Xaiv txoj cai extruder yog qhov tseem ceeb rau kev tsim khoom zoo. Ib leeg ntsia hlau extruders, tuav tshaj 40% ntawm lub ntiaj teb no kev ua lag luam sib koom nyob rau hauv 2023, tseem nrov rau daim ntawv thov yooj yim. Txawm li cas los xij, raws li kev thov rau automation thiab cov khoom siv hnyav zuj zus, nkag siab qhov sib txawv ntawm cov ntsia hlau ntxaib extruder thiab nws cov counterpart,extrusion ntxaib ntsia hlau, ua kom zoo dua kev ua haujlwm thiab kev siv nyiaj txiag zoo. Tsis tas li ntawd, rau cov ntawv thov uas xav tau ntau yam, lubntsia hlau txhaj molding tshuabthiabntsia hlau txhaj tshuabmuab cov kev daws teeb meem siab heev uas ua rau ntau yam kev xav tau ntau lawm.

Tib Ntsia Hlau Extruder Txheej txheem cej luam

Txhais thiab ua haujlwm

A ib leeg ntsia hlau extrudernta ib lub rotating ntsia hlau nyob rau hauv ib tug thermally insulated chim. Qhov kev tsim no tso cai rau kev tswj hwm qhov tsis xws li qhov kub, qhov ceev ceev, thiab lub thoob siab. Cov kev teeb tsa no raug hloov kho raws li cov khoom siv ua tiav, kom ntseeg tau tias muaj kev sib tw thiab ua kom zoo. Qhov yooj yim ntawm nws cov txheej txheem ua rau nws muaj kev ntseeg siab rau ntau lub lag luam, tshwj xeeb tshaj yog thaum ua cov thermoplastics lossis lwm yam khoom siv nrog tus cwj pwm zoo.

Cov ntawv thov siv

Ib leeg ntsia hlau extruders yog dav siv nyob rau hauv ntau yam kev lag luam. Nov yog saib sai ntawm lawv cov ntawv thov:

| Kev lag luam | Daim ntawv thov Description | Kev Ua Lag Luam Loj Loj |

|---|---|---|

| Cov yas | Melting thiab tsim cov thermoplastics, uas tau tsav los ntawm kev tsim khoom ntawm PE thiab PP. | CAGR ntawm kwv yees li 4-5% txog 2030 |

| Kev ua zaub mov | Tsim cov khoom noj xws li khoom noj txom ncauj thiab cereals. | Kev lag luam thoob ntiaj teb xav tias yuav ncav cuag ntau dua $ 75 nphom los ntawm 2026 |

| Roj Hmab Compounding | Kev sib xyaw thiab tsim cov roj hmab sib txuas rau cov log tsheb thiab kev siv tsheb. | Kev tsim cov log tsheb thoob ntiaj teb tau kwv yees kom dhau 2 billion units ib xyoos ib zaug los ntawm 2025 |

| Biomedical | Biopolymer ntau lawm rau kev ntim khoom ruaj khov thiab khoom siv kho mob. | Kev lag luam tawm tshiab nrog kev nce qib hauv kev siv tshuab extrusion. |

Qhov zoo

Ib leeg ntsia hlau extruders muaj ntau yam txiaj ntsig uas ua rau lawv xaiv qhov nrov:

- Nqi-zoo: Lawv cov qauv tsim yooj yim ua rau txo qis thawj zaug peev thiab cov nqi kho.

- Kev Tswj Siab: Advanced controllers tuaj yeem txo qhov kev hloov pauv siab los ntawm 20-40%, nyob ntawm cov khoom siv viscosity. Qhov no ua kom cov khoom zoo ib yam.

- Yooj yim siv: Autotuning nta ua kom yooj yim rau kev khiav lag luam, tshem tawm qhov xav tau ntawm phau ntawv hloov kho.

- Ntau yam: Lawv tuav ntau yam khoom siv, ua rau lawv haum rau ntau hom kev siv.

