Lub tshuab yas txhaj tshuaj molding tshuab tau zoo hloov cov yas raw rau hauv cov duab meej, nyuaj. Cov txheej txheem no muab cov txiaj ntsig zoo tshaj plaws:

- Tsim cov khoom sib txawv nrog qhov tseeb qhov tseeb.

- Muab qhov zoo ib yam thiab repeatability.

- Txo cov nqi tsim khoom hauv kev tsim khoom loj.

Advanced designs, xws li Screw Type Txhaj Moulding Tshuab thiabNtsia Hlau Hom Txhaj Moulding Tshuab, txhim khu cov khoom ntws thiab optimize kev ua tau zoo. Tsis tas li ntawd, lubOb Chav Barrel Txhaj Moulding TshuabthiabNtsia Hlau Txhaj Moulding Tshuabntxiv txhim kho efficiency thiab tso zis nyob rau hauv lub manufacturing txheej txheem.

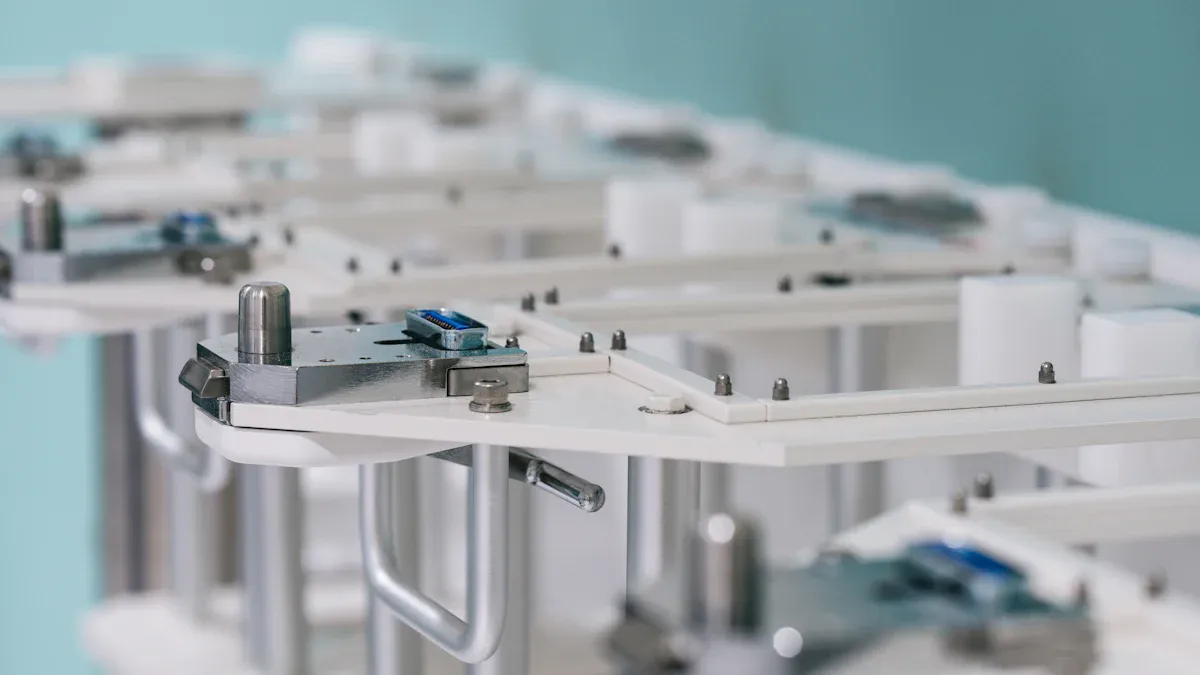

Txhaj Unit nyob rau hauv Ntsia Hlau Hom Txhaj Moulding Tshuab

Lub tshuab txhaj tshuaj hauv Screw Hom Txhaj Moulding Tshuab plays lub luag haujlwm tseem ceeb hauv kev hloov cov yas pellets rau hauv lub xeev molten thiab txhaj rau hauv pwm. Chav tsev no muaj peb yam tseem ceeb: lub hopper, chim, thiab ntsia hlau mechanism. Txhua feem ua rau kev ua tau zoo thiab qhov tseeb ntawm cov txheej txheem molding.

