Lub ntxaib yas ntsia hlau chim ua kom zoo thiab zoo ntawm cov kab niaj hnub extrusion. Cov thawj coj hauv kev lag luam qhia txog nws lub luag haujlwm hauv kev ruaj ntseg thiab kev tsim kho tshiab.

- Cov neeg tsim khoom pom kev xav tau nce ntxiv raws li kev sib txuas lus ntse ntse thiab AI-tsav controllers optimize zog siv thiab txo qis sijhawm.

- Twin Parallel Screw chim Manufacturerstshaj tawm muaj zog saws vim kev txhim kho durability thiab customization.

- Ib Screw BarrelsthiabIb leeg yas Screw chim Factoriestseem ua lub luag haujlwm, tab sis ntxaib tsim tam sim nodominate tshaj ib nrab ntawm US kev ua lag luam.

Core Functions ntawm Twin Plastic Screw Barrel

Cov khoom siv thauj khoom thiab sib tov

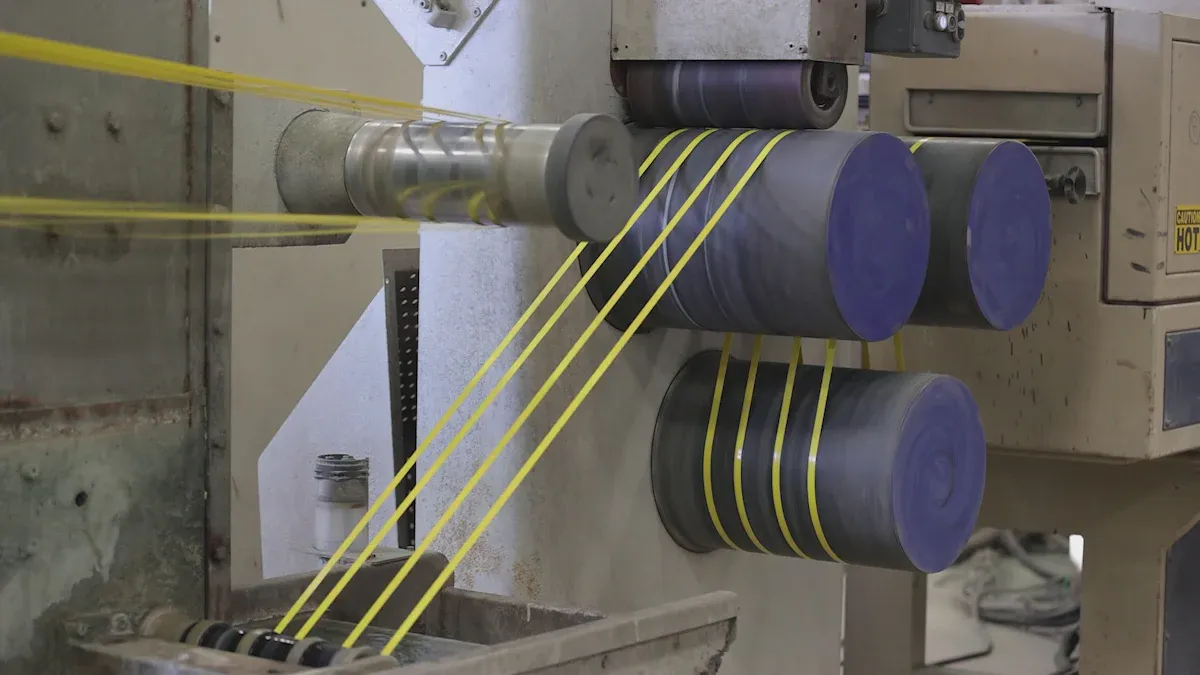

Lub taub hau yas ntxaib ua lub luag haujlwm tseem ceeb hauv kev txav thiab sib xyaw cov khoom siv raw hauv lub extruder. Cov kws tsim qauv tsim cov ntsia hlau ya dav hlau los tuav thiab thawb cov yas granules rau pem hauv ntej. Qhov kev txiav txim no ua kom cov khoom txav tau yooj yim ntawm qhov chaw pub rau hauv thaj chaw compression. Cov kws tshawb fawb tau kawm seb cov kab no ua haujlwm li cas thiab pom ntau lub ntsiab lus tseem ceeb:

