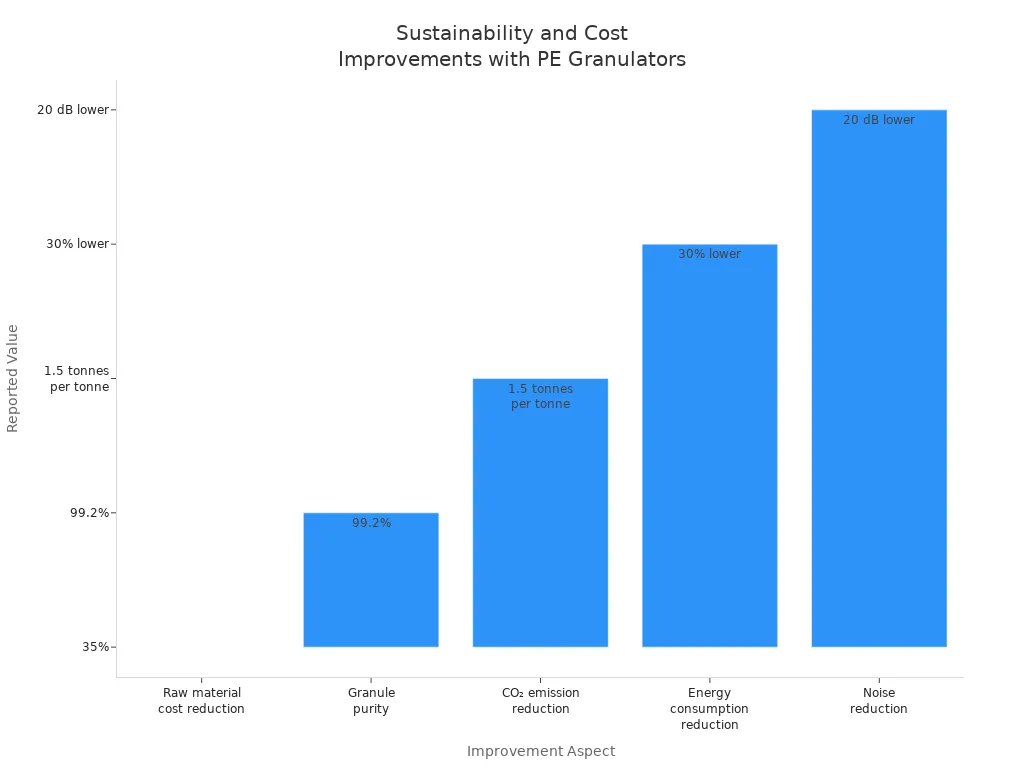

PE me me ib puag ncig granulators pab cov tuam txhab txiav hluav taws xob siv nrog cov yam ntxwv ntse thiab cov thev naus laus zis tshiab. Cov qauv tshiab tshaj plaws qhia cov txiaj ntsig zoo:

| Metric | 2025 Txo vs. Xyoo dhau los |

|---|---|

| Kev siv hluav taws xob (kW-h / tonne) | 40% qis dua |

| Greenhouse Gas Emissions | 33% tsawg dua |

| Fossil Roj siv | 45% tsawg dua |

Lawv sivhigh-efficiency motors, pov tseg tshav kub rov qab, thiab cua txias tshuab. IbIb puag ncig Mini-Pelletizer TshuabthiabWaterless Granulator Tshuabmuaj peev xwm tuav tauPvc Pelletizing Extrusion tshuabua tau zoo.

Zog-Txuag Nta ntawm PE Me Ib puag ncig Granulators

High-Efficiency Motor Systems

PE me me ib puag ncig granulators hauv xyoo 2025 siv cov cuab yeej siv lub cev muaj zog kom txuag tau lub zog thiab txhawb kev ua haujlwm. Cov tshuab no tso siab rau cov khoom siv hluav taws xob nrog lub cev muaj zog xws li 22 kW txog 110 kW, nyob ntawm tus qauv loj. Cov motors ua haujlwm nrog lub peev xwm ntawm 200 txog 1200 kg / h, ua rau lawv zoo meej rau kev ua haujlwm me me thiab nruab nrab. Cov lus hauv qab no qhia qee cov ntsiab lus tseem ceeb ntawm kev ua haujlwm:

| Specification | Paub meej |

|---|---|

| Lub cev muaj zog ntau yam | 22 kW rau 110 kW |

| Tsav hom | Cov khoom siv hluav taws xob tsav |

| Auxiliary Drive zog | 1.1 kW tsi |

| Peev Xwm Ntau | 200-1200 kg / h |

| Daim ntawv thov | PE thiab lwm yam yas granulation |

Cov motors ua haujlwm siab no siv servo tsav thiab kev tswj xyuas ntse. Lawv pab cov neeg ua haujlwm txuag tau txog li 40% ntau lub zog piv rau cov motors qub. Kev saib xyuas lub sijhawm tiag tiag thiab automation ua kom lub cev ua haujlwm zoo, txo qis sijhawm thiab txiav cov nqi hluav taws xob.