Kev txwv

Thaum ib qho ntsia hlau extruders muaj ntau yam, lawv muaj qee qhov kev sib tw:

| Kev sib tw | Kev piav qhia |

|---|---|

| Kev sib xyaw cov khoom siv tsawg | Kev ua tiav kev faib tawm ntawm cov khoom siv ntxiv lossis cov khoom ua kom zoo tuaj yeem nyuaj. |

| Teeb meem kev sib haum xeeb | Kev hloov pauv hauv cov khoom noj feem ntau ua rau muaj kev hloov pauv hauv siab. |

| Material Flow Constraints | Cov ntaub ntawv viscosity siab tuaj yeem tsis sau cov tuag tag, ua rau cov khoom puas. |

Txawm hais tias cov kev txwv no, ib qho ntsia hlau extruders tseem yog qhov kev xaiv txhim khu kev qha rau kev siv yooj yim. Rau ntau cov txheej txheem nyuaj, Twin Screw Extruder tej zaum yuav haum zoo dua vim nws muaj peev xwm sib xyaw ua ke.

Twin Screw Extruder Txheej txheem cej luam

Txhais thiab ua haujlwm

Ib tug ntxaib ntsia hlau extruder siv ob intermeshing screws rotating nyob rau hauv ib lub thoob los ua cov ntaub ntawv. Qhov kev tsim no tso cai rau kev sib tov zoo dua, kneading, thiab shearing ntawm cov ntaub ntawv piv rau ib lub tshuab ntsia hlau. Cov ntsia hlau tuaj yeem tig mus rau tib qho kev taw qhia (co-rotating) lossis cov lus qhia rov qab (counter-rotating), nyob ntawm daim ntawv thov. Qhov kev hloov pauv no ua rau nws zoo tagnrho rau kev tuav cov ntaub ntawv nyuaj lossis cov txheej txheem uas xav tau kev tswj xyuas qhov kub thiab txias.

Cov ntawv thov siv

Twin ntsia hlau extruders tau dav siv hauv kev lag luam uas xav tau kev ua haujlwm siab thiab ntau yam. Ib txhiacov ntawv thov sivsuav nrog:

- Kev sib xyaw

- Extrusion

- Rov ua dua

- Pelletizing

Cov ntawv thov no qhia txog lub peev xwm ntawm extruder los tuav cov khoom sib txawv thiab cov txheej txheem zoo.

Qhov zoo

Twin ntsia hlau extruders muaj ntau yam kev pab cuam uas ua rau lawv ib tugnyiam xaivrau kev ua haujlwm complex:

- Kev sib xyaw ua kom zoo: Lub intermeshing screws ua kom muaj kev sib faib ntawm cov khoom siv ntxiv thiab cov muab tub lim.

- Ntau yam: Lawv tuaj yeem ua cov ntaub ntawv ntau yam, suav nrog cov viscosity siab thiab cov khoom siv hluav taws xob kub.

- Txoj Cai Ua Raws Cai: Advanced designs raws li nruj emissions thiab cov ntaub ntawv kev nyab xeeb cov qauv, xws li REACH thiab ASTM International benchmarks.

| Metric/Standard | Kev piav qhia |

|---|---|

| Kev cai emissions | Twin-screw extruder gearboxes txo cov roj xau thiab ua raws li cov cai nruj dua emissions los ntawm cov ntsaws ruaj ruaj thiab cov khoom siv hluavtaws. |

| Ua raws li cov khoom siv | Ua raws li cov cai tswj kev noj qab haus huv thiab kev nyab xeeb zoo li REACH ua kom siv cov khoom tsis muaj tshuaj lom hauv kev ua zaub mov thiab tshuaj. |

| Cov qauv kev ua haujlwm | Gearbox designs raug soj ntsuam nruj raws li cov qauv ntsuas los ntawm cov koom haum xws li ASTM International, ua rau kev txhim kho thermal conductivity thiab kev ntxhov siab. |

Kev txwv

Thaum ntxaib ntsia hlau extruders ua tau zoo hauv kev ua haujlwm, lawv tuaj nrog ob peb qhov kev sib tw:

- Tus nqi pib siab dua: Cov qauv tsim thiab thev naus laus zis ua rau muaj kev nqis peev ntau dua.

