Shear force plays lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntawm cov yas ntxaib ntsia hlau extruder. Nws hais txog lub zog uas ua rau cov khaubncaws sab nraud povtseg ntawm cov khoom xaub rau ib leeg, cuam tshuam rau cov khoom siv. Piv txwv li, ntau dua shear rog txhim khu kev sib xyaw thiab kev faib hluav taws xob. Hauv ibTwin Plastic Screw Barrel, lub melting cheeb tsam tsim kom ntseeg tau cov ntaub ntawv npaum li cas thaum txo qhov kub thiab txias spikes, raws li ib tug siab ntawm 40 bar tuaj yeem nce qhov kub ntawm 20 ° C. Tsis tas li ntawd, aConical Twin Ntsia Hlau Extruder Ntsia Hlau Barrelntxiv optimizes cov txheej txheem los ntawm kev sib npaug shear force thiab throughput, thaum lubTwin Screw chimtsim pab txhawb rau tag nrho efficiency nyob rau hauv cov txheej txheem extrusion.

Lub hauv paus ntawm Yas Twin Ntsia Hlau Extruder

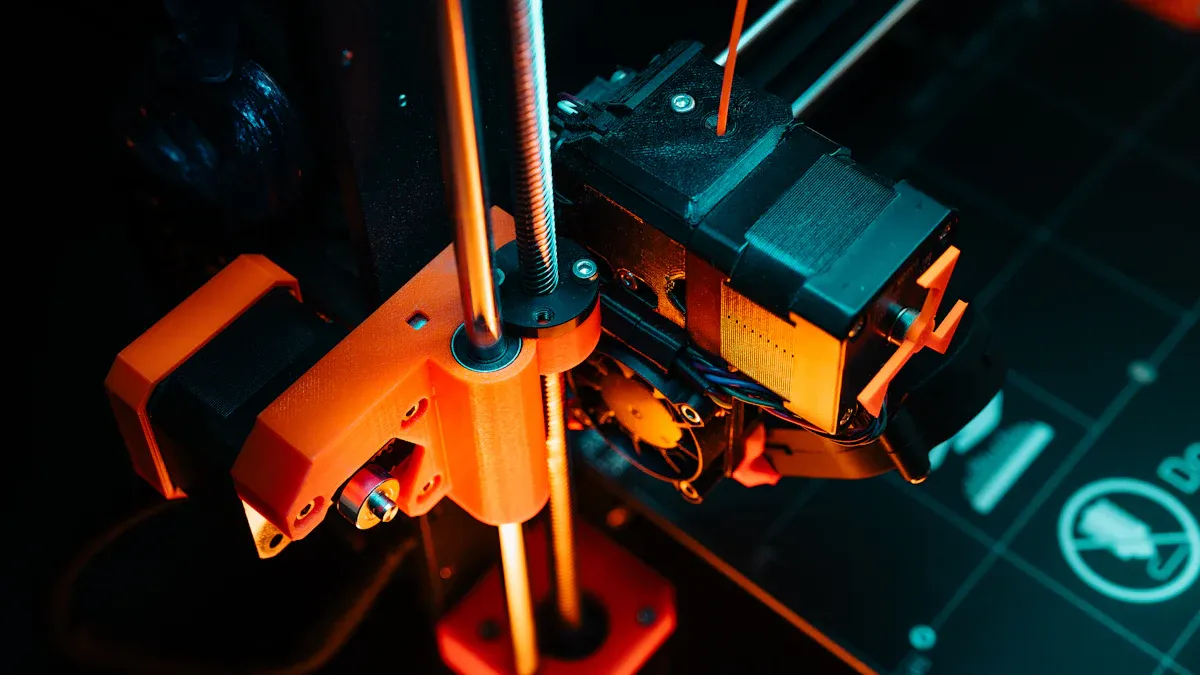

Cov ntsiab lus tseem ceeb ntawm Extruder

A yas ntxaib ntsia hlau extrudermuaj ob peb yam tseem ceeb uas ua haujlwm ua ke los ua cov ntaub ntawv zoo. Cov no suav nrog:

- Hopper: Lub ntsiab lus nkag uas cov khoom siv raw tau pub rau hauv qhov system.

