PVC yeeb nkab ib lub taub hau lub taub hau ua lub luag haujlwm tseem ceeb hauv cov txheej txheem yas extrusion, zoo melting thiab shaping PVC khoom rau hauv cov kav dej muaj zog, ruaj khov. Nyob rau hauv 2022, ib leeg ntsia hlau extruders ua lag luam, ua rau 63.2% ntawm lub ntiaj teb no cov nyiaj tau los qhia, qhia txog lawv kev ntseeg siab thiab dav siv.Pvc yeeb nkab ib leeg ntsia hlau chim factoriesthiabib leeg yas ntsia hlau chim factoriestshwj xeeb hauv kev tsim cov khoom siv no nrog qhov tseeb, ua kom muaj kev ua tau zoo thiab ua haujlwm zoo.

Cov yam ntxwv tseem ceeb ntawm PVC yeeb nkab Ib Screw Barrels

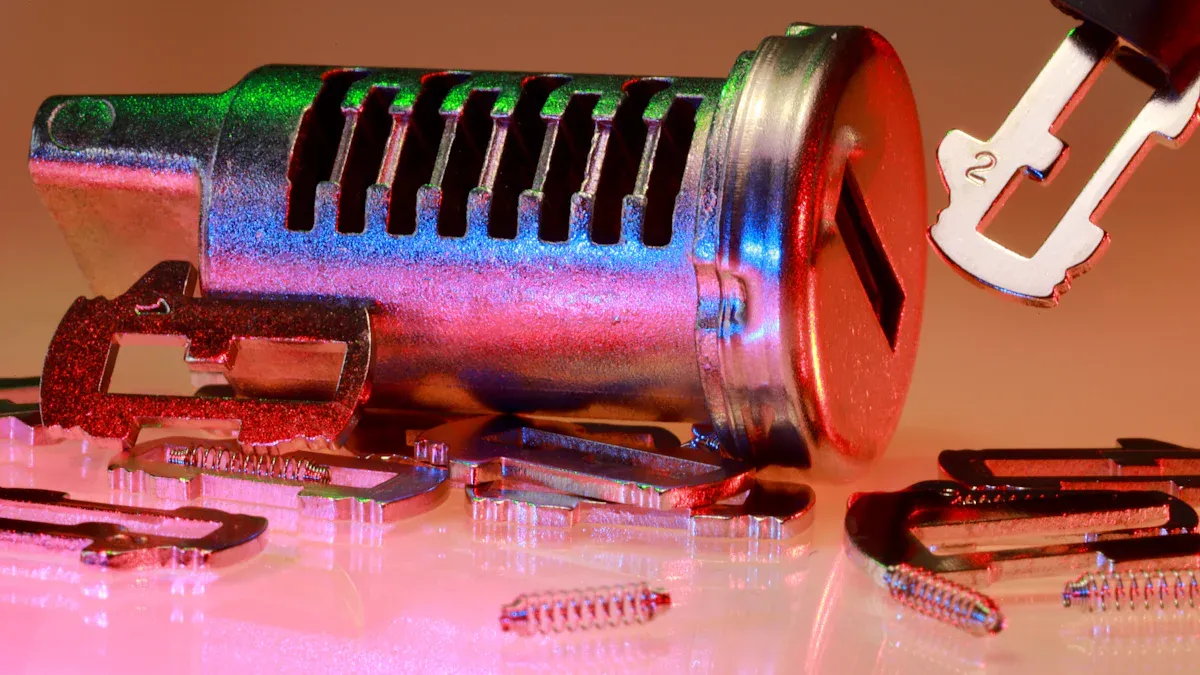

Cheebtsam thiab Tsim

Kev tsim cov yeeb nkab PVCib lub taub hau taub hauyog ob qho tib si muaj txiaj ntsig thiab ncaj ncees. Nws cov qauv muaj xws li lub cylindrical chim thiab ib tug rotating ntsia hlau, uas ua hauj lwm ua ke los ua cov khoom siv PVC. Cov ntsia hlau helical grooves xyuas kom zoo sib xyaw thiab melting ntawm cov khoom, thaum lub thoob muab ib puag ncig tswj rau extrusion.

