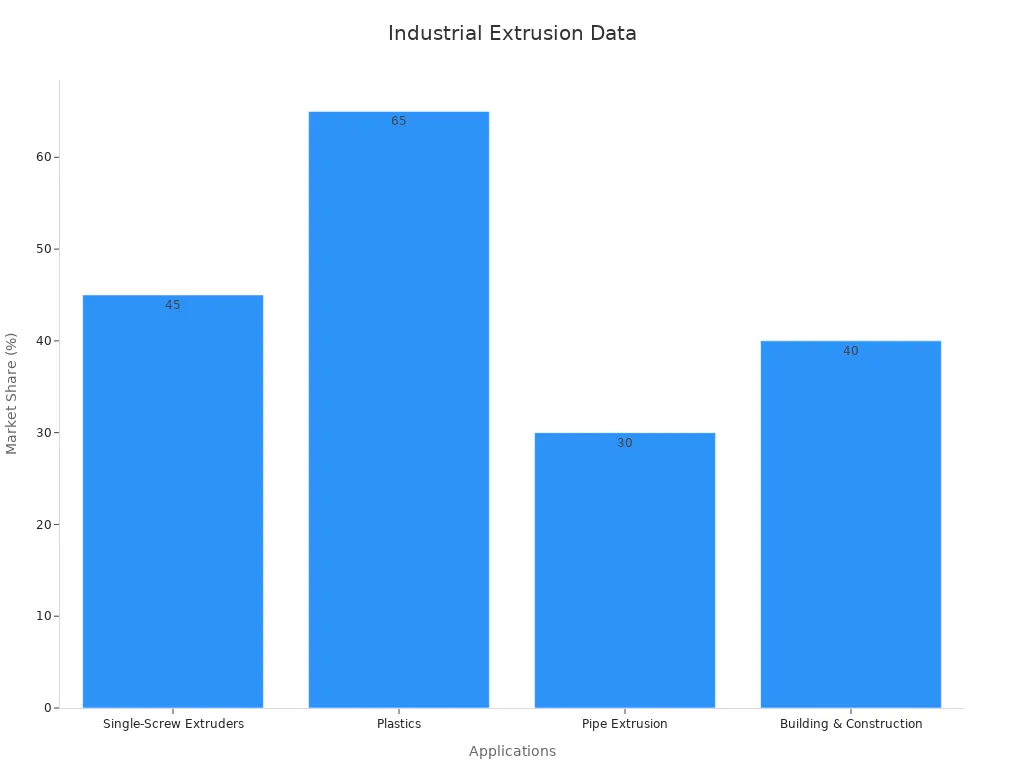

Ib leeg ntsia hlau extrusion pom siv nyob rau hauv ntau industries. Ntim ua lag luam, nrog txog 60% sib koom, tsim cov yeeb yaj kiab thiab cov ntawv los ntawm cov khoom siv polymers xws li PE, PP, thiab PVC. Kev tsim kho siv nws rau cov kav dej thiab cov profiles, thaum cov tuam txhab tsheb tso siab rau nws rau sab hauv thiab sab nrauv. Kev kho mob, cov khoom siv, thiab kev lag luam hluav taws xob kuj tau txais txiaj ntsig los ntawm cov thev naus laus zis no.

| Hom qauv | Ntsia Hlau Diameter (mm) | L:D Ratio | Lub cev muaj zog (kW) | Cov zis muaj peev xwm (kg / h) | Cov Lus Qhia Txog Kev Ua Tau Zoo thiab Cov Qauv |

|---|---|---|---|---|---|

| High Efficient Ib Screw | 60-120 : kuv | 38:1 ua | 110-315 : kuv | 465-1300 Nws | 20-30% tus nqi siab dua; Siemens AC motors, CE tau ntawv pov thawj |

| Ib txwm Standard Ib Screw | 60-120 : kuv | 33:1 ib | 55-315 : kuv | 150-900 Nws | Standard zoo Cheebtsam |