- chim: Lub ntsiab chamber uas cov ntaub ntawv yog melted thiab tov.

- Ntsia Hlau Conveyor: Lub luag haujlwm thauj khoom los ntawm extruder.

- Cua sov System: Muab cov cua sov tsim nyog rau melting yas tebchaw.

- Kev Tswj Kub Kub: Ua kom muaj kev ua haujlwm zoo ib yam.

- Extrusion taub hau: Shapes cov khoom rau hauv daim ntawv xav tau thaum nws tawm ntawm extruder.

Txhua feem ua lub luag haujlwm tseem ceeb hauv kev ua kom lub tshuab extruder ua haujlwm zoo thiab xa tawm cov khoom zoo. Piv txwv li, qhov sib txawv ntawm cov ntsia hlau ceev tso cai rau kev tswj xyuas meej ntawm cov txheej txheem extrusion, thaum hloov pauv tau ua kom muaj ntau yam duab thiab ntau thiab tsawg.

Lub luag haujlwm ntawm Screws thiab chim nyob rau hauv Shear Force Generation

Cov ntsia hlau thiab lub thoob yog lub hauv paus rau kev tsim cov shear quab yuam nyob rau hauv ib tug yas ntxaib ntsia hlau extruder. Cov ntsia hlau tig nyob rau hauv lub thoob, tsim kev sib txhuam thiab siab uas yaj thiab sib tov cov khoom. Yam xws li cov ntsia hlau ceev, txoj kab uas hla tuag, thiab cov khoom siv coj los cuam tshuam rau lub zog shear. Piv txwv li:

| Parameter | Influence ntawm Shear Force Generation |

|---|---|

| Ntsia Hlau Ceev | Kev nrawm dua ua kom lub zog dhau los thiab lub zog dissipated, txhim kho lub zog shear. |

| Tuag txoj kab uas hla | Cov kab loj dua txo qhov siab thiab lub zog, cuam tshuam rau lub zog shear. |

| Khoom Cwj Pwm | Cov ntaub ntawv shear-thinning pom qhov qis dua thiab lub zog piv rau Newtonian kua. |

Cov kev sib cuam tshuam no ua kom cov khoom siv tau zoo thiab sib xyaw ua ke.

Material Flow Dynamics hauv Extruder

Cov khoom siv ntws tawm hauv cov yas ntxaib ntsia hlau extruder txiav txim siab qhov zoo ntawm kev sib xyaw thiab cov khoom kawg. Cov txheej txheem kev suav qib siab, xws li CFD, tau txhim kho kev nkag siab ntawm cov kev hloov pauv no. Cov txuj ci zoo li lub ntim-ntawm-kua dej (VOF) thiab cov txheej txheem txheej txheem taug qab cov dej sib cuam tshuam thaum sib xyaw, ua kom muaj kev tswj xyuas meej ntawm cov txheej txheem. Twin ntsia hlau extruders yog dav siv nyob rau hauv kev lag luam xws li kws tshuaj vim lawv superior mixing peev xwm. Nyob rau hauv cov xwm txheej txheem (30 kg / hr, 200 rpm), lub siab nyob rau hauv ib lub C-zoo li tus chamber ncav cuag li ntawm 2.2 MPa, nrog lub siab poob ntawm 0.3 MPa nyob rau hauv lub intermeshing cheeb tsam thiab 0.5 MPa nyob rau hauv lub rov qab ntsia hlau caij. Cov kev ntsuas no qhia txog kev ua haujlwm ntawm extruder hauv kev tuav cov khoom sib txawv.

