Ib leeg ntsia hlau chimua lub luag haujlwm loj hauv ntau qhov kev lag luam niaj hnub no. Cov tuam txhab lag luam hauv kev tsim khoom yas, khoom noj khoom haus, kev lag luam roj hmab, kev ua tshuaj lom neeg, tshuaj, khoom siv rov ua dua tshiab, thiab cov khoom siv cable thiab xaim siv lawv txhua hnub. Kev ua lag luam rauntsia hlau chim rau ib leeg ntsia hlau extrudercov khoom ua kom loj hlob. Hauv 2023, kev lag luam thoob ntiaj teb tau nce mus txog $ 1.5 billion, nrog rau qhov kwv yees tus nqi ntawm $ 2.1 billion los ntawm 2032.

Nov yog saib ceev ntawm cov lej uas ua rau muaj kev loj hlob no:

| Metric | Tus nqi | Sau ntawv |

|---|---|---|

| Market Size (2023) | USD 1.5 billion | Ntiaj teb no bimetallic chim thiab ntsia hlau lag luam nrog rau ib tug ntsia hlau chim |

| Kev Ua Lag Luam Loj (2032) | USD 2.1 billion | Forecasted lag luam tus nqi |

| Compound Annual Growth Rate | 3.8% | CAGR thaum lub sijhawm kwv yees |

| Kev lag luam tseem ceeb tsav kev loj hlob | Plastic processing, neeg siv khoom, ntim, automotive | Industries vam khom rau ib leeg ntsia hlau chim vim kev thov rau cov khoom yas |

| Kev loj hlob hauv cheeb tsam tsom | Asia Pacific | Tsav los ntawm kev lag luam ceev ceev thiab nroog loj |

Ib leeg yas Screw chim Hoobkaspab pawg nyob tsis khoom raws li ib leeg ntsia hlau chim tseem nrov rau lawv txoj kev ntseeg siab thiab kev ua haujlwm zoo.

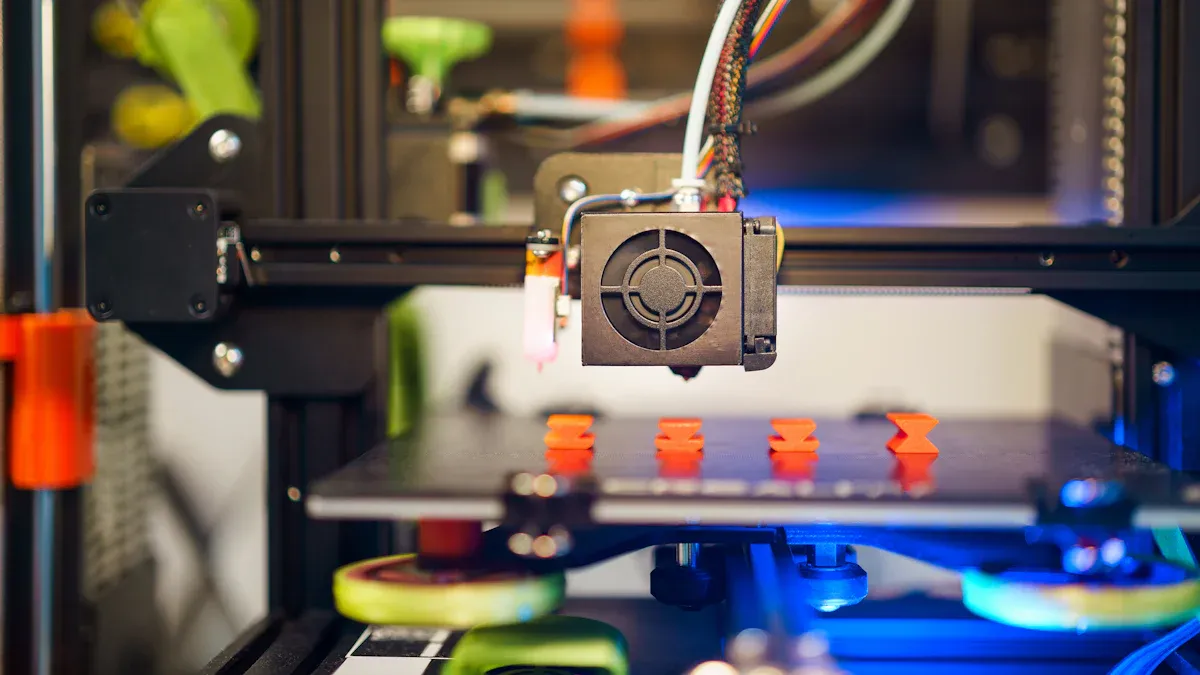

Ib Screw Barrel hauv Plastics Manufacturing

Cov ntawv thov tseem ceeb

Tib Screw Barrel technology sawv ntawm lub plawv ntawm kev tsim khoom yas. Cov tuam txhab siv cov thoob no rau ntau txoj haujlwm, xws li:

- Melting thiab conveying ntau hom polymers, nrog rau PVC, PE, thiab ABS.

- Kev tsim cov kav dej, cov yeeb yaj kiab, cov ntawv txheeb, thiab cov profiles rau kev tsim kho, ntim khoom, thiab kev lag luam tsheb.