- Kev Kho Kom Zoo: Cov txheej txheem intricate yuav tsum muaj kev paub tshwj xeeb rau kev kho thiab tu.

Txawm hais tias cov kev txwv no, ntxaib ntsia hlau extruders tseem yog qhov kev xaiv zoo tshaj plaws rau kev lag luam uas xav tau qhov tseeb thiab kev ua haujlwm zoo.

Qhov sib txawv tseem ceeb ntawm Ib leeg thiab Twin Ntsia Hlau Extruders

Tsim thiab Mechanism

Covtsim ntawm ib leeg thiab ntxaib ntsia hlau extruderssib txawv heev, cuam tshuam lawv functionality. Ib qho ntsia hlau extruder siv ib lub ntswj ntsia hlau hauv ib lub thoob, tso siab rau qhov tob channel los tswj cov khoom ntws thiab ua tiav cov txiaj ntsig xav tau. Txoj kev ncaj nraim no ua rau nws yooj yim rau kev khiav lag luam tab sis txwv nws lub peev xwm los sib xyaw cov ntaub ntawv zoo.

Ntawm qhov tod tes, ntxaib ntsia hlau extruders feature ob intermeshing screws uas tig los ntawm tib qho kev taw qhia (co-rotating) los yog cov lus qhia rov qab (counter-rotating). Qhov kev tsim no tso cai rau kev sib tov zoo, kneading, thiab shearing ntawm cov ntaub ntawv. Cov ntsia hlau ntxaib tuaj yeem siv cov shear siab hauv qhov me me, ua tsaug rau ntau qhov kev hloov pauv hauv qhov tob ntawm channel. Qhov no ua rau lawv zoo tagnrho rau cov txheej txheem nyuaj xws li melting thiab dispersing khoom fillers.

Twin ntsia hlau extruders kuj ua tau zoo hauv kev tu tus kheej, txo qis qis thaum lub sij hawm hloov khoom siv - ib qho tshwj xeeb ntawm cov ntsia hlau tsis muaj.

Muaj peev xwm ua cov khoom siv

Thaum nws los txog rau kev ua cov ntaub ntawv, ib qho ntsia hlau extruders yog tsim rau cov kev siv yooj yim xws li yas extrusion thiab yooj yim compounding. Lawv tuav cov thermoplastics, rubbers, thiab fillers zoo tab sis tawm tsam nrog cov viscosity siab lossis cov ntaub ntawv kub-rhiab. Lawv lub peev xwm sib xyaw ua ke ua rau lawv tsis tshua zoo rau cov qauv uas xav tau cov khoom sib xyaw ntxiv.

Twin ntsia hlau extruders, txawm li cas los xij, ci hauv kev tuav cov khoom sib txawv. Lawv muaj peev xwm sib xyaw ua ke zoo heev, ua rau lawv zoo meej rau kev sib xyaw cov additives lossis fillers rau hauv cov formulations complex. Lawv lub peev xwm los kho cov txheej txheem ua kom ntseeg tau yooj yim, tso cai rau cov tuam txhab ua haujlwm nrog cov viscosity siab thiab cov ntaub ntawv kub-rhiab. Tsis tas li ntawd, ntxaib screws ua tau zoo hauv kev degassing thiab devolatilization, ua kom muaj kev tswj xyuas nruj rau cov khoom tsis haum.

| Feature | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Muaj peev xwm ua tau | Haum rau yooj yim yas extrusion thiab yooj yim compounding. | Hands ib tug dav array ntawm cov ntaub ntawv nrog intricate sib tov. |

| Kev ua haujlwm thiab kev ua haujlwm | Lower throughput, haum rau cov hom phiaj ntau lawm. | Ntau dua throughput, ua rau cov khoom zoo dua. |

| Flexibility thiab Versatility | Tsawg yooj yim, ua haujlwm yooj yim, pheej yig dua rau kev tsim khoom. | Ntau dua yooj, adjustable ua tsis. |

| Khoom siv yooj yim | Txais tau rau cov thermoplastics, rubbers, thiab muab tub lim. | Txhim kho kev tuav ntawm complex formulations thiab high-viscosity cov ntaub ntawv. |

| Kev sib xyaw muaj peev xwm | Tsim nyog rau cov qauv yooj yim. | Kev sib xyaw ua ke zoo, zoo tagnrho rau kev sib xyaw cov additives. |

| Degassing thiab Devolatilization | Muaj peev xwm txwv, tsis haum rau kev tshem tawm tsis zoo. | Muaj peev xwm zoo, haum rau kev tswj xyuas kom zoo. |