Twin Screw Extrusion Txheej txheem cej luam

Yuav Ua Li Cas Twin Screw Extrusion Ua Haujlwm

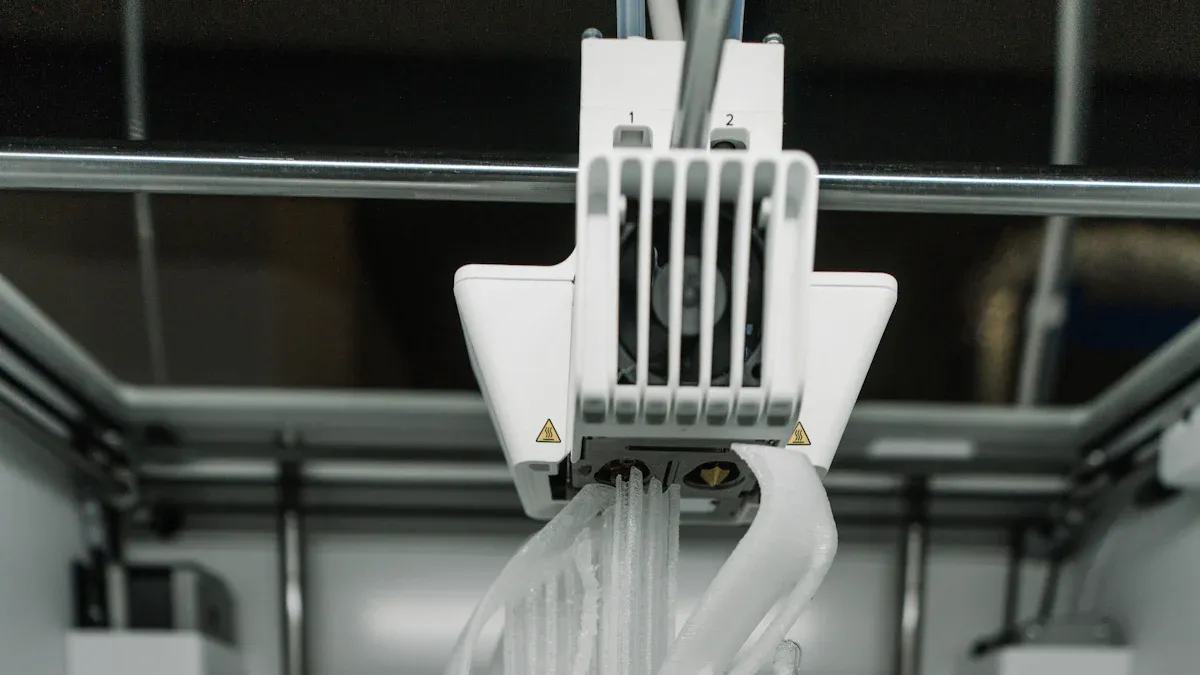

Twin ntsia hlau extrusionsiv ob lub intermeshing screws uas tig mus rau hauv ib lub thoob rhuab. Cov neeg ua haujlwm pub cov khoom nyoos xws li pellets lossis hmoov rau hauv lub plhaw. Cov screws txav cov khoom rau pem hauv ntej, compressing thiab kneading nws. Thaum tshav kub kub los ntawm lub thoob thiab kev sib txhuam los ntawm cov screws yaj cov khoom. Tshwj xeeb ntsia hlau ntsiab sib tov thiab homogenize lub yaj, kom ntseeg tau tias txawm dispersion ntawm additives. Cov khoom molten ces dhau los ntawm kev tuag los ua cov khoom kawg. Modular chim nrog cua sov thiab cua txias cheeb tsam tso cai rau kev tswj qhov kub thiab txias. Venting aav tshem tawm huab cua thiab volatiles, txhim kho cov khoom zoo.

Lub zog ntawm Twin Screw Extrusion

Twin ntsia hlau extrusion muaj ntau yam zoo:

- Superior mixing thiab homogenization vim intermeshing screws.

- Siab shear rogtxhim kho kev sib xyaw thiab cov khoom sib xws.

- Modular tsim tso cai yooj yim hloov rau cov khoom sib txawv.

- Txhim kho qhov kub thiab txias kom txo tau thermal degradation.

- High throughput thiab productivity txhawb loj-scale manufacturing.