Optimized Blade thiab Transmission Design

Cov hniav thiab kis kab mob hauv PE me me ib puag ncig granulators ua lub luag haujlwm loj hauv kev txuag hluav taws xob. Cov neeg tsim khoom siv cov hniav ua los ntawm cov hlau zoo xws li tungsten carbide lossis cov hlau kub ceev. Cov ntaub ntawv no kav ntev dua thiab txiav tau zoo dua. Nov yog qee txoj hauv kev optimized blades pab:

- Precision hniav kaum sab xis txo lub cev muaj zog thiab siv zog.

- Advanced coatings, xws li titanium nitride, txo kev sib txhuam los ntawm 40%.

- Kev tu ultrasonic tsis tu ncua ua kom cov hniav ntse thiab tiv thaiv cov khoom seem.

- Flat blades ua haujlwm zoo tshaj plaws rau cov yas mos, txo qis tsis kam thiab txuag zog.

- High-hardness cov ntaub ntawv ua kom muaj peev xwm ntau lawm txog li 30%.

Ib tsob nroj German rov ua dua tshiab pom 22% dhia hauv kev ua haujlwm thiab 14% poob hauv kev siv zog ib tuj tom qab hloov mus rau cov ntaub ntawv zoo dua. Thaum cov hniav nyob twj ywm ntse thiab huv si, tag nrho lub tshuab ua haujlwm zoo dua thiab siv zog tsawg dua.

Ntse automation thiab txheej txheem tswj

Ntse automation ua rau PE me me ib puag ncig granulators txawm ntau npaum li cas. Cov tshuab no siv PLC tswj tshuab thiab kov cov ntxaij vab tshaus kom yooj yim ua haujlwm. Automation nta muaj xws li:

- Nws pib pub noj tswj kom khov kho cov khoom ntws.

- Dual channel lim tshuab uas cia cov neeg ua haujlwm hloov cov ntxaij vab tshaus yam tsis muaj kev txwv.

- Back-flush filter systems rau cov khoom pov tseg tsis siv neeg.

- Nws pib-kho ntawm pelletizing riam ceev thiab siab rau uniform pellets.

- Online teeb meem thiab parameter optimization los ntawm huab tswj.

Tswv yim: Ntse automation tsis tsuas yog txuag lub zog tab sis kuj txo qhov xav tau ntawm kev siv tes ua haujlwm. Cov neeg ua haujlwm tuaj yeem tsom mus rau lwm yam haujlwm thaum lub tshuab ua haujlwm hloov kho raws li niaj hnub.

Integrated designs muab shredders, compactors, thiab extruders rau hauv ib qho system. Qhov kev teeb tsa no ua rau cov txheej txheem ua haujlwm tsis muaj kev so ntev, uas txhais tau hais tias tsis muaj zog thiab cov zis ntau dua.

Pov tseg Thaum tshav kub kub rov qab thiab siv

PE me me ib puag ncig granulators tsis cia cov cua sov uas muaj txiaj ntsig mus pov tseg. Thaum lub sijhawm ua haujlwm, cov tshuab no ua kom sov. Es tsis txhob poob nws, lub kaw lus ntes thiab rov ua dua cov cua sov no rau lwm cov txheej txheem tsim khoom, xws li cov khoom siv ua ntej cua sov lossis ua kom sov rau qhov chaw ua haujlwm. Txoj hauv kev no txo qis qhov xav tau rau cov khoom siv cua sov ntxiv thiab txiav kev siv zog tag nrho.

- Pov tseg cov cua sov rov qab txhawb nqa ib puag ncig cov hom phiaj los ntawm kev txo cov pa roj carbon monoxide emissions.

- Reusing cua sov pab manufacturers ua tau raws li nruj zog thiab ib puag ncig tus qauv.

- Cov txheej txheem tseem ua rau cov nqi khiav lag luam qis, ua rau cov granulators ua lag luam ntse.

Los ntawm kev sib xyaw cov nolub zog txuag nta, PE me me ib puag ncig granulators teeb tsa tus qauv tshiab rau kev ua tau zoo thiab kev ruaj khov hauv kev rov ua dua tshiab.

