Kuv tso siab rau PVC Yeeb Nkab Ntsia Hlau chim rau extrusion vim nws siv hwm alloy hlau thiab qib siab txheej txheej. Kuv pom li cas cov yam ntxwv no pab nws tiv taus cua sov, siab, thiab hnav. Piv nrog rau cov kev xaiv txheem, tus hwmPVC yeeb nkab ib leeg ntsia hlau chimkav ntev mus txog rau lub sij hawm ntev. kuv kuj vam ibib leeg ntsia hlau chim rau tshuab moldingthiab aPE yeeb nkab extruder ib leeg ntsia hlau chimrau cov hauj lwm nyuaj.

Khoom siv thiab kev tsim kho ntawm PVC Yeeb Nkab Ntsia Hlau Rau Extrusion

Premium Alloy Steel Xaiv

Thaum kuv xaiv PVC yeeb nkab ntsia hlau chim rau extrusion, kuv tsom rau cov hlau alloy. Cov hlau zoo ua rau txhua qhov sib txawv ntawm kev ua haujlwm ntev thiab kev ua haujlwm. Kuv vam khom cov ntaub ntawv zoo li38CrMoAlA thiab 42CrMovim lawv muabsiab zog thiab zoo heev hnav tsis kam. Cov hlau no tuav cov xwm txheej nyuaj ntawm extrusion, nrog rau qhov kub thiab txias. Kuv kuj nrhiav cov thoob nrog bimetallic liner lossis stainless hlau cladding thaum kuv xav tau kev tiv thaiv ntxiv tiv thaiv corrosion los ntawm PVC cov tshuaj chlorine.

Ntawm no yog qee qhov feem ntau alloy steels thiab lawv siv:

| Alloy Steel / Khoom siv | Cov yam ntxwv tseem ceeb | Kev siv hauv PVC Screw Barrels |

|---|---|---|

| TIAB SA 4140 | Lub zog zoo, kub kho tau, dav muaj | Txheem rau feem ntau PVC ntsia hlau chim |

| TIAB SA 4340 | Lub zog siab dua, zoo dua kev kho cua sov nkag | Siv rau kev sib sib zog nqus ya los yog me me txoj kab uas hla screws |

| Nitralloy 135-M | Aluminium rau nitriding, txhim kho hnav tsis kam | Nitrided nto rau lub neej ntev |

| 17-4 PH Stainless hlau | Muaj zog, corrosion resistant | Cov ntsia hlau me me xav tau kev tiv thaiv corrosion |

| D2 thiab H13 Tool Steels | High hnav tsis kam, tshav kub kho, corrosion resistant | High abrasion cheeb tsam, lub tes tsho, plasticizing screws |

| CPM Tool Steels (CPM 10V, thiab lwm yam) | Superior abrasion thiab corrosion kuj | Filled compounds, ntev hnav tsis kam |

Kuv ib txwm xaiv cov qib steel raws li qhov xav tau ntawm cov txheej txheem extrusion. High-strength alloy steels thiab bimetallic alloys muab kuv kev ntseeg siab tias PVC yeeb nkab ntsia hlau chim rau extrusion yuav kav mus txog rau xyoo ntawm hnyav siv.

Advanced Surface Treatments thiab Hardness

Kev kho saum npoo ua lub luag haujlwm loj npaum li cas kuv cov ntsia hlau ntsia hlau kav ntev npaum li cas. Kuv siv nitriding los tsim ib txheej nyuaj ntawm cov hlau, uas tuaj yeem ncav cuag li 70 HRC. Cov txheej no tiv taus hnav thiab kev ntxhov siab, txawm tias thaum lub thoob ntsib kev kub ntxhov thiab kub. Chrome plating ntxiv cov npoo du thiab txo cov kev sib txhuam, ua kom huv si yooj yim dua thiab txhim kho yaj ntws. Qee zaum, kuv xaiv bimetallic alloys lossis tungsten carbide coatings rau kev puas tsuaj ntau dua.

Tswv yim: Nitriding tsim ib txheej nitride txog 0.5-0.8mm sib sib zog nqus, uas tiv thaiv lub thoob los ntawm hnav thiab corrosion. Chrome plating, feem ntau 10-50 microns tuab, ua kom lub ntsej muag slick thiab pab tiv thaiv cov khoom tsim.