- Flexible ntsia hlau configurations optimize ua rau ntau yam polymers.

- Kev tswj cov txheej txheem zoo dua nrog kev ywj pheej hloov ntawm cov ntsia hlau ceev thiab kub.

- Cov cuab yeej siv lub neej ntev dua li kev thauj khoom sib koom ntawm ob lub hau ntswj.

| Technical Aspect | Kev piav qhia |

|---|---|

| Superior Mixing & Homogenization | Intermeshing screws tsim shear thiab kneading teebmeem rau kev sib xyaw ua ke. |

| High Throughput & Productivity | Co-rotating screws pab kom ntau lawm ntau lawm thiab efficiency. |

| Ntau yam | Muaj peev xwm ua ntau hom polymers thiab complex formulations. |

Tsis muaj zog ntawm Twin Screw Extrusion

- Twin ntsia hlau extruders muaj ib tug complex qauv thiab tus nqi siab dua.

- Qhov ntws ntawm cov khoom hauv lub extruder yog qhov nyuaj rau kev ua qauv thiab kwv yees.

- Kev hloov pauv siab tuaj yeem tshwm sim vim qhov ntsuas qhov ntsuas qhov ntsuas.

- Kev soj ntsuam particle loj thiab txheej txheem kev ruaj ntseg nthuav qhia cov teeb meem.

- Scaling los ntawm lab mus rau ntau lawm yuav tsum tau ceev faj hloov.

