Cov yas txhaj tshuaj molding ntsia hlau chim sawv ntawm lub plawv ntawm txhua txoj kev molding. Thaum lawv xaiv qhov zooYas Tshuab Ntsia Hlau Barrellos yog aYas Twin Ntsia Hlau Extruder chim, manufacturers pom smoother cov khoom ntws, tsawg defects, thiab cov nqi qis dua.Stainless Hlau Twin Ntsia Hlau Extruder chimcov kev xaiv kuj pab txuas ntxiv lub neej ntawm cov cuab yeej thiab txiav downtime.

Lub luag haujlwm tseem ceeb ntawm Kev Txhaj Tshuaj Molding Ntsia Hlau Barrel

Melting thiab homogenizing yas khoom

Cov yas txhaj tshuaj molding ntsia hlau thoob ua si ib qho tseem ceeb hauv kev xa cov yas pellets rau hauv cov khoom siv du, molten. Hauv lub thoob, cov ntsia hlau tig thiab thawb cov pellets rau pem hauv ntej. Raws li cov pellets txav mus, kev sib txhuam thiab cov cua sov bands yaj lawv. Lub thoob khaws cov cua sov, yog li cov yas melts ntawm tus nqi zoo. Cov txheej txheem no yuav pab kom tsis txhob muaj pob los yog qhov chaw txias hauv cov khoom.

Tswv yim: Lub taub hau ntsia hlau muaj peb thaj chaw tseem ceeb - pub, compression, thiab ntsuas. Txhua cheeb tsam muaj txoj haujlwm tshwj xeeb. Qhov chaw pub mov txav thiab preheats cov pellets. Qhov chaw compression melts cov yas thiab tshem tawm cua. Lub metering cheeb tsam ua kom cov yaj yog du thiab npaj rau kev txhaj tshuaj.

| Zone | Lub luag haujlwm tseem ceeb |

|---|---|

| Pub Zone | Thauj pellets, preheats lawv, thiab compacts kom tshem tawm cov hnab tshos cua. |

| Compression Zone | Melts cov yas thiab tshem tawm cua los ntawm kev siab thiab shear. |

| Kev ntsuas Zone | Homogenizes yaj, tsim siab, thiab stabilizes ntws rau txhaj. |

Kev tswj qhov kub thiab txias tseem ceeb heev. Piv txwv li, nruj UPVC xav tau ceev cua sov ntawm 180-190 ° C. Lub taub hau ntsia hlau siv ob lub tshuab cua sov sab nraud thiab cov ntsia hlau nws tus kheej txav los tsim kom muaj cua sov zoo. Qhov sib npaug no ua rau cov yas tsis txhob hlawv lossis nplaum. Cov ntsia hlau ceev kuj tseem cuam tshuam qhov zoo ntawm cov yas yaj. Yog tias cov ntsia hlau tig qeeb dhau, cov yaj yuav tsis kub txaus. Yog hais tias nws tig ceev heev, cov yas yuav overheat. Cov yas txhaj tshuaj molding ntsia hlau thoob ua kom cov yaj yog qhov zoo rau txhua qhov kev txhaj tshuaj.

Sib tov cov khoom ntxiv thiab ua kom muaj xim sib xws

Cov neeg tsim khoom feem ntau ntxiv cov xim lossis cov khoom siv tshwj xeeb rau cov yas. Cov yas txhaj tshuaj molding ntsia hlau chim sib tov cov khoom xyaw rau hauv lub yaj. Cov ntsia hlau tsim, nrog rau kev sib xyaw tshwj xeeb, pab muab txhua yam sib npaug. Qhov kev sib xyaw no txwv tsis pub cov streaks lossis cov pob los ntawm kev tshwm sim hauv cov khoom kawg.

Cov xim sib xws tuaj yeem ua kom yuam kev. Qee zaum,qhuav pigments lo rau hauv lub hopper los yog tsis sib tov zoo. Cov av noo tuaj yeem cuam tshuam nrog resin thiab pigment zoo. Precise dosing of colorants yog ib qho tseem ceeb. Cov tshuab siv gravimetric blenders los ntsuas tus nqi tsim nyog. Pwm tsim kuj tseem pab khaws cov xim txawm tias hla ntau qhov chaw.