- Kev tuav cov khoom tsis sib xws thiab cov khoom siv rov ua dua tshiab nrog lub siab ruaj khov thiab kub.

- Txhawb nqa ob qho yooj yim extrusion thiab cov txheej txheem siab heev xws li zaj duab xis tshuab thiab profile shaping.

Barrels feem ntau siv cov ntaub ntawv ua tau zoo xws li 38CrMoAlA thiab bimetallic alloys. Cov ntaub ntawv no pab lub thoob tiv taus kub, siab, thiab hnav. Kev kho deg, xws li nitriding thiab chromium-plating, ncua lub neej thiab txhim kho kev ua haujlwm.

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Lub Ib Leeg Screw Barrel coj ntau qhov zoo rau kev tsim khoom yas. Cov lus hauv qab no qhia txog qee qhov tseem ceeb thiab lawv qhov cuam tshuam:

| Yam | Paub meej thiab txiaj ntsig |

|---|---|

| Txoj kab uas hla | 16mm txog 300mm, haum rau ntau qhov ntau lawm |

| Aspect ratio (L/D) | 15 mus rau 40, boosts melting thiab mixing efficiency |

| Khoom siv | Cov hlau ruaj khov, tiv taus hnav thiab corrosion |

| Nto Hardness | High hardness, ntev-ntev nrog tshwj xeeb nto kho |

| Qauv | Yooj yim tsim, yooj yim los tswj, raug nqi zoo |

Cov thoob no tswj kub, ntws, thiab siab thaum extrusion. Lawv pab tsim cov khoom zoo ib yam. Lawv cov qauv yooj yim txhais tau tias tsawg dua kev tawg thiab cov nqi qis dua. Ntau lub chaw tsim khoom xaiv lawv rau lawv txoj kev ntseeg tau thiab hloov tau yooj yim.

Cov piv txwv tseem ceeb thiab Cov Qauv

Kev sib xyaw thiab kev tswj cov txheej txheem tau dhau los ua qhov tseem ceeb hauv kev tsim cov yas. Piv txwv li, aMaddock solidification kev simqhia tau hais tias kev sib xyaw pib li cas hauv thaj tsam melting ntawm ib qho ntsia hlau extruder. Hauv lwm qhov xwm txheej, cov tuam txhab siv ib lub taub hau taub hau los uaNylon-6 filaments nrog hlau hmoov. Lawv tau kho cov ntsia hlau ceev, qhov kub thiab txias, thiab lwm yam kev teeb tsa kom tau txais cov khoom muaj zog, zoo ib yam. Nyob rau tib lub sijhawm, ib qho ntsia hlau extruders muajevolved los ntawm cov twj yooj yim mus rau cov tshuab siab heevnrog tshwj xeeb sib xyaw seem thiab txhim kho lub thoob tsim. Cov kev hloov pauv no pab cov chaw tsim khoom ua tau raws li qhov xav tau tshiab rau kev ua tau zoo thiab kev ua haujlwm zoo.

Ib Screw Barrel hauv Kev Ua Khoom Noj

Cov ntawv thov tseem ceeb

Ib lub taub hau ntsia hlau pab cov tuam txhab ua zaub mov ua ntau yam khoom nrov. Lawv ua haujlwm zoo tshaj plaws nrog cov khoom noj uas muaj cov zaub mov yooj yim thiab xav tau kev ua haujlwm tsis tu ncua.Ntawm no yog saib ceev ntawm qhov chaw lawv ci:

| Khoom noj khoom haus qeb | Daim ntawv thov ib leeg Screw chim | Yog vim li cas thiaj tsim nyog |

|---|---|---|

| Direct-expanded khoom noj txom ncauj | Yog lawm | Nqi-zoo, yooj yim formulations |

| Pasta thiab noodles | Yog lawm | Ib txwm ua khob noom cookie, tsis muaj dej noo |

| Noj tshais cereals | No | Yuav tsum muaj kev tswj kom zoo dua qub, ntau yam pub |

| Cov khoom lag luam muaj protein (xws li TVP) | No | Yuav tsum muaj kev ntxhib los mos zoo tshaj thiab kev tswj cov khoom siv |

| Tsiaj noj | Qee zaum | Siv rau yooj yim kibble, tab sis ntxaib-ntsia hlau nyiam rau uniformity |

Cov neeg tsim khoom noj kuj tseem siv ib lub taub hau rau cov kua txiv hmab txiv ntoo, cov mov hulls, thiab tsiaj pub. Cov tshuab no tuaj yeem ua cov khoom xyaw xws li pob kws hmoov nplej, ncuav mog qab zib pluas noj, thiab txawm tias ntses pluas noj. Lawv pab txhim kho txee lub neej thiab ua zaub mov zoo dua rau tsiaj thiab tib neeg.

