PVC yeeb nkab ib lub taub hau taub hau ua lub luag haujlwm tseem ceeb hauv cov txheej txheem extrusion, tshwj xeeb tshaj yog thaum siv cov khoom siv.ib leeg yas ntsia hlau chim. Nws ncaj qha cuam tshuam cov khoom lag luam zoo los ntawm kev ua kom zoo ib yam melting thiab sib tov ntawm cov khoom. Xaiv lub thoob zoo, nrog rau cov kev xaiv zoo li covib leeg ntsia hlau chim rau tshuab molding, txhim khu kev ua haujlwm ntau lawm, muaj peev xwm nce cov nqi ntau lawm los ntawm 18% mus rau 43%. Tsis tas li ntawd, xaiv ib lub thoob tsim nyog tuaj yeem ua rau qhov tseem ceebkev txuag nqi, optimizing ob qho tib si thawj zaug kev nqis peev thiab kev siv nyiaj mus sij hawm ntev, tshwj xeeb tshaj yog thaum xav txog lwm txoj hauv kev xws liextruder conical twin ntsia hlau extruder chim.

Yam ntxwv ntawm PVC Yeeb Nkab Ib Screw Barrels

Khoom siv

Cov khoom muaj pes tsawg leeg ntawm PVC yeeb nkab ib lub taub hau ntsia hlau cuam tshuam nws cov kav ntev thiab kev ua haujlwm. Cov khoom siv raw khoom siv yog polyvinyl chloride resin, uas zoo nkaus li dawb, nkig hmoov. Cov khoom no nthuav tawm cov tshuaj tiv thaiv zoo heev, lub zog tensile siab, thiab tus nqi qis. Cov kav dej PVC niaj hnub no feem ntau raug kho nrog cov stabilizers txhawm rau txhim kho lawv txoj sia, tshwj xeeb tshaj yog thaum raug UV rays thiab tshav ntuj.

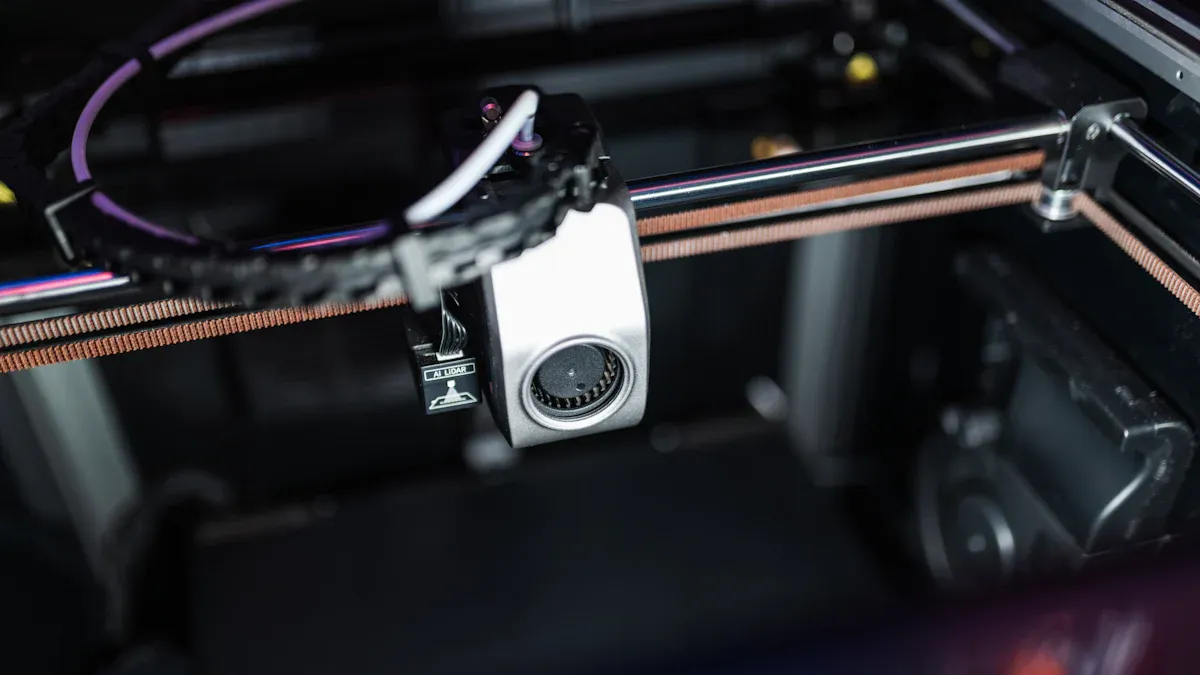

Tsim nta

Cov qauv tsim ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntawm PVC yeeb nkab ib leeg ntsia hlau chim. Cov ntsiab lus tseem ceeb suav nrog:

| Tsim Feature | Kev piav qhia |

|---|---|

| Kev xaiv khoom | Bimetallic chim liners tiv thaiv tshuaj corrosion; tshwj xeeb alloy steels tiv taus nruj PVC. |

| Tsawg Shear, Yooj Yim Plasticizing | Optimized ntsia hlau davhlau qhov tob thiab compression piv tiv thaiv overheating thiab degradation ntawm PVC. |

| Optimized L/D Ratio | Shorter L / D piv txo lub sij hawm nyob, txo thermal decomposition txaus ntshai. |

| Temperature Control nyob rau hauv Barrel | Cov cua sov tshwj xeeb thiab cov cua txias channel tiv thaiv hotspots thaum extrusion. |

| Kev sib xyaw tshwj xeeb | Maj mam sib xyaw seem ua tiav homogeneity yam tsis muaj degrading cov khoom. |

| Hnav Resistance | Kev hnav tsis kam yog qhov tseem ceeb vim muaj cov khoom ntim; chromium plating los yog nitriding muab kev tiv thaiv. |

Loj thiab Configuration

Qhov loj thiab teeb tsa ntawm PVC yeeb nkab ib lub taub hau ntsia hlau ncaj qha cuam tshuam cov txiaj ntsig extrusion. Cov txheej txheem melting thiab homogenization yog txhim kho los ntawm lub thoob tsim. Kev teeb tsa cuam tshuam li cas cov khoom siv yog sheared thiab melted, txhawb kev sib xws hauv cov khoom ntws. Cov ntsia hlau tsim zoo thiab lub thoob teeb pom kev zoo ua kom pom cov cua sov kom zoo, ua rau muaj qhov sib xws ntawm cov yeeb yaj kiab yaj thaum lub sij hawm extrusion txheej txheem.

Kev cuam tshuam rau kev tsim khoom zoo

Consistency nyob rau hauv cov zis

Qhov kev xaiv ntawm aPVC yeeb nkab ib leeg ntsia hlau chimsignificantly txhim kho covsib xws ntawm cov zisthaum lub sij hawm extrusion txheej txheem. Advanced chim designstxo pinholes hauv cov khoom tiav txog li 90%. Qhov kev txhim kho no yog los ntawm qhov optimized flow dynamics nyob rau hauv lub chim, uas xyuas kom meej tias cov khoom ntws uniformly. Cov cuab yeej saib xyuas lub sijhawm tiag tiag muab cov lus tawm tswv yim tam sim ntawm cov yam ntxwv zoo, tso cai rau cov tuam txhab tsim nyog hloov kho tam sim. Txhim khu kev sib xyaw ua ke ua rau kev txhim kho tag nrho cov khoom ua tau zoo, ua rau cov kav dej zoo dua uas ua tau raws li cov qauv kev lag luam nruj.

Nto tiav ntawm cov kav dej

Qhov saum npoo tiav ntawm extruded PVC kav yog qhov tseem ceeb rau ob qho tib si zoo nkauj thiab ua haujlwm zoo. Kev xaiv ntawm txoj cai chim tsim ncaj qha cuam tshuam rau qhov no. Piv txwv li, parallel twin ntsia hlau chim txhim kho qhovuniform flow ntawm PVC khoomthaum lub sij hawm extrusion. Qhov kev sib txuam no yog qhov tseem ceeb rau kev ua kom tiav qhov chaw du, tsis muaj qhov tsis xws luag xws li ridges lossis npuas. Lub polished nto tsis tsuas yog txhim kho qhov pom kev pom ntawm cov kav dej tab sis kuj txhim kho lawv txoj haujlwm los ntawm kev txo qis kev sib txhuam thiab txhim kho cov dej ntws. Cov neeg tsim khoom lees paub tias kev nqis peev hauv cov khoom lag luam zoo ua rau muaj kev ua tiav zoo tshaj plaws, uas thaum kawg tau txais txiaj ntsig zoo rau lawv cov khoom muag.