Cov txheej txheem tseem ceeb ntawm cov khoom no suav nrog:

| Specification | Paub meej |

|---|---|

| Txoj kab uas hla | Ф16-F300 |

| Aspect Ratio | L/D = 15-40 |

| Cov yam ntxwv zoo | Cov qauv yooj yim, tus nqi qis, zoo sib xyaw thiab muaj peev xwm plasticizing |

Cov kev qhia tshwj xeeb no qhia txog ntau yam ntawm cov qauv tsim, ua rau nws haum rau ntau yam kev siv PVC. Tsis tas li ntawd, cov kev tshawb fawb kev lag luam tau pom tias cov phab ntsa plam tus cwj pwm hauv ib leeg-ntsia hlau extruders cuam tshuam rau cov nqi ntws. Cov qauv tsim rau tus nqi ntws, siab poob, thiab ntsia hlau ceev ntxiv optimize extrusion kev ua tau zoo.

Khoom siv thiab tsim kom zoo

Cov khoom siv hauv kev tsim cov yeeb nkab PVC ib lub taub hau taub hau ua lub luag haujlwm tseem ceeb hauv lawv cov kav ntev thiab kev ua haujlwm. Feem ntau cov thoob yog tsim los ntawm 38crMoAIA, lub siab-lub zog alloy hlau paub rau nws zoo heev hnav tsis kam thiab toughness. Qhov saum npoo tau txais kev kho nitriding los txhim kho hardness thiab ntev lub thoob lub neej.

Cov khoom tseem ceeb muaj xws li:

- Nto HardnessHV ≥900

- Nitride Txheej Qhov tobLoj: 0.5-0.8mm

Cov yam ntxwv no ua kom lub thoob tuaj yeem tiv taus qhov kub thiab txias thaum lub sij hawm extrusion txheej txheem. Lub zog tsim tau zoo txo qis hnav thiab tsim kua muag, txo cov nqi tu thiab sijhawm poob. Cov neeg tsim khoom zoo li Zhejiang Jinteng Machinery Manufacturing Co., Ltd. siv cov cuab yeej CNC siab heev thiab kev kho cua sov thev naus laus zis kom ua tiav cov qauv siab.

Cua sov thiab cua txias Systems

Cov cua kub zoo thiab cua txias yog qhov tseem ceeb rau kev tswj xyuas qhov kub thiab txias thaum lub sij hawm extrusion txheej txheem. Lub thoob lub tshuab cua sov kom ntseeg tau tias cov khoom siv PVC melts tusyees, thaum lub tshuab cua txias tiv thaiv overheating thiab tswj cov khoom zoo.

Cov kev tshawb fawb soj ntsuam cov teebmeem ntawm cov ntsia hlau ceev thiab qhov kub thiab txias ntawm extrusion kev ua tau zoo tau pom qhov tseem ceeb ntawm kev tswj qhov kub thiab txias. Kub-siab transducers ntsia ua ntej thiab tom qab lub phaj phaj saib xyuas cov xwm txheej hauv lub sijhawm tiag tiag, ua kom pom kev ua haujlwm zoo. Kev hloov kho rau cov ntsia hlau ceev, qhov kub thiab txias, thiab tus nqi ntws ncaj qha cuam tshuam qhov zoo ntawm cov khoom kawg.

Cov tshuab no tsis tsuas yog txhim kho kev ua tau zoo tab sis kuj txhim kho qhov sib xws ntawm cov txheej txheem extrusion, ua PVC yeeb nkab ib leeg ntsia hlau chim qhov kev xaiv txhim khu kev qha rau cov tuam txhab.

Yuav ua li cas PVC Yeeb Nkab Ib Screw Barrels Ua Haujlwm

Lub luag haujlwm ntawm Screw hauv PVC Extrusion

Cov ntsia hlau nyob rau hauv ib lub PVC yeeb nkab ib lub taub hau taub hau ua hauj lwm raws li lub caj qaum ntawm cov txheej txheem extrusion. Nws pab txhawb kev txav, yaj, thiab sib xyaw ntawm cov khoom siv PVC hauv lub thoob. Lub helical tsim ntawm cov ntsia hlau ua kom muaj kev sib faib ntawm cov cua sov thiab siab, uas yog qhov tseem ceeb rau kev ua tiav cov khoom zoo ib yam.

- Optimized ntsia hlau tsim tau ua kom pom kev txhim kho zoo kawg nkaus. Piv txwv li:

- Kev tsim khoom tau nce ob npaug los ntawm 4.5 tons rau 8.5 tons ntawm ib qho kev hloov pauv hauv daim ntawv thov tiag tiag.

- Txhim khu kev yooj yim hauv kev ua ntau yam ntaub ntawv thiab cov khoom ntxiv txhim kho cov khoom zoo.

- Tailored ntsia hlau tsim txo cov khoom siv, nce profitability.