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Ib leeg ntsia hlau chimua lub luag haujlwm tseem ceeb hauv kev nyab xeeb khoom noj thiab zoo. Cov kev tshawb fawb tshawb fawb pom tau tias cov tshuab no tuaj yeem txo cov co toxins hauv cov nplej los ntawm kev tswj cov dej noo, pub tus nqi, thiab cov ntsia hlau ceev. Qhov no txhais tau tias muaj kev nyab xeeb dua hmoov nplej thiab khoom noj txom ncauj rau txhua tus. Cov chaw tsim khoom noj khoom haus cia siab rau tib lub taub hau rau kev sib tov, ua noj, thiab ua zaub mov. Lawv tuaj yeem ntxiv cov khoom xyaw tshiab thiab hloov cov textures, ua rau nws yooj yim dua los tsim cov khoom noj txom ncauj, pasta, thiab zaub mov tsiaj. Cov tuam txhab kuj nyiam lawv vim lawvsiv lub zog tsawg dua thiab yooj yim los tswj.

Lus Cim: Ib qho ntsia hlau ntsia hlau pab cov tuam txhab zaub mov txuag nyiaj thaum ua kom muaj kev nyab xeeb, cov khoom zoo.

Cov piv txwv tseem ceeb thiab Cov Qauv

Kev ua zaub mov hloov pauv, thiab ib lub taub hau ntsia hlau pab coj txoj hauv kev. Cov tshuab no siv cov cua sov thiab lub zog los rhuav tshem cov hmoov txhuv nplej siab thiab cov protein. Qhov no ua rau cov zaub mov yooj yim zom thiab muab cov duab zoo thiab kev ntxhib los mos. Piv txwv li, qhov kub thiab txias siab dua pab cov hmoov txhuv nplej siab ua kom zoo dua, thaum ntsia hlau ceev hloov pauv li cas du lossis crunchy cov khoom kawg xav tau. Cov tshuab tshiab tso cai rau cov tuam txhab tswj cov cua sov thiab nrawm dua, yog li lawv tuaj yeem ua cov ntses noj pellets thiab khoom noj txom ncauj uas ib txwm saib thiab saj zoo ib yam. Qhov kev tswj hwm qib no pab cov neeg tsim khoom noj kom tau raws li cov qauv tshiab thiab cov neeg siv khoom xav tau.

Ib Screw Barrel hauv Kev Lag Luam Roj Hmab

Cov ntawv thov tseem ceeb

Ib qho ntsia hlau ntsia hlau pab cov tuam txhab roj hmab ua ntau yam khoom tseem ceeb. Cov tshuab no tuav cov ntaub ntawv tawv, nplaum nplaum thiab tig mus rau hauv cov duab zoo. Nov yog qee qhov kev siv tseem ceeb:

- Ua cov ntsaws ruaj ruaj thiab gaskets rau tsheb thiab tshuab

- Ua hoses rau tsheb, factories, thiab tsev

- Tsim cov ntawv roj hmab thiab cov profiles rau lub tsev thiab kev lag luam

- Siv cov vented chim kom tshem tawm cov dej noo thiab ua kom cov roj hmab ntshiab

Roj hmab extrusion yuav siv li ntawm 30% ntawm cov khoom noj khoom haus thoob khw. Qhov no qhia tias cov tshuab no tseem ceeb npaum li cas rau kev lag luam roj hmab. Cov tuam txhab feem ntau xaiv bimetallic chim vim lawv kav ntev dua thiab ua haujlwm zoo dua nrog cov roj hmab ntxhib.

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Factories cia siab rauib leeg ntsia hlau chimkom cov khoom siv roj hmab muaj zog thiab txhim khu kev qha. Cov tshuab no yaj, sib tov, thiab zoo li roj hmab nrog lub siab thiab kub. Cov thoob tshiab siv cov khoom tshwj xeeb xws li nitride steel. Qhov no ua rau lawv tawv thiab pab lawv kav ntev dua, txawm tias thaum ua haujlwm nrog cov roj hmab tawv los yog gritty. CovAsia Pacific cheeb tsam, tshwj xeeb tshaj yog Tuam Tshoj thiab Southeast Asia, coj lub ntiaj teb no siv cov tshuab no. Kev loj hlob sai nyob rau hauv cov cheeb tsam no txhais tau hais tias xav tau ntau dua rau cov khoom siv roj hmab muaj zog thiab zoo. Cov tuam txhab kuj ua raws li cov cai nruj, zoo li ISO 9001, kom paub tseeb tias txhua yam khoom ua tau raws li cov qauv siab.

Cov piv txwv tseem ceeb thiab Cov Qauv

Kev lag luam roj hmab tau siv tib lub taub hau taub hau rau ntau tshaj ib puas xyoo. Cov tshuab thaum ntxov ua haujlwm zoo li twj, tab sis cov neeg tsim khoom sai sai ntxiv cov yam ntxwv los sib xyaw roj hmab zoo dua. Nyob rau xyoo 1920 thiab 1930s, engineers tsim cov thoob nrog serrated nto los txhim kho kev sib xyaw. Tom qab Tsov Rog Ntiaj Teb Zaum II, cov qauv tshiab suav nrogkev sib xyaw tshwj xeebthiab pins nyob rau hauv lub chim. Cov kev hloov pauv no tau pab cov chaw tsim khoom ua cov khoom siv roj hmab zoo dua, sai dua thiab tsis muaj pov tseg. Niaj hnub no, cov tuam txhab khaws cia kev txhim kho ib qho ntsia hlau chim tsim kom tau raws li cov kev xav tau tshiab hauv tsheb, kev tsim kho, thiab kev lag luam.