Kev ua tau zoo thiab Efficiency

Kev ua tau zoo thiab kev ua haujlwm yog qhov tseem ceeb thaum xaiv ntawm cov extruders. Ib qho ntsia hlau extruders tab tom txhim kho mus rau qhov nrawm dua thiab ua haujlwm tau zoo, ua rau lawv tsim nyog rau cov ntawv thov txheem. Txawm li cas los xij, lawv cov kev coj tus cwj pwm zoo tuaj yeem ua rau cov khoom seem ntau dua vim qhov tsis zoo ntawm cov khoom tsim tawm.

Twin ntsia hlau extruders, nyob rau hauv sib piv, xa superior kev kawm nyob rau hauv blending thiab reactive extrusion. Lawv cov txiaj ntsig ntau dua thiab cov txiaj ntsig zoo dua txo cov nqi seem, ua rau lawv ua tau zoo dua rau cov qauv tsim. Piv txwv li, ntxaib screws yog tshwj xeeb tshaj yog zoo nyob rau hauv kev ua cross-linkable polyethylene (PE), ua kom ntseeg tau zoo ib yam thiab txuag hluav taws xob.

Thaum cov ntsia hlau ib leeg yog kev lag luam rau kev ua haujlwm yooj yim, cov ntsia hlau ntxaib muab kev ua haujlwm ntev ntev rau cov kev xav tau tshwj xeeb.

Nqi thiab complexity

Nqi thiab complexity feem ntau cuam tshuam qhov kev txiav txim ntawm ib leeg thiab ntxaib ntsia hlau extruders. Ib leeg ntsia hlau tshuab yog kev lag luam ntau dua, nrog kev nqis peev qis dua thiab kev saib xyuas tus nqi. Lawv cov qauv tsim yooj yim ua rau lawv nkag mus rau cov lag luam me thiab nruab nrab (SMEs) thiab ua haujlwm yooj yim dua.

Twin ntsia hlau extruders, txawm li cas los xij, tuaj nrog cov nqi siab dua vim lawv cov qauv tsim thiab thev naus laus zis. Cov nuj nqis tu kuj tseem ceeb, vim tias lawv cov txheej txheem sib txawv yuav tsum muaj kev paub tshwj xeeb rau kev kho. Txawm hais tias cov kev cov nyom no, cov ntsia hlau ntxaib muab cov txiaj ntsig zoo rau lub sijhawm ntev rau kev lag luam uas xav tau qhov tseeb thiab ntau yam.

| Yam | Twin Ntsia Hlau Extruder |

|---|---|

| Kev nqis peev pib | Tus nqi pib nqis peev siab |

| Cov nqi kho mob | Cov nuj nqis tseem ceeb tsis tu ncua |

| Kev ua lag luam cuam tshuam | Txwv kev nthuav dav kev lag luam rau SMEs |

| Barriers rau Adoption | Cov nqi siab tsim teeb meem rau kev siv tshuab tshiab |

Cov neeg tsim khoom yuav tsum ntsuas cov yam ntxwv no ua tib zoo txiav txim siab uas extruder ua raws li lawv cov hom phiaj tsim khoom thiab pob nyiaj siv.