Hopper

Lub hopper ua qhov chaw nkag rau cov ntaub ntawv yas raw. Nws tuav cov yas pellets thiab pub rau hauv lub thoob rau kev ua haujlwm ntxiv. Cov hoppers niaj hnub no feem ntau suav nrog cov yam ntxwv zoo li cov khoom siv ziab kom tshem tawm cov dej noo ntawm cov pellets, kom ntseeg tau tias qhov zoo tshaj plaws yaj. Los ntawm kev tswj hwm cov khoom siv zoo ib yam, lub hopper txhawb kev tsim khoom tsis cuam tshuam rau hauv cov Ntsia Hlau Hom Txhaj Moulding Tshuab.

chim

Lub thoob yog ib lub cylindrical chamber uas muaj cov ntsia hlau mechanism. Nws heats cov yas pellets rau lawv qhov melting point siv ntau qhov chaw cua sov. Cov cheeb tsam no-feem ntau muab faib rau hauv pub, rear, nruab nrab, thiab pem hauv ntej-tso cai tswj qhov kub thiab txias, uas yog ib qho tseem ceeb rau kev ua tau zoo ntawm cov yaj zoo. Qhov ntsuas kub kom raug nyob rau hauv lub thoob tiv thaiv cov teeb meem xws li warpage, seem tsis raug, thiab cov khoom degradation. Qhov kev tswj xyuas zoo no ua kom ntseeg tau tias Screw Hom Txhaj Moulding Tshuab muab cov khoom lag luam zoo sib xws.

- Qhov ntsuas kub kom zoo yog qhov tseem ceeb rau kev ua haujlwm zoo.

- Kev teeb tsa tsis raug tuaj yeem ua rau muaj qhov tsis xws ntawm cov khoom kawg.

- Advanced designs txhim kho lub zog efficiency thiab txo cov nqi khiav lag luam.

Ntsia Hlau Mechanism

Cov ntsia hlau mechanism yog lub plawv ntawm lub tshuab txhaj tshuaj. Nws tig hauv lub thoob, sib tov thiab yaj cov yas pellets thaum thawb cov khoom molten rau pem hauv ntej. Kev tsim ntawm cov ntsia hlau cuam tshuam rau cov txheej txheem melting thiab txhaj tshuaj. Piv txwv li, nyob ruaj ruajntsia hlau tsimtxhim kho plastication los ntawm kev ua kom muaj kev sib raug zoo sib xws thiab txhaj tshuaj ntim. Tsis tas li ntawd, cov yam ntxwv zoo li poppet li qub muab kev tswj xyuas meej los ntawm kev kaw tam sim ntawd thaum cov ntsia hlau nres.

Nyob rau hauv tag nrho-hluav taws xob Screw Hom Txhaj Moulding Tshuab, cov ntsia hlau mechanism muaj kev tswj tsis sib xws ntawm kev ceev, siab, thiab qhov chaw. Qhov no precision minimizes variations ntawm cycles, kom ntseeg tau zoo ib yam sau tus nqi thiab txhaj tshuaj ntau thiab tsawg. Cov kev nce qib no tsis tsuas yog txhim kho cov yaj zoo tab sis kuj txhim kho tag nrho cov txiaj ntsig ntawm cov txheej txheem molding.

- Automation thiab robotics kev koom ua ke ntxiv txhawb cov khoom tsim tawm.

- Lub zog txuag hluav taws xob tsim qauv ua rau kev txuag nqi.

- Kev siv cov khoom siv ruaj khov ua ke nrog kev tsim khoom niaj hnub.

Lub tshuab txhaj tshuaj nyob rau hauv lub Ntsia Hlau Hom Txhaj Moulding Tshuab piv txwv li kev sib koom ua ke ntawm kev ua haujlwm siab heev thiab kev tswj xyuas qhov tseeb. Nws cov khoom ua haujlwm ua ke tsis sib haum xeeb kom xa cov khoom zoo, muaj txiaj ntsig, thiab txhim khu kev qha.

Clamping thiab Mould Units

Cov clamping thiab pwm units yog cov khoom tseem ceeb ntawm lub tshuab yas txhaj tshuaj molding. Lawv xyuas kom cov pwm tseem nyob ruaj ntseg kaw thaum lub sij hawm txhaj tshuaj thiab pab txhawb kev tsim cov khoom zoo, cov khoom zoo. Cov chav no muaj cov pwm, platens, thiab lub cev muaj zog tsav, txhua tus ua lub luag haujlwm sib txawv hauv cov txheej txheem molding.