Ib Screw chim nyob rau hauv tshuaj ua

Cov ntawv thov tseem ceeb

Cov nroj tsuag ua tshuaj siv ib lub taub hau rau ntau txoj haujlwm tseem ceeb. Cov tshuab no pab uaPVC kav rau kev tsim kho, kav dej, thiab hluav taws xob kav. Factories kuj siv lawv rau kev lag luam piping, irrigation systems, thiab txawm cov zaub mov thiab dej haus thauj. Nov yog qee qhov kev siv tseem ceeb:

- Extruding PVC kav rau lub tsev thiab kev lag luam

- Ua cov kav dej rau tsheb hloov cov kua dej

- Ua cov kav dej chemical-resistant rau kev ua liaj ua teb thiab kev ua zaub mov

- Siv cov khoom tawv tawv nrog abrasive fillers thiab additives

Cov kws ua choj xaiv cov hlau alloy uas muaj zog heev rau cov thoob no. Lawv kho qhov chaw kom nws nyuaj, yog li nws tuaj yeem tswj tau qhov kub thiab txias. Cua sov thiab cua txias tshuab ua kom qhov kub thiab txias. Sensors saib cov txheej txheem kom paub tseeb tias txhua cov yeeb nkab tawm los muaj zog thiab du. Ntau cov nroj tsuag tau txiav lawv cov khoom seem los ntawm kev siv lub sijhawm saib xyuas thiab zoo dua cov ntsia hlau tsim.

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Factories xav tau ib lub hau ntsia hlau vim tias kev ua tshuaj lom neeg tuaj yeem nyuaj rau cov khoom siv. Abrasive fillers thiab corrosive polymers tuaj yeem hnav cov tshuab ceev ceev. Txoj cai ntsia hlau thiab lub thoob tsim kom txhua yam khiav zoo. Nta xws ligrooved feed seem thiab barrier mixing seempab yaj thiab sib tov cov khoom sib npaug. High compression ratios ua kom cov kav dej tawm muaj zog thiab sib xws. Cov kev xaiv tsim no pab tiv thaiv qhov tsis xws luag thiab khaws pov tseg kom tsawg. Cov nroj tsuag tuaj yeem siv cov thoob no nrog ntau hom polymers, ua rau lawv xaiv tau yooj yim rau ntau txoj haujlwm.

