Ib leeg ntsia hlau chim tshuab tsis koom nrog kev sib koom ua ke lossis counter-rotating sib txawv pom nyob rau hauv cov qauv ntxaib-ntsia hlau. Nyob rau hauv 2025, ib leeg ntsia hlau chim tseem coj lub extrusion lag luam. Cov lus hauv qab no qhia txog lawv qhov tseem ceeb txuas ntxiv:

| Xyoo | Ib Screw Barrel Market Share (%) | Sau ntawv |

|---|---|---|

| 2023 | 60 | Kev lag luam loj tshaj plaws ntawm cov hom extruder |

| 2025 | ~ 60 lossis siab dua me ntsis | Kev kwv yees raws li kev loj hlob ruaj khov |

Manufacturers xaiv ntawm cov kev xaiv xws liPVC yeeb nkab ib leeg ntsia hlau chim, ib leeg ntsia hlau chim rau tshuab molding, thiabib leeg yas ntsia hlau chimlos ntawm kev xav txog kev tsim cov ntsia hlau, cov khoom siv lub tog raj kheej, thiab cov khoom xav tau.

Ib Screw chim: Cov khoom tseem ceeb Classifications

PVC yeeb nkab ib leeg ntsia hlau chim

PVC yeeb nkab ib leeg ntsia hlau ua lub luag haujlwm tseem ceeb hauv kev tsim cov kav dej rau kev tsim kho, kav dej, thiab kev siv hluav taws xob. Manufacturers tsim cov thoob nrog aqauv yooj yim, uas txo cov neeg kho tshuab tsis ua hauj lwm thiab ua rau kev saib xyuas ncaj qha. Kev siv high-strength alloy steel nrogkev kho nitridingnce hardness thiab hnav tsis kam. Qhov kev tsim no ua kom zoo sib xws, sib tov, thiab xa cov khoom siv PVC. Cov lus hauv qab no qhia txog cov yam ntxwv tseem ceeb:

| Feature | PVC Yeeb Nkab Ib Screw Barrels |

|---|---|

| Tsim | Yooj yim, txhim khu kev qha qauv |

| Kev tu | Yooj yim, tsawg dua kev txawj ntse xav tau |

| Cov Nqi Ua Haujlwm | Tsawg dua, ua haujlwm tau zoo |

| Kev Tswj Kub Kub | Kev tswj tau yooj yim dua |

| Durability | High-strength alloy steel, nitrided rau hnav tsis kam |

| Kev thov kom haum | Zoo tagnrho rau txheem PVC yeeb nkab extrusion |

Cov thoob no tswj cov me me mus rau nruab nrab-teev PVC yeeb nkab ntau lawm vim lawv txoj kev ntseeg siab thiab kev ua tau zoo.

Ib Screw chim rau tshuab Moulding

Ib leeg ntsia hlau chim rau tshuab moulding txhawb kev tsim cov fwj, ntim, thiab lwm yam khoom hollow. Cov engineers muab cov thoob no nroggrooved feed screwsthiab sib sib zog nqus ya ya los txhim kho resin melting thiab sib tov. Ib qho kev sib xyaw ua ke nyob ze ntawm cov ntsia hlau kawg txhim kho cov khoom sib xyaw polymer thiab ua kom zoo ib yam. High compression ratios pab ua kom yaj homogeneity, uas yog ib qho tseem ceeb rau npuas stability thiab zaj duab xis zoo. Cov qauv tsim tshwj xeeb tuaj yeem suav nrog cov sensors rau kev saib xyuas lub siab thiab qhov kub thiab txias, ua kom cov txheej txheem tswj tau meej. Kev siv cov cua kub-kho alloy steel muab durability thiab hnav tsis kam.

- Grooved feed screws txhim kho resin melting thiab conveying.

- Integrated txias tshuab tswj qhov kub thiab txias thaum extrusion.

- Kev xaiv sensors pab saib xyuas cov txheej txheem ntawm lub sijhawm.