Feem ntau siv rau Twin Screw Extrusion

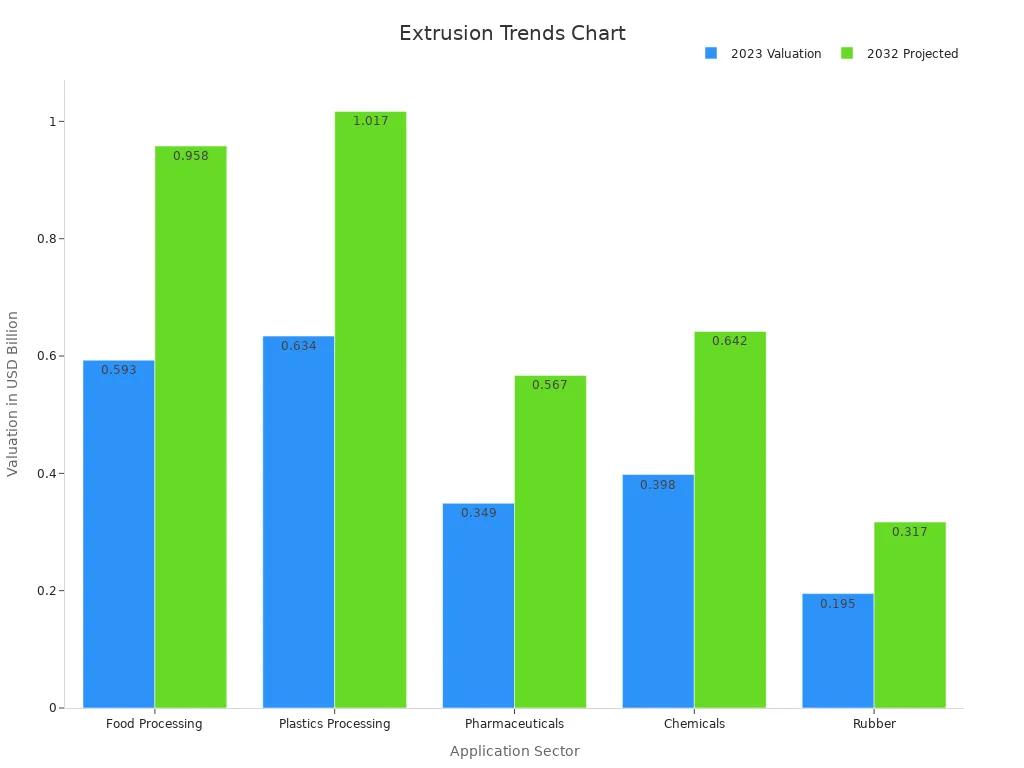

Twin ntsia hlau extruders ua lub luag haujlwm tseem ceeb hauv ntau qhov kev lag luam. Cov neeg tsim khoom siv lawv rau kev sib xyaw plastics, ua cov khoom siv rov ua dua tshiab, thiab tsim cov khoom siv bioplastics. Kev lag luam zaub mov cia siab rau lawv rau khoom noj txom ncauj, cereals, thiab tsiaj noj. Cov tuam txhab lag luam siv cov ntsia hlau ntxaib extrusion los ua cov ntaub ntawv ntau npaum li cas. Chemical thiab roj hmab sectors kuj tau txais txiaj ntsig los ntawm lawv cov kev sib xyaw thiab kev tswj xyuas. Kev ua lag luam rau ntxaib ntsia hlau extruders txuas ntxiv mus, tau tsav los ntawm kev thov hauv Asia-Pacific, Europe, thiab North America.

Ib leeg ntsia hlau Extrusion vs Twin Ntsia Hlau Extrusion: Qhov tseem ceeb sib piv

Tsim thiab Mechanism Qhov txawv

Ib leeg ntsia hlau extrusionsiv ib tug rotating ntsia hlau nrog ib tug yooj yim helical qauv. Qhov kev tsim no thawb cov khoom mus rau pem hauv ntej ntawm lub thoob. Nyob rau hauv sib piv, ntxaib ntsia hlau extruders feature ob intermeshing screws. Cov ntsia hlau no tuaj yeem tig rau hauv tib qho lossis cov lus qhia rov qab thiab feem ntau suav nrog kneading blocks kom zoo dua sib xyaw. Cov lus hauv qab no qhia txog qhov tseem ceeb ntawm kev sib txawv:

| Yam | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Ntsia Hlau Tsim | Tib rotating ntsia hlau nrog ib qho yooj yim helical qauv thawb khoom rau pem hauv ntej. | Ob tug intermeshing screws, tejzaum nws co- los yog counter-rotating, nrog complex geometry nrog rau kneading blocks. |

| Kev sib xyaw muaj peev xwm | Haum rau homogeneous cov ntaub ntawv thiab sib tov yooj yim. | Superior mixing vim intermeshing screws, enabling zoo dispersion ntawm additives thiab muab tub lim. |

| Kev Tshaj Tawm & Tso Tawm | Feem ntau qis throughput thiab tso zis tus nqi. | Higher throughput thiab tso zis, haum rau loj-scale ntau lawm. |

| Kev Tswj Kub Kub | Yooj yim tswj qhov kub, ntsia hlau ceev, thiab chim siab. | Txhim khu kev tswj qhov kub thiab txias nrog cov cua sov sab hauv / cua txias ntawm lub thoob. |

| Khoom siv | Siv tau rau cov thermoplastics, elastomers, thiab cov khoom siv rov ua dua tshiab nrog cov khoom zoo sib xws. | Zoo dua haum rau high-viscosity, tshav kub-sensitive, thiab complex formulations yuav tsum tau tswj meej. |

| Txheej txheem Flexibility | Tsawg yoog raws, kev ua haujlwm yooj yim thiab kev saib xyuas. | Kev hloov pauv ntau dua vim yog kev tsim qauv ntawm cov ntsia hlau modular thiab adjustable tsis. |

| Degassing muaj peev xwm | Tsawg degassing thiab devolatilization muaj peev xwm. | Siv tau zoo degassing thiab devolatilization, tseem ceeb rau kev tswj kom zoo. |

| Piv txwv daim ntawv thov | Yas zaj duab xis, kav dej, compounding, hlau txheej, ntawv extrusion, ua zaub mov. | Polymer compounding, khoom noj khoom haus, tshuaj, thiab complex cov ntaub ntawv ua. |

Cov kws tshawb fawb zoo li Shen et al. thiab Sastrohartono et al. tau pom tias ntxaib ntsia hlau extruders muaj ntau yam kev tsim qauv, xws li zoo shear flux thiab zog efficiency, tshwj xeeb tshaj yog rau cov ntaub ntawv complex.