Cov piv txwv tseem ceeb thiab Cov Qauv

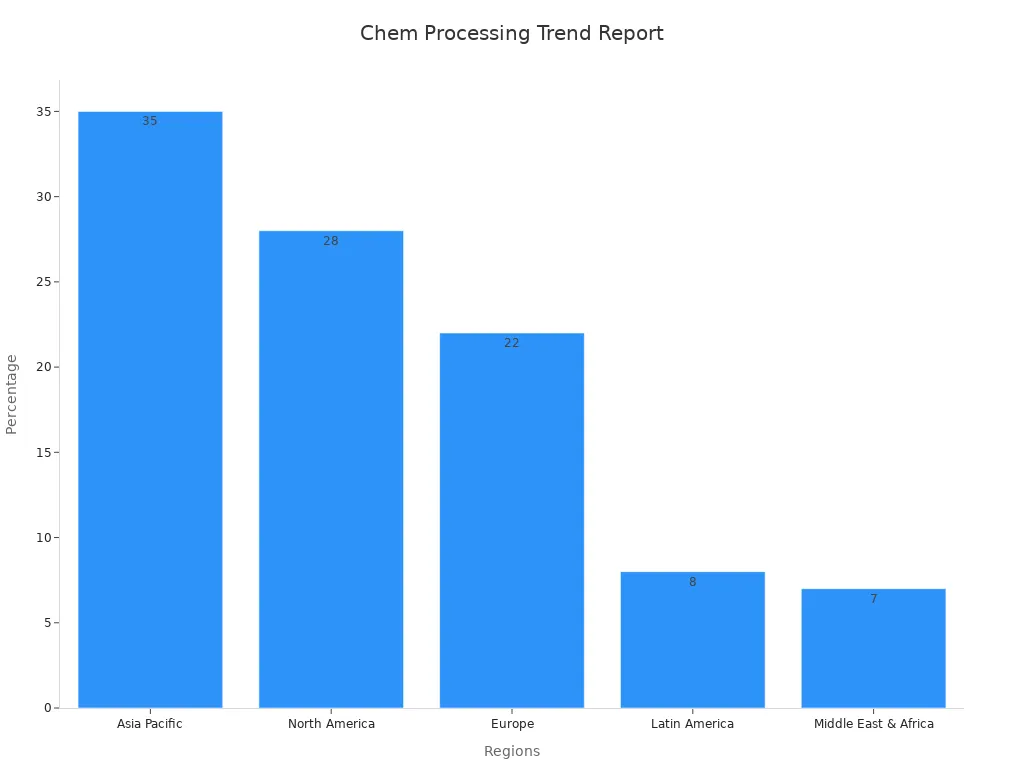

Cov ntawv ceeb toom kev lag luam qhia tau hais tias ib qho ntsia hlau pub khoom lag luam loj hlob sai. Xyoo 2024, ntu no tau muaj nuj nqis ntawm $ 840 lab thiab tuaj yeem ncav cuag $ 1.38 nphom los ntawm 2034. Cov tuam txhab xav tau cov tshuab yooj yim, txhim khu kev qha uas ua haujlwm zoo nrog cov ntaub ntawv tsis sib xws. Automation, cov ntaub ntawv tshiab, thiab cov kev daws teeb meem hauv eco-friendly yog tsav kev loj hlob. Factories tam sim no siv cov cuab yeej ntse thiab IoT rau kev saib xyuas lub sijhawm. High-kev ua tau zoo alloys thiab composite coatings yog ua nrov. Kev lag luam tshuaj lom neeg yog ib qho ntawm cov neeg siv khoom loj tshaj plaws ntawm cov thoob no, tshwj xeeb tshaj yog nyob rau hauv Asia Pacific thiab North America.

| Yam | Paub meej |

|---|---|

| Kev loj hlob sai tshaj plaws | Kev lag luam tshuaj, tau tsav los ntawm kev thov rau cov khoom siv yas thiab cov khoom siv siab heev |

| Ntsiab Lus | High-performance alloys, sustainability, nqi-efficiency |

| Kev Pabcuam Hauv Cheeb Tsam (2023) | Asia Pacific (35%), North America (28%), Europe (22%) |

| Technological Advances | Txhim kho lub thoob tsim, hnav tsis kam, saib xyuas IoT |

Ib Screw Barrel hauv Pharmaceutical Industry

Cov ntawv thov tseem ceeb

Cov tuam txhab lag luam siv cov ntsia hlau ib leeg hauv ntau txoj hauv kev tseem ceeb. Cov tshuab no pab tig hmoov thiab sib tov rau hauv cov ntaub ntawv zoo li rods, raj, los yog nyias zaj duab xis. Cov txheej txheem hu ua kub-melt extrusion. Nws siv lub rotating ntsia hlau rau hauv ib lub thoob kom sov thiab thawb cov khoom rau pem hauv ntej. Txoj kev no ua haujlwm zoo rau kev cog cov tshuaj, cov tshuaj tiv thaiv-tso tawm, thiab cov yeeb yaj kiab xa tshuaj.

- Ib leeg ntsia hlau extruderstsim cov tshuaj thiab cov khoom nqa mus rau hauv cov khoom sib xws.

- Cov tshuab muaj hluav taws xob tswj rau cov ntsia hlau ceev, qhov kub thiab txias.

- Cov tuam txhab lag luam tuaj yeem kho cov ntsia hlau ntev-rau-qhov sib piv los hloov cov khoom siv melts thiab sib tov li cas.

Cov thev naus laus zis no pab cov tuam txhab txav los ntawm cov chaw sim me me mus rau kev tsim khoom loj yam tsis tau poob zoo.

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Ib leeg ntsia hlau chimyog qhov tseem ceeb hauv kev tsim tshuaj. Lawv ua kom cov khoom txav tau yooj yim thiab pab sib tov tshuaj nrog lwm cov khoom xyaw. Qhov zoo ntawm kev sib txhuam ntawm cov ntsia hlau thiab lub thoob melts cov khoom thiab ua kom cov txheej txheem khov kho. Ntxuav cov thoob thiab cov ntsia hlau tiv thaiv cov khoom seem los ntawm kev tsim teeb meem lossis sib xyaw nrog cov khoom tshiab. Qhov no tseem ceeb heev rau kev nyab xeeb tshuaj.

Cov tuam txhab lag luam xaiv cov thoob uas ua los ntawm cov khoom muaj zog, corrosion-resistant. Cov thoob no tuaj yeem tuav cov tshuaj hnyav thiab cov hmoov gritty. Kev tu tsis tu ncua thiab ua tib zoo saib xyuas pab ua kom lub tshuab ua haujlwm zoo thiab tsis txhob raug nqi poob qis.

Tswv yim: Khaws cov ntsia hlau thiab lub thoob kom huv si pab tiv thaiv kom tsis txhob muaj kab mob thiab ua kom txhua pawg tshuaj ua tau raws li cov qauv nruj.

Cov piv txwv tseem ceeb thiab Cov Qauv

Cov tuam txhab lag luam feem ntau siv cov ntsia hlau ib leeg rautsis tu ncua ntau lawm. Txoj kev no pab lawv ua tshuaj sai dua thiab ua yuam kev tsawg dua li cov txheej txheem batch qub. Cov tshuab muaj ntau qhov chaw hauv lub thoob rau kev pub mis, compressing, thiab shaping cov khoom. Cov tuam txhab tuaj yeem hloov cov ntsia hlau tsim kom haum cov khoom sib txawv.

- Ib leeg ntsia hlau extruders ua haujlwm zoo tshaj plaws rau kev ua cov ntaub ntawv tshuaj uas xav tau kev siab ruaj khov thiab kub.