Pwm

Cov pwm ua haujlwm raws li cov kab noj hniav uas cov yas molten yuav zoo li qub. Nws tus qauv tsim ncaj qha cuam tshuam qhov zoo thiab sib xws ntawm cov khoom kawg.Cov kev coj ua zoo tshaj plaws hauv kev tsim pwmhais txog cov phab ntsa tuab kom tsis txhob muaj qhov tsis xws luag xws li warping thiab dab dej cim thaum lub caij txias. Kev hloov pauv ntawm qhov sib txawv thicknesses, ua tiav los ntawm chamfers lossis fillets, ntxiv txhim khu kev ntseeg ruaj khov.

- Cov phab ntsa tuab kom zoo tsis txhob muaj qhov tsis zoo xws li warping thiab sinking.

- Lub zog muaj zog tuaj yeem txhim kho nrog ribs thiab gussets es tsis txhob nce thickness.

- Tsim cov kev sim (DOE) cov tswv yim pab txheeb xyuas qhov tsis zoo thaum ntxov, ua kom pom kev ua tau zoo thiab kev ntseeg tau.

Nyob rau hauv ib tug ntsia hlau hom Txhaj Moulding Tshuab, cov pwm qhov precision xyuas kom meej tias intricate designs thiab nruj tolerances yog tiav. Qhov kev muaj peev xwm no ua rau nws zoo tagnrho rau kev tsim cov khoom siv nrog cov khoom zoo sib xws.

Platens

Platens yog cov phaj loj, tiaj tus uas tuav cov pwm nyob rau hauv qhov chaw thiab faib clamping quab yuam sib npaug. Lawv cov qauv tsim thiab kev ncaj ncees yog qhov tseem ceeb rau kev tswj pwm kev sib raug zoo thiab ua kom lub siab sib xws thaum lub sijhawm txhaj tshuaj. Cov txheej txheem tseem ceeb uas cuam tshuam rau kev ua tau zoo ntawm cov platen muaj xws li qhov hnyav hnyav, lub peev xwm thauj khoom, thiab kev ua kom zoo dua qub.

| Parameter | Kev cuam tshuam rau Pwm Alignment |

|---|---|

| Nyhav cuam tshuam | Muaj ze li ntawm 70% ntawm tag nrho qhov hnyav ntawm lub tshuab, cuam tshuam kev ruaj ntseg thiab kev sib tw. |

| Economic tseem ceeb | Optimizing tsim txo cov khoom siv raw, txhim kho tus nqi efficiency. |

| Kev cuam tshuam kev ua haujlwm | Ua kom zoo pwm kev sib raug zoo thiab kev sib faib siab, qhov tseem ceeb rau kev tsim khoom zoo. |

| Kev tsim kho kom zoo | Txhim kho qhov loj me, cov duab, thiab cov khoom faib khoom kom zoo dua qub. |

| Load-Bearing Peev Xwm | Txhim kho durability thiab txhawb pwm kev sib raug zoo raws li kev ua haujlwm nyuaj. |

Nyob rau hauv ib lub Screw Hom Txhaj Moulding Tshuab, platens pab txhawb lub tshuab muaj peev xwm los tsim cov khoom uas muaj qhov raug siab. Lawv cov qauv tsim kom muaj kev ruaj khov thiab ua haujlwm zoo ib yam, txawm tias nyob rau hauv siab clamping quab yuam.

Tsav Tsav

Lub cev muaj zog tsav powers lub clamping mechanism, ua rau cov pwm qhib thiab kaw nrog precision. Nws ua lub luag haujlwm tseem ceeb hauv kev tswj xyuas qhov nrawm thiab raug ntawm cov txheej txheem clamping.Niaj hnub nimno motors, tshwj xeeb tshaj yog nyob rau hauv tag nrho cov tshuab hluav taws xob, muab kev tswj kom zoo dua clamping quab yuam thiab qhov chaw. Qhov no precision minimizes hnav ntawm pwm thiab txo lub sij hawm voj voog, kev txhim kho tag nrho efficiency.