Kev sib xyaw thiab kev ua haujlwm muaj peev xwm

Kev sib xyaw thiab kev muaj peev xwm ua tau teeb tsa ob lub thev naus laus zis sib nrug. Ib qho ntsia hlau extrusion ua haujlwm zoo rau cov ntaub ntawv yooj yim, homogeneous. Nws tuaj yeem tuav cov haujlwm sib xyaw ua ke, tab sis tawm tsam nrog kev sib xyaw ua ke lossis cov qauv tsim uas xav tau kev tswj xyuas meej. Twin ntsia hlau extruders ua tau zoo hauv kev sib xyaw. Lawv intermeshing screws tsim muaj zog shear thiab kneading teebmeem. Qhov kev txiav txim no xyuas kom meej txawm tias dispersion ntawm additives thiab fillers, uas yog ib qho tseem ceeb rau cov khoom zoo. Cov neeg khiav dej num tuaj yeem kho cov ntsiab lus ntawm lub tog raj kheej thiab cov kav dej kom zoo rau cov txheej txheem rau cov khoom sib txawv. Raws li qhov tshwm sim, ntxaib ntsia hlau tshuab txhawb nqa cov zaub mov tsis yooj yim thiab xav tau ntau lawm.

Lus Cim: Rau cov tuam txhab lag luam uas yuav tsum tau muab ntau yam polymers los yog ntxiv cov fillers, ntxaib ntsia hlau extruders muab qhov txiaj ntsig zoo hauv kev sib xyaw ua haujlwm.

Kev ua haujlwm thiab kev ua haujlwm

Kev xa tawm thiab kev ua tau zoo ua lub luag haujlwm tseem ceeb hauv kev xaiv ntawm cov tshuab no. Ib qho ntsia hlau extrusion feem ntau muab qis dua, ua rau nws tsim nyog rau cov hom phiaj me me. Nws ua haujlwm ntawm kev ua haujlwm qeeb qeeb thiab muab cov txiaj ntsig zoo ib yam rau cov khoom lag luam. Twin ntsia hlau extruders, ntawm qhov tod tes, ua tiav cov kev sib tw siab dua thiab ua kom nrawm dua. Lawv txhawb nqa loj muaj peev xwm yuav tsum tau thiab tswj cov khoom zoo txawm tias complex granulation. Cov lus hauv qab no piv cov metrics tseem ceeb:

| Metric | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Tshaj tawm | Lower throughput, haum rau cov hom phiaj ntau lawm | Higher throughput, haum rau loj muaj peev xwm yuav tsum tau |

| Kev ceev ceev | Kev ua haujlwm qeeb qeeb | Kev ua haujlwm ceev dua |

| Khoom Zoo | Tsawg sib tov siv, tsawg dua complex granulation | Kev sib xyaw ua kom zoo, txhawb nqa cov granulation nyuaj |

| Cov Nqi Ua Haujlwm | Cov nqi ua haujlwm qis dua vim qhov yooj yim thiab lub zog ua haujlwm | Cov nqi ua haujlwm siab dua vim qhov nyuaj thiab kev saib xyuas |

| Yooj yim | Tsawg yoog raws, kev ua haujlwm yooj yim dua | Kev hloov pauv ntau dua, tuaj yeem ua cov txheej txheem nyuaj |

| Tus nqi tso zis | Feem ntau qis tso zis tus nqi | Cov zis ntau dua |

Twin ntsia hlau extruders feem ntau pom zoo rau lawv cov nqi ua haujlwm siab dua nrog cov khoom tsim tau ntau dua thiab muaj peev xwm los daws cov ntaub ntawv nyuaj dua.