- Potente thiab Melish faib thaj chaw xa khoom mus rau hauv qhov chaw pub thiab compression. Lawv siv lub zog thiab lub zog sib npaug los xam qhov ua tau zoo tshaj plaws, kev hloov pauv, thiab lub zog xav tau los tsav cov ntsia hlau. Lawv cov hauj lwm qhia tau hais tias lub ntxaib yas ntsia hlau thoob xa cov khoom muaj zog thiab ruaj khov.

- Wilczyński thiab Dawb tau pom tias feem ntau cov yas granules taug kev hauv qab ntawm lub thoob, ze rau cov ntsia hlau ya dav hlau. Lub thoob thiab ntsia hlau ua kom sov cov granules thaum lawv txav mus, uas pab lawv yaj sib npaug.

- Lwm cov kws tshaj lij, xws li Dawb thiab Bawiskar, tau tsim cov qauv uas piav qhia txog yuav ua li cas cov ntxaib yas ntsia hlau lub thoob tsim cov txheej txheem yaj thiab sib tov cov khoom thiab cov kua. Cov qauv no pab cov chaw tsim khoom nkag siab thiab txhim kho kev sib xyaw thiab yaj.

Lub taub hau yas ntxaib ua kom ntseeg tau tias txhua feem ntawm cov khoom tau sib xyaw thiab ua kom sov. Cov txheej txheem no ua rau cov khoom lag luam zoo dua thiab tsawg dua qhov tsis xws luag.

Melting, homogenization, thiab tswj siab

Melting thiab blending cov yas sib npaug yog lwm txoj haujlwm tseem ceeb ntawm cov yas ntxaib ntsia hlau thoob. Lub thoob yuav tsum tswj lub siab kom cov txheej txheem ruaj khov. Engineers siv ntau yam qauv tsim kom ua tiav cov hom phiaj no. Cov lus hauv qab no qhia tau hais tias qhov sib txawv ntawm cov ntsia hlau thiab cov txheej txheem muaj feem cuam tshuam rau melting, blending, thiab siab:

| Ntsia Hlau Parameter | Impact / Numerical Detail |

|---|---|

| L/D Ratio | Kev sib piv L / D siab dua txhim kho polymer sib xyaw thiab plasticization los ntawm kev ncua sij hawm nyob thiab kev faib hluav taws xob |

| Compression Ratio | Siab compression ratios txhim kho plasticization thiab densification; Qhov txiaj ntsig zoo nyob ntawm cov khoom siv |

| Compression Ratios rau Common Plastics | PE: 3-4, PP: 2.5-4, PS: 2-4, Rigid PVC (Granules): 2-3, Rigid PVC (Powder): 3-4, Flexible PVC (Granules): 3.2-3.5, Flexible PVC (Powder): 3-5, ABS: 1.5-PC, 2. 2.8-4, PPE: 2-3.5, PA66: 3.7, PA1010: 3, Reinforced Polyester: 3.5-3.7 |

| Parameter / Aspect | Tus lej tshwm sim / piav qhia |

|---|---|

| Siab hauv C-shaped chamber | Kwv yees li 2.2 MPa |

| Kev poob siab hauv cheeb tsam intermeshing | 0.3 MPa siab |

| Kev poob siab hauv qhov rov qab ntsia hlau | 0.5MPa |

| Kub nce vim siab | 40 bar siab ua rau ~ 20 ° C kub nce |

| Optimal pub tus nqi thiab ntsia hlau ceev | 3.6 kg / h pub tus nqi ntawm 95 rpm maximizes kub thiab minimizes fiber ntau breakage |

| Thaum tshav kub kub tsim qhov chaw | Kwv yees li 80% ntawm melting kub generated los ntawm kev sib txhuam shear |

| Qhov cuam tshuam ntawm cov ntsia hlau ceev ntawm lub zog | Cumulated strain nce linearly nrog cov ntsia hlau ceev |

| Qhov cuam tshuam ntawm tus nqi pub rau cov kab mob | Kev sib xyaw ua ke txo qis nrog tus nqi pub |

Cov txiaj ntsig no qhia tau tias ob lub hau yas ntsia hlau tuaj yeem tswj tau qhov kub thiab txias npaum li cas cov khoom tau txais. Cov chaw tsim nyog yuav pab cov yas yaj tag nrho thiab sib tov zoo. Qhov kev tswj no ua rau cov khoom muaj zog, zoo ib yam.

