Conical Twin Screw Barrel nta cov qauv tsim uas txhim kho cov khoom sib xyaw thiab kev ua haujlwm zoo. Nyob rau hauv yas extrusion, lubConical ntxaib ntsia hlau extruder PVCsystem ua kom pom kev zoo melting thiab ua cov ntaub ntawv PVC. Cov tuam txhab ua lag luam, suav nrogConical Twin Screw Extruder Barrels Hoobkas, siv cov txheej txheem ua qauv siab heev thiab meejtapered twin ntsia hlau chim thiab ntsia hlauparameters rau maximize kev ua tau zoo.

| Market Size 2024 | Peb 2033 | CAGR (2025-2033) |

|---|---|---|

| USD 1.2 billion | USD 2.5 billion | 8.9% |

Engineers nyob ntawm txoj cai tapered twin ntsia hlau chim thiab ntsia hlau kom ua tau zoo ib yam thiab zoo extrusion tau.

Conical Twin Screw Barrel Cheebtsam thiab Tsim

Structure thiab Tapered Geometry

Tus qauv ntawm aConical Twin Ntsia Hlau Barrelsawv tawm vim nws qhov tshwj xeeb tapered geometry. Qhov kev tsim qauv no maj mam txo qis hauv txoj kab uas hla ntawm qhov chaw pub noj mus rau qhov chaw tawm. Lub tapering tsim ib tug dynamic thiab uniform shear force tis. Qhov no pab txhim kho kev sib xyaw thiab ua kom cov ntaub ntawv sib xyaw ua ke. Lub geometry kuj txo qhov ntim hauv lub thoob thaum cov khoom txav mus tom ntej. Qhov kev hloov no optimizes cov ntaub ntawv conveying thiab txo qhov kev pheej hmoo ntawm blockages.

Cov qauv tapered txo qis tsis kam thiab kev siv hluav taws xob, uas ua rau kom muaj zog ua haujlwm. Nws tseem txhawb nqa txawm tias cua sov faib. Qhov no tiv thaiv hotspots thiab txhim kho thermal tswj. Lub geometry induces complex flow qauv uas txhim khu kev sib xyaw efficiency. Yog li ntawd, cov txheej txheem tsis xav tau ntau dhau shear lossis ntxiv zog tawm tswv yim. Kev tswj qhov txo qis hauv txoj kab uas hla tso cai rau kev tswj xyuas meej txog qhov ntev npaum li cas cov ntaub ntawv nyob hauv lub thoob. Qhov no ua rau kev ua haujlwm zoo thiab cov khoom siv zoo dua.

Lwm qhov tseem ceeb ntawm kev tsim qauv muaj xws li:

- Nce qhov ntev-rau-inch piv, uas txuas ntxiv txoj kev ua haujlwm thiab tso cai rau ntau lub sijhawm rau kev hloov khoom siv.

- Ntau qhov kub thiab txias, txhua tus tswj nws tus kheej, rau kev tswj xyuas qhov kub thiab txias.

- Txo cov kev ntxhov siab shear, uas tiv thaiv cov ntaub ntawv kub-sensitive thiab txhim kho cov txheej txheem kev kwv yees.

- Versatility hauv kev ua cov ntaub ntawv sib txawv, ua tsaug rau qhov adaptable tapered tsim.

Cov ntaub ntawv tseem ceeb siv

Manufacturers xaiv cov ntaub ntawv rauConical Twin Screw Barrel Cheebtsamraws li durability thiab kev ua tau zoo. Lub thoob thiab cov ntsia hlau feem ntau siv cov hlau alloy uas muaj zog heev. Cov ntaub ntawv no tiv taus hnav thiab corrosion, uas yog qhov tseem ceeb rau kev ua haujlwm ntev. Qee lub thoob tau txais kev kho mob tshwj xeeb los yog txheej txheej. Cov kev kho mob no ntxiv dag zog rau kev puas tsuaj thiab tshuaj tua kab mob.

Cov ntaub ntawv uas muaj xws li:

- Nitrided steel, uas muaj zoo heev hardness.

- Bimetallic alloys, uas muab kev tiv thaiv ntxiv nyob rau hauv ib puag ncig hnav.

- Stainless hlau, uas tiv thaiv corrosion thaum ua aggressive lossis reactive compounds.