Flexibility thiab Versatility

Flexibility thiab versatility yog qhov tseem ceeb rau kev tsim khoom niaj hnub. Ib leeg ntsia hlau extrusion muab kev ntseeg tau zoo rau cov khoom siv thiab cov khoom siv. Txawm li cas los xij, nws muaj qhov hloov pauv yooj yim thaum hloov pauv ntawm cov qauv sib txawv lossis hom khoom. Twin ntsia hlau extruders sawv tawm hauv cheeb tsam no. Ntawm K 2016 kev lag luam yeeb yam, cov kab ntxaib ntxaib txuas ntxiv tau pom kev hloov pauv sai ntawm cov ntaub ntawv, xim, thiab thicknesses. Qee lub tshuab tau hloov cov qauv hauv feeb, tsis yog teev. Cov extruders ua cov txheej txheem ntau txheej nrog txog 11 txheej, tuav cov ntaub ntawv zoo li EVOH, nylon, thiab ntau qib polyethylene. Cov ntaub ntawv tsim tawm tau pom ib45.8% txo cov khoom pov tsegthiab ze li ntawm 29% kev txuag hluav taws xob tom qab kev txhim kho kom hloov kho cov ntsia hlau ntxaib. Lub sijhawm rov qab los ntawm kev nqis peev kuj tseem luv dua li 26%. Cov kev txhim kho no qhia txog kev ua haujlwm zoo ntawm ntxaib ntsia hlau extruders nyob rau hauv complex, ntau yam khoom ib puag ncig.

Cov nqi thiab kev saib xyuas

Tus nqi thiab kev saib xyuas cuam tshuam qhov kev txiav txim zaum kawg rau ntau lub tuam txhab. Ib leeg ntsia hlau extrusion tshuab raug nqi tsawg dua los yuav thiab ua haujlwm. Lawv cov qauv tsim yooj yim txhais tau tias tsawg dua qhov chaw kom tswj tau thiab txo qis kev siv zog. Kev saib xyuas niaj hnub yog ncaj nraim, thiab lub sijhawm poob qis tseem tsawg. Twin ntsia hlau extruders xav tau kev nqis peev ntau dua. Lawv cov qauv complex thiab cov yam ntxwv siab heev ua rau muaj kev xav tau kev saib xyuas thiab kev siv zog ntau dua. Txawm li cas los xij, rau cov tuam txhab tsim cov khoom lag luam muaj txiaj ntsig zoo lossis cov khoom lag luam nyuaj, cov txiaj ntsig ntawm kev hloov pauv tau yooj yim, dhau los, thiab ua tau zoo feem ntau tshaj cov nqi ntxiv. Kev xaiv qhov system yog nyob ntawm qhov ntsuas qhov ntsuas no nrog cov hom phiaj tsim khoom thiab pob nyiaj siv.

Xaiv txoj cai Extruder rau koj xav tau

Khoom haum

Xaiv txoj cai extruder pib nrog kev nkag siab cov ntaub ntawv sib xws. Cov tshuab tseem ceeb xws lintsia hlau ceev, txoj kab uas hla, thiab ntev-rau-inch ratiocuam tshuam zoo npaum li cas cov extruder ua cov khoom sib txawv. Piv txwv li, ntau dua L / D piv pab nrog cov ntaub ntawv nyuaj uas xav tau kev sib xyaw ua ke thiab sib xyaw. Lub thoob tsim, suav nrog thaj chaw kub thiab qhov cua, txhawb nqa cov ntaub ntawv rhiab lossis siv dua tshiab. Cov txheej txheem kev lag luam pom zoo kom sib piv cov extruder rau cov khoom ua haujlwm kub, viscosity, thiab ntws tus nqi. Ib qho ntsia hlau extrusion ua haujlwm zoo rau kev ua haujlwm loj ntawm cov thermoplastics, thaum ntxaib ntsia hlau extruders tuav cov qauv tsim hauv cov zaub mov, tshuaj, thiab kev lag luam polymer.

Ntau lawm Scale thiab tso zis

Kev tsim cov nplai thiab cov khoom tsim tawm ua lub luag haujlwm tseem ceeb hauv kev xaiv extruder. Cov zis ntau dua tuaj yeem ua rau muaj kev siv zog thiab kev xav tau kev saib xyuas. Modular ntsia hlau configurations cia rau zoo scalability thiab kev ua tau zoo. Kev tshawb fawb qhia tiasthroughput thiab sau qib cuam tshuam cov khoom zoo thiab sib tov efficiency. Cov extruders loj dua yuav tsum tau ua tib zoo hloov kho ntawm kev ua haujlwm tsis zoo kom muaj txiaj ntsig zoo ib yam. Cov tuam txhab yuav tsum sib npaug cov hom phiaj tsim khoom nrog cov nqi ua haujlwm thiab kev ua haujlwm nyuaj.