PE yeeb nkab Extruder ib leeg ntsia hlau chim

PE yeeb nkab extruder ib leeg ntsia hlau chim yog tsim los rau cov khoom tshwj xeeb ntawm polyethylene. Cov thoob no ua kom muaj txiaj ntsig zoo, sib tov, thiab xa cov khoom PE. Cov qauv tsim txhawb nqa siab dhau los thiab ua kom zoo ib yam, ua tau raws li qhov xav tau ntawm cov khoom siv PE yeeb nkab. Cov neeg tsim khoom siv cov khoom siv thiab cov qauv tsim, xws li hlau alloys thiab nitrided steel, kom phim cov polymer thiab cov kev xav tau ntau lawm. Daim ntawv segmentation suav nrog kev lag luam xws li tsheb, khoom siv hauv tsev, thiab cov yas dav dav, uas qhia txog kev siv ntau yam ntawm cov thoob.

- Me, nruab nrab, thiab loj txoj kab uas hla xaivhaum cov nplai ntau lawm.

- Optimized rau high-volume industrial processing thiab cov zis zoo ib yam.

Kev ua tau zoo thiab kev ua haujlwm tau zoo nyob rau hauv ib qho Screw Barrel Systems

Kev sib xyaw thiab Homogenization muaj peev xwm

Kev sib xyaw thiab homogenization ua lub luag haujlwm tseem ceeb hauv cov txheej txheem extrusion. Cov ntsia hlau ib leeg txav cov khoom siv raw los ntawm kev pub mis, yaj, thiab ntsuas qhov chaw. Lub rotating ntsia hlau, ua ke nrog chim cua sov, melts cov khoom thiab thawb nws mus rau pem hauv ntej. Cov txheej txheem no compresses thiab sib tov cov molten polymer, kom ntseeg tau tias ib qho kev faib ua ntej nws tawm hauv qhov tuag.

Cov engineers feem ntau ntxiv cov khoom sib xyaw ua ke los txhim kho kev ua haujlwm. Dispersive mixers, xws li Egan thiab Maddock hom, rhuav tshem clumps thiab txhim khu cov yaj zoo los ntawm kev siv shear. Distributive mixers, zoo li Saxton los yog tus pin mixers, faib thiab rov faib cov yaj, uas pab ua tiav cov xim thiab cov khoom ntxiv. Barrier screws cais cov khoom thiab molten theem, tso cai rau kom tiav melting ua ntej sib tov. Cov kev xaiv tsim no nyob ntawm cov khoom siv thiab cov khoom zoo.

Tswv yim:Kev xaiv cov khoom sib tov zoo thiab cov ntsia hlau geometry tuaj yeem txhim kho homogenization, tshwj xeeb tshaj yog rau cov khoom siv nrog cov xim lossis cov khoom ntxiv.

Txawm li cas los xij, lubib channel flow pathnyob rau hauv ib lub taub hau taub hau tuaj yeem txwv kev sib xyaw. Polymer tshaj tawm txawv ntawm cov channel, uas tuaj yeem ua rau tsis tiav. Txhawm rau hais txog qhov no, cov kws tshaj lij siv cov davhlau ntxiv thiab sib xyaw ua ke, txawm tias cov no tuaj yeem ua rau muaj kev kub ntxhov thiab kub. Optimized ntsia hlau tsim pab kov yeej cov teeb meem no, xa cov khoom zoo, zoo ib yam.