Tej yam uas yuav tsum tau xav txog thaum xaiv

Daim ntawv thov thiab cov ntaub ntawv xav tau

Thawj kauj ruam hauv kev xaiv tus extruder txoj cai yog nkag siab koj daim ntawv thov thiab cov ntaub ntawv koj yuav ua. Cov kev lag luam sib txawv muaj cov kev xav tau tshwj xeeb, thiab cov extruder yuav tsum ua raws li cov kev xav tau. Piv txwv li, ib qho ntsia hlau extruders ua haujlwm zoo rau kev siv ncaj qha xws li yas extrusion. Txawm li cas los xij, kev lag luam xws li kev lag luam tshuaj lossis kev tsim tsheb tsheb feem ntau xav tau lub peev xwm siab tshaj ntawm cov ntsia hlau ntxaib extruder.

Yam tseem ceeb uas yuav tau xav txog muaj xws li:

- Khoom siv: Cov ntaub ntawv zoo ib yam yog qhov tseem ceeb kom tsis txhob muaj kev cuam tshuam los yog qhov tsis xws luag thaum tsim khoom.

- Kev Tswj Kub Kub: Kev tswj xyuas qhov kub thiab txias ua kom cov ntaub ntawv tsis degrade thiab cov khoom kawg ua tau raws li cov qauv zoo.

- Tuag Design Complexity: Complex profiles yuav tsum tau cov qauv tuag, uas xav tau kev txawj ntse thiab precision engineering.

Koj puas paub? Aluminium 6xxx-series extrusion yog nrov hauv cov qauv tsheb vim lawv qhov yooj yim thiab lub zog. Txawm li cas los xij, xaiv txoj cai alloy thiab temper yog qhov tseem ceeb kom ua tau raws li cov khoom tensile specifications.

Rau cov ntawv tshwj xeeb, xws li nano-compounding lossis kev ua haujlwm siab polymer ntau lawm, ntxaib ntsia hlau extruder muaj qhov tseeb thiab qhov xav tau los daws cov qauv tsim. Nws lub peev xwm los sib xyaw cov additives uniformly thiab tswj qhov zoo ib yam ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev lag luam xav tau.

Kev txwv nyiaj txiag thiab tus nqi

Nyiaj txiag plays lub luag haujlwm tseem ceebhauv kev txiav txim siab ntawm extruder hom. Thaum ib qho ntsia hlau extruders yog pheej yig dua pem hauv ntej, ntxaib ntsia hlau extruders feem ntau muab cov txiaj ntsig zoo rau lub sij hawm ntev rau cov ntawv thov nyuaj.