Kev ntxuav tus kheej thiab txheej txheem ruaj khov

Lub taub hau yas ntxaib kuj tseem pab kom lub extruder huv si thiab ruaj khov. Kev tsim ntawm cov ntsia hlau thiab lub thoob tso cai rau kev tu tus kheej. Raws li cov screws tig, lawv so ib leeg thiab lub chim phab ntsa. Qhov kev ua no tshem tawm cov khoom seem thiab tiv thaiv kev tsim. Cov thoob huv si txo qis lub sijhawm thiab ua kom cov txheej txheem ua haujlwm zoo.

Cov txheej txheem ruaj khov yog lwm qhov txiaj ntsig. Cov ntsia hlau ntxaib yas tuav tuav txawm tias lub siab thiab qhov kub thiab txias thoob plaws hauv cov txheej txheem extrusion. Qhov kev ruaj ntseg no txhais tau tias lub tshuab tuaj yeem khiav mus ntev yam tsis muaj teeb meem. Factories tuaj yeem tsim cov khoom lag luam ntau dua nrog tsawg nres thiab tsawg pov tseg.

Tswv yim: Kev saib xyuas tsis tu ncua thiab kev saib xyuas ntawm lub hau yas ntxaib tuaj yeem txhim kho cov txheej txheem kev ruaj ntseg thiab txuas ntxiv lub neej ntawm cov khoom siv.

Kev nce qib thiab qhov cuam tshuam tiag tiag hauv ntiaj teb ntawm Twin Plastic Screw Barrel hauv 2025

Innovative Materials thiab Coatings rau Durability

Cov neeg tsim khoom tam sim no siv cov khoom siv qib siab thiab txheej txheej los ua kom cov yas ntxaib ntsia hlau kav ntev thiab ua haujlwm zoo dua. Stainless hlau, CPM10V, ceramics, thiab tungsten carbide coatings pab lub thoob tiv taus hnav thiab corrosion. Cov ntaub ntawv no ua rau lub thoob muaj zog txawm tias thaum nws ntsib qhov kub thiab txias thaum lub sij hawm yas extrusion. Kev ntsuas kev ua tau zoo qhia tau tias cov txheej txheem no txhim kho kev sib xyaw ua haujlwm thiab ua kom cov txheej txheem ruaj khov. Piv txwv li, nitriding kev kho mob tuaj yeem ncav cuag qib hardness ntawm HRC50-65, uas pab lub thoob tiv thaiv kev puas tsuaj. Cov ntaub ntawv tiag tiag hauv ntiaj teb los ntawm cov chaw tsim khoom qhia tau hais tias cov kev txhim kho no txo qis kev poob qis thiab tiv thaiv kev xau. Pab pawg tu tsev tseem ceeb toom tias cov thoob no xav tau kev kho tsawg dua thiab siv tau ntev dua, uas txuag nyiaj thiab ua kom cov khoom lag luam zoo.

Kev sim hauv chav sim, xws li cov uas siv Coperion ZSK 18 MEGAlab, pab engineers sim cov ntaub ntawv tshiab thiab txheej. Cov kev sim no ntsuas tau zoo npaum li cas lub thoob tuav cov khoom sib txawv thiab cov khoom ntxiv. Cov txiaj ntsig tau pom tias cov txheej txheem tshiab txhim kho thermal stability thiab hnav tsis kam. Cov tuam txhab pom kev tawg tsawg dua thiab cov khoom lag luam zoo dua vim qhov kev hloov kho tshiab no.