Tus Nqi Tshaj Tawm thiab Tshaj Tawm

Kev ntsuas ntsuas ntau npaum li cas cov khoom siv extruder ua raws sijhawm. Nyob rau hauv 2025, ib tug ib txwm ntsia hlau chim chim nrog ib tug 100 mm txoj kab uas hla ncav ib ncig ntawm 150 kg / hr. Optimized ntsia hlau tsim tuaj yeem txhawb tus nqi no los ntawm 18% mus rau 36%. Cov lus hauv qab no qhia txog qhov tseem ceeb ntawm kev nkag mus tsis tau:

| Parameter | Paub meej / Tus nqi |

|---|---|

| Ntsia Hlau Diameter | 100 hli |

| Hom Kev Tshaj Tawm | 150 kg / h |

| Metering-Channel Qhov tob | 4mm rau 8mm |

| Tus nqi nce los ntawm Screw Optimization | 18% mus rau 36% |

| Maximum tso zis kub | ~ 230 ° C |

| Limiting Factors | Txias, extrudate kub |

Kev sib sib zog nqus channel qhov tob hauv cov ntsia hlau txo cov nqi shear thiab tawm qhov kub, uas tso cai rau kev nkag mus ntau dua. Txawm li cas los xij, qhov qis qis qis qis thiab qhov kub thiab txias txwv feem ntau cap qhov siab tshaj plaws tso zis. Screw geometry, xws li suab thiab zawj dav, kuj cuam tshuam tus nqi extrusion thiab plasticization zoo.

Kev siv hluav taws xob thiab txheej txheem ruaj khov

Ib leeg ntsia hlau extruders sawv tawm rau lawv lub zog efficiency nyob rau hauv ncaj qha extrusion dej num. Lawv cov qauv tsim yooj yim thiab ncaj qha kev hloov pauv hluav taws xob ua rau lub zog qis dua piv rau cov tshuab siv ntau dua. Rau cov ntaub ntawv homogeneous, lawv siv tsawg zog thiab ua haujlwm nrog cov nqi qis.

Ntau yam cuam tshuam rau kev siv zog:

- Lub cev muaj zog efficiency thiab ntsia hlau tsim cuam tshuam rau kev siv fais fab.

- Cua sov thiab cua txias tshuab ua lub luag haujlwm hauv kev tswj xyuas qhov kub thiab txias.

- Cov txheej txheem tsis, xws li ntsia hlau ceev thiab chim kub, cuam tshuam tag nrho efficiency.

Txheej txheem stabilityua kom cov khoom zoo ib yam thaum lub sijhawm ua haujlwm tas mus li. Qhov ntev-rau-inch ratio, compression ratio, thiab ntsia hlau profile tag nrho cuam tshuam rau melting thiab sib tov.Kev xaiv khoomrau cov ntsia hlau thiab chim influences durability thiab compatibility nrog txawv plastics. Cov neeg khiav dej num saib xyuas qhov kub thiab txias siv cov sensors los xyuas thiab tswj qhov kev hloov pauv. Advanced tswj systems, xws li fuzzy logic controllers, pab tswj kev ruaj khov thiab txhim kho yaj zoo.

Nco tseg:Cov txheej txheem ruaj khov tiv thaiv kev hloov pauv hauv cov khoom lag luam thiab txo cov khoom pov tseg, ua cov txheej txheem saib xyuas thiab tswj qhov tseem ceeb rau kev tsim khoom lag luam.

Daim ntawv thov tsim nyog ntawm ib leeg ntsia hlau chim tsim

Material Compatibility thiab kev xav tau

Cov ntaub ntawv sib raug zoo sawv cev yog qhov tseem ceeb thaum xaiv ib lub taub hau rau extrusion. Cov neeg tsim khoom xaiv cov ntaub ntawv ntim thiab kev kho mob raws li hom yas thiab qhov chaw ua haujlwm tshwj xeeb. Cov ntaub ntawv hauv qab no feem ntau siv:

- 38CrMoAIA thiab SKD61 muab kev hnav zoo thiab corrosion tsis kam rau cov yas dav dav.

- Bimetallic alloysmuab kev txhim kho durability, tshwj xeeb tshaj yog rau abrasive los yog recycled plastics.

- Kev cai ntsia hlau thiab lub thoob tsim kom haum raws li qhov xav tau ntawm cov tshuab thiab cov khoom sib txawv.