Nco tseg: Cov qauv ntsia hlau siab tshaj plaws, zoo li thaiv thaiv lossis Maddock screws, tawg cov pob thiab kis cov xim zoo dua. Cov qauv no tuaj yeem ua tauboost mixing efficiency ntau dua 20% thiab txiav cov nqi seem txog li 30%. Kev tu thiab tu tsis tu ncua ua kom lub taub hau ntsia hlau ua haujlwm ntawm nws qhov zoo tshaj plaws, yog li cov xim nyob twj ywm ntawm batch mus rau batch.

Conveying thiab Txhaj Molten Yas

Thaum cov yas yog yaj thiab sib tov, lub hau ntsia hlau txav cov khoom molten mus rau pwm. Cov ntsia hlau tig mus rau hauv lub qhov cub kub, thawb lub yaj mus rau pem hauv ntej. Thaum cov khoom tsim muaj txaus, cov ntsia hlau ua zoo li lub plunger. Nws txhaj cov yas molten rau hauv pwm ntawm kev kub siab.

Nov yog qhov txheej txheem ua haujlwm li cas:

- Yas pellets nkag mus rau hauv seem pub thiab txav mus tom ntej thaum lub hau ntswj tig.

- Kev sib txhuam thiab kub yaj cov pellets.

- Cov ntsia hlau compresses lub yaj, ua kom nws du thiab txawm.

- Cov ntsia hlau nce thiab txhaj cov yas molten rau hauv pwm.

Covyas txhaj molding ntsia hlau chimua kom txhua yam txav mus tau yooj yim. Nws tswj lub siab thiab ntws, yog li txhua qhov txhaj tshuaj puv pwm zoo kawg nkaus. Lub thoob cov ntaub ntawv tawv sawv ntsug kom hnav thiab tsim kua muag, ua kom cov txheej txheem nyob ruaj khov nyob rau lub sijhawm.

Optimizing Performance nrog txoj cai yas txhaj Molding Ntsia Hlau chim

Kev cuam tshuam ntawm Screw Geometry thiab Barrel Design

Ntsia hlau geometryua kom cov yas melts thiab sib tov hauv lub thoob li cas. Qhov ntev, xov zoo, suab, thiab ceev ntawm cov ntsia hlau tag nrho ua lub luag haujlwm. Thaum cov engineers kho cov kev ntsuas no, lawv tuaj yeem tswj tau qhov kub thiab txias npaum li cas cov yas tau txais. Qhov no yuav pab tsim kom muaj qhov sib xws thiab txo qhov tsis xws luag xws li streaks lossis npuas.

Qhov sib piv compression, uas sib piv qhov tob ntawm cov ntsia hlau qhov chaw pub thiab ntsuas qhov chaw, cuam tshuam rau cov yas ntim nruj npaum li cas. Qhov sib piv ntau dua yuav ua rau kom qhov ntom ntom thiab sib xyaw tab sis yuav tsis haum rau cov yas uas muaj cua sov. Rov qab siab kuj tseem ceeb. Nws thawb cov molten resin nyuaj dua, rhuav tshem cov khoom tsis sib xws thiab txhim kho kev sib xyaw. Txawm li cas los xij, kev siab rov qab ntau dhau tuaj yeem ua rau cov khoom muag tsis zoo.