Kev xaiv ntawm cov khoom nyob ntawm seb hom polymer lossis cov khoom sib xyaw ua tiav. Piv txwv li, cov thoob uas siv rau PVC extrusion feem ntau xav tau cov ntaub ntawv uas tuaj yeem tiv taus cov tshuaj chlorine-based compounds. Qhov kev xaiv ua tib zoo no ua kom ntseeg tau tias Conical Twin Screw Barrel tswj kev ua haujlwm siab thiab ua haujlwm ntev.

Ntsia Hlau Hom thiab Lawv Lub Luag Haujlwm

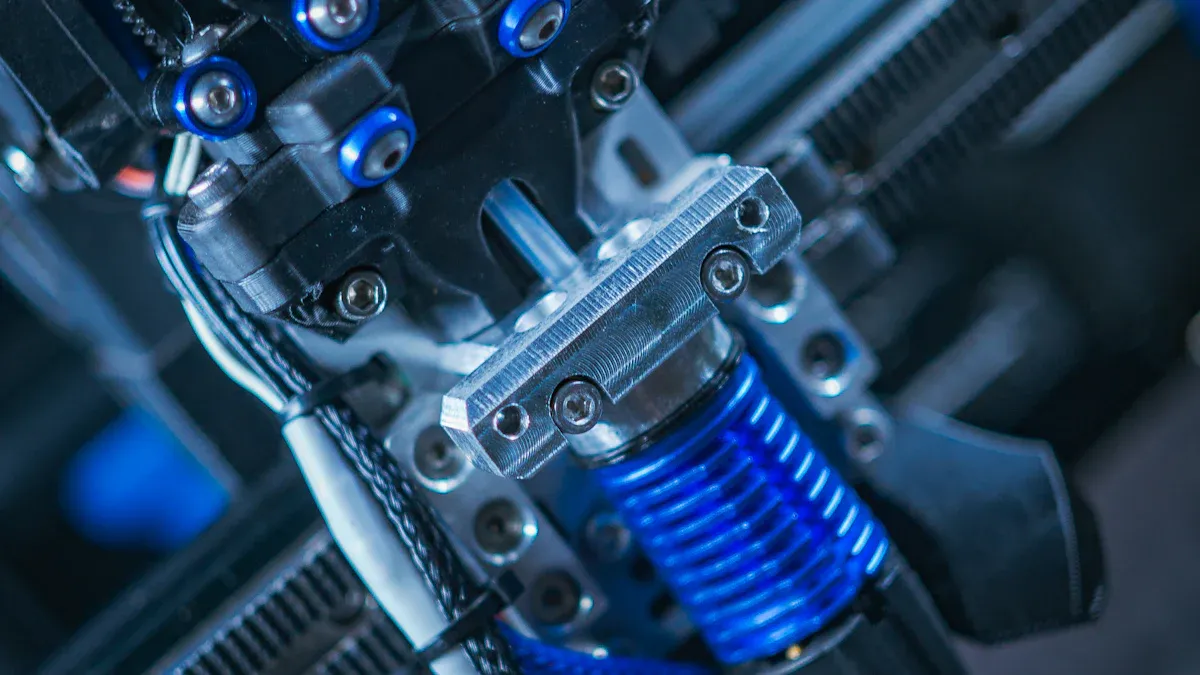

Cov ntsia hlau yog ib qho tseem ceeb ntawm Conical Twin Screw Barrel. Cov ntsia hlau sib txawv ua haujlwm tshwj xeeb thaum lub sijhawm extrusion txheej txheem. Cov kws tsim qauv tsim cov ntsiab lus no los txhim kho kev sib xyaw, melting, thiab conveying.

| Screw Element Hom | Quantitative Parameter ntsuas | Lub luag haujlwm hauv kev sib xyaw / cuam tshuam rau txheej txheem |

|---|---|---|

| Ib Leeg Lead Elements | Lub Sijhawm Chaw Nyob | Influence axial mixing thiab flow yam ntxwv |

| Mix Hindiaz | Viscous Dissipation, RTD | Txhim khu dispersive thiab distributive mixing los ntawm nce shear thiab elongational quab yuam |

| Reversed Pitch Elements | Curve Spread, Stagnancy | Hloov cov qauv ntws los txo qhov stagnancy thiab txhim kho kev faib khoom sib xyaw |

Cov ntsiab lus txhuas ib leeg tswj xyuas cov ntaub ntawv ntev npaum li cas nyob hauv lub thoob thiab pab txav mus rau tom ntej. Kev sib xyaw paddles nce shear thiab stretching zog, uas tawg thiab sib xyaw cov ntaub ntawv ntau dua. Reversed suab ntsiab hloov cov kev taw qhia ntawm ntws. Qhov no txo cov cheeb tsam uas cov khoom yuav stagnate thiab txhim kho kev sib xyaw tag nrho.