Scholarly kev tshawb fawb ntxiv underscores qhov tseem ceeb ntawm cov ntsia hlau tsim. Cov qauv lej thiab cov kev tshawb fawb tshawb fawb tau lees paub tias cov ntsia hlau thaiv kev ua kom zoo dua qhov kev ua tau zoo ntawm kev sib tsoo thiab cov txiaj ntsig extrusion. Cov kev tshawb pom no qhia txog qhovntsia hlau lub luag haujlwm tseem ceebnyob rau hauv kom ntseeg tau cov efficiency thiab kev cia siab ntawm PVC yeeb nkab manufacturing.

Melting thiab Mixing txheej txheem

Covmelting thiab mixing txheej txheemnyob rau hauv ib tug PVC yeeb nkab ib lub taub hau ntsia hlau yog ib tug ua tib zoo engineered ib theem zuj zus. Raws li cov khoom siv PVC nkag mus rau hauv lub thoob, cov ntsia hlau sib hloov ua kom muaj kev sib txhuam thiab kub, maj mam yaj cov khoom. Cov helical grooves ntawm cov ntsia hlau ua kom yooj yim sib xyaw, kom ntseeg tau tias cov khoom siv ntxiv thiab cov muab tub lim tau sib npaug.

- Kev tshawb fawb soj ntsuam kev thaiv-ntsia hlau extruders qhia lawv cov txiaj ntsig hauv kev txhim kho polymer extrusion, suav nrog PVC.

- Kev tshawb fawb ntawm plasticating sequences muab kev sim cov ntaub ntawv txhawb kev ua kom zoo ntawm cov txheej txheem extrusion.

Kev tswj qhov kub thiab txias plays lub luag haujlwm tseem ceeb hauv cov txheej txheem no. Precise adjustments rau cov ntsia hlau ceev thiab yaj kub kom cov khoom ncav cuag qhov xav tau sib xws. Txoj kev zoo siab no txo qis qhov tsis xws luag thiab txhim kho tag nrho qhov zoo ntawm cov khoom kawg.

Ua kom muaj kev ua tau zoo thiab sib xws

Kev ua tau zoo thiab sib xws yog qhov tseem ceeb hauv PVC yeeb nkab extrusion. Cov neeg tsim khoom siv cov txheej txheem siab heev los tswj cov txheej txheem kev ruaj ntseg thiab txo qhov sib txawv. Kev Tswj Xyuas Txheej Txheem Txheej Txheem (SPC) txheeb xyuas qhov sib txawv thiab txhim kho cov txheej txheem, thaum Six Sigma's DMAIC txoj hauv kev ntxiv ua kom muaj peev xwm tsim tau.

- Cov ntaub ntawv tiag tiag hauv ntiaj teb qhia txog qhov cuam tshuam ntawm cov txheej txheem optimization:

- Lub kaw lus tau txais cov ntaub ntawv txo cov nqi seem ntawm 15% mus rau 5% hauv peb lub hlis.

- Kev saib xyuas lub sijhawm tiag tiag tiv thaiv cov khoom tsis raug, ua kom cov qauv zoo.

- Lub kaw lus tus nqi-zoo tau tshwm sim vim nws them sai sai rau nws tus kheej los ntawm kev txo cov pov tseg.

Cov tswv yim no tsis tsuas yog txhim kho kev ua tau zoo tab sis kuj ua kom cov khoom zoo sib xws, ua rau PVC yeeb nkab ib leeg ntsia hlau qhov tseem ceeb hauv kev tsim khoom niaj hnub no.

Qhov zoo ntawm PVC Yeeb Nkab Ib Screw Barrels

Simplicity thiab nqi-zoo

PVC yeeb nkab ib leeg ntsia hlau yog dav lees paub rau lawv cov qauv ncaj nraim thiab kev ua haujlwm raug nqi. Lawv cov qauv yooj yim minimizes mechanical tsis ua hauj lwm, ua rau lawv zoo tagnrho rau manufacturers nrhiavtxhim khu kev qha thiab ruaj khov kev ua haujlwm. Ib leeg ntsia hlau extruders tsis tu ncua xa cov siab sib xws thiab cov zis tawm, uas yog qhov tseem ceeb rau kev tsim cov kav dej PVC zoo.

- Cov txiaj ntsig tseem ceeb suav nrog:

- Txo kev nqis peev thawj zaug vim lawv cov qauv tsim tsis yooj yim.

- Cov nqi ua haujlwm qis dua piv rau cov tshuab siv ntau dua.

- High haum rau cov txheej txheem ua haujlwm, xws li cov yeeb nkab thiab cov ntawv ntau lawm.