- Ntau lub tuam txhab tam sim no siv cov qauv hauv computer los kuaj seb cov hmoov nplej txav mus los ntawm cov ntsia hlau. Qhov no pab lawv nrhiav qhov chaw zoo tshaj plaws rau txhua yam khoom.

- Kev lag luam tab tom txav mus rau cov txheej txheem txuas ntxiv, siv ib lub taub hau ntsia hlau los txhim kho qhov zoo thiab cov nqi qis dua.

Ib Screw chim nyob rau hauv Recycling Industry

Cov ntawv thov tseem ceeb

Recycling nroj tsuag sivib leeg ntsia hlau chimhloov cov yas qub rau hauv cov khoom tshiab. Cov tshuab no siv ntau hom yas, xws li PE, PP, PVC, thiab PET. Lawv yaj, sib tov, thiab ua cov yas rov ua dua tshiab rau hauv pellets lossis zaj duab xis. Cov kws tsim qauv tsim cov thoob nrog cov ntaub ntawv muaj zog, xws li 38CrMoAl, thiab kho qhov chaw kom lawv nyob ntev dua. Qee lub thoob muaj cov txheej txheem tshwj xeeb uas pab lawv tiv thaiv hnav los ntawm cov khoom siv rov ua dua tshiab.

Nov yog qee qhov kev siv tseem ceeb:

- Ua cov yas pellets rau cov khoom tshiab

- Kev tsim tawmcov yeeb yaj kiab yas rov siv duathiab ntawv

- Tuav foams, fibers, thiab txawm lub raj mis yas

Ib lub rooj hauv qab no qhia qee qhov kev ua haujlwm:

| Feature | Paub meej |

|---|---|

| Txoj kab uas hla | 60-300 hli |

| L/D Ratio | 25-55 : kuv |

| Nto Hardness | HV ≥900 (nitriding) |

| Daim ntawv thov | Granulation, zaj duab xis, thiab daim ntawv ntau lawm |

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Ib leeg ntsia hlau chim ua lub luag haujlwm loj hauv kev rov ua dua tshiab. Lawv ua kom cov txheej txheem ruaj khov thiab pab tswj qhov zoo ntawm cov yas rov ua dua tshiab. Cov kws tshawb fawb tau pom tias cov tshuab no ua haujlwm zoo nrog cov khoom siv rov ua dua tshiab thiab rov ua dua tshiab. Kev tsim ntawm lub thoob thiab ntsia hlau cia cov chaw tsim khoom ua ntau hom yas yam tsis tau poob zoo. Thaum lub thoob thiab ntsia hlau cua sov, lawv nthuav dav ntawm tib tus nqi, uas ua rau txhua yam ua haujlwm zoo. Qhov no yog ib qho tseem ceeb rau kev ua kom cov yas yaj yaj ntws sib npaug thiab cov khoom kawg yuav nyob ruaj khov.

Lus Cim: Cov thoob uas ua rau rov siv dua feem ntau siv cov ntaub ntawv siab heev thiab txheej txheej. Qhov no pab kom lawv nyob ntev dua, txawm tias thaum ua haujlwm nrog cov khoom tawv tawv, qias neeg.

Cov piv txwv tseem ceeb thiab Cov Qauv

Ntau lub tuam txhab rov ua dua tshiab xaiv ib qho ntsia hlau extruders vim lawvraug nqi tsawg thiab ua haujlwm zoo nrog cov pov tseg yas ruaj khov. Qee lub tshuab, zoo li Erema Corema, siv ib qho ntsia hlau extruder los yaj thiab lim cov yas rov ua dua tshiab ua ntej xa mus rau ntxaib-ntsia hlau extruder rau kev sib xyaw ntxiv. Qhov kev teeb tsa no pab ua kom cov yas rov ua dua tshiab muaj zog dua thiab muaj txiaj ntsig zoo dua.

Cov kev xav tsis ntev los no muaj xws li:

- Siv cov cuab yeej ntse los saib xyuas thiab tswj cov txheej txheem rov ua dua tshiab

- Tsim cov thoob nrog cov qauv tsim qauv rau cov kev xav tau sib txawv

- Kev sib xyaw ib leeg thiab ntxaib-ntsia hlau extruders kom tau txais txiaj ntsig zoo dua

Ib lub taub hau ntsia hlau tseem yog qhov kev xaiv zoo tshaj plaws rau kev rov ua dua tshiab vim tias lawv ntseeg tau, hloov tau, thiab pab txhawb kev lag luam ncig.