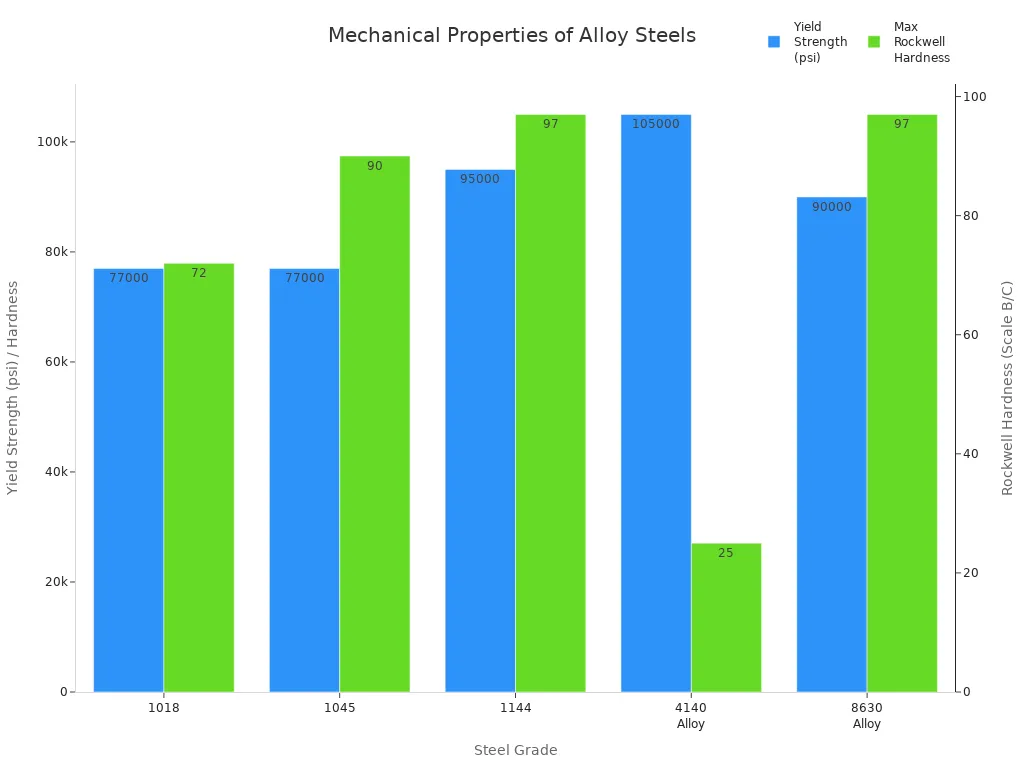

Ntawm no yog saib ceev ceev ntawm cov khoom siv hluav taws xob ntawm cov hlau kuv siv:

| Qib Steel | Yield zog (psi) | Max Rockwell Hardness (Nqe) | Cov Lus Qhia Txog Cov Khoom Siv thiab Siv |

|---|---|---|---|

| 4140 Alloy | 60,000-105,000 | C20-C25 | Tawv, ductile, hnav resistant |

| 17-4 PH stainless | 110,000 ib | C40 | Muaj zog, corrosion resistant |

| D2 Tool Steel | 90,000 ib | C55 | High hnav tsis kam, corrosion resistant |

Kuv ib txwm phim cov kev kho saum npoo rau hom yas thiab cov khoom siv ntxiv uas kuv siv. Txoj kev no, kuv PVC yeeb nkab ntsia hlau chim rau extrusion nyob twj ywm txhim khu kev qha thiab npaum.

Precision Manufacturing thiab cov qauv kev ntseeg siab

Precision manufacturing yog lub caj qaum ntawm lub taub hau ntsia hlau. Kuv ntseeg CNC machining kom tolerances nruj, qee zaum raws li meej li ± 0.01 hli. Qhov tseeb no ua kom cov ntsia hlau thiab lub thoob mesh zoo kawg nkaus, uas yog qhov tseem ceeb rau kev siv tau zoo PVC thiab sib tov. Kuv ua tib zoo mloog rau cov ntsia hlau geometry - dav hlau, qhov tob, qhov tob, thiab qhov sib piv. Cov yam ntxwv no pab kuv tswj lub siab thiab kub, tiv thaiv cov khoom degradation.

- Kuv siv lub tshuab nqus tsev vacuum seem thiab cov khoom sib xyaw kom tshem tawm cov pa phem thiab muab cov khoom ntxiv kom huv si.

- Cov cua kub thiab cov cua txias hauv lub thoob cia kuv tswj qhov kub thiab txias, ua kom cov yaj ruaj khov.

- Kev tswj hwm kev sib koom ua ke tso cai rau kuv los saib xyuas thiab kho cov txheej txheem hauv lub sijhawm tiag tiag, tswj xyuas qhov tseeb thiab tiv thaiv qhov tsis xws luag.