Qib siab

Cov qib siab kam rau ua hauv PVC yeeb nkab yog qhov tseem ceeb rau kev ua kom cov kav dej haum raws li lawv cov kev xav tau. Cov qauv ntsia hlau sib txawv tuaj yeem cuam tshuam cov qib siab ntev. Piv txwv li, conical twin ntsia hlau chim tsimtxhim khu kev qha compounding efficiencythiab xyuas kom uniformity nyob rau hauv lub yaj. Qhov kev sib txuam no ncaj qha ua rau muaj qhov raug zoo dua qhov tseeb thiab lub zog txhua yam hauv cov kav dej PVC. Lub peev xwm los tswj kev ua haujlwm ruaj khov nyob rau hauv cov xwm txheej sib txawv tso cai rau kev hloov kho hauv cov ntsia hlau ceev, qhov kub thiab txias. Xws li kev hloov pauv yog qhov tseem ceeb rau kev tswj cov kev hloov pauv hauv cov khoom siv raw zoo, ua rau cov khoom lag luam siab thiab cov khoom zoo, txawm tias tsawg dua qhov kev tsim khoom zoo tagnrho.

Kev txiav txim siab zoo

Kev ceev ceev

Kev ceev ceev yog qhov tseem ceeb hauv kev ua haujlwm ntawm PVC yeeb nkab ntau lawm. Covtsim ntawm PVC yeeb nkab ib leeg ntsia hlau chimho cuam tshuam cov khoom noj zoo sib xws. Cov ntsiab lus tseem ceeb muaj xws li ntsia hlau geometry, compression ratios, thiab chim venting systems. Cov yam tseem ceeb no cuam tshuam cov yaj zoo thiab kev ua haujlwm tag nrho, cuam tshuam ncaj qha rau kev ua haujlwm ceev. Multi-theem ntsia hlau tsim txhim kho cov khoom noj sib xws los ntawm kev faib cov ntsia hlau rau hauv cov cheeb tsam uas ua haujlwm tshwj xeeb. Qhov kev tsim no ua rau kev txhim kho melting sib xws thiab txo kev siv zog. Ib tug zoo-xaiv compression piv kom zoo ib yam melting thiab khov kho cov ntaub ntawv txaus, optimizing ua ceev.

Kev siv hluav taws xob

Kev siv hluav taws xobyog lwm qhov tseem ceeb hauv kev ua haujlwm ntawm PVC yeeb nkab ib leeg ntsia hlau chim. Qhov ntev-rau-inch (L / D) piv thiab compression piv yog qhov tseem ceeb hauv cov ntsia hlau thiab lub thoob tsim. Kev sib piv L / D siab dua tuaj yeem ua rau lub sijhawm nyob hauv qhov sib tov thiab yaj, uas tuaj yeem nce kev siv zog. Tus qauv regression tau pom muaj kev sib raug zoo ntawm kev siv zog tshwj xeeb thiab yam xws li cov khoom siv thiab cov ntsia hlau ceev. Cov neeg tsim khoom tuaj yeem ua tiav kev txuag hluav taws xob tseem ceeb los ntawm kev ua kom zoo dua cov qauv tsim, ua rau txo cov nqi ua haujlwm.

Kev Kho Kom Zoo

Kev saib xyuas yuav tsum sib txawv ntawm tus qauv thiab qib siab PVC yeeb nkab ib leeg ntsia hlau chim. Kev tu tsis tu ncua, lubrication, thiab tshuaj xyuas yog qhov tseem ceeb rau ob hom. Txawm li cas los xij, cov kab mob siab heev yuav xav tau cov cuab yeej tshwj xeeb thiab cov txheej txheem rau kev saib xyuas. Kev tshuaj xyuas niaj hnub yuav tsum tshwm sim txhua rau rau lub hlis rau cov kab mob siab heev, thaum cov thoob txheem yuav tsum tau kuaj xyuas txhua xyoo. Cov txheej txheem kev tiv thaiv kev tiv thaiv yog qhov tseem ceeb rau cov kab mob siab heev vim lawv qhov nyuaj. Txoj hauv kev zoo tshaj plaws no pab ua kom pom kev ua haujlwm zoo thiab ua haujlwm ntev.

Tus nqi cuam tshuam

Kev nqis peev pib

Covpib nqis peevnyob rau hauv ib tug PVC yeeb nkab ib tug ntsia hlau chim yuav txawv ho raws li tsim thiab nta. Cov khoom zoo siab feem ntau tuaj nrog tus nqi siab dua vim lawv cov khoom siv siab heev thiab engineering. Txawm li cas los xij, kev nqis peev hauv ib lub thoob zoo dua them tawm hauv lub sijhawm ntev. Ib lub thoob tsim tau zoo txhim kho kev tsim khoom thiab cov khoom zoo, ua rau muaj qhov tsis xws luag thiab txo cov khoom pov tseg. Cov neeg tsim khoom yuav tsum xav txog cov txiaj ntsig ntev ntev thaum ntsuas cov nqi ua ntej.