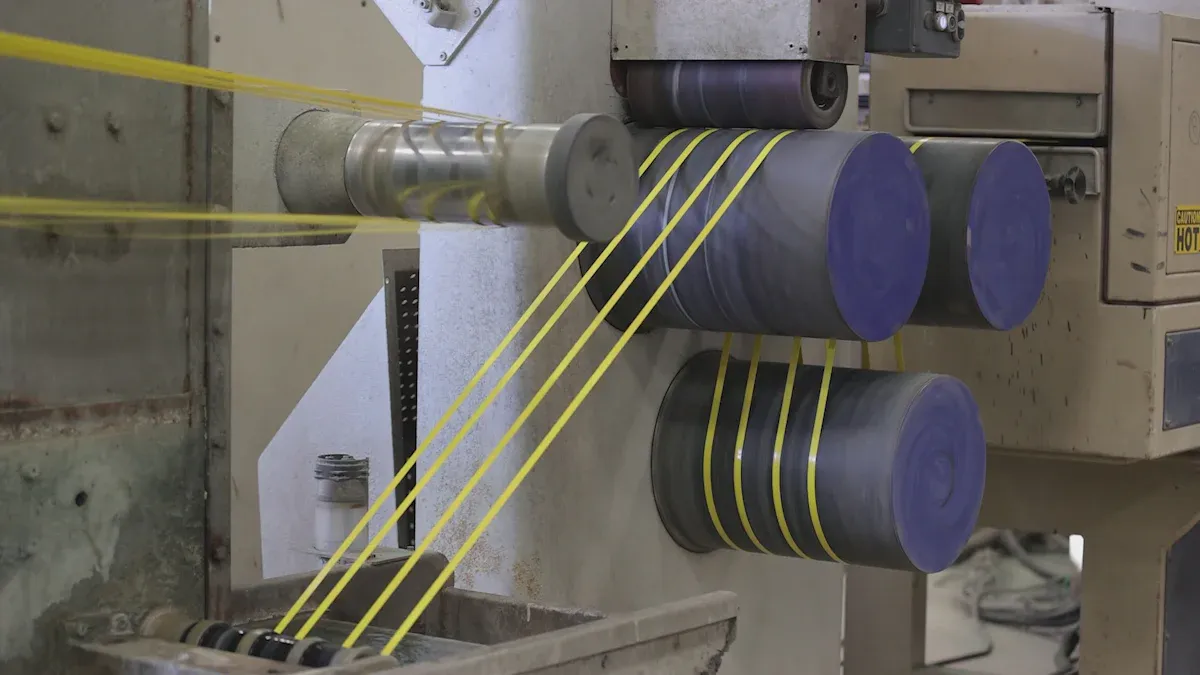

Tib Screw chim nyob rau hauv Cable thiab Hlau Manufacturing

Cov ntawv thov tseem ceeb

Cable thiab hlau factories siv ib lub taub hau ntsia hlau los coated xov hlau nrog yas. Cov tshuab no yaj cov yas pellets thiab thawb cov khoom melted nyob ib ncig ntawm cov hlau. Cov txheej txheem tsim ib tug du, txawm txheej uas tiv thaiv cov hlau thiab ua kom cov hluav taws xob ntws zoo. Ntau lub tuam txhab siv cov tshuab no los ua cov rwb thaiv tsev thiab sab nrauv rau cov hluav taws xob cables, cov ntaub ntawv cables, thiab xov tooj.

Ntawm no yog ib lub rooj uas qhia txog cov ntsiab lus tseem ceeb:

| Yam | Paub meej |

|---|---|

| Daim ntawv thov | Extrusion ntawm insulating thiab tiv thaiv cov khaubncaws sab nraud povtseg nyob ib ncig ntawm hluav taws xob xov hlau thiab cables |

| Cov yam ntxwv tseem ceeb | Raws li txheej txheej thickness, dielectric zog |

| Ntsia Hlau Hom | Ib leeg helical ntsia hlau rau melting thiab thawb yas |

| Cov ntaub ntawv siv | Hardened steel, bimetallic alloys, nitrided steel, tungsten carbide txheej |

| Barrel Nta | Lub zog muaj zog, cov ntaub ntawv kub-resistant, cov khoom siv hluav taws xob sab nraud, cov ntsuas kub |

Yog vim li cas Ib Screw Barrels yog qhov tseem ceeb

Ib lub taub hau ntsia hlau pab cov neeg tsim khoom ua haujlwm sai dua thiab txuag nyiaj. Covyooj yim tsimua rau lawv yooj yim siv thiab kho. Cov neeg ua haujlwm tauhloov cov ntsia hlau los yog lub thoobsai sai yog tias xav tau. Cov tshuab ua kom cov yas kub thiab ntws zoo, yog li txhua lub cable tau txais lub zog, txawm tias txheej. Cov txheej txheem siv lub zog tsawg dua thiab muab kev tswj xyuas zoo dua ntawm cov txheej txheem yas. Qhov no pab cov tuam txhab ua raws li cov cai tswj kev nyab xeeb thiab ua cov khoom zoo.

Tswv yim: Ib leeg ntsia hlau chim yog zoo meej rau kev nruam ntau lawm. Lawv ua kom cov txheej txheem tsis tu ncua thiab txo cov khoom pov tseg.

Cov piv txwv tseem ceeb thiab Cov Qauv

Ntau lub tuam txhab xaiv ib leeg ntsia hlau extruders rau cable thiab hlau vim tias lawv txhim khu kev qha thiab raug nqi. Piv txwv li,Milacron extruderssiv cov iav muaj zog thiab cov txheej txheem tshwj xeeb kom kav ntev. Qee lub tshuab muaj kev tswj tsis siv neeg uas kho cov cua sov thiab ceev rau txhua txoj haujlwm. Cov qauv tsim tshiab tsom rau kev hloov pauv sai dua thiab hloov pauv kom sov dua. Cov qauv no pab cov chaw tsim khoom tsim cov kab ntau dua hauv lub sijhawm tsawg thiab ua yuam kev tsawg dua.