Hauv xyoo 2024,ib leeg ntsia hlau extruderssuav txog 62.7% ntawm cov nyiaj tau los hauv kev lag luam, qhia txog lawv txoj kev tswj hwm hauv kev ua haujlwm me thiab nruab nrab. Lawv cov nqi pheej yig thiab kev ntseeg siab ua rau lawv nyiam xaiv rau ntau lub tuam txhab.

Kev tu thiab kav ntev

Lub durability ntawm PVC yeeb nkab ib leeg ntsia hlau chim stems los ntawm lawv cov kev tsim kho thiab cov ntaub ntawv siab heev. High-strength alloys, ua ke nrog hardened coatings, txhim khu kev tiv thaiv rau hnav thiab corrosion tshwm sim los ntawm PVC lub abrasive xwm.

| Qhov xwm txheej | Kev piav qhia |

|---|---|

| Hom yas | Corrosive xwm ntawm PVC cuam tshuam rau hnav. |

| Hardened Txheej | Coatings txhim kho kev tiv thaiv thiab kev ua haujlwm ntev. |

| Txheej txheem chaw | Qhov kub thiab txias kom zoo txo qhov hnav. |

Kev siv cov kev tiv thaiv kev tiv thaiv txuas ntxiv txuas ntxiv lub neej ntawm cov thoob no. Kev txheeb xyuas kev sib raug zoo tsis tu ncua thiab kev cob qhia cov neeg ua haujlwm ntawm kev ntsuas kev hnav kom ntseeg tau tias kev ua haujlwm zoo ib yam nyob rau lub sijhawm.

Sib piv rau Twin Screw Barrels

Ib leeg ntsia hlau chim sib txawv ntawm cov ntsia hlau ntxaib hauv kev tsim, nqi, thiab kev saib xyuas. Thaum ntxaib ntsia hlau chim excel nyob rau hauv tshwj xeeb daim ntaub ntawv, ib tug ntsia hlau chim barrels muab kev yooj yim thiab kev cia siab rau cov txheej txheem txheem.

| Feature | Ib Screw Barrels | Twin Screw Barrels |

|---|---|---|

| Tsim | Yooj yim, txo cov neeg kho tshuab tsis ua haujlwm | Complex, siab dua kev ua tsis tiav |

| Kev tu | Yooj yim, tsawg dua kev txawj ntse yuav tsum tau | Kev kho dua tshiab |

| Cov Nqi Ua Haujlwm | Tsawg heev vim muaj kev tsim qauv zoo | Siab dua vim qhov nyuaj |

Ib leeg ntsia hlau chim kuj muab kev tswj kub yooj yim dua thiab tsim nyog rau kev hloov txheej ntau yam. Cov txiaj ntsig zoo no ua rau lawv xaiv qhov ua tau zoo rau cov tuam txhab lag luam ua ntej tus nqi-zoo thiab kev ua haujlwm zoo.

Daim ntawv thov ntawm PVC Yeeb Nkab Ib Screw Barrels

Kev tsim kho thiab kav dej

PVC yeeb nkab ib leeg ntsia hlau chimua lub luag haujlwm tseem ceeb hauv kev tsim kho thiab kav dej. Cov thoob no tso cai rau kev tsim cov kav dej PVC zoo, uas yog siv dav hauv cov dej, dej, thiab cov kav dej phwj tuaj. Lawv lub peev xwm los tsim cov kav dej nrog cov phab ntsa tuab zoo ib yam thiab cov chaw du kom ntseeg tau tias kev ua tau zoo hauv kev xav tau.

Cov neeg tsim khoom thiab cov neeg cog lus nyiam cov kav dej PVC rau lawv qhov sib sib zog nqus, tiv thaiv corrosion, thiab yooj yim ntawm installation. Qhov tseeb muab los ntawm ib lub taub hau taub hau kom ntseeg tau tias cov kav dej ua tau raws li cov qauv kev lag luam nruj, ua rau lawv muaj kev ntseeg siab rau thaj chaw, kev lag luam, thiab kev lag luam.

Hluav taws xob Conduits thiab Industrial Piping

Hluav taws xob cov kav dej thiab cov kav dej muaj kev vam khom rau cov kav dej PVC uas tsim los siv tib lub taub hau. Cov thoob no ua kom muaj kev sib haum xeeb hauv cov yeeb nkab qhov ntev, uas yog qhov tseem ceeb rau cov ntawv thov uas xav tau cov fittings thiab kev sib txuas.