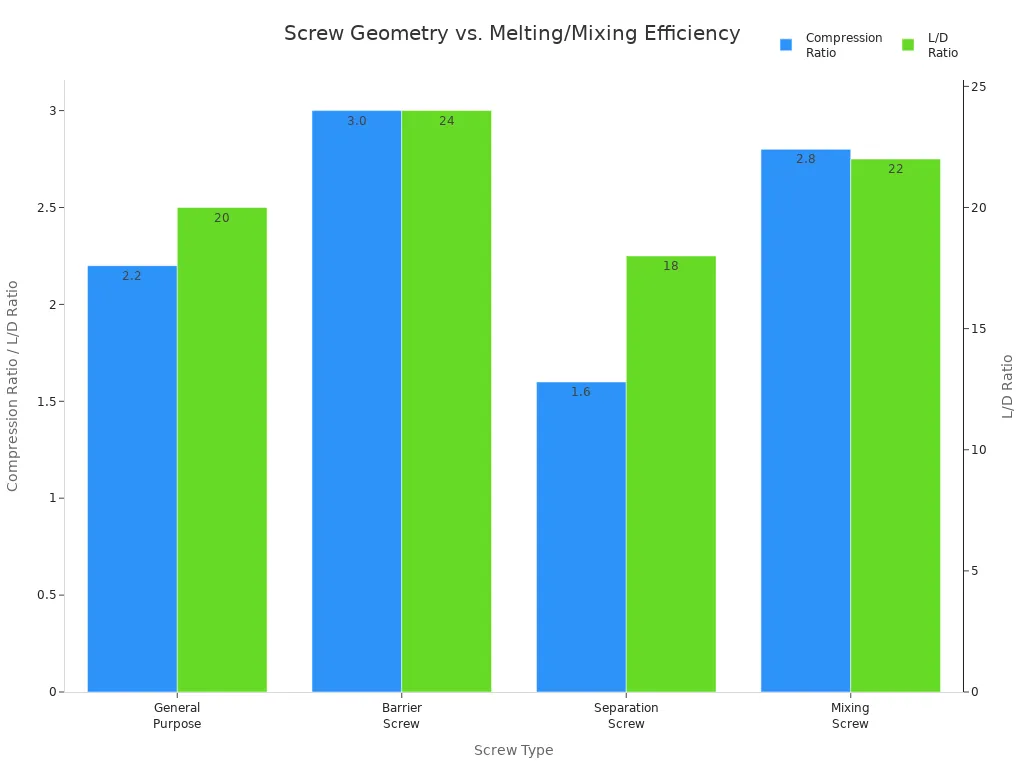

Ntawm no yog ib lub rooj qhia seb hom ntsia hlau sib txawv thiab lawv cov geometry cuam tshuam li cas thiab kev sib xyaw ua haujlwm:

| Ntsia Hlau Hom | Cov ntaub ntawv tsim nyog | Compression Ratio | L/D Ratio | Hom kev siv | Qhov cuam tshuam rau Melting thiab Mixing Efficiency |

|---|---|---|---|---|---|

| Lub Hom Phiaj | ABS, PP, PE | 2.2:1 ib | 20: 1 | Khoom vaj khoom tsev | Versatile melting thiab sib tov nrog nruab nrab shear thiab uniformity. |

| Barrier Ntsia Hlau | PA + GF, PC | 3.0: 1 | 24: 1 | Yam Khoom | Siab shear thiab sib tov, zoo yaj homogeneity thiab cov khoom zoo. |

| Kev sib cais Screw | PVC, POM | 1.6: 1 | 18:1 | Cov kav dej, cov khoom siv | Tswj shear, txo degradation, kom zoo ib yam melting. |

| Mixing Ntsia Hlau | PMMA, PC + GF | 2.8:1 ib | 22:1 ib | Lub teeb npog | Kev sib xyaw ua kom zoo dua qub, zoo li yaj, txhim kho cov khoom kho qhov muag. |

Engineers feem ntau siv cov kab kos los sib piv cov duab geometry. Daim ntawv qhia hauv qab no qhia tau hais tias compression piv thiab L / D piv txawv li cas rau ntau hom ntsia hlau:

Ib tug zoo-tsim Yas Txhaj molding ntsia hlau chim nrog txoj cai geometry kom ruaj khov plasticization, zoo ib yam ntawm cov melting kub, thiab cov khoom du ntws. Qhov no ua rau lub ntsej muag zoo dua, tsis muaj qhov tsis xws luag, thiab muaj zog molded qhov chaw.