Sib piv cov ntsiab lus ntawm Kev Siv Cov Ntsia Hlau Ib Leeg

Kev siv tshwj xeeb los ntawm kev lag luam

Txhua qhov kev lag luam siv cov ntsia hlau thoob hauv nws txoj kev. Piv txwv li,plastics factories cia siab rau cov tshuab nokom yaj thiab cov ntaub ntawv zoo li polyethylene thiab polypropylene. Cov ntaub ntawv tshawb fawb los ntawm cov tshuab ua yeeb yaj kiab tau pom tias cov ntsia hlau hnav tuaj yeem txo cov zis los ntawm 130 kg / hr mus rau 117 kg / hr. Qhov kev poob no ua rau poob ib xyoos ib zaug txog 79,000 kg. Thaum engineers txhim kho cov ntsia hlau tsim, lawv tsis tsuas yog kho qhov teeb meem xwb tab sis kuj nce ntau lawm saum tus nqi qub. Qhov no qhia ntau npaum li cas kev ua haujlwm tseem ceeb rau cov txiaj ntsig.

Nov yog saib ceev npaum li cas cov kev lag luam sib txawv siv cov ntsia hlau chim:

| Kev lag luam | Kev siv tshwj xeeb | Kev Ua Lag Luam Loj Loj |

|---|---|---|

| Cov yas | Melting thiab ua cov thermoplastics (PE, PP) | CAGR ntawm 4-5% txog 2030 |

| Kev ua zaub mov | Ua khoom txom ncauj thiab cereals | Kev ua lag luam kom tshaj $ 75 nphom los ntawm 2026 |

| Roj Hmab Compounding | Sib tov thiab shaping roj hmab rau cov log tsheb thiab nws pib qhov chaw | Cov log tsheb tsim kom dhau 2 billion units los ntawm 2025 |

| Biomedical | Tsim biopolymer rau ntim thiab cov khoom siv kho mob | Kev loj hlob sai nrog cov cuab yeej tshiab |

Overlapping daim ntawv thov

Muaj ntau qhov kev lag luam qhia cov kev xav tau zoo sib xws thaum nws los txogntsia hlau chim. Cov qauv tsim yooj yim ua haujlwm rau cov yas, khoom noj khoom haus, roj hmab, thiab txawm tias tshuaj. Qhov kev siv dav no tau pib rov qab rau xyoo 1935, thaumPaul Troester tau tsim thawj zaug ib leeg-ntsia hlau extruder hauv lub teb chaws Yelemees. Nyob rau tib lub sijhawm, cov kws tshaj lij xws li Darnell thiab Mol tau kawm txog tias cov tshuab no txav cov khib nyiab thiab cov ntaub ntawv yaj li cas. Lawv cov qauv, thawj zaug ua rau cov yas, tam sim no pab cov hmoov nplej, pastes, thiab cov hmoov txhuv nplej siab.

Cov khoom tseem ceeb - cov khoom xa khoom thiab cov chaw yaj - ua haujlwm tib yam rau ntau cov ntaub ntawv. Cov kws tsim khoom siv tib lub tswv yim los ua cov kav dej, khoom noj txom ncauj, lossis cov ntawv roj hmab. Kev sim nrog cov hmoov txhuv nplej siab tau ua pov thawj tias cov qauv haum rau ntau yam khoom. Lub hauv paus sib koom no piav qhia vim li cas ntau lub chaw tsim khoom xaiv cov ntsia hlau rau cov haujlwm sib txawv.

Tib Screw Barrel thev naus laus zis tsim ntau qhov kev lag luam niaj hnub no. Nws pab cov tuam txhab ua cov khoom lag luam zoo dua sai dua. Cov kws tshaj lij pom cov qauv tshiab tuaj sai sai no:

- AI thiab IoTua tshuab smarter.

- Factories siv cov khoom ntsuab ntau dua.

- Cov tuam txhab tsim kev koom tes tshiab. Cov kev hloov pauv no tau cog lus tias yuav ua tau zoo dua thiab ua haujlwm zoo dua.

FAQ

Ib lub taub hau taub hau siv rau dab tsi?

Ib lub taub hau ntsia hlau melts, sib tov, thiab thawb cov khoom xws li yas, roj hmab, lossis khoom noj los ntawm lub tshuab. Ntau lub factories siv nws los tsim cov khoom.

Ntau npaum li cas lub Hoobkas yuav tsum hloov ib lub taub hau ntsia hlau?

Feem ntau cov chaw tsim khoom kuaj cov thoob txhua xyoo. Lawvhloov lawvthaum lawv pom hnav lossis poob rau hauv cov khoom zoo.

Yuav ua li cas ib tug neeg xaiv txoj cai ib leeg ntsia hlau chim?

Lawv saib cov khoom, hom khoom, thiab tshuab loj. Cov kws tshaj lij pab cuam lub thoob rau txoj haujlwm kom tau txais txiaj ntsig zoo tshaj plaws.

Post lub sij hawm: Jun-17-2025