Cov ntaub ntawv no hais txog ntau yam kev xav tau, xws li hnav tsis kam, tiv thaiv corrosion, thiab tswj kev ua haujlwm siab. High-wear-resistance barrels ua qhov tseem ceeb thaum ua cov khoom ntim lossis cov khoom siv rov ua dua tshiab. Corrosion-resistant kev xaiv tiv thaiv kev txhoj puab heev additives los yog polymers. Cov lus hauv qab no qhia txog cov ntaub ntawv sib txawv li cas raws li ntau yam kev xav tau:

| Hom khoom | Kev kho mob / txheej | Cov kev xav tau ua nyob rau | Plastics sib xws |

|---|---|---|---|

| SCM-4 High-Hardness Alloy hlau | High-Frequency Quenching / Hard Chrome | Hnav tsis kam, corrosion kuj, tiv taus shear thiab tshav kub | PE, PP, PVC, ABS, thiab lwm yam. |

| SACM-1 Alloy hlau | Kev kho Nitriding | Txhim kho hnav thiab corrosion kuj | PE, PP, PVC, ABS, thiab lwm yam. |

| SCM-4 Bimetallic Alloy | Hardened nto txheej (0.8-1.2mm) | Txhim kho hnav thiab corrosion kuj | Ntau yam plastics suav nrog cov khoom siv rov ua dua tshiab thiab ntim cov yas |

Engineers kuj xav txog qhov thermal expansion ntawm corrosion-resistant cov ntaub ntawv. Lawv ua tib zoo muab cov ntsia hlau thiab lub thoob los tiv thaiv kev khi lossis kev puas tsuaj thaum ua haujlwm. Advanced coatings, xws li Colmonoy los yog tungsten alloys, tiv thaiv abrasive hnav thiab ntev kev pab cuam lub neej. Cov kev xaiv no ua kom lub taub hau ib lub taub hau tswj kev ua haujlwm zoo thoob plaws ntau yam ntawm cov yas thiab kev ua haujlwm.