Shear Force Mechanism hauv Twin Screw Extrusion

Generation ntawm Shear Force hauv txheej txheem Extrusion

Shear quab yuam nyob rau hauv ib tug ntxaib ntsia hlau extrusion txheej txheem tshwm sim los ntawm kev sib cuam tshuam ntawm cov rotating screws thiab lub chim nyob twj ywm. Raws li cov ntsia hlau tig, lawv tsim kev sib txhuam thiab siab, ua rau cov khoom deform thiab ntws. Qhov deformation no ua rau lub zog shear uas ua lub luag haujlwm tseem ceeb hauv melting, sib tov, thiab homogenizing cov khoom. Lub screws 'intermeshing tsim kom ntseeg tau tias cov khoom muaj kev sib raug zoo shearing thoob plaws hauv cov txheej txheem.

Kev txheeb xyuas lej siv qhov ntim-ntawm-kua (VOF) txoj kev tau nthuav tawm cov txheej txheem hydrodynamic koom nrog hauv cov txheej txheem no. Nws qhia txog yuav ua li cas shearing rog, viscosity ratios, thiab turbulence cuam tshuam lub microstructure ntawm immiscible alloys thaum sib tov. Cov kev tshawb pom no qhia txog qhov tseem ceeb ntawm shear rog hauv kev txiav txim siab tus cwj pwm rheological thiab tag nrho kev ua tau zoo ntawm cov txheej txheem extrusion.

Cov kev tshawb fawb soj ntsuam ntxiv txhawb nqa qhov txheej txheem no. Piv txwv li, kev tshawb fawb ntawm polypropylene-av nplaum nanocomposites pom tau hais tias ntxaib ntsia hlau extruders ua tau zoo dispersion piv rau ib tug ntsia hlau extruders. Qhov no yog ntaus nqi rau lub siab shear rog tsim nyob rau hauv ntxaib ntsia hlau tshuab, uas txhim khu cov exfoliation ntawm cov ntaub ntawv thiab txhim kho lawv txhua yam thiab thermal zog.

Tej yam cuam tshuam rau Shear Force

Ntau yam cuam tshuam rau tiam thiab qhov loj ntawm shear quab yuam nyob rau hauv ib lub yas ntxaib ntsia hlau extruder. Cov no suav nrog cov ntsia hlau ceev, ntsia hlau geometry, thiab cov khoom siv viscosity.

- Ntsia Hlau Ceev: Ua kom cov ntsia hlau nrawm nce tus nqi shear, ua rau muaj zog shear ntau dua. Txawm li cas los xij, kev ceev ntau dhau tuaj yeem ua rau cov khoom degradation lossis overheating.

- Ntsia Hlau Geometry: Cov qauv tsim ntawm cov ntsia hlau, suav nrog lawv lub suab, lub dav hlau qhov tob, thiab lub kaum sab xis intermeshing, cuam tshuam ncaj qha rau kev txiav txiav. Piv txwv li, screws nrog sib sib zog nqus ya ya ua rau qis shear rog, thaum tighter intermeshing ces kaum nce shearing siv.

- Khoom siv viscosity: Cov ntaub ntawv viscosity siab xav tau ntau dua shear rog kom ua tiav kev sib xyaw thiab melting. Piv txwv li, cov ntaub ntawv uas tsis muaj viscosity yuav ntws yooj yim heev, txo cov kev ua haujlwm ntawm shearing.

Cov kev tshawb fawb txheeb cais tau txheeb xyuas cov xwm txheej no kom ntxaws. Piv txwv li, kev tshawb fawb tau qhia tias cov kab mob sib xyaw ua ke nce linearly nrog cov ntsia hlau ceev tab sis txo qis nrog tus nqi pub. Kev ua haujlwm zoo, xws li pub tus nqi ntawm 3.6 kg / h ntawm tus ntsia hlau ceev ntawm 95 rpm, ua kom kub siab tshaj plaws thaum txo cov fiber ntau tawg. Cov kev tshawb pom no qhia txog qhov yuav tsum tau sib npaug ntawm cov xwm txheej no kom ua tau zoo extrusion.