Lub zog txuag lub cev muaj zog kuj tseem ua rau kev txuag nqi thiab kev ruaj khov. Los ntawm kev txhim kho kev siv hluav taws xob zoo, lawv ua raws li kev tsim khoom niaj hnub uas ua kom muaj lub luag haujlwm tseem ceeb hauv ib puag ncig. Nyob rau hauv ib tug Screw Hom Txhaj Moulding Tshuab, lub cev muaj zog tsav kom seamless kev khiav hauj lwm, txhawb high-ceev ntau lawm yam tsis muaj kev cuam tshuam zoo.

Tswv yim:Kev saib xyuas tsis tu ncua ntawm lub cev muaj zog tuaj yeem txuas ntxiv nws txoj sia thiab tiv thaiv lub sijhawm poob qis, ua kom tsis muaj kev cuam tshuam ntau lawm.

Cov clamping thiab pwm ua piv txwv ua piv txwv ntawm kev sib koom ua ke ntawm engineering thiab precision hauv cov yas txhaj tshuaj molding tshuab. Lawv cov qauv tsim thiab kev ua haujlwm ncaj qha cuam tshuam lub tshuab lub peev xwm los tsim cov khoom lag luam zoo thiab muaj kev ntseeg siab.

Cua sov thiab kub tswj qhov system

Cov cua kub zoo thiab kev tswj qhov kub thiab txias yog qhov tseem ceeb rau kev tswj xyuas qhov zoo thiab sib xws ntawm cov txheej txheem yas txhaj tshuaj molding. Cov tshuab no xyuas kom meej tias cov khoom siv yas tau ncav cuag qhov raug melting point thiab cov pwm kub tseem nyob ruaj khov thoob plaws hauv lub voj voog.

Cov Cuab Yeej Cuab Yeej

Lub tshuab cua sovua lub luag haujlwm tseem ceeb hauv melting yas pellets rau lawv qhov kub thiab txias. Lawv siv ntau qhov chaw cua sov kom ua tiav qhov kev tswj xyuas qhov kub thiab txias, uas yog qhov tseem ceeb rau kev ua kom zoo li qub. Kev tswj xyuas qhov kub thiab txias ua kom muaj zog ua haujlwm tau zoo thiab txhim kho qhov chaw tiav ntawm molded qhov chaw.

- Kev tswj kom zoo ntawm lub thoob qhov kub thiab txias tiv thaiv cov khoom degradation, tshwj xeeb tshaj yog nyob rau lub sij hawm ncua sij hawm nyob.

- Kev tuav lub hom phiaj kub ntawm kwv yees li 490 ° F ua kom cov ntaub ntawv zoo ib yam thiab txo qhov tsis xws luag.

- Kev hloov pauv hauv qhov ntsuas kub tuaj yeem cuam tshuam cov khoom zoo, ua rau kev soj ntsuam ze qhov tseem ceeb.

Advanced chim designs feem ntau suav nrog cov khoom siv hluav taws xob txuag hluav taws xob, txo cov nqi ua haujlwm thaum tswj kev ua haujlwm siab. Cov yam ntxwv no ua raws li cov kev coj ua niaj hnub no uas ua kom muaj kev ruaj ntseg thiab ua haujlwm tau zoo.

Pwm rhaub

Pwm tso cua sov tswj qhov kub ntawm pwm, kom ntseeg tau qhov zoo ib yam thiab txo lub sij hawm voj voog. Lub thickness ntawm cov khoom pwm ho cuam tshuam rau cov cua sov hloov pauv. Thicker seem khaws cov cua sov ntev dua, thaum cov seem thinner txias dua sai. Kho cov pwm tso cua sov raws li cov khoom tuab tiv thaiv cov teeb meem xws li warping thiab ua kom muaj qhov sib txawv ntawm qhov kub thiab txias.

Kev tshawb fawb Moulding cov txheej txheem ntxiv ua kom zoo dua pwm lub rhaub ua haujlwm. Cov txheej txheem no txo qis lub sijhawm pib, txo cov nqi seem, thiab txhim kho cov txheej txheem sib xws. Los ntawm kev tswj cov pwm pwm kub, cov tuam ntxhab ua tiav cov txiaj ntsig zoo dua thiab ua haujlwm zoo.