Cov kws tshaj lij tuaj yeem kho qhov kev teeb tsa ntawm cov ntsia hlau no kom phim cov kev xav tau ntawm cov khoom sib txawv thiab cov txheej txheem. Qhov kev hloov pauv no ua rau Conical Twin Screw Barrel haum rau ntau yam kev siv extrusion.

Yuav Ua Li Cas Conical Twin Screw Barrel Ua Haujlwm hauv Yas Extrusion

Cov Cai Ua Haujlwm

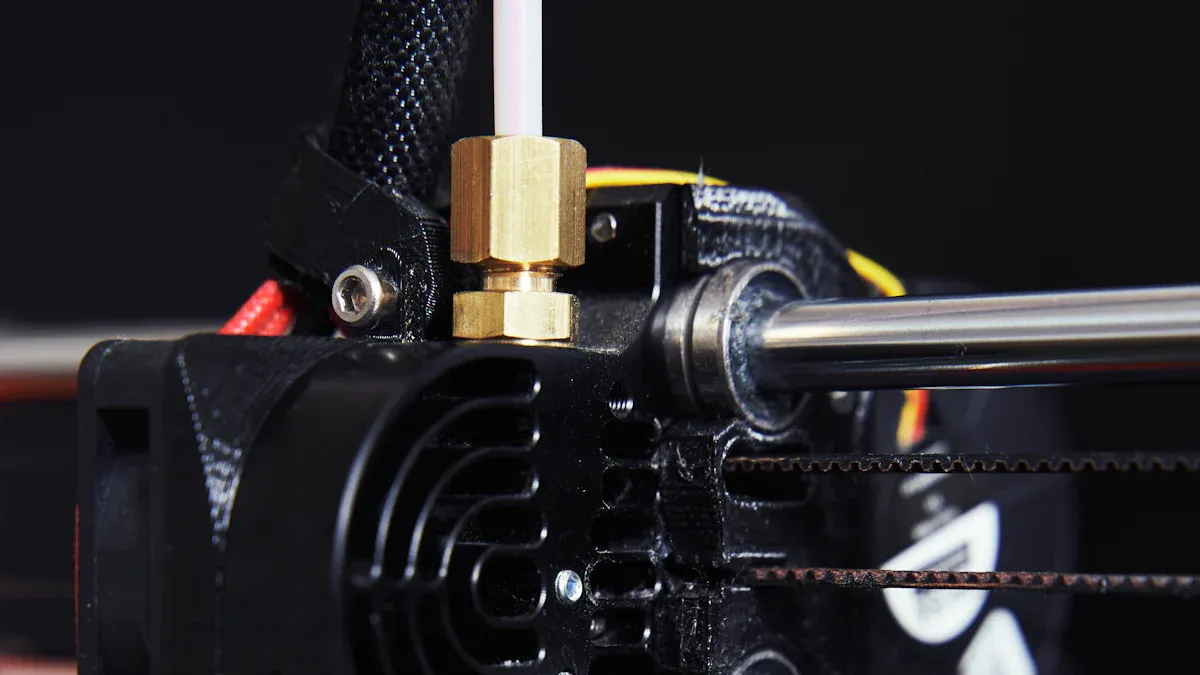

Conical Twin Screw Barrel ua haujlwm nrog kev tsom mus rau qhov yooj yim thiab ua haujlwm tau zoo. Cov kws tsim qauv tsim cov tshuab no los tswj ntau yam kev xav tau ntawm cov yas extrusion. Lub conical geometry ua rau siab torque thaum tuav cov yas maj mam. Qhov no feature yog qhov tseem ceeb rau kev ua cov ntaub ntawv uas rhiab heev rau cua sov thiab shear. Cov ntsia hlau muaj thaj chaw siab thiab qis shear profile, uas tso cai rau cov cua sov hloov mus rau lub sijhawm extrusion.