Precision Engineering thiab Modular Barrel Designs

Precision engineering tsim txhua feem ntawm cov yas ntxaib ntsia hlau thoob. Factories siv cov tshuab CNC thiab cov kev kuaj xyuas nruj kom paub tseeb tias txhua lub thoob ua tau raws li cov qauv. Engineers ntsuas ntsia hlau ncaj rau 0.015 hli thiab nto roughness rau Ra 0.4. Cov kev tiv thaiv nruj no pab lub thoob sib tov thiab yaj cov yas sib npaug.

Modular chim tsim tso cai hloov ceev thiab kho. Cov neeg ua haujlwm tuaj yeem hloov cov ntu uas hnav tsis tau sib cais tag nrho lub tshuab. Qhov kev tsim no txodowntime txog li 20% thiab txo cov nqi kho txog li 30%. Cov lus hauv qab no qhia qee qhov kev txhim kho tseem ceeb:

| Parameter | Tus lej Tus Nqi / Ntau |

|---|---|

| Downtime txo vim modularity | Txog li 20% |

| Kho tus nqi txo vim yog modularity | Txog li 30% |

| Nitrided nto hardness (HV) | 920-1000 Nws |

| Alloy hardness (HRC) | 50–65 : kuv |

| Ntsia hlau ncaj | 0.015 hli |

| Nto roughness (Ra) | 0.4 |

Cov kev nce qib no pab cov chaw tsim khoom khaws lawv cov yas ntxaib ntsia hlau rau hauv cov duab saum toj kawg nkaus, ua rau kev ua haujlwm zoo dua thiab tsis muaj pov tseg.

Kev koom ua ke nrog Smart Manufacturing thiab Automation

Kev tsim khoom ntse thiab automation tau hloov pauv li cas cov chaw tsim khoom siv cov ntsia hlau ntxaib yas thoob. Automated systems tam sim no tswj qhov kub, siab, thiab ceev nrog qhov tseeb. Manufacturing Execution Systems (MES) pab taug qab txhua kauj ruam ntawm cov txheej txheem. Cov tshuab no txhawb nqantau lawm ceev los ntawm 40-50% thiab txiav downtime txog li 30%. Kev saib xyuas tsis tu ncua, coj los ntawm cov sensors thiab cov ntaub ntawv, ua kom cov tshuab ua haujlwm ntev dua.

Cov lus hauv qab no qhia txog qee qhov cuam tshuam uas ntsuas tau:

| Txhim kho Aspect | Ntsuas qhov cuam tshuam |

|---|---|

| Ntau lawm ceev | Nce 40-50% |

| Kev txo qis qis | Txo kom txog li 30% |

| Efficiency Improvement (MES) | Txog li 25% nce |

| Material Flow Optimization | Uniform RTD, tsawg qhov tsis xws luag thiab pov tseg tsawg dua |

| Kev siv hluav taws xob | Tsawg dua li cov txheej txheem ib txwm muaj |

| Cov Nqi Ua Haujlwm | Txo los ntawm kev siv cov peev txheej zoo dua |

| Khoom Zoo | Kev txhim kho tas mus li |

Factories uas siv ISO9001-certified systems nrog advanced ntsia hlau chim pom kev smoother thiab cov khoom zoo dua. Cov neeg siv khoom tau txais cov khoom lag luam zoo dua, thiab cov tuam txhab muaj kev sib tw hauv kev ua lag luam.

Efficiency, Product Quality, and Sustainability Benefits

Twin yas ntsia hlau thoob coj qhov kev nce qib hauv kev ua tau zoo, zoo, thiab kev ruaj khov. Upgrades rau motors thiab drives txuag10-20% zog. Thaum tshav kub kub lub zog poob los ntawm 10%, thiab lub voj voog lub sij hawm poob ntawm 30 mus rau 15 vib nas this nrog cua txias zoo dua. Lub tshuab hluav taws xob khib nyiab tuaj yeem ntes tau txog li 15% ntawm lub zog poob, txo cov nqi ntau dua.