Yog tias kuv pom qhov hnav lossis qhov sib txawv ntawm qhov sib txawv, kuv ua nrawm. Txawm tias cov kev hloov me me tuaj yeem txo qhov kev xa tawm thiab kev ua haujlwm ntawm plasticizing, ua rau cov yeeb nkab tsis sib xws lossis cov khoom tsis sib xws. Los ntawm kev tswj xyuas qhov tseeb, Kuv paub tseeb tias kuv PVC Yeeb Nkab Ntsia Hlau chim rau extrusion muab qhov zoo ib yam thiab ua haujlwm ntev.

Tsim thiab ua haujlwm tau txiaj ntsig ntawm PVC Yeeb Nkab Ntsia Hlau Rau Extrusion

Optimized Screw Geometry thiab Uniform Pub

Thaum kuv xaiv PVC yeeb nkab ntsia hlau chim rau extrusion, kuv ua tib zoo mloog rau cov ntsia hlau geometry. Kev tsim qauv zoo pab kuv ua tiav kev noj zaub mov zoo ntawm PVC khoom. Kuv nrhiav cov yam ntxwv uas txhawb nqa kev thauj mus los thiab kev sib xyaw. Nov yog qee qhov kev tsim qauv tseem ceeb uas kuv xav txog:

- Sib sib zog nqus ya dav hlau thiab raws hauv seem conveying txav cov ntaub ntawv sai sai yam tsis ua rau shear ntau dhau.

- Cov channel qhov tob txo qis los ntawm cheeb tsam conveying mus rau thaj tsam metering, uas sib npaug melting thiab sib tov.

- Lub dav hlau loj dua txav cov khoom siv nrog tsawg zog, thaum cov ntsiab lus rov qab pab tswj kev ntws thiab txhim kho kev sib xyaw.

- Cov seem pub khaws cov khoom ntws thiab tiv thaiv kev thaiv.

- Cov seem compression melts thiab sib tov cov PVC, siv cua sov los ntawm kev sib txhuam.

- Lub metering seem ua kom muaj qhov tso tawm tsis tu ncua ntawm cov khoom siv molten.

Kuv ib txwm ua kom cov ntsia hlau geometry phim cov khoom ntawm PVC thiab cov kev xav tau ntawm cov txheej txheem extrusion. Qhov kev tsim kom zoo no pab kuv kom tsis txhob muaj qhov tsis xws luag thiab ua kom cov khoom ntws tsis tu ncua.

Yog tias kuv pom ib qho hnav ntawm cov ntsia hlau, kuv ua sai sai. Txawm tias me me hloov pauv hauv geometry tuaj yeem ua rau tsis sib xws thiab qhov tsis xws ntawm cov yeeb nkab kawg. Los ntawm kev ua kom cov ntsia hlau nyob rau hauv sab saum toj zoo, kuv tuav zoo extrusion thiab txo cov pov tseg.

Integrated cua sov thiab cua txias system

Kev tswj qhov kub thiab txias yog qhov tseem ceeb rau kev tsim cov kav dej PVC muaj zog thiab zoo ib yam. Kuv vam khom rau cov cua kub siab tshaj thiab txias tshuab ua rau hauv cov ntsia hlau chim. Cov tshuab no pab kuv khaws qhov kub thiab txias thaum txhua theem ntawm extrusion.

| System Hom | Kev piav qhia | Cov ntsiab lus thov |

|---|---|---|

| Cua sov System | Kev siv hluav taws xob cua sov, xws li induction thiab cua sov, siv sab nraum lub thoob | Muab cov cua sov uas xav tau los yaj PVC |

| Txias System | Dej los yog cua txias tshuab; cua txias rau me me extruders, dej rau cov loj loj | Tiv thaiv kom tsis txhob muaj cua sov thiab ua kom sov sov |

Kuv siv cov ntsuas kub ntsuas los saib xyuas cov txheej txheem hauv lub sijhawm. Automated tswj kho cov cua sov thiab cua txias raws li xav tau. Qhov kev teeb tsa no ua kom qhov kub thiab txias tsis tu ncua, uas yog qhov tseem ceeb rau cov yeeb nkab zoo thiab qhov tseeb qhov tseeb.

- Kev tswj kub hauv txhua cheeb tsam ua kom cov PVC melts tag nrho thiab sib npaug.

- Kev ntsuas kub kom zoo tiv thaiv cov yeeb nkab los ntawm sagging lossis solidifying sai dhau.

- Cov tshuab cua txias pab cov yeeb nkab kom nws cov duab thiab txo cov kev ntxhov siab sab hauv.