Cov neeg tsim khoom feem ntau siv cov txheej txheem tshwj xeeb, xws li nitride lossis tungsten, rau cov ntsia hlau thiab cov thoob. Cov coatings no ua rau kom hnav tsis kam thiab txhim kho cov cua sov. Lub modular tsim thiab customizable ntsia hlau configurations pab optimize lub extrusion txheej txheem rau txawv daim ntaub ntawv. Cov khoom zoo DIN steel tsim cov khoom siv hauv paus, nrog rau kev xaiv rau chrome plating lossis carbide encapsulation rau kev xav tau siv.

Cov neeg khiav dej num saib xyuas ntau yam tsis zoo thaum lub sij hawm extrusion:

- Kub

- Melt siab

- Torque

- Ntsia hlau ceev

- Pub tus nqi

Cov kev ntsuas no qhia txog yuav ua li cas cov khoom coj tus cwj pwm hauv lub thoob thiab paub meej tias lub cev ua haujlwm tau zoo.

Melting, Mixing, thiab Conveying txheej txheem

Lub melting, mixing, thiab conveying mechanisms cia siab rau kev tswj cov txheej txheem tsis thiab ntsia hlau tsim. Cov lus hauv qab no qhia tau hais tias yuav ua li cas txhua qhov parameter lossis cov qauv tsim siv tau siv cov txheej txheem no:

| Txheej Txheem Parameter / Tsim Element | Lub luag haujlwm hauv Validating Mechanism |

|---|---|

| Screw ceev (rpm) | Tswj shear npaum li cas, influences melting thiab mixing siv |

| Pub tus nqi | Muaj feem xyuam rau lub sij hawm nyob thiab melting efficiency |

| Torque | Indices mechanical load thiab zog input rau melting thiab conveying |

| Siab | Reflects cov khoom ntws tsis kam thiab conveying efficiency |

| Kub | Saib xyuas lub xeev melting thiab thermal tej yam kev mob |

| Lub Sijhawm Chaw Nyob (RTD) | Validates sib tov uniformity thiab raug lub sij hawm rau shear thiab tshav kub |

| Ntsia Hlau Geometry | Txiav txim siab conveying ceev, shear siv, thiab sib tov hom |

| Cov ntsiab lus sib xyaw | Yooj yim faib thiab dispersive sib tov, cuam tshuam cov yaj homogeneity |

Cov neeg ua haujlwm kho cov kev txwv no kom ua tiav cov txheej txheem melting, kev sib xyaw ua ke, thiab kev thauj khoom zoo. Kev tsim ntawm Conical Twin Screw Barrel ua kom ntseeg tau tias txhua theem ntawm cov txheej txheem txhawb nqa cov txiaj ntsig zoo extrusion.

Conical Twin Screw Barrel vs

Conical vs. Parallel Twin Screw Barrels

Conical thiab parallel ntxaib ntsia hlau chim ua haujlwm zoo sib xws hauv cov yas extrusion, tab sis lawv cov qauv tsim muaj qhov ua tau zoo sib txawv. Lub conical tsim siv tapered screws, uas tsim ib tug me me qhov sib txawv raws li cov khoom txav mus rau pem hauv ntej. Qhov no feature ua kom cov ntaub ntawv compression thiab txhim kho degassing. Nws kuj tseem tso cai rau kev sib kis ntau dua, ua rau nws zoo tagnrho rau cov khoom siv uas tsis tshua muaj qhov ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom ntom. Parallel ntxaib ntsia hlau chim, ntawm qhov tod tes, siv cov ntsia hlau nrog ib txoj kab uas hla tsis tu ncua. Cov tshuab no zoo heev hauv kev sib xyaw thiab kev sib xyaw ua ke, tshwj xeeb tshaj yog thaum cov ntsia hlau tig rau tib qho kev taw qhia. Parallel designs txhawb kev tu tus kheej thiab kev sib cais tsis sib xws. Cov qauv lej qhia tau hais tias conical ntxaib ntsia hlau chim txhim kho qhov ntim ntim thiab lub zog siab, uas ua rau kom zoo dua extrusion efficiency piv rau cov qauv tsim.

- Conical chim: Zoo rau compression, degassing, thiab torque.

- Parallel chim: Zoo dua rau kev sib tov, sib xyaw, thiab ntxuav tus kheej.

