Ib Screw chim

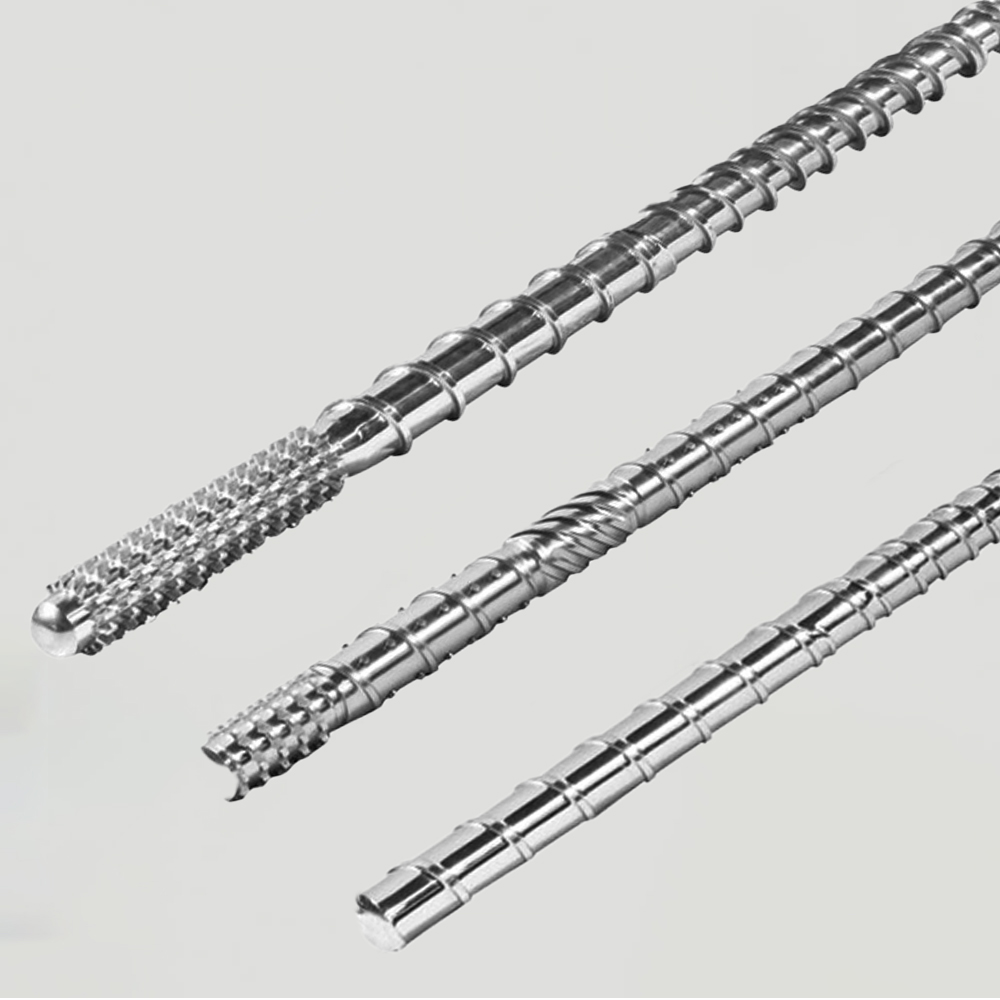

Cov khoom faib ntawm ib lub taub hau taub hau tuaj yeem piav qhia los ntawm peb nqe lus hauv qab no:PVC yeeb nkab ib leeg ntsia hlau chim, ib leeg ntsia hlau chim rau tshuab molding, thiabPE yeeb nkab extruder ib leeg ntsia hlau chim.

PVC yeeb nkab ib lub taub hau taub hau: Cov khoom lag luam no yog hais txog tib lub taub hau taub hau tshwj xeeb tsim rau extrusion ntawm PVC kav. Cov thoob no yog engineered nrog cov ntaub ntawv tshwj xeeb thiab geometries los xyuas kom meej melting, sib tov, thiab conveying ntawm PVC tebchaw. Lawv tau tsim los tiv thaiv cov txheej txheem tshwj xeeb ntawm cov khoom siv PVC, muab cov khoom sib xws thiab cov txiaj ntsig zoo rau PVC yeeb nkab ntau lawm.

Tib lub taub hau rau tshuab moulding: Cov pawg no suav nrog ib lub taub hau ntsia hlau uas tsim nyog rau cov txheej txheem tshuab molding. Cov thoob no yog tsim los muab kev tswj xyuas meej txog kev yaj thiab ua kom zoo ntawm cov khoom siv polymer thaum lub tshuab molding txheej txheem. Lawv tau ua kom zoo tshaj plaws kom xa cov qauv sib xws thiab tsis sib xws, ua kom yooj yim rau kev tsim cov tshuab pwm zoo xws li lub raj mis, ntim, thiab lwm yam hollow duab.