Nrog rau cov tshuab no, kuv tuaj yeem hloov kho sai sai thiab zam qhov tsis xws li cov phab ntsa tsis sib xws lossis qhov chaw ntxhib.

Resistance rau hnav, Corrosion, thiab siab siab

PVC Yeeb Nkab Ntsia Hlau chim rau extrusion ntsib cov xwm txheej nyuaj. Kuv xaiv cov thoob ua los ntawm cov alloys tshwj xeeb thiab nrog cov txheej txheem siab heev los tiv thaiv kev hnav thiab corrosion. PVC ua tau tuaj yeem tso tawm hydrochloric acid, uas tawm tsam cov hlau tsis tu ncua. Txhawm rau tiv thaiv qhov no, kuv siv bimetallic chim nrog nickel-nplua nuj liners thiab tawv txheej zoo li tungsten carbide.

- Adhesive hnav tshwm sim thaum cov khoom siv hlau txhuam ua ke.

- Abrasive hnav los ntawm cov khoom ntim xws li iav fibers lossis cov ntxhia hauv PVC.

- Corrosive hnav yog tshwm sim los ntawm cov tshuaj tso tawm thaum ua.

Kuv kuj paub tseeb tias cov khoom siv ntsia hlau thiab lub thoob sib tw. Qhov no tiv thaiv cov teeb meem ntawm qhov sib txawv ntawm kev nthuav dav thaum rhuab. Kev kuaj xyuas thiab kev saib xyuas tsis tu ncua pab kuv pom thaum ntxov thiab zam kev kho loj.

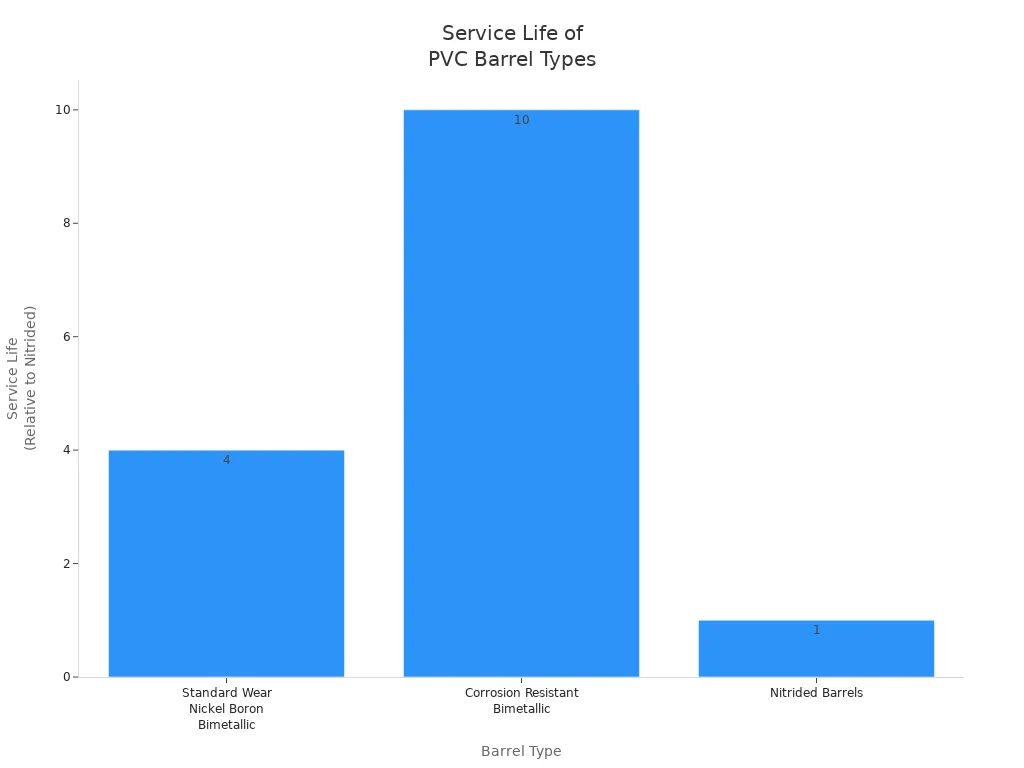

| Barrel Hom | Hnav Resistance | Corrosion Resistance | Kev Pabcuam Lub Neej Piv rau Nitrided Barrels |

|---|---|---|---|

| Txheem Hnav Nickel Boron Bimetallic | Zoo heev abrasion tsis kam | Nruab nrab corrosion kuj | Tsawg kawg yog 4 zaug ntev dua |

| Corrosion Resistant Bimetallic | Zoo heev hnav tsis kam | Zoo heev tiv thaiv HCl thiab acids | Tshaj 10 npaug ntev dua hauv cov huab cua corrosive |

| Nitrided Barrels | High deg hardness | Tsis zoo corrosion kuj | Lub hauv paus (1x) |

Los ntawm kev siv cov ntaub ntawv thiab cov qauv tsim, kuv txuas lub neej ntawm kuv cov khoom siv thiab ua kom cov khoom ua haujlwm zoo, txawm tias nyob rau hauv siab thiab nrog cov ntaub ntawv abrasive.