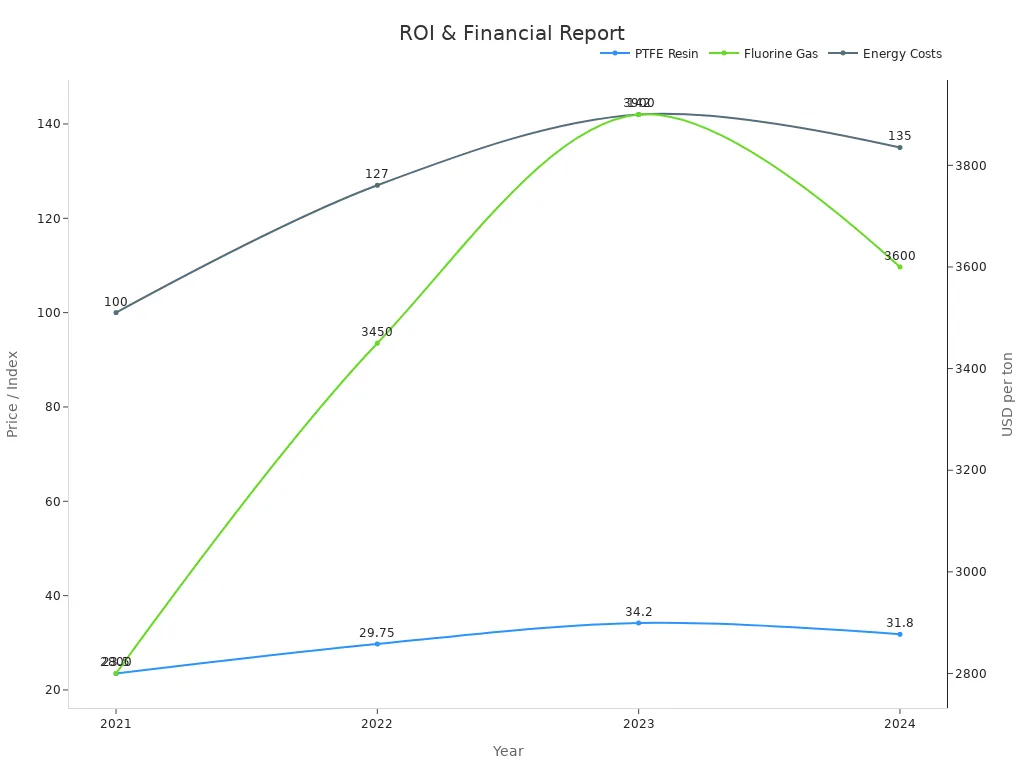

| Hom pov thawj | Paub meej |

|---|---|

| Kev txiav txim siab nqi | Cov tuam txhab muag tshuaj them 20-35% cov nqi them rau cov thermal profile meej. |

| Kev txwv nyiaj txiag | Cov neeg tsim khoom noj khoom haus ntxiv nyiam cov txheej txheem kho dua tshiab hauv qab $ 150,000. |

| Kev Lag Luam Kev Lag Luam | Tuam Tshoj cov tuam txhab muab 60-70% tus nqi txuag tshaj European qauv. |

| Tus nqi tag nrho ntawm kev muaj tswv | Lub zog txuag hluav taws xob txo cov nqi ua haujlwm los ntawm 18-22% tshaj tsib xyoos. |

| ROI Kev Cia Siab | Labs tsom rau nruab nrab nqi extruders ($ 120,000- $ 180,000) rau kev txuag hluav taws xob. |

Cov nqi raw khoom kuj cuam tshuam rau pob nyiaj siv. Piv txwv li, cov nqi txhuas tuaj yeem suav txog 60-70% ntawm tag nrho cov nqi extrusion. Txhawm rau tswj cov kev hloov pauv no, cov tuam txhab tsim khoom feem ntau siv cov tswv yim xws li cov ntawv cog lus mus sij hawm ntev lossis rov ua dua tshiab.

Tswv yim: Yog tias koj ua haujlwm nrog cov peev nyiaj nruj, xav txog cov tshuab kho dua tshiab lossis cov qauv siv hluav taws xob kom txo tau cov nqi yam tsis muaj kev cuam tshuam rau kev ua haujlwm.

Kev ua tau zoo thiab tso zis cia siab

Kev cia siab rau kev ua tau zoo sib txawv nyob ntawm kev lag luam thiab kev siv. Ib qho ntsia hlau extruders yog qhov zoo tagnrho rau cov haujlwm ua haujlwm nrog cov kev xav tau qis dua. Txawm li cas los xij, kev lag luam uas xav tau siab precision thiab tso zis, xws li kev tsim khoom siv kho mob, tau txais txiaj ntsig los ntawm covadvanced muaj peev xwm ntawm ntxaib ntsia hlau extruders.

| Feature | Ib leeg ntsia hlau Extruder | Twin Ntsia Hlau Extruder |

|---|---|---|

| Tshaj tawm | Tsawg dua, haum rau kev tsim khoom me me. | Siab dua, zoo tagnrho rau kev ua haujlwm loj. |

| Kev sib xyaw muaj peev xwm | Txwv tsis pub, txaus rau cov formulations yooj yim. | Zoo heev, ua kom cov khoom sib ntxiv sib faib. |

| Temperature Uniformity | Basic, tej zaum yuav txawv nyob rau hauv lub chim cheeb tsam. | Validated uniformity, tseem ceeb rau kev siv kho mob. |

Piv txwv li, 92% ntawm cov chaw tsim khoom siv kho mob xav tau qhov ntsuas kub zoo sib xws thoob plaws txhua qhov chaw thoob. Qhov no ua kom cov khoom zoo ib yam thiab ua raws li cov qauv kev lag luam nruj.