Cov txheej txheem rau Kev Tswj Shear Force

Tswj shear quab yuam yog qhov tseem ceeb rau optimizing cov txheej txheem extrusion thiab ua kom cov khoom zoo ib yam. Muaj ntau txoj hauv kev tuaj yeem ua haujlwm los tswj lub zog shear nyob rau hauv ib tug ntxaib ntsia hlau extruder:

- Kho Screw Speed: Cov neeg ua haujlwm tuaj yeem nce lossis txo cov ntsia hlau nrawm los hloov kho tus nqi shear thiab ua tiav cov khoom xav tau.

- Customizing Screw Design: Tailoring cov ntsia hlau geometry, xws li hloov lub suab los yog lub dav hlau qhov tob, tso cai rau kev tswj xyuas meej ntawm kev txiav txiav.

- Siv cov qauv Shear-Thinning: Cov qauv no pab kwv yees tus cwj pwm ntawm cov khoom siv nyob rau hauv qhov sib txawv ntawm cov txheej txheem shear, ua kom muaj kev tswj xyuas cov txheej txheem zoo dua. Txawm li cas los xij, kev cia siab ib leeg rau cov qauv no tuaj yeem ua rau qhov tsis txaus ntseeg ntawm qhov tseem ceeb xws li siab thiab viscosity.

- Ua raws li Cov Txheej Txheem Saib Xyuas Txheej Txheem: Kev saib xyuas lub sijhawm tiag tiag ntawm qhov tsis xws li qhov kub thiab txias, siab, thiab lub zog torque muab kev nkag siab zoo rau cov txheej txheem extrusion. Cov ntaub ntawv no tuaj yeem siv los hloov kho thiab tswj cov qib siab shear force.

Kev tshawb fawb tau pom tias cov ntsia hlau lub luag haujlwm hauv kev hloov hluav taws xob yog qhov tseem ceeb rau kev tswj lub zog shear. Lub tshuab hluav taws xob rov ua dua nyob rau hauv lub extruder, uas pab faib cov cua sov kom sib npaug thiab tiv thaiv cov cua sov hauv zos. Qhov no xyuas kom meej tias cov polymer melts uniformly, txhim kho tag nrho cov efficiency ntawm extrusion txheej txheem.

Kev cuam tshuam ntawm Shear Force rau cov khoom vaj khoom tsev

Qhov cuam tshuam rau kev sib xyaw thiab homogeneity

Shear force plays lub luag haujlwm tseem ceeb hauv kev ua tiav kev sib xyaw ua ke thiab homogeneity hauv cov ntaub ntawv ua tiav los ntawm cov yas ntxaib ntsia hlau extruder. Kev sib cuam tshuam ntawm cov ntsia hlau thiab lub thoob ua kom muaj kev sib txhuam, uas ua rau kev sib xyaw ntawm cov polymers thiab cov khoom ntxiv. Cov txheej txheem no ua kom ntseeg tau tias cov khoom kawg nthuav tawm cov khoom sib xws thoob plaws nws cov qauv.

Cov kev tshawb fawb empirical qhia txog ntau yam ntawm kev cuam tshuam lub zog shear:

| Ib feem ntawm Shear Force Impact | Kev piav qhia |

|---|---|

| Fiber tawg | Shear rog nyob rau hauv molten matrix ua rau fiber ntau tawg, cuam tshuam cov yam ntxwv ntawm cov khoom kawg. |

| Thaum tshav kub kub tiam | Kwv yees li 80% ntawm cov cua sov uas yuav tsum tau ua rau melting yog tsim los ntawm kev sib txhuam vim shear ntawm screws thiab chim. |

| Mixing Efficiency | Kev tsim ntawm kev sib xyaw cov cheeb tsam nrog rau pem hauv ntej- thiab rov qab-kev xa tawm cov ntsiab lus cuam tshuam rau lub zog siab thiab tag nrho kev sib xyaw ua haujlwm. |

| Lub Sijhawm Chaw Nyob | RTD cuam tshuam rau cov khoom yam ntxwv los ntawm kev txiav txim siab lub sij hawm raug kub, siab, thiab shear. |

Tsis tas li ntawd, nce rotor ceev thaum lub sij hawm polypropylene-sisal melt-sib xyaw ua rau muaj fiber ntau tawg, ua rau me me fiber ntau ntev. Qhov tshwm sim no, pom nyob rau hauv ntuj fibers, tshwm sim vim shear cais bundled fibers, txo lawv txoj kab uas hla. Cov kev tshawb pom no qhia txog qhov tseem ceeb ntawm kev ua kom zoo zog shear kom sib npaug sib xyaw ua haujlwm thiab kev ncaj ncees ntawm cov khoom.