Cov txiaj ntsig tshwj xeeb ntawm Conical Design

Lub conical tsim muaj ntau yam txiaj ntsig. Nws txhim kho cov khoom tsim tawm thiab tsim khoom, tshwj xeeb tshaj yog nyob rau hauv cov yeeb nkab PVC. Kev txo qis hauv cov ntsia hlau channel ntim nce siab thiab txhim kho kev sib xyaw ua ke. Qhov kev tsim no kuj txhawb cov shearing maj mam, uas tiv thaiv cov ntaub ntawv kub-rhiab heev. Cov neeg ua haujlwm tuaj yeem kho cov ntsia hlau ceev thiab txoj kab uas hla los ua kom zoo dua cov zis thiab yaj zoo. Lub conical twin ntsia hlau chim txhim kho kev sib xyaw, ua rau cov xim tsis sib xws thiab cov khoom siv zoo dua qub hauv cov khoom tiav. Advanced tswj systems ntxiv boost txheej txheem efficiency thiab cov khoom sib xws.

Cov qauv tsim conical kuj pab txo qis kev siv hluav taws xob thiab pov tseg, txhawb nqa cov nqi tsim nyog thiab ruaj khov.

Tej kev siv

Conical Twin Screw Barrel pom siv hauv ntau qhov kev lag luam. Nws uaPVC yeeb nkab, profiles, thiab nplooj ntawvnrog high efficiency. Cov neeg tsim khoom siv nws rau cov khoom siv tawv tawv thiab cov khoom siv kho mob-qib polymers. Tus tsim txhawb siab tso zis tus nqi, nrogprofiles ncav cuag li 550 lb/hr thiab kav mus txog 1000 lb/hr. Nws kuj tseem txhim kho cov khoom zoo los ntawm kev txo cov pinholes thiab kom ntseeg tau tias cov ntsiab lus tsis sib xws. Kev lag luam xws li kws tshuaj, plastics, thiab cov khoom sib xyaw tau txais txiaj ntsig los ntawm nws cov qauv tsim thiab hloov tau.

| Daim ntawv thov cheeb tsam | Muab txiaj ntsig |

|---|---|

| PVC yeeb nkab Manufacturing | High tso zis, uniform yaj, ruaj khov zoo |

| Profile Extrusion | Txhim khu kev sib tov, meej qhov ntev |

| Kev kho mob Polymers | Maj mam ua, cov khoom sib xws |

| Recycled Plastics | Ntau yam khoom tuav, txuag nqi |

Xaiv lub Conical Twin Screw Barrel

Khoom Compatibility

Xaiv txoj cai Conical Twin Screw Barrel pib nrog kev nkag siab cov ntaub ntawv sib xws. Cov engineers yuav tsum sib phim lub thoob thiab ntsia hlau tsim rau cov khoom tshwj xeeb ntawm cov khoom ua tiav. Piv txwv li,PVC compoundsxav tau cov ntsia hlau sib txawv dua li polyolefins lossis engineering plastics. Cov kev tshawb fawb txog zauv pab engineers simulate yuav ua li cas txawv cov ntsia hlau tsim thiab chim setups cuam tshuam cov khoom ntws, melting, thiab sib tov. Cov kev simulation no qhia tau hais tias yuav ua li cas ntsia hlau geometry thiab cov txheej txheem tsis-xws li kub, ntsia hlau ceev, thiab tus nqi pub- cuam tshuam cov khoom siv tus cwj pwm hauv lub thoob.

Thaum ua cov ntaub ntawv rhiab heev, engineers yuav tsum tswj shear thiab cua sov kom tsis txhob degradation. Lawv kho cov ntsia hlau qhov chaw tso thiab lub thoob ntev kom ntseeg tau tias sib tov thiab melting. Abrasive los yog corrosive cov ntaub ntawv yuav tsum tau tshwj xeeb lub thoob hauv ob sab phlu los yog ntsia hlau txheej kom tsis txhob puas. Los ntawm kev ua tib zoo xaiv txoj cai ua ke ntawmntsia hlau thiab chim, cov neeg ua haujlwm tswj xyuas cov khoom ncaj ncees thiab ua tiav cov khoom zoo ib yam.