Temperature Control Mechanism

Covkub tswj mechanismkom ruaj khov thiab raug thaum lub sij hawm molding txheej txheem. Cov tswv yim zoo tshaj plaws, xws li cov kws tshaj lij kho qhov fuzzy tswj, sib txuas cov kev tswj hwm PID nrog fuzzy logic los ua kom zoo tshaj qhov kub ntawm lub thoob. Txoj kev no txo qis overshoot thiab oscillation, txhim kho kev ua haujlwm tag nrho.

| Tswj lub tswv yim | Kev piav qhia |

|---|---|

| Tus kws tshaj lij Adjustable Fuzzy Control | Muab cov kws tshaj lij, fuzzy, thiab PID tswj kom txhim kho kev ruaj ntseg thiab raug. |

| PID tswj | Cov txheej txheem ib txwm ua rau overshoot thiab oscillation. |

| Qauv Predictive Control | Tracks txhaj ceev, txhim kho precision nyob rau hauv molding txheej txheem. |

Cov qauv kev kawm tshuab, xws li random hav zoov algorithms, kuj pab txhawb kev siv hluav taws xob los ntawm kev txheeb xyuas qhov tseem ceeb cuam tshuam rau kev siv hluav taws xob. Cov kev tsim kho tshiab no ua rau cov tuam txhab lag luam sib npaug siv hluav taws xob nrog ib feem zoo, ntxiv dag zog rau kev ua haujlwm ntawm kev txhaj tshuaj molding.

Hydraulic thiab Control Units

Cov hydraulic thiab tswj chav nyob yog qhov tseem ceeb ntawm cov yas txhaj tshuaj molding tshuab. Cov tshuab no ua haujlwm ua ke los xyuas kom meej kev ua haujlwm, kev ua haujlwm zoo, thiabzoo ib yam khoom zoo.

Hydraulic System

Lub hydraulic system powers lub zog ntawm kev txhaj tshuaj thiab clamping mechanisms. Nws tsim lub zog uas yuav tsum tau txhaj cov yas molten rau hauv pwm thiab tswj lub clamping siab thaum lub sij hawm molding txheej txheem. Hydraulic twj, li qub, thiab lub tog raj kheej tsim lub hauv paus ntawm qhov system no, xa cov kev tswj xyuas thiab txhim khu kev qha.

Niaj hnub nimno hydraulic systems suav nrog cov thev naus laus zis siab heev rautxhim khu kev ua tau zoo. Cov twj tso kua mis hloov pauv hloov pauv hloov tus nqi ntws raws li lub tshuab ua haujlwm xav tau, txo qis kev siv zog. Tsis tas li ntawd, proportional li qub muab kev tswj xyuas meej ntawm lub siab thiab ntws, kom ntseeg tau tias kev txav tau yooj yim thiab raug. Cov yam ntxwv no ua rau lub tshuab muaj peev xwm tsim cov khoom zoo nrog cov khib nyiab tsawg.

Tswv yim:Kev saib xyuas tsis tu ncua ntawm cov khoom siv hydraulic, xws li tshuaj xyuas cov dej xau thiab saib xyuas cov roj zoo, tuaj yeem ua rau lub neej ntev thiab tiv thaiv kev poob qis.

Tswj Vaj Huam Sib Luag

Cov tswj vaj huam sib luag ua raws li lub hlwb ntawm lub tshuab txhaj tshuaj molding. Nws saib xyuas thiab tswj txhua lub tshuab ua haujlwm, ua kom pom kev ua haujlwm zoo. Nruab nrog cov sensors, cov tswj vaj huam sib luag sau cov ntaub ntawv ntawm lub sijhawm ntawm qhov tseem ceeb xws li kub, siab, thiab txoj haujlwm. Piv txwv li:

- Sensors ntsuas thiab muab cov lus qhia txog qhov kub thiab txias.

- Lub nplhaib membrane sensors xyuas kom meej txoj hauj lwm ntsuas siv strain gauge hlwb.

Cov qauv kev kawm tshuab tau muab tso rau hauv kev tswj vaj huam sib luag ntxiv txhim kho nws cov peev xwm. Cov qauv no kwv yees ib feem tsis zoo xws li cov txiaj ntsig kev ntxhov siab thiab cov qauv, ua kom cov txheej txheem ua kom zoo rau cov txiaj ntsig zoo ib yam. Cov kev tshawb fawb pom tau ua pov thawj cov qauv no los ntawm kev sib piv cov txiaj ntsig kwv yees nrog cov txiaj ntsig tiag tiag, lees paub lawv cov txiaj ntsig hauv kev txhim kho kev tsim khoom.