Kev cuam tshuam ntawm Thermal Properties thiab Heat Distribution

Shear force ho cuam tshuam cov khoom siv thermal thiab kev faib hluav taws xob thaum lub sij hawm extrusion. Kev sib txhuam tsim los ntawm cov ntsia hlau suav txog kwv yees li 80% ntawm cov cua sov uas yuav tsum tau ua kom yaj cov khoom yas. Qhov kev faib hluav taws xob no ua kom lub cev sib txawv thiab tiv thaiv kev kub ntxhov hauv cheeb tsam, uas tuaj yeem ua rau cov khoom tsis zoo.

Kev tsim ntawm cov extruder qhov sib xyaw ua ke ntxiv txhim kho cov cua sov hloov mus. Forward- thiab thim rov qab cov ntsiab lus tsim cov kev hloov pauv siab uas txhim kho thermal conductivity. Residence time distribution (RTD) kuj tseem ua lub luag haujlwm tseem ceeb. Cov ntaub ntawv raug rau cov shear rog sib xws muaj cov cua sov sib xws, ua rau muaj kev ruaj ntseg zoo dua thermal.

Piv txwv li, cov lej simulations qhia tau tias lub zog shear cuam tshuam rau microstructure ntawm immiscible alloys thaum sib tov. Cov rog no cuam tshuam rau qhov sib piv viscosity thiab turbulence, kom ntseeg tau tias muaj cua sov faib thoob plaws hauv cov khoom. Cov kev tshawb pom zoo li no qhia txog qhov tseem ceeb ntawm lub zog shear hauv kev tswj cov thermal sib npaug thaum lub sij hawm extrusion.

Kev hloov pauv hauv cov cuab yeej cuab tam thiab cov khoom siv zog

Shear quab yuam ncaj qha cuam tshuam rau cov khoom siv kho tshuab thiab lub zog ntawm cov khoom siv extruded. Kev hloov pauv hauv kev siv zog tuaj yeem hloov pauv cov qauv molecular, ua rau hloov pauv lub zog tensile, elasticity, thiab durability.

Kev tshawb nrhiav lej qhia txog cov teebmeem no:

- Lub ncov shear lub zog ntawm qhov sib txawv ntawm lub kaum ntse ntse sib koom ua ke nce qhov tsis sib xws nrog cov kev ntxhov siab ib txwm muaj, thaum qhov seem shear lub zog qhia tau tias muaj kev sib raug zoo nrog kev sib koom ua ke morphology.

- Ntawm qhov kev ntxhov siab qis dua, cov qauv qhia pom qhov kev txiav txim siab, uas txo qis ntawm kev ntxhov siab ntau dua. Qhov kev coj cwj pwm no qhia txog qhov tsis zoo ntawm kev sib raug zoo ntawm qhov qub thiab tangential hloov chaw.

- Cov yam ntxwv tsis zoo sib txawv nrog cov kaum sib koom ua ke. High-angle aav qhia ntsug thiab shear tawg, thaum lub kaum sab xis qis pom shear tsis ua hauj lwm raws li shear kev taw qhia.

Cov kev tshawb pom no hais txog qhov xav tau los tswj cov quab yuam kom ua tiav cov khoom siv kho tshuab uas xav tau. Piv txwv li, ntau shear tuaj yeem ua rau fiber ntau tawg, txo cov khoom siv zog. Hloov pauv, tsis txaus shear yuav ua rau tsis tiav kev sib xyaw, cuam tshuam cov khoom zoo.