Cov nqi ua haujlwm ntev

Cov nqi ua haujlwm ntevNws yog ib qho tseem ceeb rau cov tuam txhab lag luam los ntsuas thaum xaiv cov yeeb nkab PVC ib lub taub hau taub hau. Cov nqi no suav nrog kev saib xyuas, kev siv lub zog, thiab lub sijhawm poob qis.

| Feature | Twin Ntsia Hlau Extruder | Ib leeg ntsia hlau Extruder |

|---|---|---|

| Nqi | Feem ntau hais txog ob zaug siab li ib qho ntsia hlau | pheej yig dua thiab yooj yim dua rau kev tswj xyuas |

| Mixing Efficiency | Kev sib xyaw ua haujlwm zoo dua | Limited mixing efficiency |

| Kev Ua Tau Zoo | Ntau lawm efficiency | Tsawg ntau lawm ceev |

| Yuav tsum muaj kev txawj ntse | Yuav tsum muaj kev txawj ntse ntxiv | Yooj yim rau kev khiav lag luam thiab khaws cia |

Cov lus saum toj no qhia txog qhov sib txawv ntawm cov nqi ua haujlwm ntawm cov ntsia hlau ntxaib thiab ib qho ntsia hlau extruders. Ib leeg ntsia hlau extruders feem ntau yuav txo qis tus nqi kho vim lawv cov qauv yooj yim dua. Lawv xav tau kev txawj ntse tsawg dua rau kev kho, ua rau lawv yooj yim dua rau cov neeg tsim khoom. Tsis tas li ntawd, cov khoom siv zoo ua kom muaj zog, ua rau muaj kev ntseeg siab rau kev ua haujlwm. Qhov kev ntseeg siab no txo qis kev cuam tshuam hauv kev tsim khoom, txo cov nqi ntxiv.

Rov qab los ntawm Kev nqis peev

Rov qab los ntawm kev nqis peev (ROI) yog qhov ntsuas tseem ceeb rau kev ntsuas qhov ua tau zoo ntawm PVC yeeb nkab ib lub taub hau taub hau. Ib lub thoob uas tau xaiv zoo tuaj yeem ua rau muaj kev txuag nyiaj ntau dhau sijhawm. Los ntawm kev txhim kho kev tsim khoom thiab cov khoom lag luam zoo, cov tuam ntxhab tuaj yeem ua tiav cov zis ntau dua thiab txo cov khoom pov tseg.

Kev nqis peev hauv ib lub thoob zoo feem ntau ua rau:

- Ntau tus nqi ntau lawm: Txhim khu kev ua tau zoo tuaj yeem ua rau muaj kev nkag siab dua.

- Txo qhov tsis xws luag: Txhim kho kev tswj xyuas kom txo tau qhov kev xav tau ntawm kev rov ua haujlwm dua.

- Tus nqi zog qis dua: Optimized designs yuav txo tau lub zog noj thaum lub sij hawm ua hauj lwm.

Cov neeg tsim khoom yuav tsum suav cov ROI los ntawm kev sib piv cov peev txheej thawj zaug tiv thaiv cov nyiaj khaws cia ntev los ntawm kev txhim kho kev ua haujlwm thiab txo cov nqi ua haujlwm. Kev tsom xam kom meej yuav qhia tau tias txoj cai PVC yeeb nkab ib lub taub hau tsis yog tsuas yog them rau nws tus kheej xwb tab sis kuj tseem txhawb nqa tag nrho cov txiaj ntsig ntawm cov txheej txheem tsim khoom.

Kev sib piv ntawm Sab saum toj PVC Yeeb Nkab Ib Screw chim Model

Zhejiang Jinteng Txheej txheem cej luam

Zhejiang Jinteng PVC yeeb nkab ib leeg ntsia hlau chim sawv tawm rau nws cov qauv tsim thiab kev ua haujlwm zoo. Cov qauv no suav nrog precision machining cov cuab yeej, kom ntseeg tau cov khoom zoo. Cov yam ntxwv tseem ceeb muaj xws li:

| Feature/Metric | Kev piav qhia |

|---|---|

| Tsim | Advanced tsim nrog kev nplua nuj thiab precision machining khoom. |

| Kev ua tau zoo | Txhim kho cov txheej txheem rov ua dua tshiab, txhim kho cov khoom ntws thiab txo kev siv zog. |

| Daim ntawv thov | Qhov tseem ceeb rau recycling granulation, txhim kho cov khoom zoo thiab txo cov khoom pov tseg. |

Cov txiaj ntsig tseem ceeb ntawm Zhejiang Jinteng chim suav nrogtxhim kho cov khoom ntws thiab txo kev siv zog. Nws ua kom yooj yim yaj thiab sib xyaw ntawm cov yas, ua rau cov khoom siv zoo dua qub.