Qhov tseeb lom zem: Twin ntsia hlau extruders ua tau zoo hauv kev tuav cov ntaub ntawv kub-rhiab zoo li PCL, ua tsaug rau lawv cov tshuab txias txias thiab lub sijhawm hloov pauv sai.

Kev tu thiab kav ntev

Kev tu thiab kev ua neej ntev yog qhov tseem ceeb thaum ntsuas extruders. Ib leeg ntsia hlau extruders yooj yim dua los tswj vim lawv cov qauv ncaj nraim. Lawv yog ib qho kev xaiv zoo rau cov lag luam uas tsis tshua muaj kev txawj ntse.

Twin ntsia hlau extruders, thaum ntau txoj hauv kev, muaj cov yam ntxwv zoo li kev tu tus kheej lub peev xwm uas txo qis qis thaum lub sijhawm hloov khoom siv. Qhov no ua rau lawv muaj kev xaiv zoo dua rau kev lag luam nrog kev hloov pauv ntau zaus.

Txhawm rau ua kom lub neej ntev ntev, xav txog cov hauv qab no:

- Tsim Complexity: Cov qauv tsim yooj yim yog yooj yim los tswj tab sis yuav tsis muaj cov yam ntxwv siab heev.

- Kev xaiv khoom: Cov khoom siv ruaj khov txuas ntxiv lub neej ntawm extruder.

- Zog Efficiency: Cov qauv nrog lub zog txuag hluav taws xob txo qhov hnav thiab tsim kua muag thaum lub sijhawm.

Pro Lub Tswv Yim: Kev saib xyuas tsis tu ncua thiab siv cov ntaub ntawv zoo tuaj yeem txuas ntxiv lub neej ntawm koj cov extruder, kom ntseeg tau tias muaj txiaj ntsig zoo dua ntawm kev nqis peev.

Tus nqi thiab kev saib xyuas cuam tshuam

Kev nqis peev pib

Ob leeg ib leeg thiabntxaib ntsia hlau extruderxav tau kev nqis peev tseem ceeb ua ntej. Qhov no tuaj yeem yog qhov teeb meem rau cov lag luam me thiab nruab nrab (SMEs) tab tom nrhiav los siv cov thev naus laus zis no. Twin ntsia hlau extruders, nrog lawv cov qauv tsim thiab muaj peev xwm, feem ntau tuaj nrog tus nqi siab dua piv rau cov ntsia hlau ib leeg. Tsis tas li ntawd, qhov nyuaj ntawm cov tshuab no xav tau cov neeg ua haujlwm txawj, uas ntxiv rau cov nqi pib.

Rau cov lag luam ua lag luam hauv cov lag luam tus nqi-rhiab, lwm cov cuab yeej extrusion nrog cov nqi qis dua yuav zoo li txaus siab. Txawm li cas los xij, xaiv tus qauv muaj npe nrov tuaj yeem txo qis qis thiab ua kom muaj txiaj ntsig zoo dua mus ntev.

Kev Kho Lub Sij Hawm Ntev

Muaj tus extruder muaj ntau tshaj li qhov pib yuav khoom. Cov nqi mus sij hawm ntev suav nrog cov nqi tu thiab kev ua haujlwm. Kev pabcuam tsis tu ncua, zoo li kev tuav lub tsheb, yog qhov tseem ceeb kom tsis txhob muaj kev cuam tshuam ntau lawm. Kev saib xyuas tsis saib xyuas tuaj yeem ua rau raug nqi kho thiab poob sijhawm.

- Cov ntsiab lus tseem ceeb rau kev saib xyuas:

- Kev tshuaj xyuas niaj hnub los txheeb xyuas qhov hnav thiab tsim kua muag.

- Lub sijhawm hloov ntawm qhov chaw kom tswj tau qhov ua tau zoo.

- Kev lubrication kom zoo los txo kev sib txhuam thiab ua kom lub neej ntev.

Kev nqis peev hauv kev saib xyuas tsis tu ncua tsis tsuas yog ua kom muaj kev ua haujlwm zoo xwb tab sis kuj tseem ua rau lub tshuab ua haujlwm ntev.