Ua raws li Extrusion Zoo thiab Extended Service Life

Kuv paub tias qhov zoo ib yam yog qhov tseem ceeb hauv kev tsim cov yeeb nkab PVC. Kuv saib xyuas qhov tsis tseem ceeb xws li kub, siab, thiab ceev kom cov txheej txheem ruaj khov. Kuv siv cov cuab yeej precision los xyuas cov yeeb nkab qhov ntev thiab nrhiav qhov tsis xws luag. Automated systems pab kuv ntes teeb meem thaum ntxov thiab ua kom cov txheej txheem khiav.

- Kuv taug qab cov zis ntim, qhov tsis xws luag, thiab siv lub zog los ntsuas kev ua haujlwm.

- Kev saib xyuas tsis tu ncua thiab kev kuaj xyuas kom zoo pab kuv kom tsis txhob muaj sijhawm poob.

- Cov ntsia hlau ntev ntev nrog cov txheej bimetallic txo qis npaum li cas kuv yuav tsum nres rau kev kho.

Thaum kuv nqis peev rau hauv qhov zoo PVC Yeeb Nkab Ntsia Hlau chim rau extrusion, kuv pom tsawg dua thiab pov tseg tsawg dua. Kuv cov nqi kho mob poob qis, thiab kuv tuaj yeem ua cov khoom siv rov qab tau yooj yim dua. Kuv kuj pom tias kev siv hluav taws xob qis dua vim tias cov cuab yeej siv tau zoo dua.

Hauv kuv qhov kev paub, cov txiaj ntsig no ntxiv rau kev txuag nqi tseem ceeb thiab kev tsim khoom ntau dua. Kuv tuaj yeem ua tau raws li lub sijhawm xa khoom thiab ua kom kuv cov neeg siv khoom zoo siab.

Kuv nqis peev hauv PVC Yeeb Nkab Ntsia Hlau chim rau extrusion vim nws muab kev ua haujlwm ntev ntev thiab zoo ib yam yeeb nkab.

- Modular chim designs thiab cov ntaub ntawv siab heev txo qis downtime thiab tu nqi.

- Kev tshuaj xyuas tsis tu ncua thiab cov txheej txheem tsim nyog pab kuv ua tau raws li cov qauv kev lag luam.

| Cov txiaj ntsig | Kev tshwm sim |

|---|---|

| High durability | Cov nqi ua haujlwm qis dua |

| Advanced technology | Txhim kho cov neeg siv khoom txaus siab |

FAQ

Kuv yuav ua li cas tuav kuv PVC yeeb nkab ntsia hlau chim rau extrusion?

Kuv ntxuav lub thoob tsis tu ncua. Kuv tshuaj xyuas qhov hnav thiab corrosion. Kuv hloov qhov hnav sai sai. Kuv siv cov lubricants pom zoo thiab saib xyuas qhov kub thiab txias.

Tswv yim: Teem caij tshuaj ntsuam xyuas txhua hli kom ntes tau thaum ntxov ntawm kev hnav.

Dab tsi yog qhov kev kho deg ua haujlwm zoo tshaj plaws rau high-abrasion PVC extrusion?

Kuv nyiam nitriding rau ntau txoj haujlwm. Kuv siv bimetallic lossis tungsten carbide coatings thaum kuv ua cov tshuaj abrasive. Cov kev kho mob no txuas ntxiv lub neej kev pabcuam thiab tiv thaiv kev hnav.

Kuv puas tuaj yeem kho cov ntsia hlau geometry rau cov yeeb nkab PVC sib txawv?

Kuv ua hauj lwm nrog manufacturers los khontsia hlau txoj kab uas hla, suab, thiab dav dav. Kev cai geometry pab kuv ua tiav cov dej ntws zoo thiab cov yeeb nkab zoo ib yam rau txhua qhov loj.

| Customization Options | Cov txiaj ntsig |

|---|---|

| Txoj kab uas hla | Sib piv cov yeeb nkab thickness |

| Suab | Tswj cov khoom ntws |

| Davhlau Dav | Txhim kho kev sib tov zoo |

Post lub sij hawm: Aug-27-2025