Cov lus hauv qab no qhia txog cov txiaj ntsig no:

| Efficiency thiab Sustainability Aspect | Txhawb nqa Statistics lossis Description |

|---|---|

| Kev txuag hluav taws xob | 10-20% txo |

| Cua sov Optimization | 10% tsawg zog, lub sij hawm voj voog halved |

| Khib kub rov qab | Txog li 15% ntawm lub zog poob rov qab los |

| Plasticizing tus nqi | Nce ntawm 104 g / s mus rau 120 g / s |

| Lub Sijhawm Rov Qab | Ib nrab ntawm 18s rau 9s |

| Predictive Maintenance | Downtime txiav 15-30% |

| Eco-phooj ywg cov ntaub ntawv | Tsawg kev sib txhuam thiab hnav |

| Txhim kho cov khoom zoo | 90% tsawg qhov tsis xws luag, tso zis zoo dua |

| Khib kom tsawg | Tsawg raw khoom pov tseg |

Cov kev txhim kho no pab cov chaw tsim khoom ua cov khoom lag luam nrog tsawg zog thiab pov tseg. Twin yas ntsia hlau chim txhawb kev tsim khoom ruaj khov los ntawm kev txo qhov tsis xws luag thiab siv cov peev txheej kom zoo.

Lus Cim: Cov tuam txhab xws li Zhejiang Jinteng Machinery Manufacturing Co., Ltd. sivadvanced engineeringthiab nruj zoo tshuab kom xa cov yas ntxaib ntsia hlau uas txhim khu kev qha. Lawv cov khoom pab cov chaw tsim khoom ua tau raws li qhov xav tau ntawm kev ua cov yas niaj hnub hauv xyoo 2025.

Lub Twin Plastic Screw Barrel sawv ntawm lub plawv ntawm niaj hnub extrusion tshuab. Cov neeg tsim khoom tau txais kev ua haujlwm siab dua, kev ua haujlwm ntev dua, thiab cov khoom zoo ib yam.

- Kev tsim kho ruaj khovtxo cov nqi hloov

- Precision engineering txhim kho kev siv hluav taws xob

- Cov qauv siv tau yooj yim txhawb kev siv ntau yam

Cov yam ntxwv no ua rau muaj kev vam meej mus ntev hauv kev lag luam thoob ntiaj teb loj hlob.

FAQ

Yuav ua li cas ua ib tug ntxaib yas ntsia hlau chim qhov tseem ceeb rau niaj hnub extruders?

Twin yas ntsia hlau thoob muab kev sib xyaw ua ke, melting, thiab tswj siab. Cov yam ntxwv no ua kom cov khoom zoo thiab ua haujlwm tau zoo hauv cov kab extrusion siab heev.

Tswv yim: Kev ua tau zoo ib yam nyob ntawm qhov tsim nyog ntsia hlau thiab chim.

Yuav ua li cas ntau npaum li cas cov factories yuav tsum tuav ob tug yas ntsia hlau chim?

Factories yuav tsum tshuaj xyuas thiab ntxuav cov thoob tsis tu ncua. Cov kws tshaj lij feem ntau pom zoo kom kuaj xyuas txhua hli los tiv thaiv kev hnav, txhim kho, thiab lub sijhawm poob qis.

- Kev saib xyuas tsis tu ncua ncua lub neej ntawm cov cuab yeej siv.

- Kev tshawb pom ntxov ntawm cov teeb meem txo cov nqi kho.

Yuav ua li cas manufacturers xaiv txoj cai ntxaib yas ntsia hlau chim?

Cov neeg tsim khoom xaiv cov thoob raws li cov khoom siv, cov khoom xav tau, thiab lub tshuab specifications. Kev sab laj nrog cov neeg muag khoom paub txog ua kom pom kev ua tau zoo thiab kav ntev.

| Xaiv Factor | Qib tseem ceeb |

|---|---|

| Hom khoom | Siab |

| Kev xav tau | Siab |

| Tshuab Qauv | Nruab nrab |

Post lub sij hawm: Jul-03-2025