Zog Efficiency

Zog efficiencyplays lub luag haujlwm tseem ceeb hauv kev txo cov nqi ua haujlwm. Cov kev tshawb fawb sib piv ib leeg thiab ntxaib ntsia hlau extruders qhia txog qhov sib txawv ntawm kev siv zog.

| Hom pov thawj | Kev piav qhia |

|---|---|

| Cov ntaub ntawv siv hluav taws xob | Empirical qauv qhia qhov txawv ntawm kev siv zog ntawm extruder tsim. |

| Kev khiav hauj lwm Parameter | Kho cov kev txwv xws li kev txwv tuag cuam tshuam rau kev siv hluav taws xob. |

| SEC Sib piv | Specific Energy Consumption (SEC) qhov tseem ceeb qhia txog kev ua tau zoo sib txawv. |

Optimizing kev ua haujlwm tsis tuaj yeem txo qis kev siv hluav taws xob, ua rau extruders tau txais txiaj ntsig zoo dua lub sijhawm.

Rov qab los ntawm Kev nqis peev

Kev xa rov qab rau kev nqis peev (ROI) rau extruders nyob ntawm cov khoom xws li txo cov khoom pov tseg, txuag hluav taws xob, thiab kev tsim khoom. Kev hloov kho mus rau tus qauv ua tau zoo dua tuaj yeem ua rau lub sijhawm ROI luv, ua rau nws muaj txiaj ntsig kev nqis peev.

| Metric | Txhim kho ua ntej | Post-Upgrade | Kev txhim kho |

|---|---|---|---|

| Khoom pov tseg | 12% | 6.5% | 45.8% txo |

| Kev siv zog / kg | 8.7 kWh wb | 6.2 kWh e | 28.7% Txuag |

| ROI Lub Sijhawm | 5.2 xyoo | 3.8 xyoo | 26.9% nrawm dua |

Los ntawm kev tsom mus rau kev ua tau zoo thiab kev saib xyuas tsis tu ncua, kev lag luam tuaj yeem ua tiav ROI sai thiab txuag nyiaj mus sij hawm ntev.

Ib leeg ntsia hlau extruders ua haujlwm zoo rau kev ua haujlwm ncaj nraim, muab kev pheej yig thiab yooj yim. Twin ntsia hlau extruders, ntawm qhov tod tes, ua tau zoo hauv cov txheej txheem nyuaj nrog lawv cov peev txheej sib xyaw ua ke.

Tswv yim: Ib txwm phim koj qhov kev xaiv extruder rau koj cov khoom xav tau thiab pob nyiaj siv. Kev saib xyuas mus sij hawm ntev thiab cov nqi khiav lag luam tuaj yeem cuam tshuam tag nrho cov txiaj ntsig thiab txiaj ntsig.

FAQ

Dab tsi yog qhov txawv ntawm ib leeg thiab ntxaib ntsia hlau extruders?

Ib leeg ntsia hlau extruders yooj yim dua thiab raug nqi, thaumntxaib ntsia hlau extrudermuab kev sib xyaw ua ke zoo dua thiab tuav cov ntaub ntawv nyuaj ntau dua.

Cov kev lag luam twg tau txais txiaj ntsig zoo tshaj plaws los ntawm ntxaib ntsia hlau extruders?

Kev lag luam xws li kws tshuaj, tsheb, thiab kev ua zaub mov cia siab rau ntxaib ntsia hlau extruders rau lawv cov precision, versatility, thiab muaj peev xwm los lis complex formulations.

Kuv tuaj yeem txo tus nqi tu rau kuv tus extruder li cas?

Kev tshuaj xyuas tsis tu ncua, hloov cov khoom raws sij hawm, thiab lubrication kom zoo pab txuas ntxiv lub neej ntawm koj cov extruder thiab txo cov nqi tu.

Tswv yim: Ib txwm ua raws li cov chaw tsim khoom cov txheej txheem saib xyuas kom tsis txhob muaj kev poob qis thiab kev kho tus nqi kim.

Lub sij hawm xa tuaj: Plaub Hlis-30-2025