Kev xaiv cov khoom siv rau Durability thiab hnav tsis kam

Kev xaiv cov khoom siv zoo rau lub taub hau taub hau ua rau muaj qhov sib txawv loj ntawm nws nyob ntev npaum li cas thiab nws ua tau zoo npaum li cas. Cov neeg tsim khoom siv cov hlau tawv thiab cov txheej txheem siab heev los tiv thaiv hnav thiab corrosion. Piv txwv li, 38CrMoAlA nitrided steel ua haujlwm zoo rau cov haujlwm txheem, thaum SKD61 (H13) cov cuab yeej steel tuav cov khoom siv tawv tawv. Bimetallic barrels nrog tungsten carbide los yog npib tsib xee-raws li alloys muab lub siab tshaj plaws tiv thaiv rau abrasion thiab tshuaj.

| Hom khoom | Hnav Resistance | Corrosion Resistance | Hom Hardness | Daim ntawv thov Highlights |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~ 1000 HV (Nitrided) | Txhim khu kev qha rau cov qauv siv |

| SKD61 (H13) Cov cuab yeej hlau | ★★★★★☆ | ★★★☆☆ | 48–52 HRC | Nyuaj engineering resins, thermal stress |

| Bimetallic Barrels | ★★★★★ | ★★★★★☆ | 60–68 HRC | Abrasive, fiberglass, nplaim retardant, recycled plastics |

Lwm qhov kev xaiv nrov suav nrog AISI 4140 thiab 4340 alloy steels rau kev siv dav dav, D2 thiab CPM cov cuab yeej steels rau cov yas abrasive, thiab Hastelloy lossis Inconel rau qhov chaw corrosive. Cov kev kho deg zoo li nitriding thiab chromium plating txhawb nqa hardness thiab lifespan. Thaum cov tuam ntxhab xaiv cov khoom tsim nyog, lawv txo qis sijhawm thiab cov nqi tu, ua kom cov khoom lag luam zoo.

Tswv yim: Bimetallic tej kas tham nrog siab tungsten carbide cov ntsiab lus yuav kav ntev npaum li cas, tshwj xeeb tshaj yog thaum ua abrasive los yog puv polymers.

Matching Screw chim rau cov yas sib txawv

Tsis yog txhua lub plastics coj tib yam li thaum molding. Txhua hom xav tau ib qho tshwj xeeb ntsia hlau chim tsim kom tau txais txiaj ntsig zoo tshaj plaws. Cov kws kho tsheb saib cov yas qhov kub thiab txias, viscosity, thiab stability. Lawv phim cov ntsia hlau geometry, zawj qhov tob, thiab cov txheej txheem ntawm lub thoob rau cov khoom xav tau.

Piv txwv li, polycarbonate (PC) yuav tsum tau ib tug ntsia hlau ntev nrog ib tug gradual compression piv thiab ib tug sib tov seem los tiv thaiv degradation. Nylon (PA) xav tau ib tug mutant ntsia hlau nrog ib tug siab compression piv thiab ib tug me me qhov sib txawv ntawm cov ntsia hlau thiab chim los tswj shear. PVC xav tau lub thoob-resistant corrosion thiab ib tug tsawg-shear ntsia hlau kom tsis txhob overheating thiab cov ntaub ntawv buildup.

| Hom yas | Screw Design Parameters | Kev cuam tshuam rau kev ua tau zoo |

|---|---|---|

| Polycarbonate (PC) | Loj L / D ratio (~ 26), maj mam ntsia hlau, compression piv ~ 2.6, nws seem | Zoo plasticizing, tiv thaiv degradation, txhim kho homogeneity |

| Nylon (PA) | Mutant ntsia hlau, L / D 18-20, compression piv 3-3.5, qhov sib txawv me me | Tiv thaiv overheating, tswj shear, tswj cov yaj zoo |

| PMMA | Maj mam ntsia hlau, L / D 20-22, compression piv 2.3-2.6, sib xyaw nplhaib | Qhov tseeb melting, tiv thaiv cov teeb meem noo noo, tswj precision |

| PET | L / D ~ 20, qis shear ntsia hlau, compression piv 1.8-2, tsis muaj qhov sib xyaw | Tiv thaiv overheating, tswj shear, haum rau cov khoom siv rov ua dua tshiab |

| PVC | Tsawg shear ntsia hlau, corrosion-resistant chim, L / D 16-20, tsis muaj check nplhaib | Tiv thaiv overheating thiab corrosion, ruaj khov kub tswj |

Sib piv cov yas txhaj tshuaj molding ntsia hlau thoob rau hom yas pab kom tsis txhob muaj qhov tsis xws luag xws li tsis muaj xim, tsis tiav melting, los yog warping. Nws kuj tseem txhim kho lub sij hawm voj voog thiab kev siv hluav taws xob.