Cov kev tshawb fawb txog kev ua tau zoo qhia txog qhov cuam tshuam ntawm ntau yam tsis zoo ntawm cov khoom extrudate thaum lub sij hawm extrusion txheej txheem. Cov lus hauv qab no qhia txog cov kev tshawb pom tseem ceeb:

| Parameter | Qhov cuam tshuam rau Extrudate Properties |

|---|---|

| DDGS Qib | Kev txo qis hauv kev tuag siab nrog cov qib siab dua |

| Cov ntsiab lus noo noo | Qhov sib txawv tseem ceeb ntawm cov xim thiab nthuav dav |

| Tuag Dimensions (L / D ratios) | Muaj feem xyuam rau tuag siab thiab expansion ratio |

| Ntsia Hlau Compression Ratios | Siab compression ua rau muaj kev hloov pauv tseem ceeb hauv cov khoom |

| Txheej txheem txheej txheem | Influences extruder torque, tuag siab, thiab huab hwm coj txaus tus nqi |

Cov kev nkag siab no qhia tau hais tias yuav ua li cas optimized ua tej yam kev mob thiab cov ntsia hlau tsim txhim khu kev zoo ntawm PVC kav rau hluav taws xob thiab kev lag luam daim ntawv thov. Cov kav dej uas tau tshwm sim muaj qhov ua tau zoo heev, kev tiv thaiv tshuaj lom neeg, thiab thermal stability, ua rau lawv zoo tagnrho rau kev tiv thaiv hluav taws xob thaiv thiab thauj cov kua dej.

Lwm yam kev lag luam-kev siv tshwj xeeb

Tshaj li kev tsim kho thiab kev siv hluav taws xob, PVC yeeb nkab ib leeg ntsia hlau txhawb nqa ntau yam kev lag luam tshwj xeeb. Agricultural irrigation systems tau txais txiaj ntsig los ntawm lub teeb yuag thiab huab cua-resistant cov khoom ntawm PVC kav. Hauv kev lag luam tsheb, cov kav dej no tau siv rau kev hloov pauv cov kua dej vim lawv cov tshuaj tsis haum thiab yooj.

Kev lag luam zaub mov thiab dej haus kuj tseem siv cov kav dej PVC rau kev thauj khoom tsis muaj tshuaj lom thiab tu cev. Lub versatility ntawm ib lub taub hau ntsia hlau tso cai rau cov tuam txhab tsim cov yeeb nkab yeeb nkab kom ua tau raws li cov kev cai tshwj xeeb ntawm txhua qhov kev lag luam, ua kom pom kev ua tau zoo thiab kev ntseeg tau.

PVC cevib leeg ntsia hlau chimpiv txwv precision engineering, combining optimized ntsia hlau geometry thiab ua hauj lwm zones los txhim kho extrusion efficiency. Lawv cov qauv tsim muaj peev xwm ua kom muaj qhov kub thiab txias profile, txhim kho cov khoom zoo thiab txo cov khoom pov tseg. Cov thoob no ua lub luag haujlwm tseem ceeb hauv kev tsim cov yeeb nkab PVC, txhawb kev siv ntau yam thoob plaws kev tsim kho, kav dej, thiab kev lag luam, thaum tsav tsheb cov txheej txheem tsim nqi thiab txhim khu kev qha.

FAQ

Dab tsi yog qhov lifespan ntawm PVC yeeb nkab ib leeg ntsia hlau chim?

Lub neej ntev nyob ntawm kev siv thiab kev saib xyuas. Cov thoob zoo, zoo li cov uas ua los ntawm 38crMoAIA alloy steel, feem ntau kav ntau xyoo nrog kev saib xyuas kom raug.

Kev tswj qhov kub thiab txias li cas cuam tshuam qhov zoo ntawm extrusion?

Kev tswj qhov kub thiab txias kom ntseeg tau tias cov khoom sib tov sib xyaw thiab sib xyaw ntawm cov khoom siv PVC. Qhov no txo qhov tsis xws luag thiab txhim kho qhov sib xws ntawm cov khoom kawg.

Ib lub taub hau taub hau puas tuaj yeem ua cov txheej txheem PVC sib txawv?

Yog lawm, ib leeg ntsia hlau chim hloov mus rau ntau yam PVC formulations. Lawv cov qauv tsim txhawb kev ua haujlwm zoo ntawm cov khoom siv ntxiv thiab cov muab tub lim, kom ntseeg tau tias kev ua haujlwm zoo tshaj plaws.

Post lub sij hawm: Jun-05-2025