Case Studies: Cov khoom coj tus cwj pwm nyob rau hauv Varying Shear Conditions

Cov ntaub ntawv tshawb fawb muab cov kev pom muaj txiaj ntsig rau qhov kev quab yuam shear cuam tshuam li cas rau cov khoom coj cwj pwm. Kev tshawb fawb ntawm polypropylene-clay nanocomposites qhia tau tiasntxaib ntsia hlau extruderua tiav superior dispersion piv rau ib qho ntsia hlau tshuab. Siab shear rog txhim khu exfoliation, txhim kho txhua yam thiab thermal zog.

Lwm txoj kev tshawb fawb ntawm ntuj fibers qhia tau hais tias shear siv thaum lub sij hawm compounding cais bundled fibers, txo lawv txoj kab uas hla. Cov txheej txheem no txhim kho cov khoom sib xws tab sis tuaj yeem cuam tshuam nws cov qauv kev ncaj ncees.

Hauv cov ntawv thov kev lag luam, kev ua kom zoo dua qub tau ua pov thawj qhov tseem ceeb rau kev tsim cov khoom zoo. Piv txwv li, kho cov ntsia hlau ceev thiab geometry nyob rau hauv ib lub yas ntxaib ntsia hlau extruder ua kom zoo sib xws thiab cov khoom zoo ib yam. Cov ntaub ntawv tshawb fawb no qhia txog qhov tseem ceeb ntawm kev txiav lub zog shear rau cov kev siv tshwj xeeb.

Optimization Strategies rau Yas Twin Ntsia Hlau Extruder

Screw Design thiab Configuration Adjustments

Optimizing ntsia hlau tsimyog qhov tseem ceeb rau kev txhim kho kev ua tau zoo ntawm cov yas ntxaib ntsia hlau extruder. Kev hloov kho rau cov ntsia hlau geometry, xws li suab, lub dav hlau qhov tob, thiab lub kaum sab xis intermeshing, cuam tshuam ncaj qha rau lub zog shear tsim thiab cov khoom ntws. Piv txwv li, screws nrog sib sib zog nqus flights txo shear siv, thaum lub sij hawm tighter intermeshing ces kaum kev sib tov efficiency.

Cov neeg ua haujlwm feem ntau kho cov ntsia hlau teeb tsa kom phim cov khoom tshwj xeeb. High-viscosity plastics tau txais txiaj ntsig los ntawm cov ntsia hlau tsim nrog qhov dav dav dav dav kom yooj yim ntws ntws. Piv txwv li, cov ntaub ntawv uas tsis tshua muaj viscosity yuav tsum tau nruj dua intermeshing cov ces kaum kom paub meej txaus shearing. Cov kev hloov kho no txhim kho cov khoom sib xws thiab txo kev siv zog thaum lub sij hawm extrusion.

Sib npaug Shear Force thiab kub

Kev tswj kom muaj qhov sib npaug ntawm lub zog shear thiab qhov kub thiab txias yog qhov tseem ceeb rau kev ua tiav zoo ib yam extrusion zoo. Lub zog shear ntau dhau tuaj yeem ua rau overheating, thaum tsis txaus shear yuav ua rau kev sib tov tsis tiav. Kev tswj lub siab nyob rau hauv lub extruder plays lub luag haujlwm tseem ceeb hauv kev tswj cov kev hloov pauv no.

Piv txwv li, ib tug qauv qhia txog kev sib raug zoo ntawm lub siab thiab kub: ∆T (°C) = ∆P (bar) ÷ 2. Ua 500 kg/hr ntawm ib tug tuag siab ntawm 40 bar tuaj yeem ua kom kub kub li ntawm 20 ° C. Kev sib koom ua ke ntawm lub iav twj tso kua mis txo qhov tso tawm, txo qhov kub thiab txias thiab hnav ntawm cov ntsia hlau tawm. Kaw-voj siab tswj ntxiv txhim khu kev ruaj ntseg extrusion, kom ntseeg tau tias cov khoom siv hluav taws xob zoo sib xws thiab cov khoom siv zoo tshaj plaws.