Cov txiaj ntsig zoo thiab kev cuam tshuam ib puag ncig

Kev siv hluav taws xob qis dua

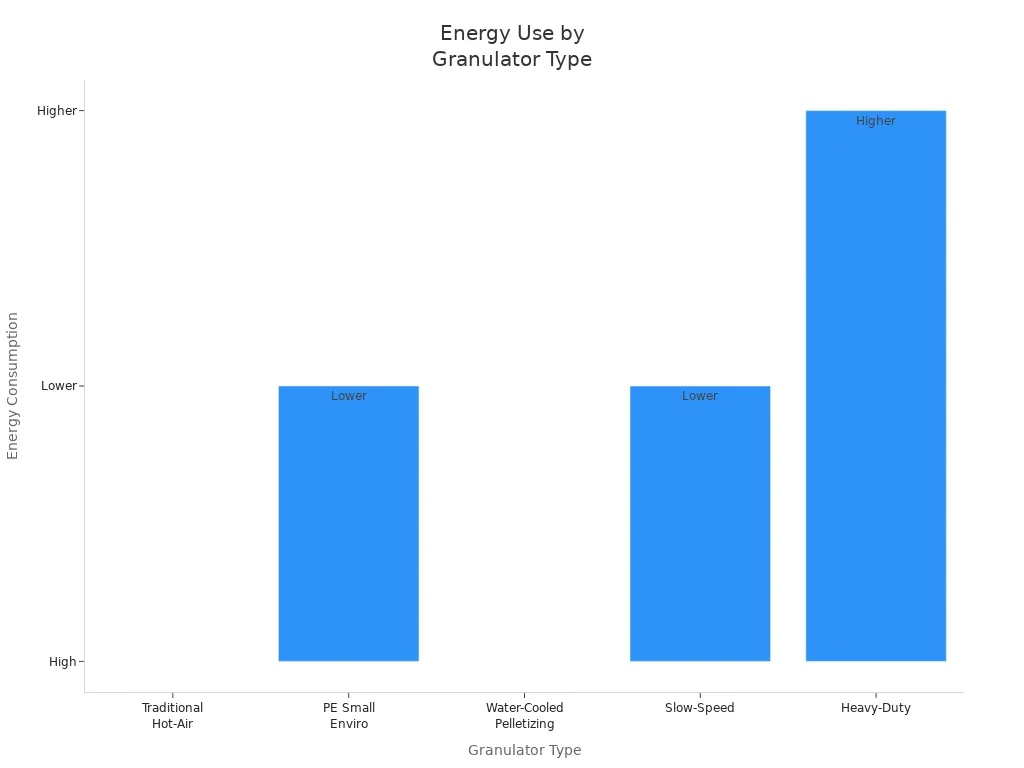

PE me me ib puag ncig granulators sawv tawm rau lawv cov kev siv hluav taws xob tsawg. Ntau lub tshuab granulators, xws li cua kub lossis dej txias, siv hluav taws xob ntau dua thiab tsim kom muaj kuab paug ntau dua. Cov lus hauv qab no qhia seb hom granulator sib txawv li cas:

| Granulator Hom | Kev siv hluav taws xob | Environmental Impact | Cov Lus Qhia Ua Haujlwm |

|---|---|---|---|

| Tsob Ntoo Kub Cua Yas Granulators | Siab | Cov pa phem tseem ceeb | Tshaj li 75% ntawm cov khoom siv; xav tau kev kho dua tshiab |

| PE Small Environmentally Friendly Granulators | Tsawg dua vim huab cua txias thiab ua haujlwm qis | Txo emissions vim kev txuag hluav taws xob | Siv cov peev txheej txuas dua tshiab thiab pov tseg cov cua sov rov qab |

| Dej-txias Pelletizing Systems | High (dej thiab hluav taws xob) | Ib puag ncig lub nra ntawm kev siv dej | Loj hneev taw, complex ua haujlwm |

| Slow-Speed Granulators | qis | Tsawg suab nrov thiab hnav | Zoo rau qhov me me, siv ib sab-tus-xovxwm |

| Heavy-duty Granulators | Siab dua | Siab dua vim kev xa khoom | Rau cov ntaub ntawv tawv; tsawg zog npaum |

Cua txias, ua haujlwm kub qis pab cov granulators siv zog tsawg. Lawv kuj hla cov kauj ruam kom qhuav, uas txuag tau ntau lub zog.