PE yeeb nkab extruder ib leeg ntsia hlau chim: Lub PE yeeb nkab extruder ib leeg ntsia hlau chim qeb tsom rau tej chim tshwj xeeb engineered rau extrusion ntawm PE (polyethylene) kav. Cov thoob no yog tsim los kom haum rau cov khoom tshwj xeeb rheological ntawm PE cov ntaub ntawv, kom ntseeg tau tias melting zoo, sib tov, thiab conveying thaum lub sij hawm extrusion txheej txheem. Lawv tau ua kom zoo tshaj plaws kom xa cov khoom siv tau zoo thiab ua kom zoo sib xws, ua tau raws li cov cai nruj ntawm PE yeeb nkab ntau lawm.

-

Ib leeg ntsia hlau chim rau tshuab zaj duab xis

-

Ib leeg ntsia hlau chim rau recycling granulation

-

Ntsia hlau chim rau tshuab PP / PE / LDPE / HDPE zaj duab xis

-

Lub raj mis tshuab molding ntsia hlau chim

-

PVC yeeb nkab ntsia hlau chim rau extrusion

-

Ib leeg ntsia hlau chim rau cov yeeb nkab extrusion

-

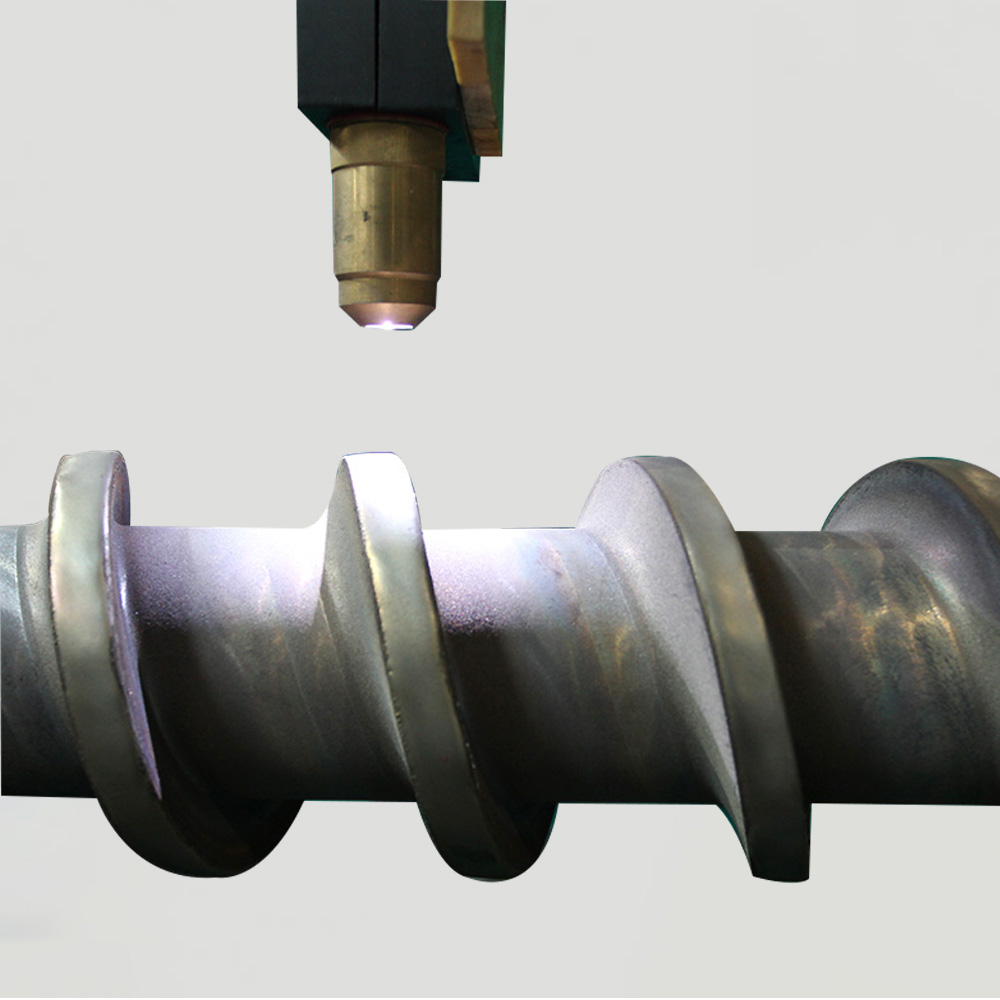

Gas nitriding ntsia hlau thiab chim

-

High quality nitrided ntsia hlau thiab chim

-

Professional extruder alloy ntsia hlau chim