Cov Nyiaj Txiag thiab Cov Nqi Them Nqi

Cov nqi txiav txim siab suav nrog ob qho tib si ua ntej thiab cov nuj nqis tsis tu ncua. Cov lus hauv qab no qhia txog tus nqi tseem ceeb:

| Nqi Factor | Kev piav qhia | Kev cuam tshuam nyiaj txiag |

|---|---|---|

| Kev yuav khoom pib | Nws txawv ntawm qhov loj thiab hom | Kev nqis peev tseem ceeb |

| Daim ntawv pov thawj | ISO 9001, CE, thiab lwm yam. | Tej zaum yuav nce tus nqi yuav khoom |

| Kev tu | Kev pabcuam tsis tu ncua | Cov nqi them txhua xyoo tsis tu ncua |

| Kev siv hluav taws xob | Cov qauv siv tau zoo txuag cov nqi mus sij hawm ntev | Siab dua pem hauv ntej, qis dua txhua hli |

| Kev cob qhia | Xav tau kev ua haujlwm kom raug | 1-3% ntawm tus nqi yuav khoom |

Cov neeg tsim khoom hauv Asia-Pacific feem ntau tau txais txiaj ntsig los ntawm cov nqi ua haujlwm qis dua vim qhov zoo hauv cheeb tsam.

Daim ntawv thov-raws li cov lus pom zoo

Thaum twgxaiv qhov system extrusion, cov tuam txhab yuav tsum xav txog qhov ntim ntau lawm, cov khoom lag luam yooj yooj yim, thiab cov kev xav tau zoo. Rau cov khoom siv yooj yim thiab kev khiav me me, ib qho ntsia hlau extrusion muab kev yooj yim thiab cov nqi qis dua. Twin ntsia hlau extruders haum cov ntim siab, txoj haujlwm, lossis cov khoom lag luam tshiab uas xav tau kev sib xyaw ua ke thiab hloov tau yooj yim. Kev lag luam xws li tsheb, khoom noj khoom haus, thiab tshuaj feem ntau nyiam ntxaib ntsia hlau tshuab rau lawv cov khoom siv ntau yam thiab cov khoom zoo. Cov tuam txhab lag luam tsom rau kev lag luam sib txawv tuaj yeem hloov mus rau ntxaib ntsia hlau extrusion kom ua tiav cov khoom tshwj xeeb.

- Twin ntsia hlau extrudersiv ob lub hau ntswj kom zoo sib xyaw thiab cov khoom siv ruaj khov.

- Lawv tuav ntau hom khoom siv thiab muab kev tsim khoom ntau dua.

- Ib qho ntsia hlau extrusion ua haujlwm zoo tshaj plaws rau cov ntaub ntawv yooj yim, qis-viscosity.

- Rau cov khoom lag luam nyuaj lossis kev ua haujlwm siab dua, cov tuam txhab yuav tsum xaiv cov ntsia hlau ntxaib extruders.

FAQ

Dab tsi yog qhov txawv ntawm ib leeg ntsia hlau thiab ntxaib ntsia hlau extrusion?

Ib qho ntsia hlau extrusion siv ib lub ntsia hlau rau kev ua haujlwm yooj yim. Twin ntsia hlau extrusion siv ob lub hau ntswj kom zoo dua sib xyaw thiab tuav cov ntaub ntawv nyuaj.

Dab tsi yog extruder ua haujlwm zoo tshaj plaws rau kev rov ua dua cov yas?

Twin ntsia hlau extruders tuav cov yas siv dua tshiab zoo dua. Lawv muab kev sib xyaw thiab kev tswj kom zoo dua qub, uas txhim kho cov khoom zoo.

Kev saib xyuas zoo li cas sib piv ntawm ob hom?

Ib leeg ntsia hlau extruder xav tau kev saib xyuas tsawg dua.Twin ntsia hlau extruders xav tau kev saib xyuas ntxivvim lawv cov qauv tsim thiab cov khoom ntxiv.

Lub sij hawm xa tuaj: Plaub Hlis-08-2025