Lub tshuab hydraulic thiab tswj tau ua piv txwv txog kev sib koom ua ke ntawm cov tshuab thiab cov thev naus laus zis, kom ntseeg tau qhov tseeb thiab kev ntseeg siab hauv cov yas txhaj tshuaj molding tshuab.

Feeding thiab Ejection Mechanisms

Pub Pub

Covchav pub misua kom cov khoom zoo ib yam ntawm cov khoom siv yas rau lub tshuab txhaj tshuaj molding. Nws feem ntau muaj lub hopper thiab ib qho kev pub noj. Lub hopper khaws cov yas pellets thiab coj lawv mus rau hauv lub thoob, qhov twg cov khoom siv melting. Lub ntiajteb txawj nqus thiab tswj kev vibrations pab txhawb txoj kev khiav ntawm pellets, tiv thaiv kev thaiv lossis cuam tshuam thaum tsim khoom.

Cov chav pub noj niaj hnub no feem ntau suav nrog cov yam ntxwv zoo li cov khoom siv ziab khaub ncaws. Cov tshuab no tshem tawm cov dej noo los ntawm cov pellets, uas yog qhov tseem ceeb rau kev tswj cov yaj zoo thiab tiv thaiv qhov tsis xws luag hauv cov khoom kawg. Tsis tas li ntawd, automated feeding mechanisms txhim khu kev ua tau zoo los ntawm synchronizing cov khoom siv nrog lub tshuab ua haujlwm ceev. Qhov no synchronization txo cov khoom siv khib nyiab thiab ua kom tsis muaj kev cuam tshuam ntau lawm.

Ejection Unit

Covejection unitplays lub luag haujlwm tseem ceeb hauv kev tshem tawm cov pwm los ntawm pwm kab noj hniav tom qab txias. Nws siv ejector pins, daim hlau, los yog cua blasts los tso cov khoom tiav yam tsis muaj kev puas tsuaj. Precision nyob rau hauv ejection lub sij hawm thiab quab yuam yog ib qho tseem ceeb kom muaj kev ncaj ncees ntawm molded ib feem thiab tiv thaiv tsis xws luag xws li warping los yog cracking.