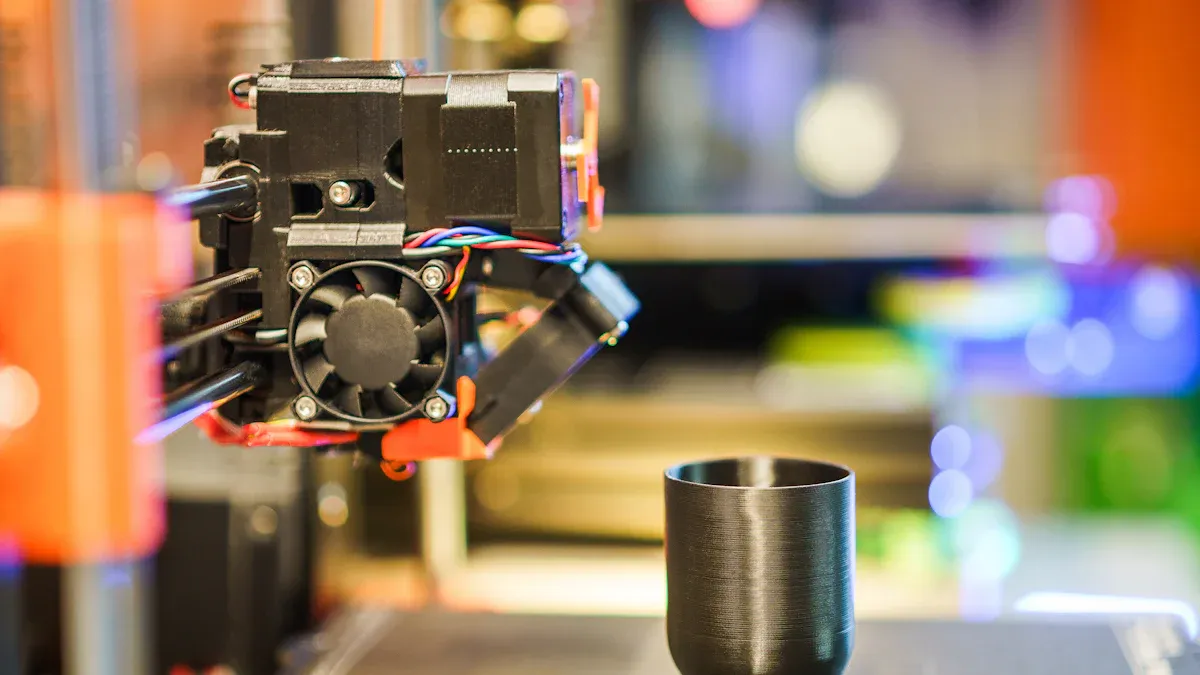

Cov khoom zoo thiab kev sib raug zoo

Kev tsim ntawm ib lub taub hau ntsia hlau ncaj qha cuam tshuam qhov zoo thiab sib xws ntawm cov khoom extruded. Ib lub thoob tsim tau zoo ua kom muaj txiaj ntsig zoo, sib xyaw ua ke, thiab ruaj khov ntawm cov khoom siv polymer. Cov txheej txheem no txo qhov tsis xws luag thiab tswj kev sib luag ntawm cov khoom kawg. Cov qauv tsim tseem ceeb muaj xws li:

- Qhov ntev-rau-inch (L / D) piv tswj lub sijhawm nyob thiab tswj thermal.

- Compression ratio thiab ntsia hlau geometry txiav txim siab sib xyaw thiab yaj homogeneity.

- Barrel metallurgy, xws li bimetallic los yog nitrided nto, txhim khu kev hnav tsis kam thiab stabilizes ntau lawm zoo.

Kev sib xyaw ua kom zoo thiab sib xyaw tiv thaiv kev tsis sib xws, xws li xim streaking lossis qhov tsis raug. Screw geometry pab tswj qhov kub thiab txias, tsis txhob degradation lossis over-melting. Kev tswj xyuas kom zoo thiab kev khiav dej num tswj cov khoom zoo ib yam, uas yog qhov tseem ceeb rau cov khoom sib xws thiab qhov ntev. Kev cai ntsia hlau profiles, zoo li barrier screws los yog cov khoom sib xyaw, txhim kho yaj uniformity thiab xim dispersion. Kev saib xyuas tsis tu ncua thiab kho cov ntsia hlau thiab lub thoob pab txhawb nqa cov khoom lag luam zoo nyob rau lub sijhawm.

Tswv yim: Matching ntsia hlau tsim rau hom yas tshwj xeeb kom pom cov khoom zoo thiab txo qhov kev pheej hmoo ntawm qhov tsis xws luag.

Kev lag luam-Specific Requirements

Cov kev lag luam sib txawv xav tau cov yam ntxwv tshwj xeeb los ntawm lawv cov khoom siv extrusion. Ib lub taub hau ntsia hlau yuav tsum ua kom tau raws li cov kev xav tau tshwj xeeb kom ntseeg tau tias kev tsim khoom tsim tau zoo thiab muaj txiaj ntsig. Cov lus hauv qab no qhia txog cov cai tseem ceeb rau thaj chaw thov loj:

| Kev lag luam / Daim Ntawv Thov | Cov ntsiab lus tseem ceeb thiab kev txiav txim siab |

|---|---|

| Yas Extrusion | Match ntsia hlau chim tsim rau cov khoom siv (virgin, recycled, puv, blended polymers); L / D piv feem ntau 24: 1 txog 36: 1; Compression ratio thiab mixing zones tailored rau txheej txheem; Kev kho deg zoo li nitriding lossis bimetallic txheej rau hnav tsis kam; High-hnav daim ntaub ntawv yuav tsum tau bimetallic chim rau durability |

| Khoom noj khoom haus Extrusion | Qhov tsawg kawg nkaus ntsia hlau-thooj qhov sib txawv kom muaj kev nyiam huv thiab tiv thaiv kev sib kis; Tsawg shear gap rau cov khoom kub-rhiab heev |

| Roj Hmab thiab Tshuaj Extrusion | Txhim kho, hnav-resistant coatings los lis abrasive puv roj hmab; Qee lub sij hawm dav dav kom txo qis zog |