Tswv yim: Nco ntsoov xyuas cov khoom siv lub melting point, viscosity, thiab tshuaj reactivity ua ntej xaiv ib lub thoob thiab ntsia hlau configuration.

Hnav Resistance thiab Durability

Durability plays lub luag haujlwm tseem ceeb hauv kev ua haujlwm thiab kev ua neej nyob ntawm lub taub hau ntxaib. Cov neeg tsim khoom siv lub zog muaj zog alloy steels, nitrided nto, thiab bimetallic linings los tiv thaiv hnav thiab corrosion. Cov ntaub ntawv no tiv thaiv lub thoob thiab cov ntsia hlau los ntawm kev puas tsuaj los ntawm cov khoom ntim, iav fibers, lossis cov ntxhia ntxiv. Rau cov ntawv thov abrasive los yog corrosive heev, engineers tuaj yeem hais qhia ntxiv txog kev kho deg lossis txheej txheej.

Ib lub rooj hauv qab no qhia txog kev xaiv cov khoom siv thiab lawv cov txiaj ntsig:

| Hom khoom | Muab txiaj ntsig | Daim ntawv thov |

|---|---|---|

| Nitrided Hlau | High deg hardness | Standard polymer ua |

| Bimetallic alloy | Superior abrasion tsis kam | Plastics puv los yog muaj zog |

| Stainless hlau | Corrosion kuj | Reactive lossis aggressive compounds |

Kev tshuaj xyuas tsis tu ncua thiab hloov raws sij hawm ntawm cov khoom hnav pab tswj kom zoo ib yam extrusion zoo. Xaiv cov khoom tsim nyog rau lub thoob thiab cov ntsia hlau yuav txo tau lub sijhawm poob thiab ua rau lub neej ntev ntawm cov khoom siv.

Kev saib xyuas thiab kev teeb tsa

Kev saib xyuas kom zoo thiab kev teeb tsa kom ntseeg tau tias kev ua haujlwm ruaj khov thiab ua haujlwm ntev rau lub conical twin ntsia hlau chim. Niaj hnub nimno extruders, xws li Gemini® Conical Twin Screw Extruders, muaj qhov tsis tshua muaj rpm screws nrog cov dej txias sab hauv, lub thawv muaj zog, thiab cov cua txias cua txias. Cov yam ntxwv no yuav tsum tau ua tib zoo npaj thaum lub sijhawm teeb tsa. Cov neeg ua haujlwm yuav tsum muab cov txheej txheem ua kom txias zoo, kev txhawb nqa lub zog khov kho, thiab cov khoom noj kom txaus kom ua tiav qhov kev ua tau zoo.

Cov kev pabcuam tu, zoo li cov uas muaj los ntawm Milacron, suav nrog kev ntim khoom thiab rov tsim cov thoob thiab cov ntsia hlau. Cov kev pabcuam no tso cai rau cov neeg ua haujlwm txuas ntxiv lub neej ntawm lawv cov khoom siv thiab tswj xyuas kev ncaj ncees. Gearbox rov tsim kho thiab hloov kho tshiab kuj tseem ua lub luag haujlwm tseem ceeb hauv kev ua kom lub extruder ruaj khov thiab txhim khu kev qha.

Nco tseg: Teem sijhawm kuaj xyuas tsis tu ncua thiab khaws cov ntaub ntawv saib xyuas kom ntxaws. Kev nkag mus sai rau kev tsim kho cov kev pabcuam thiab cov khoom seem yuav pab txo qis qis thiab ua kom muaj kev tsim khoom tas mus li.

Kev cuam tshuam ntawm Conical Twin Screw chim rau Extrusion Performance

Efficiency thiab Output Quality

Conical Twin Screw Barrel txhim kho extrusion efficiency los ntawm optimizing cov khoom ntws thiab sib tov. Lub intermeshing ntsia hlau tsim thiab cov duab conical ua rau thaj tsam ntawm qhov chaw hauv plasticizing seem. Qhov kev tsim no pab faib cov cua sov kom sib npaug thiab txo cov khoom siv hluav taws xob. Cov neeg ua haujlwm pom tias muaj kev sib faib yaj ntau dua thiab kev tswj qhov kub zoo dua. Cov yam ntxwv no txo qhov kev pheej hmoo ntawm cov khoom degradation thiab txhim kho cov khoom sib xws.