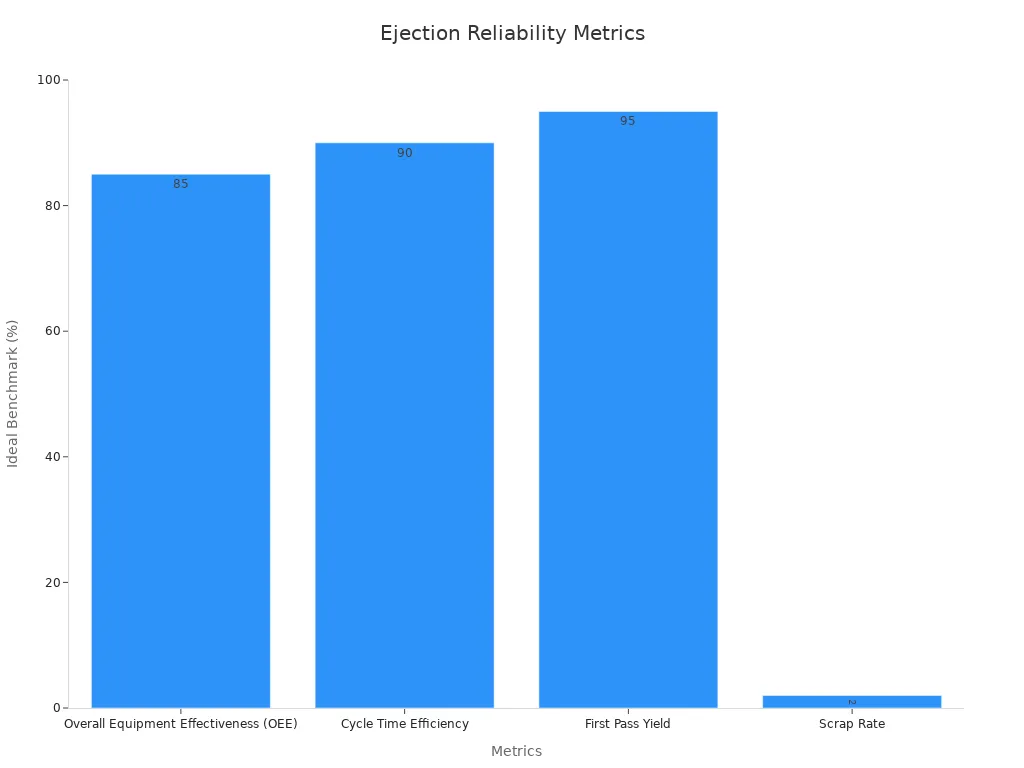

Txhim khu kev ejection units ho txo cov voj voog ntau lawm downtimes. Kev ntsuas xws li Cov Khoom Siv Tag Nrho Cov Khoom Siv Zoo (OEE), Lub Sijhawm Sijhawm Ua Haujlwm Zoo, thiab First Pass Yield (FPY) ua haujlwm tau zoo. Piv txwv li:

| Metric | Kev piav qhia | Zoo tagnrho Benchmark |

|---|---|---|

| Tag Nrho Cov Khoom Siv Tau Zoo (OEE) | Kev ntsuas kev tsim khoom; xam los ntawm kev muaj, kev ua tau zoo, thiab zoo. | ~ 85% |

| Cycle Time Efficiency | Tracks lub sij hawm ua kom tiav ib lub voj voog ntau lawm; qis dua lub sij hawm txhim khu throughput. | 90% lossis siab dua |

| First Pass Yield (FPY) | Feem pua ntawm cov khoom tau ua kom raug thawj zaug; cov txiaj ntsig siab qhia txog cov txheej txheem zoo. | > 95% |

| Qhwv tus nqi | Feem pua ntawm cov khoom pov tseg; qis tus nqi txhim kho profitability. | <2% |

Advanced ejection systems integrate sensors los saib xyuas thiab kho ejection quab yuam dynamically. Cov kev tsim kho tshiab no ua kom muaj qhov zoo ib yam thaum txo qis hnav ntawm cov pwm thiab cov khoom siv tshuab. Kev saib xyuas tsis tu ncua ntawm lub ejection unit ntxiv txhim kho nws txoj kev ntseeg tau thiab txuas ntxiv nws txoj haujlwm ua haujlwm.

Yas txhaj tshuaj molding tshuab integrates advanced Cheebtsam kom xa exceptional kev ua tau zoo. Txhua feem txhawb rau kev tsim khoom, zoo, thiab kev ntseeg siab. Mastering cov tshuab no ua kom cov txiaj ntsig zoo.

| Metric | Kev piav qhia |

|---|---|

| Kev Ua Tau Zoo | Xav txog yuav ua li cas cov ntaub ntawv raw tau hloov mus rau hauv cov khoom tiav. |

| Qhwv tus nqi | Qhia txog qhov feem pua ntawm kev tsim khoom uas tsis ua raws li cov qauv zoo. |

| Lub sijhawm tshuab | Impacts ntau lawm efficiency thiab cov nqi khiav lag luam, tseem ceeb rau profitability. |

Kev nkag siab txog cov kev ntsuas no qhia txog lub tshuab lub luag haujlwm hauv kev ua tiav cov txiaj ntsig zoo, cov txiaj ntsig zoo.

FAQ

1. Cov ntaub ntawv dab tsi tuaj yeem siv rau hauv cov yas txhaj tshuaj molding tshuab?

Yas txhaj tshuaj molding tshuab ua cov thermoplastics xws li ABS, polypropylene, thiab nylon. Lawv kuj tuav cov yas engineering xws li polycarbonate thiab PEEK.

2. Kev tswj qhov kub thiab txias li cas rau cov khoom zoo?

Kev tswj qhov kub thiab txias ua kom zoo ib yam zoo, txo qhov tsis xws luag, thiab txhim kho qhov tseeb qhov tseeb. Nws tiv thaiv cov khoom degradation thaum lub sij hawm txuas ntxiv mus.

3. Kev saib xyuas dab tsi txhim kho lub tshuab ua haujlwm?

Tsis tu ncua lubrication, hydraulic system checks, thiab ntxuav cov khoom noj kom tsis txhob hnav thiab downtime. Kev soj ntsuam sensors ua kom muaj kev ua haujlwm zoo ib yam thiab ua rau lub tshuab ua haujlwm ntev.

Post lub sij hawm: May-28-2025