Txo cov pa roj carbon hneev taw thiab ua raws

Cov tshuab no pab cov tuam txhab txo qis lawv cov pa roj carbon hneev taw. Lawv siv hluav taws xob tsawg dua thiab rov ua dua cov khoom pov tseg yas ntawm qhov chaw, uas txhais tau tias cov tsheb thauj khoom tsawg dua ntawm txoj kev thiab muaj kuab paug tsawg.Cov tshuab siv yas me mekuj khaws pov tseg ntawm qhov chaw pov tseg. Los ntawm kev hloov cov yas qub rau hauv cov pellets tshiab, lawv txo qis qhov xav tau cov khoom siv tshiab. Ntau lub tuam txhab tam sim no ua tau raws li kev cai ib puag ncig nruj ua tsaug rau cov kev hloov kho tshiab no.

Nco tseg: Lub tuam txhab tsheb German tau cawm 300 tonnes ntawm cov yas tshiab txhua xyoo los ntawm kev rov ua dua cov khib nyiab nrog cov granulators me me.

Kev txuag nqi thiab kev ua haujlwm zoo

Cov neeg tsim khoom pom kev txuag nyiaj tiag nrog cov granulators. High-efficiency motors thiab ntse automation txo nqi hluav taws xob. Kev ua haujlwm tsawg dua txhais tau tias ua yuam kev tsawg dua thiab tsis muaj sijhawm poob qis. Cov lus hauv qab no qhia tau hais tias aCov txheej txheem txheej txheem boosts efficiency thiab profits:

| Theem | Kev piav qhia | Cov Ntsiab Cai |

|---|---|---|

| Kev npaj | Txhais lub hom phiaj thiab KPIs | Teem lub hom phiaj SMART, faib cov peev txheej |

| Kev ua tiav | Siv cov kev hloov pauv hauv kev tswj hwm env | Pilot tej yaam num, standardize kev cob qhia |

| Kev ntsuam xyuas | Saib xyuas kev nce qib thiab sau cov lus qhia | Siv cov ntaub ntawv analytics, kho raws li xav tau |

| Kev nthuav dav | Scale kev ua tau zoo | Ua ke cov kev kawm tau kawm, cob qhia |

Ib qho 20% poob rau lub sijhawm voj voog tuaj yeem ua rau cov nyiaj tau los ntau dua. Kev siv hluav taws xob pov tseg thiab kev siv hluav taws xob qis dua kuj txo cov nqi.

Compact Size thiab Space Efficiency

Lub compact tsim ntawm cov granulators txuag qhov chaw muaj txiaj ntsig hauv pem teb. Cov chaw ua haujlwm me me thiab cov chaw rov ua dua tshiab tuaj yeem haum rau lawv yam tsis tau hloov pauv lawv qhov kev teeb tsa. Cov neeg ua haujlwm pom lawv yooj yim los tswj thiab ntxuav, uas txhais tau tias tsis muaj sijhawm poob qis. Kev teeb tsa modular txhawb kev kaw-voj rov ua dua tshiab, ua rau tag nrho cov txheej txheem ua haujlwm tau zoo dua thiab ruaj khov.

Tswv yim: Ib tug hneev taw me me txhais tau tias muaj chaw ntxiv rau lwm yam khoom siv lossis kev nthuav dav yav tom ntej.

PE me me ib puag ncig granulators teeb tsa tus qauv tshiab rau kev siv hluav taws xob hauv xyoo 2025. Cov neeg tsim khoom pom cov txiaj ntsig tiag tiag:

- Cov nqi qis dua thiab pov tseg tsawg dua

- Cov nqi rov ua dua siab dua

- Kev txhawb nqa rau lub hom phiaj sustainability

- Fast payback thiab muaj zog ua raws

FAQ

PE me me ib puag ncig granulator pab txuag hluav taws xob li cas?

Lub granulator siv high-efficiency motors thiab ntse automation. Cov yam ntxwv no txiav kev siv hluav taws xob thiab ua kom cov khoom lag luam ruaj khov.

Tswv yim: Cov kev tswj ntse cia cov neeg ua haujlwm kho cov teeb tsa sai sai kom txuag tau ntau dua.

Cov kev cob qhia me puas tuaj yeem siv cov granulator no?

Yog lawm, lawv ua tau. Qhov loj me me haum rau qhov chaw nruj. Cov neeg ua haujlwm pom nws yooj yim rau nruab thiab tswj.

- Fits me me cov kab ntau lawm

- Yooj yim rau kev khiav lag luam

Cov ntaub ntawv dab tsi tuaj yeem ua tus txheej txheem PE me ib puag ncig granulator?

Nws tuavPE thiab lwm yam yas. Lub tshuab ua haujlwm zoo rau kev rov ua dua cov pov tseg yas rau hauv cov pellets tshiab.

| Hom khoom | Puas haum rau Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| PVC | ✅ |

Post lub sij hawm: Aug-14-2025