Lus Cim: Kev hloov kho cov ntsia hlau thoob rau cov yas tshwj xeeb tuaj yeem txhawb nqa txog li 25% thiab txo qhov tsis xws luag, txuag sijhawm thiab nyiaj txiag.

Cov Tswv Yim Kho Kom Zoo Rau Lub Neej Ntev thiab Kev Ntseeg

Kev saib xyuas tsis tu ncua ua kom lub taub hau ntsia hlau ua haujlwm zoo tshaj plaws. Cov neeg ua haujlwm yuav tsum tshuaj xyuas lub thoob rau hnav, khawb, lossis pitting thaum twg cov ntsia hlau raug tshem tawm. Kev ntxuav nrog kev lag luam purging compounds tshem tawm cov seem thiab tiv thaiv cov pa roj carbon buildup. Kev soj ntsuam qhov siab, qhov kub thiab txias, thiab ceev ceev yuav pab pom cov teeb meem thaum ntxov.

Nov yog qee cov lus qhia txog kev tu vaj tse:

- Tshawb xyuas lub hau ntsia hlau kom pom tseeb thiab nrog ntsuas ntsuas txhua zaus thaum tshem cov ntsia hlau.

- Ntxuav lub thoob txhua lub lim tiam rau kev khiav tas mus li, lossis txhua 2-3 hnub yog tias hloov cov yas ntau zaus.

- Lubricate txav qhov chaw txhua hnub thiab roj lawv txhua lub limtiam nrog cov roj zoo.

- Siv cov khoom nyoos ntshiab thiab khaws cia kom tsis txhob muaj kab mob.

- Tsheb ciav hlau cov neeg tsav tsheb kom paub txog kev hnav cov paib thiab khaws cov ntaub ntawv saib xyuas kom ntxaws.

- Tshuag spare qhov chaw kom txo qis downtime.

- Tom qab kaw, khiav cov ntsia hlau ntawm qhov ceev kom faib cov yas seem, ntxuav nrog cov tshuaj detergents tshwj xeeb, thiab siv cov roj tiv thaiv.

Callout: Bimetallic chim nrog hlau-raws li liners tuaj yeem kav peb zaug ntev dua li cov ntsia hlau txheem.Kev sib raug zoo thiab lubricationncua lifespan thiab txo cov zaus txij nkawm.

Cov yas txhaj tshuaj molding ntsia hlau thoob thoob zoo khaws cia zoo ib yam, txo qis sijhawm, thiab txhawb kev tsim khoom.

Yas Txhaj Molding Ntsia Hlau chim ua lub luag haujlwm tseem ceeb hauv kev xa cov khoom zoo ib yam thiab ua haujlwm tau zoo.

- Cov ntsia hlau zoo zoo txhim kho qhov sib xws, txo cov seem, thiab txhawb kev ua haujlwm.

- Kev saib xyuas tsis tu ncua tiv thaiv kev poob qis thiab txuas ntxiv lub neej ntawm cov cuab yeej siv.

- Cov khoom siv thiab lub zog txuag ntxiv sai sai.

- Kev hloov pauv sai dua ua rau muaj peev xwm thiab tau txais txiaj ntsig.

FAQ

Cov cim qhia dab tsi uas qhia tias lub taub hau taub hau yuav tsum tau hloov?

Cov neeg khiav dej num pom tias tsis sib xws, muaj qhov tsis xws luag, lossis qeeb mus. Lawv kuj pom pom hnav, khawb, lossis pitting hauv lub thoob.

Muaj pes tsawg tus neeg yuav tsum ntxuav lub taub hau ntsia hlau?

Feem ntau manufacturers ntxuav lub thoob txhua lub lim tiam. Yog tias lawv hloov cov yas ntau zaus, lawv ntxuav nws txhua ob mus rau peb hnub.

Ib lub taub hau taub hau puas tuaj yeem ua haujlwm rau tag nrho cov yas?

Tsis yog, txhua hom yas xav tau ib qho tshwj xeeb ntsia hlau chim tsim. Kev siv qhov kev sib tw zoo txhim kho cov khoom zoo thiab txo cov khoom pov tseg.

Post lub sij hawm: Aug-15-2025