Xaloy X-800 Txheej txheem cej luam

Xaloy X-800 qauv ua tau zoo nyob rau hauv hnav tsis kam thiab tso zis zoo. Nws kev tsim kho siv cov ntaub ntawv siab heev xws li tungsten carbide thiab npib tsib xee alloy, uas muab qhov tshwj xeeb ua haujlwm ntev. Cov ntsuas kev ua haujlwm tseem ceeb suav nrog:

| Feature | Kev piav qhia |

|---|---|

| Hnav Resistance | Exceptional tsis kam rau abrasive hnavthiab corrosion vim cov khoom siv siab heev. |

| Cov zis zoo | Optimized ntsia hlau geometries txhim khu kev ua hauj lwm efficiency thiab txo cov teeb meem pib. |

| Khoom Compatibility | Muaj peev xwm ua cov ntaub ntawv nyuaj-rau-kua thiab cov khoom sib xyaw ua kom zoo, suav nrog cov iav fiber ntau 25% lossis ntau dua. |

Cov qauv tsim no ua kom cov khoom zoo sib xws thiab cov khoom pov tseg tsawg, ua rau nws muaj kev ntseeg siab rau cov tuam ntxhab.

Lwm Cov Qauv Tseem Ceeb

Ob peb lwm cov qauv kuj ua rau kev ua lag luam muaj ntau haiv neeg. Lawv muab cov txiaj ntsig zoo sib xws, xws li:

- Productivity: Muaj peev xwm khiav tsis tu ncua rau lub sij hawm ntev, nrog rau cov qauv loj uas tsim tau mus txog2000kg ntawm cov khoom tiav ib teev.

- Zog Efficiency: Koom nrog cov tsav tsheb ncaj qha uas txo kev siv hluav taws xob los ntawm 10-15% piv rau cov qauv qub.

- Nqi-zoo: Kev tsim qauv yooj yim ua rau txo tus nqi yuav khoom thiab cov nqi kho mob, yuav tsum muaj kev cob qhia tshwj xeeb rau cov neeg ua haujlwm.

- Kev ntseeg tau: Tsawg qhov txav mus los ua rau muaj teeb meem kev siv tshuab tsawg dua, feem ntau kav ntau xyoo nrog kev saib xyuas kom raug.

- Txheej Txheem Stability: Ua kom cov khoom zoo sib xws thiab cov khoom pov tseg tsawg.

Cov yam ntxwv no ua rau cov qauv sib tw hauv PVC yeeb nkab ntau lawm toj roob hauv pes, catering rau ntau yam kev tsim khoom xav tau.

Xaiv txoj cai PVC yeeb nkab ib lub taub hau taub hau yog qhov tseem ceeb rau kev ua tiav. Nws ncaj qha cuam tshuam cov khoom zoo, kev ua haujlwm zoo, thiab tag nrho cov nqi. Cov neeg tsim khoom yuav tsum ua tib zoo ntsuas lawv cov kev xaiv kom ua tiav cov txiaj ntsig zoo tshaj plaws. Ib lub thoob xaiv tau zoo txhim kho kev ua tau zoo thiab ua rau muaj txiaj ntsig mus ntev.

FAQ

Dab tsi yog PVC yeeb nkab ib lub taub hau taub hau?

PVC yeeb nkab ib lub taub hau taub hau yog ib qho tshwj xeeb uas tsim los rau extrusion ntawm PVC kav, kom ntseeg tau zoo melting thiab sib tov ntawm cov ntaub ntawv.

Lub chim tsim muaj feem cuam tshuam rau kev tsim khoom li cas?

Lub thoob tsim cuam tshuam cov khoom ntws, melting sib xws, thiab lub zog noj, ncaj qha cuam tshuam rau tag nrho cov khoom ceev thiab efficiency.

Vim li cas cov khoom muaj pes tsawg leeg tseem ceeb hauv kev xaiv lub thoob?

Cov khoom muaj pes tsawg leeg cuam tshuam rau durabilitythiab kev ua haujlwm. Cov ntaub ntawv zoo txhim khu kev tiv thaiv hnav thiab corrosion, ua kom muaj kev ua haujlwm ntev thiab cov khoom zoo ib yam.

Post lub sij hawm: Sep-09-2025