Cov kab ntau lawm siv hom chim no feem ntau pom cov extrusion nrawm dua thiab cov txiaj ntsig zoo dua.Kev siv hluav taws xob tuaj yeem poob mus txog 30%piv rau cov khoom siv niaj hnub. Kev txhim kho durability ntawm cov ntsia hlau thiab cov thoob kuj txhais tau tias tsis tshua muaj sijhawm rau kev txij nkawm. Covcov lus hauv qab no qhia txog kev ntsuas kev ua haujlwm tseem ceeb:

| Metric / Feature | Tus nqi / Nqe lus piav qhia |

|---|---|

| Kev Ua Tau Zoo | Kho tau zoo heev |

| Kev siv hluav taws xob | Kev txo qis |

| Cov nqi seem | Kev txo qis |

| Screw hnav txo | Txog li 60% txo |

| Kev nce ntxiv | nce txog 25% nce |

| Pov tseg tus nqi | ~ 1.5% |

| Pib Lub Sijhawm Rau Qhov Loj Tshiab | 1 rau 2 h |

Cov txiaj ntsig no qhia tau hais tias Conical Twin Screw Barrel txhawb kev tsim khoom ruaj khov, txo cov khoom pov tseg, thiab ua kom cov khoom tsim tau zoo.

Nqi-zoo

Cov neeg tsim khoom tau txais txiaj ntsig los ntawm tus nqi-zoo ntawm qhov tsim lub thoob no. Kev siv hluav taws xob qis ncaj qha txo cov nqi khiav lag luam. Cov ntaub ntawv muaj zog thiab cov txheej txheem qib siab txuas ntxiv lub neej ntawm ob lub thoob thiab cov ntsia hlau. Qhov no durability txhais tau hais tias tsawg dua hloov thiab tsis tu ncua tsis tu ncua.

Txo cov nqi seem thiab lub sijhawm pib sai dua kuj pab txuag nyiaj. Cov neeg ua haujlwm siv sijhawm tsawg dua los ntxuav thiab kho cov khoom siv. Cov lus saum toj no qhia tau tiasCov nqi pov tseg poob mus txog li 1.5%, thiab pib lub sij hawm rau cov khoom tshiab qhov ntev luv rau 1 mus rau 2 teev xwb. Cov kev txhim kho no tso cai rau cov tuam txhab tsim khoom ntau dua nrog cov peev txheej tsawg.

Tswv yim: Kev nqis peev hauv Conical Twin Screw Barrel tuaj yeem ua rau kev txuag nyiaj mus sij hawm ntev thiab txhim khu kev qha ntau lawm.

Conical Twin Screw Barrel muab kev tswj xyuas meej thiab kev ua haujlwm siab hauv cov yas extrusion. Cov kev tshawb fawb pom tau tias qhov zoo tshaj plaws extrusion tsis ua rau cov txiaj ntsig zoo ib yam thiab txhim kho cov txiaj ntsig zoo. Cov neeg siv yuav tsum sib piv cov qauv tsim rau cov khoom xav tau thiab saib xyuas cov txheej txheem sib txawv. Kev paub xaiv kom ntseeg tau tias kev ua tau zoo thiab cov khoom zoo tshaj plaws.

FAQ

Dab tsi industries siv conical twin ntsia hlau chim?

Cov neeg tsim khoom hauv plastics, kev tsim kho, thiab cov cuab yeej siv kho mob sivconical twin ntsia hlau chimrau kev tsim cov kav dej, profiles, thiab cov khoom tshwj xeeb polymer.

Ntau npaum li cas cov neeg ua haujlwm yuav tsum tshuaj xyuas lub conical twin ntsia hlau chim?

Cov neeg ua haujlwm yuav tsumsoj ntsuam lub thoobtsis tu ncua. Cov kws tshaj lij feem ntau pom zoo kom kuaj xyuas txhua hli kom ntseeg tau tias qhov ua tau zoo thiab tiv thaiv lub sijhawm poob qis.

Puas yog lub conical twin ntsia hlau chim txheej txheem cov ntaub ntawv uas tsis yog PVC?

Yog lawm. Conical ntxaib ntsia hlau chim tuav ntau yam polymers, nrog rau polyolefins thiab engineering yas, los ntawm kev kho cov ntsia hlau tsim thiab cov txheej txheem tsis.

Lub sij hawm xa tuaj: Plaub Hlis-02-2025