Yas extrusion feem ntau yuav tsum nruj ntsia hlau-thooj tolerances thiab tshwj xeeb coatings los lis ntau yam polymers, nrog rau cov uas muaj fillers los yog recycled cov ntsiab lus. Khoom noj khoom haus extrusion muab tus nqi them rau kev nyiam huv, xav tau qhov sib txawv me me thiab cov qauv tsim qis los tiv thaiv cov khoom lag luam. Roj hmab thiab tshuaj extrusion tau txais txiaj ntsig los ntawm cov txheej txheem ntxiv thiab, qee zaum, qhov sib txawv dav dua los tswj cov khoom siv abrasive thiab txo qhov hnav.

Kev sib raug zoo, kev saib xyuas, thiab kev tswj qhov kub thiab txias ntxiv cuam tshuam rau kev xaiv cov thoob thoob plaws txhua qhov kev lag luam. Kev ua kom zoo, sib tov, thiab kev xa khoom tseem ceeb heev rau kev tswj cov khoom zoo thiab cov kab ntau lawm.

Tus nqi thiab kev saib xyuas kev txiav txim siab rau ib leeg ntsia hlau chim

Pib nqis peev thiab cov cuab yeej siv tau ntev

Kev nqis peev thawj zaug rau ib leeg ntsia hlau chim system hauv 2025 tseem siv tau rau feem ntau cov tuam txhab. Cov nqi feem ntau yog los ntawm$10,000 txog $50,000, uas yog qis dua tus nqi ntawm cov ntsia hlau ntxaib tshuab. Cov lus hauv qab no qhia txog yam tseem ceeb uas cuam tshuam rau cov nqi no:

| Qhov xwm txheej | Kev cuam tshuam rau tus nqi |

|---|---|

| Khoom zoo | Qib siab = tus nqi siab dua |

| Qib Automation | Ntau automation = tus nqi siab dua |

| Kev kho kom haum | Cov qauv tsim tshwj xeeb = tus nqi siab dua |

| Supplier Reputation | Paub zoo = tus nqi siab dua |

Ib leeg ntsia hlau pub cov thoob siv cov cuab yeej yooj yim thiab tsim, uas ua rau thawj zaug peev thiab kev saib xyuas xav tau tsawg. Qhov kev yooj yim no kuj pab txo qhov kev pheej hmoo ntawm kev siv tshuab tsis ua haujlwm. Cov cuab yeej siv tau ntev nyob ntawm kev xaiv cov khoom siv, ntsia hlau tsim, thiab kev saib xyuas tsis tu ncua. Advanced coatings thiab bimetallic chim tuaj yeem txuas ntxiv lub neej kev pab cuam, tshwj xeeb tshaj yog thaum ua cov khoom siv abrasive.

Cov nqi khiav lag luam thiab kev siv zog

Kev khiav hauj lwm cov nqi rau ib leeg ntsia hlau chim tshuab nyob twj ywm kwv yees vim muaj kev ruaj ntseg zog noj. Kev siv hluav taws xob feem ntau yog los ntawm cua sov lub chim thiab khiav lub hau ntswj, uas feem ntau xav tau ntawm 3 thiab 50 kW. Lub tshuab ntsia hlau nws tus kheej siv 7 mus rau 15 kW. Vim tias qhov kev xav tau ntawm lub zog tseem nyob ruaj khov, cov tuam ntxhab tuaj yeem siv nyiaj tau yooj yim dua thiab khaws cov nqi tsim khoom raws li kev tswj hwm. Covmechanical ua hauj lwm ntawm cov ntsia hlau kuj tsim cov cua sov sab hauv, uas txo qhov kev xav tau ntawm cov cua sov ntxiv thiab txhim kho kev siv hluav taws xob. Siv cov thev naus laus zis txuag hluav taws xob xws li cov tsav tsheb sib txawv thiab kev saib xyuas cov tshuab tuaj yeem txo nqi ntxiv.