Tailoring Shear Force rau cov ntawv thov yas tshwj xeeb

Tailoring shear quab yuam rau cov kev siv tshwj xeeb txhim kho kev ua haujlwm ntawm cov ntaub ntawv yas. Piv txwv li, ntxiv plasticizers rau PLA composites txhim kho qhov yooj yim, cuam tshuam tsis kam, thiab cov khoom siv kho tshuab. Scanning electron microscopy (SEM) dluab qhia tau hais tias plasticized PLA nthuav tawm ntau dua ductility piv rau unplasticized composites, uas qhia nkig tus cwj pwm.

Flexural tests qhia tau hais tias cov yas sib xyaw ua ke muaj qis dua flexural modulus qhov tseem ceeb, qhia tau tias muaj zog ntxiv. Tsis tas li ntawd, qhov sib ntxiv ntawm plasticizers txo cov iav hloov pauv kub (Tg), ua kom yooj yim ua haujlwm. Cov kev hloov kho no qhia txog qhov tseem ceeb ntawm kev kho lub zog shear kom tau raws li qhov tshwj xeeb ntawm cov ntawv thov yas sib txawv.

Lub Sijhawm Saib Xyuas thiab Ntsuas Cov Txheej Txheem

Real-time soj ntsuam systemsmuab cov kev pom muaj txiaj ntsig rau hauv cov txheej txheem extrusion, ua rau cov neeg ua haujlwm ua kom zoo dua shear force zoo. Sensors ntsuas qhov tseem ceeb tsis xws li kub, siab, thiab lub zog torque, muab kev tswj xyuas meej ntawm cov xwm txheej extrusion.

Cov txheej txheem kev soj ntsuam qib siab, xws li kaw lub voj kaw, tswj xyuas qhov chaw siab zoo ib yam thiab tiv thaiv kev hloov pauv uas tuaj yeem cuam tshuam cov khoom zoo. Cov tshuab no tseem kuaj pom qhov tsis txaus ntseeg hauv cov khoom ntws, tso cai rau cov neeg ua haujlwm hloov kho tam sim. Los ntawm leveraging real-time cov ntaub ntawv, manufacturers xyuas kom meej tias cov yas ntxaib ntsia hlau extruder ua hauj lwm ntawm lub ncov efficiency, xa high-zoo tso zis.

Shear force tseem yog lub hauv paus ntawm cov yas ntxaib ntsia hlau extrusion, shaping cov khoom zoo li kev sib xyaw, thermal stability, thiab txhua yam muaj zog. Optimizing no quab yuam txhim kho cov khoom zoo thiab cov txheej txheem efficiency.

Kev hloov tshiab txuas ntxiv hauv kev tswj lub zog shear yuav qhib qhov muaj peev xwm tshiab hauv kev ua cov yas. Cov kws tshawb fawb thiab engineers yuav tsum tshawb nrhiav cov txuj ci siab heev los kho cov txiaj ntsig extrusion ntxiv.

FAQ

Dab tsi yog lub luag haujlwm tseem ceeb ntawm shear force hauv ntxaib ntsia hlau extrusion?

Shear force pab txhawb cov khoom melting, sib tov, thiab homogenization. Nws ua kom cov khoom zoo ib yam los ntawm kev cuam tshuam cov thermal thiab mechanical zog thaum extrusion.

Yuav ua li cas cov neeg teb xov tooj tswj shear quab yuam nyob rau hauv ib tug ntxaib ntsia hlau extruder?

Cov neeg ua haujlwm kho cov ntsia hlau ceev, kho cov ntsia hlau geometry, thiab saib xyuas lub sijhawm tsis zoo xws li lub siab thiab lub zog los tswj lub zog shear kom zoo.

Vim li cas qhov sib npaug shear force thiab kub tseem ceeb?

Balancing shear force thiab kubtiv thaiv cov khoom degradation, ua kom cov khoom sib xyaw ua ke, thiab tswj xyuas cov txheej txheem extrusion zoo rau cov khoom tsim tawm.

Post lub sij hawm: Jun-11-2025