Tswv yim: Kev siv zog ruaj khov hauv extrusion ua rau cov khoom seem tsawg dua thiab cov khoom siv zoo dua piv rau lwm cov txheej txheem molding.

Kev tu thiab kev hnav khaub ncaws

Kev saib xyuas rau ib lub taub hau ntsia hlau tsom rau kev tswj kev hnav thiab ua kom lub cev ua haujlwm zoo. Cov teeb meem feem ntau suav nrog kev ua kom tsis zoo ntawm cov yaj zoo, hnav sai los ntawm cov khoom siv abrasive, thiab kev ua haujlwm tsis zoo. Hnav yam xws li abrasive fillers, corrosive additives, thiab kub kub tuaj yeem ua kom qhov kev xav tau ntawm kev kho. Cov chaw hnav khaub ncaws siab, zoo li qhov chaw pub mis thiab tso tawm, yuav tsum tau kuaj xyuas tsis tu ncua. Kev siv cov khoom siv siab heev thiab cov coatings pab txuas ntxiv lub neej kev pab cuam thiab txo qhov kev tu ncua sij hawm. Kev tiv thaiv kev saib xyuas, kev tu tsis tu ncua, thiab kev saib xyuas kev hnav khaub ncaws tso cai rau cov tuam txhab lag luam npaj kho thiab zam kom tsis txhob poob siab.

Yav tom ntej Trends thiab Innovations nyob rau hauv ib tug Screw chim Technology

Technological Advancements hauv 2025

Cov neeg tsim khoom txuas ntxiv qhia cov thev naus laus zis tshiab uas txhim kho kev ua haujlwm thiab kev ua haujlwm ntawm cov tshuab extrusion. Ntau qhov kev tsim kho tshiab sawv tawm hauv 2025:

- Txhim kho cov ntaub ntawv ntws txo cov blockages thiab downtime, uas nce lub sij hawm ntau lawm.

- Optimized heat transfer tswj qhov kub thiab txias ua haujlwm zoo, txhim kho cov khoom siv thiab cov khoom sib xws.

- Kev ua kom ruaj khov los ntawm cov ntaub ntawv zoo ua rau muaj kev kho thiab hloov kho tsawg dua, txuag sijhawm thiab nqi.

- Customizable configurations cia adaptation rau tej yam kev xav tau ntau lawm, ntxiv boosting efficiency.

Lub Helibar tsim nyob rau hauv lwm tiam extruders muab ntau dua throughput thiab zoo dua melt-pressure buildup. Qhov kev tsim no kuj tseem txo qis qhov kub thiab txias thiab txhim kho yaj homogeneity. Txo lub thoob hnav thiab lub sij hawm nyob luv luv pab tswj cov khoom zoo. Ntau lub chaw tsim khoom tam sim no siv kev saib xyuas kev kwv yees thiab kev tswj hwm qib siab ua ib feem ntawm kev tsim khoom ntse. Cov tshuab no saib xyuas cov khoom siv kev noj qab haus huv thiab cov txheej txheem tsis raws sijhawm, uas pab tiv thaiv lub sijhawm poob qis thiab ua kom muaj kev ua haujlwm ruaj khov.

Kev Ua Lag Luam Xav Tau thiab Sustainability

Kev lag luam tiam sis xyoo 2025 qhia txog kev hloov pauv sai hauv kev lag luam plastics thiab kev paub txog ib puag ncig. Ntau yam ua rau kev thov rau cov khoom siv extrusion siab heev:

- Kev lag luam plastics loj hlob sai, tshwj xeeb tshaj yog nyob rau hauv Asia-Pacific, vim kev siv nroog thiab cov neeg siv khoom xav tau.

- Cov khoom siv hnyav pom kev siv ntau ntxiv hauv tsheb thiab aerospace sectors.

- Kev tsim kho thev naus laus zis, xws li barrier screws thiab CAD / CAM customization, txhim kho efficiency thiab txo kev siv zog.

- Cov kev cai ib puag ncig nruj me ntsis thawb cov tuam txhab lag luam kom siv cov khoom siv hluav taws xob txuag hluav taws xob thiab khib nyiab tsawg.

- Kev lag luam ntim khoom nthuav dav, tsom mus rau saj zawg zog, biodegradable, thiab recyclable cov ntaub ntawv.

- Kev lag luam 4.0 thiab kev tsim khoom ntse pab saib xyuas lub sijhawm thiab kev ua haujlwm zoo.

- Kev sib koom ua ke thiab kev yuav khoom pab cov tuam txhab txhim kho cov peev txheej thev naus laus zis.

Sustainability kev txhawj xeeb tsim kev txhim kho ntawm extrusion technology.Cov neeg tsim khoom siv cov khoom siv rov ua dua tshiab thiab txo cov khoom pov tseg. Ntau tus siv cov khoom siv rov ua dua tshiab thiab cov tshuab ntxuav dej los txhawb cov hom phiaj kev lag luam ncig. Cov khoom siv hluav taws xob tauj dua tshiab thiab cov cuab yeej siv hluav taws xob pab txo qis carbon emissions. Advanced coatings thiab precision engineering txo cov khoom siv nplaum thiab siv zog, uas txo cov hneev taw ib puag ncig. Cov kev coj ua no pab cov tuam txhab ua tau raws li cov qauv ib puag ncig nruj dua thiab txhim kho lawv lub koob npe nrov hauv khw.

Cov kev cai ib puag ncig hauv cheeb tsam xws li Fabkis thiab European Union yuav tsum tau nruj me ntsis emissions thiab recycling qauv. Cov neeg tsim khoom yuav tsum tsim kho tshiab kom ua raws li cov cai no thaum tswj hwm tus nqi zoo. Txoj cai tswjfwm no ua rau muaj kev daws teebmeem ntau dua thiab kev nqis peev tsis tu ncua hauv kev tshawb fawb thiab kev tsim kho.

Kev sib koom ua ke tiv thaiv kev sib cav sib ceg tsis siv rau cov tshuab no. Cov neeg tsim khoom nyiam lawv hauv 2025 rau lawv cov kev ua tau zoo, kev ntseeg tau, thiab hloov tau. Thaum xaiv, lawv yuav tsum phim lub thoob tsim rau cov khoom xav tau, xav txoghnav tsis kam, thiab nrhiav cov yam ntxwv uas txhawb kev saib xyuas digital thiab kev tsim khoom ruaj khov.

FAQ

Dab tsi yog qhov txiaj ntsig tseem ceeb ntawm ib lub taub hau ntsia hlau hauv extrusion?

Ib leeg ntsia hlau chimmuab kev txhim khu kev qha, kev saib xyuas yooj yim, thiab kev siv nyiaj txiag. Lawv haum rau feem ntau cov txheej txheem extrusion daim ntawv thov nyob rau hauv 2025.

Yuav ua li cas ntau npaum li cas manufacturers yuav tshuaj xyuas ib leeg ntsia hlau chim?

Cov neeg tsim khoom yuav tsum tshuaj xyuas ib lub taub hau taub hau txhua peb mus rau rau lub hlis. Kev kuaj xyuas tsis tu ncua pab tiv thaiv kev hnav thiab tswj cov khoom zoo ib yam.

Ib lub taub hau taub hau puas tuaj yeem siv cov yas rov ua dua tshiab?

Yog lawm,ib leeg ntsia hlau chimtuaj yeem ua cov yas rov ua dua tshiab. Siv bimetallic chim lossis coatings tshwj xeeb txhim kho kev hnav tsis kam thiab ua rau lub neej ntev.

Post lub sij hawm: Lub Xya hli ntuj-10-2025